ZnIn2S4 nano materials and their synthesis method and application

A synthesis method and nanomaterial technology, applied in the field of preparation of ZnIn2S4, can solve problems such as unreported, and achieve the effects of wide applicability, strong controllability and excellent optoelectronic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

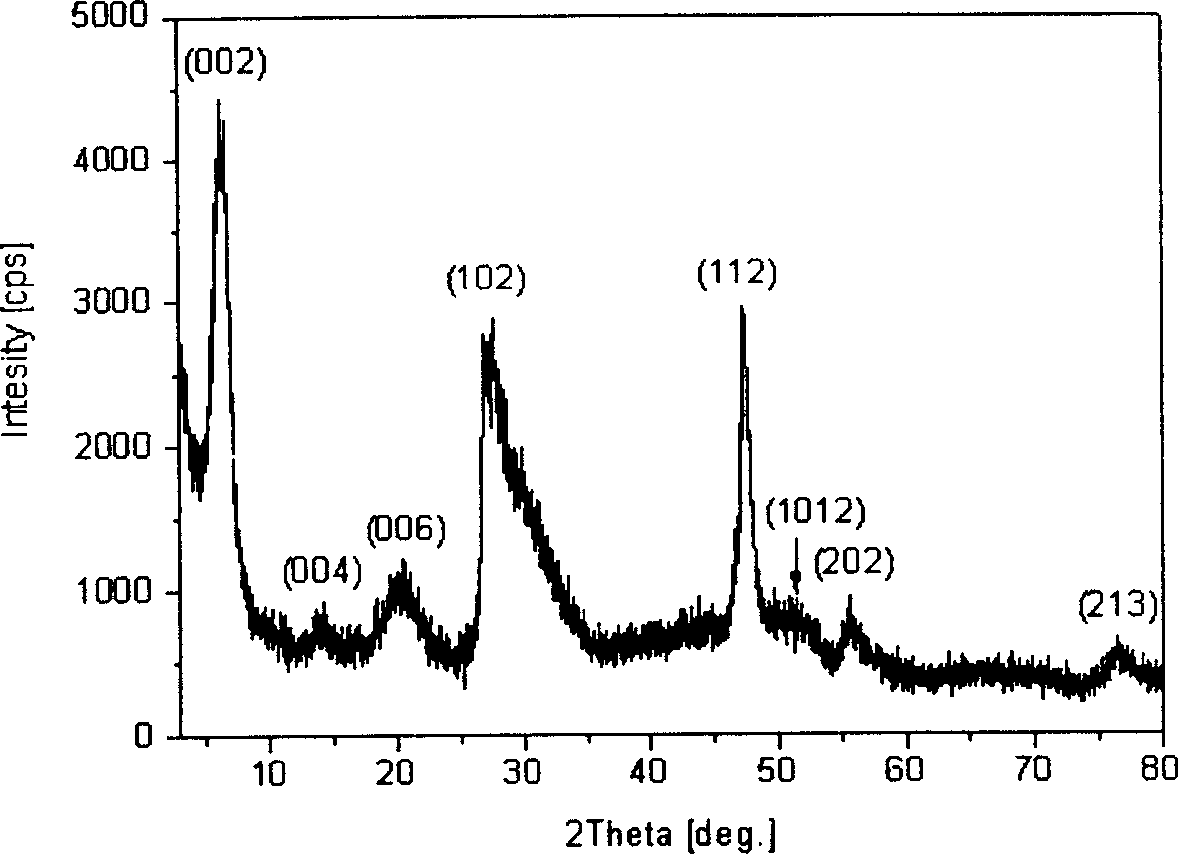

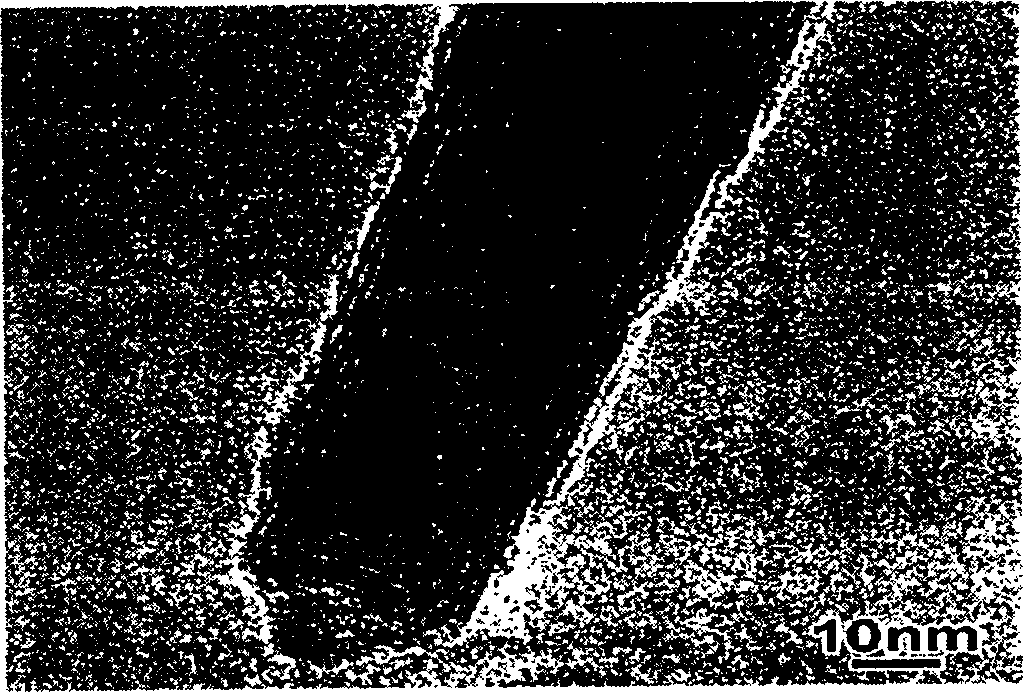

[0033] Weigh 0.25mmol ZnSO 4 ·7H 2 O, 0.5mmol InCl 3 4H 2 O and 1mmol TAA were put into a 25mL polytetrafluoroethylene liner, 12mL pyridine was added, and after magnetic stirring for 1h, the reaction vessel was sealed and heated at 180°C for 16h. After it was naturally cooled, it was filtered, washed with water and absolute ethanol several times in sequence, and dried in vacuum at 60° C. for 4 hours to obtain a yellow powder. The product was identified as hexagonal ZnIn by X-ray powder diffraction 2 S 4 (attached figure 1 ). The morphology of the product was characterized by a transmission electron microscope (TEM), and the results showed that the product was a multi-walled nanotube (attached figure 2 ), the inner diameter is 17-25nm, the outer diameter is 40-60nm, and the length is about 500nm-5μm.

Embodiment 2

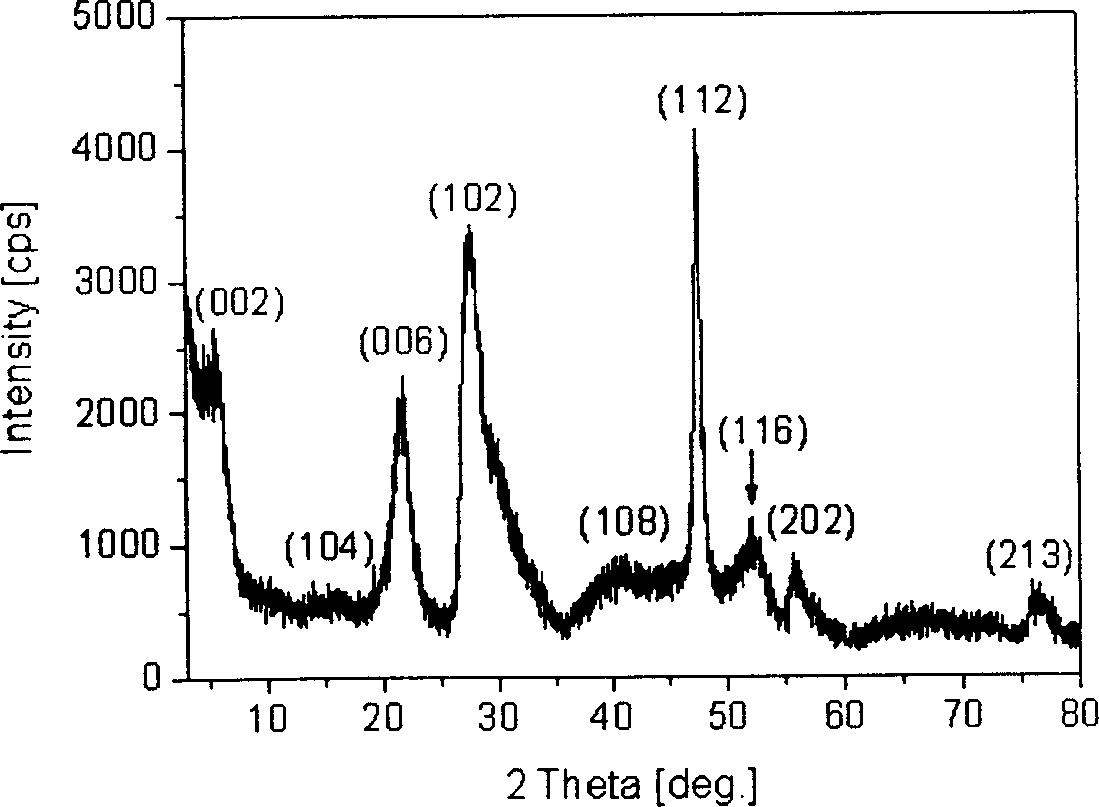

