Antioxidant conductive copper nanowire film and preparation method and application thereof

A copper nanowire, anti-oxidation technology, applied in chemical instruments and methods, conductive layers on insulating carriers, nanotechnology for materials and surface science, etc., can solve the problem of reducing the resistance of copper nanowire electrodes and reducing copper nanowire Contact resistance, lack of anti-oxidation ability and other problems, to solve the effect of unstable conduction, low price and cost, and good anti-oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039]Prepare copper nanowires with a diameter of 20-200nm and a length of 30-200 microns; weigh 0.252g CuCl2 2H2O, 1.596g HDA (hexadecanylamine) and dissolve them in 40ml deionized water to obtain a light blue solution; then weigh 0.7g Glucose is added to the above solution, and then the solution is transferred to a three-necked flask and heated to 100°C for 7 hours to react to obtain copper nanowires, which are then fully centrifuged and washed with deionized water, absolute ethanol, and n-hexane to obtain high-quality copper. Nano wires, finally the washed copper nano wires are dispersed in n-hexane solution and preserved, the length of copper nano wires is 30-200 microns, and the diameter is about 20-200 nm. Such as figure 2 shown.

Embodiment 2

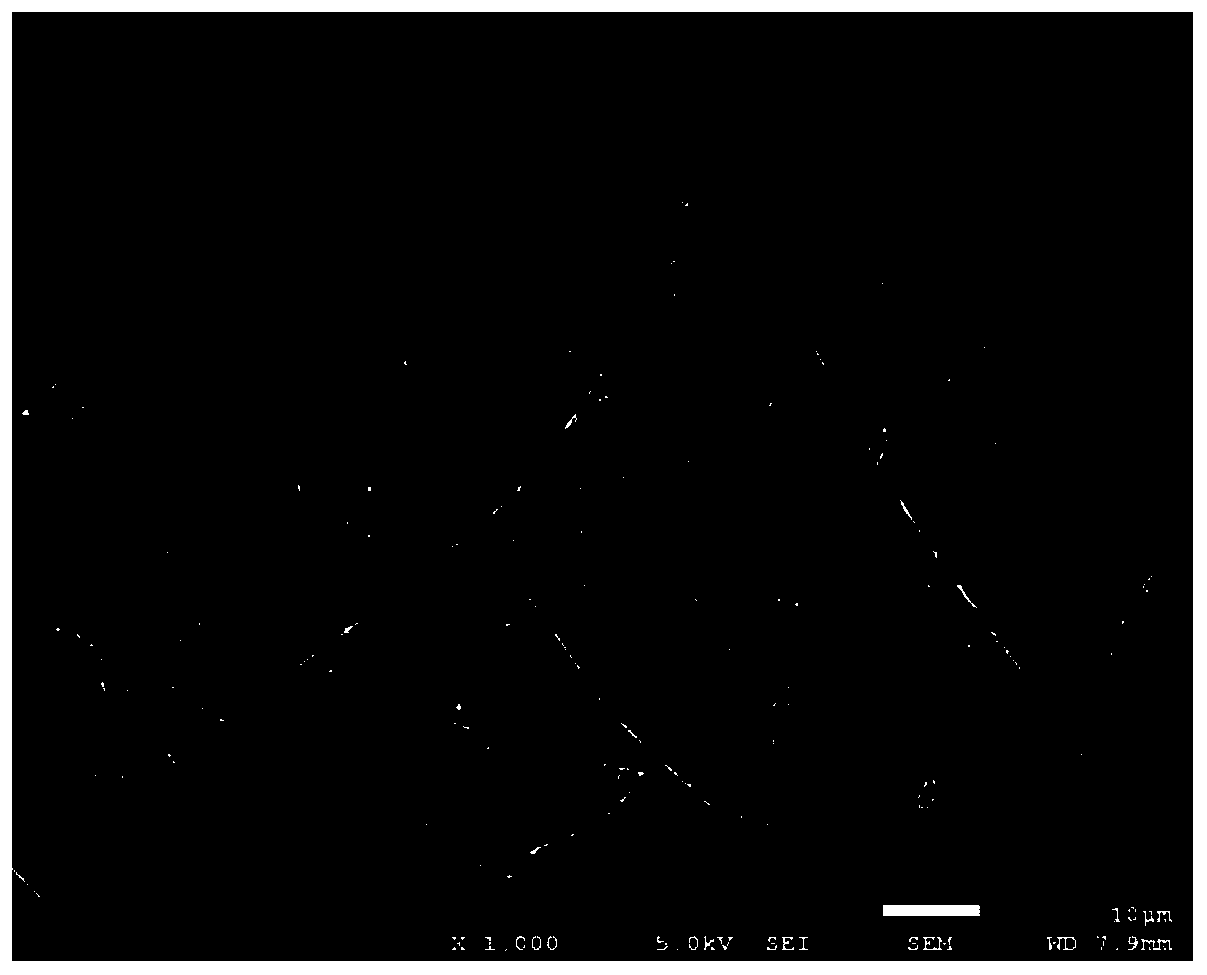

[0041] Take the 10 mg copper nanowires prepared in Example 1, the length is 30-200 microns, and the diameter is about 20-200 nm, dispersed in n-hexane solution (being a pure solvent), and suction-filtered to form a film of copper nanowires. The copper nanowire thin film was reduced in the atmosphere, the reduction temperature was 180° C., and the reduction time was 120 minutes. The reduced conductive copper nanowire film can be obtained, such as image 3 , is the SEM image of the reduced copper nanowire film, Figure 4 It is the local reduced copper nanowire film, and it can be seen from the figure that the surface of the copper nanowire is smooth.

