Coke inhibitor as well as preparation method and use thereof

An organic solvent and compound technology, applied in the field of coke inhibitor and preparation of coke inhibitor, can solve the problems of inability to apply coke inhibition, complex coke mechanism, single component, etc., and achieves low cost, good coke inhibition performance and simple preparation method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Diphosphonate, 4,6-dinitro-2-sec-butylphenol, liquid alkylated diphenylamine, polyisobutylene succinimide and heavy aromatics according to 10%, 10%, 10%, 40% % and 20% were added to a container, stirred at 50°C for 30 minutes, then added 10% benzothiophene, continued to stir for 20 minutes, mixed evenly and cooled to room temperature to obtain the coke inhibitor product A-1.

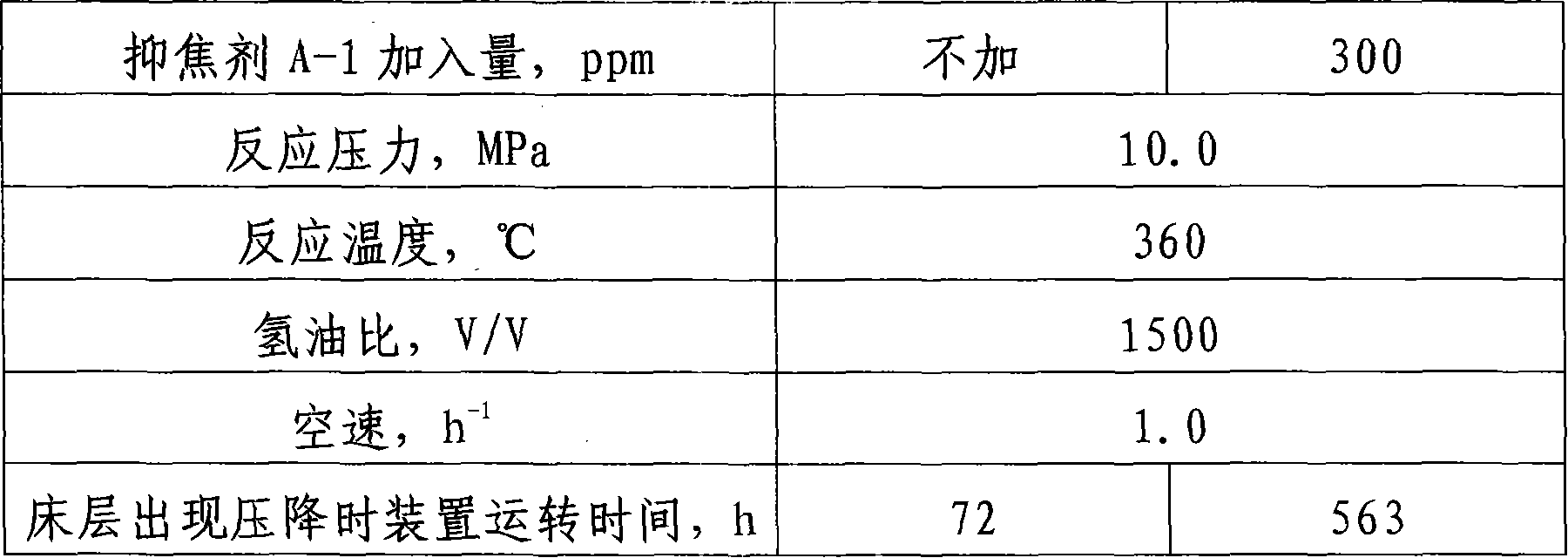

[0025] Coke inhibitor A-1 was tested in the 100ml coal tar hydrogenation test device for coal tar hydrogenation modification. The test raw material is medium and low temperature coal tar produced by a coking plant. The test compares the operation time of the device and the polymer content of the hydrogenated oil when the pressure drop occurs in the bed of the test device with coke suppressor A-1 added to the raw material and without any coke suppressor added to the raw material under the same conditions. The properties and test results of the test raw materials are shown in Table 1 and Table 2, r...

Embodiment 2

[0032] Diphosphonate, hydroquinone, di-sec-butyl-p-phenylenediamine, polyalkenyl succinimide and coal tar hydrogenation oil < 200 ° C fraction according to 8%, 30%, 15%, Add 10% and 30% contents into a container respectively, stir at 60°C for 60 minutes, then add 7% benzothiophene, continue stirring for 15 minutes, mix well and cool to room temperature to obtain coke suppressor product A-2.