[0035] The temperature of the above reaction system is lowered to 160-120°C, while keeping other conditions unchanged, ZnIn 2 S 4 nanobelt. The product was identified as hexagonal ZnIn by X-ray powder diffraction 2 S 4 (attached image 3 ). The morphology of the product was characterized by TEM, and the results showed that the product was a nanobelt (attached Figure 4 ), with a width of 40-100 nm, a thickness of about 10 nm, and a length of 10 μm.

Embodiment 3

[0037] Weigh 1mmol ZnSO 4 ·7H 2 O and 2 mmol InCl 3 4H 2 O was placed in a small beaker, and 20 mL of deionized water was added, and magnetically stirred to dissolve it completely. Then add 0.45g PEG-6000 (polyethylene glycol, molecular weight 6000), after it is completely dissolved, finally add 4mmol TAA, and continue stirring for 30min to obtain a colorless and clear solution. Transfer this mixed solution to a 50mL polytetrafluoro-lined stainless steel self-boosting reactor, seal it, and continue heating at 160°C for 16h. After it was naturally cooled to room temperature, it was filtered, washed and dried to obtain a yellow powder. The product was identified as hexagonal ZnIn by X-ray powder diffraction 2 S 4 (attached Figure 5 ). Scanning electron microscopy (SEM) characterized the morphology of the product, and the results showed that the product was a hollow fiber ball (attached Image 6 ). Ultrasonic disperse the above powder in ethanol for 1h to obtain ZnIn ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com