[0042] Immerse the reduced copper nanowire film in the prepared anti-oxidation treatment solution for 2 minutes, and then dry it with nitrogen to obtain an anti-oxidation-treated conductive copper nanowire film. The anti-oxidation treatment solution is 100mL aqueous solution containing 0.1mmol formic acid, 0.1mmol copper formate ...

Embodiment 3

[0044] Take 10 mg of copper nanowires prepared in Example 1 with a diameter of 20-200 nm and a length of 30-200 microns, disperse them in n-hexane solution (pure solvent), and filter them by suction to form a film of copper nanowires. The copper nanowire film was reduced in a hydrogen and argon atmosphere, the reduction temperature was 160° C., and the reduction time was 360 minutes. The reduced conductive copper nanowire film can be obtained.

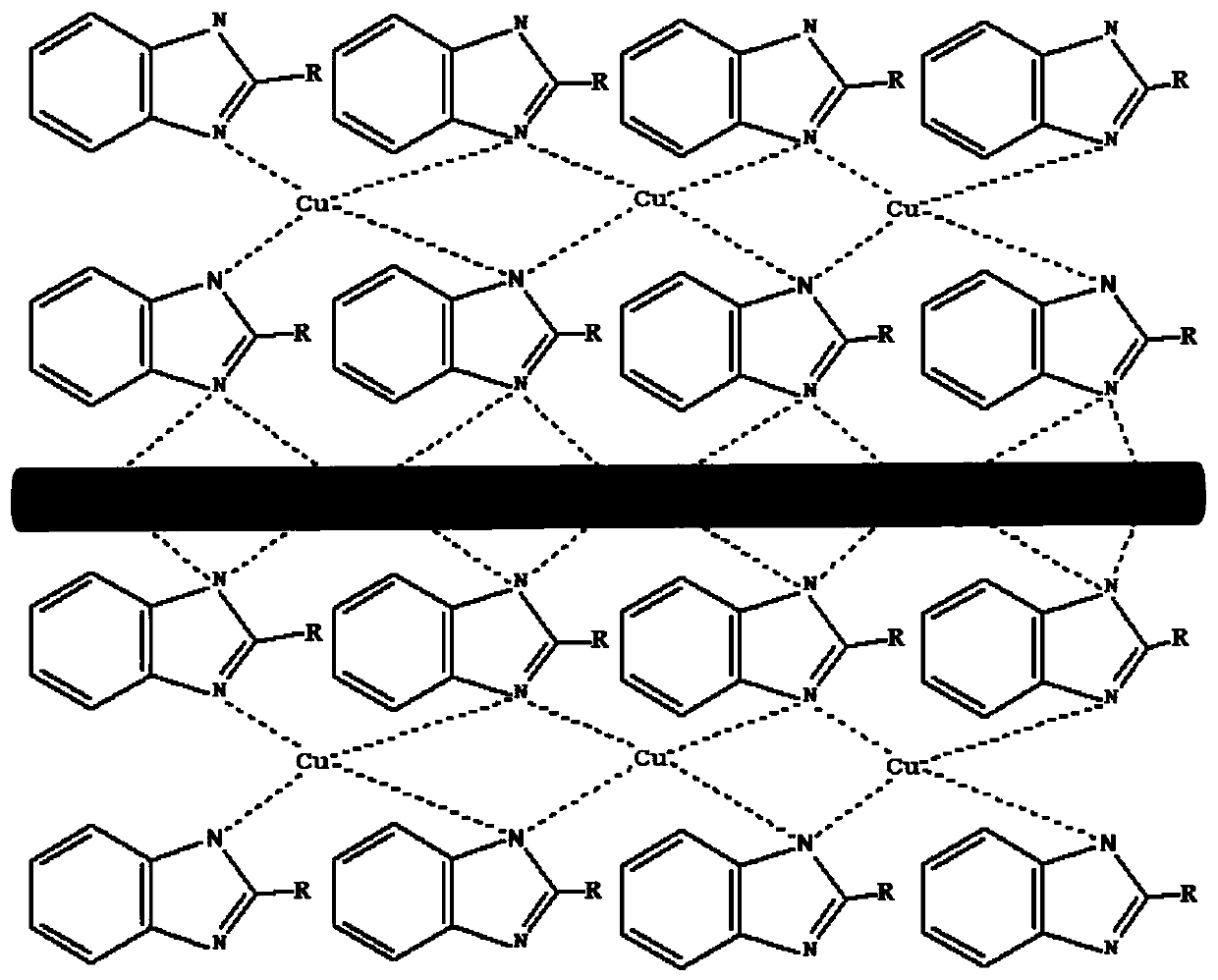

[0045] Immerse the reduced copper nanowire film in the prepared anti-oxidation treatment solution for 4 minutes, and then dry it with nitrogen to obtain the anti-oxidation-treated conductive copper nanowire film. The anti-oxidation treatment solution is 100mL solution containing 0.1mmol formic acid, 0.1mmol copper formate , 2 g of benzoimazole, pH 5. Treated copper nanowire films, such as Figure 6 As shown, it can be seen from the SEM image that a layer of benzoimazole is wrapped on the surface of the copper nanowire film. Figure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com