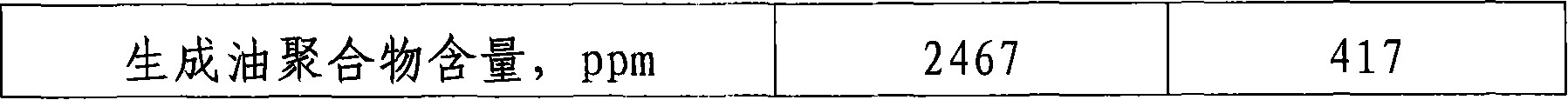

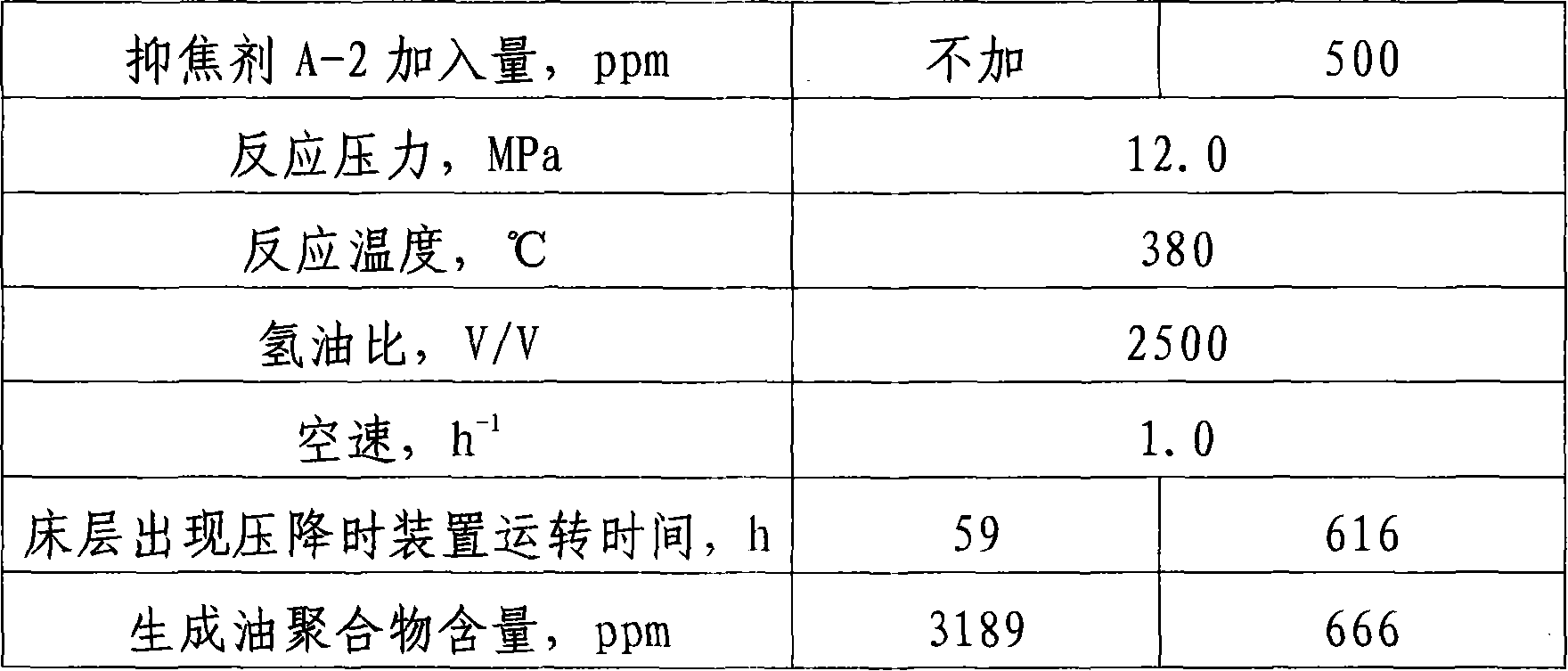

[0033] Coke inhibitor A-2 Coal tar hydrogenation upgrading test carried out in 100ml coal tar hydrogenation test device. The test raw material is high-temperature coal tar produced by a coking plant. The test compares the operation time and hydrogenation production time of the test device when the pressure drop occurs in the bed of the test device with coke suppressant A-2 added to the raw material and without any coke suppressor added to the raw material under the same conditions. The polymer content of the oil. The properties and test results of the test raw materials are shown in Tabl...

Embodiment 3

[0040] Hydrogenate triisooctyl phosphate, p-methoxyphenol, dinaphthylamine, high-nitrogen polyisobutylene succinimide and crude benzene to generate oil according to the content of 5%, 10%, 30%, 30% and 20% Add them to a container respectively, stir at 80°C for 40 minutes, then add 5% benzothiophene, continue to stir for 25 minutes, mix well and cool to room temperature to obtain the coke inhibitor product A-3.

[0041] The coke inhibitor A-3 was tested in a 100ml crude benzene hydrogenation test device for hydrogenation modification of crude benzene. The test raw material is the crude benzene raw material produced by a coking plant. The test compares the operation time of the device and the production time when the pressure drop occurs in the bed of the test device with the coke suppressant A-3 added to the raw material and without any coke suppressant added to the raw material under the same conditions. The polymer content of the oil. The properties and test results of the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com