Solid-liquid separation processor

A technology of solid-liquid separation and processor, applied in the direction of filtration separation, sludge treatment, separation methods, etc., can solve the problem of shortening the processing time and processing cost of the filter screen, and achieve the effect of large gap on the back

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

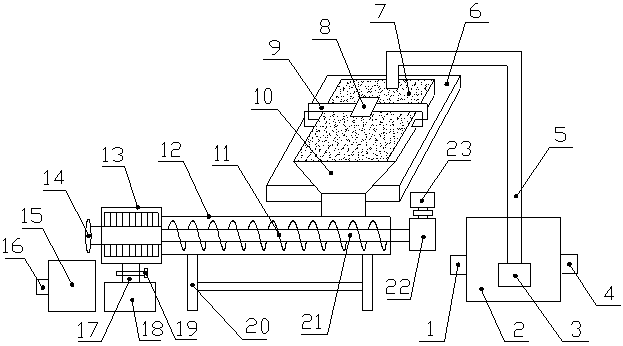

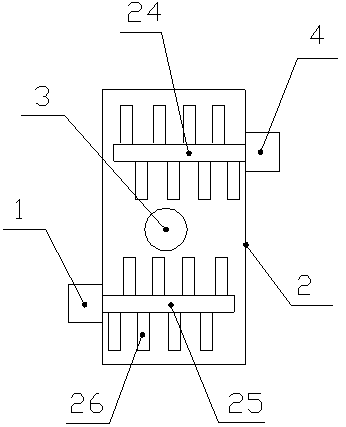

[0013] like Figure 1-2 Shown, a kind of solid-liquid separation processing machine, it comprises slag-liquid storage box 2 and extrusion screw conveyor 12, the left front part of described slag-liquid storage box 2 is connected with stirring motor A1, and described stirring motor The output shaft of A1 is connected with the stirring shaft A25, the stirring shaft A25 penetrates the left side wall of the slag liquid storage tank 2 and extends into the slag liquid storage tank 2, the right rear part of the slag liquid storage tank 2 A stirring motor B4 is connected, and the output shaft of the stirring motor B4 is connected with a stirring shaft B24, and the stirring shaft B24 penetrates the right side wall of the slag liquid storage tank 2 and extends into the slag liquid storage tank 2. Stirring blades 26 are fixedly installed on the stirring shaft A1 and the stirring shaft B24, a submersible cutting pump 3 is arranged in the middle of the slag liquid storage tank 2, and a dis...

Embodiment 2

[0016] like Figure 1-2 Shown, a kind of solid-liquid separation processing machine, it comprises slag-liquid storage box 2 and extrusion screw conveyor 12, the left front part of described slag-liquid storage box 2 is connected with stirring motor A1, and described stirring motor The output shaft of A1 is connected with the stirring shaft A25, the stirring shaft A25 penetrates the left side wall of the slag liquid storage tank 2 and extends into the slag liquid storage tank 2, the right rear part of the slag liquid storage tank 2 A stirring motor B4 is connected, and the output shaft of the stirring motor B4 is connected with a stirring shaft B24, and the stirring shaft B24 penetrates the right side wall of the slag liquid storage tank 2 and extends into the slag liquid storage tank 2. Stirring blades 26 are fixedly installed on the stirring shaft A1 and the stirring shaft B24, a submersible cutting pump 3 is arranged in the middle of the slag liquid storage tank 2, and a dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com