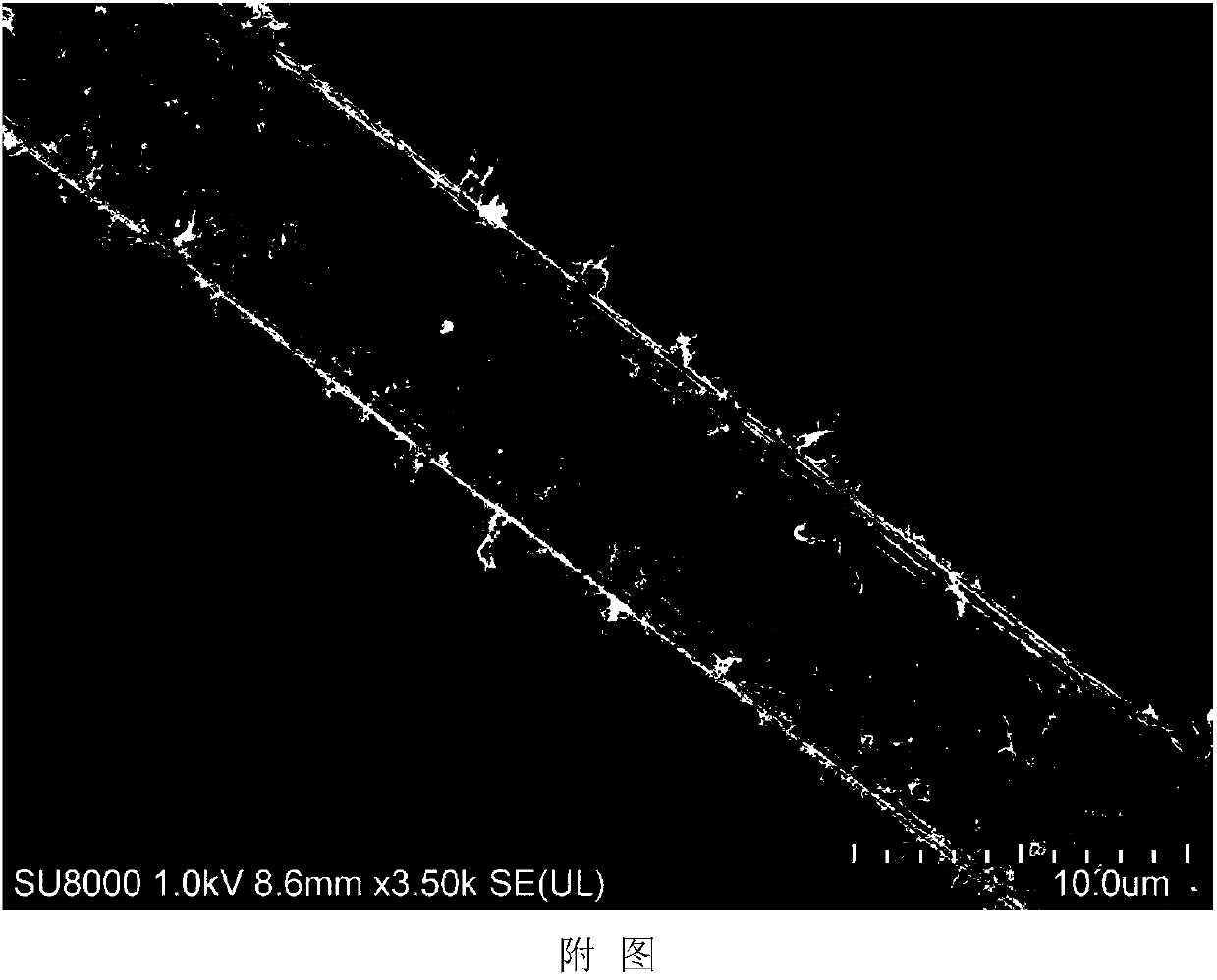

Treatment method for contact end of surface of oriented carbon nano tube-modified carbon fiber on the basis of gas-phase carbon nano tube dispersion mist

A carbon nanotube modification, carbon nanotube technology, applied in fiber processing, carbon fiber, textiles and papermaking, etc., to achieve the effect of simple operation, enhanced bonding force, and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in detail below. However, these implementations do not limit the present invention, and method or functional changes made by those skilled in the art according to these implementations are included in the protection scope of the present invention.

[0023] Specific steps are as follows:

[0024] (1) Evenly mix carbon nanotubes, sizing agent, and deionized water in a mass ratio of 1:1:4;

[0025] (2) Press the mixture described in step (1) into a block and connect it to the cathode of the pulsed high-voltage DC power supply, use a tungsten columnar electrode to connect to the anode of the pulsed high-voltage DC power supply, and keep the distance between the adjacent ends of the cathode and the anode at 1 mm, and turn on Power supply to complete the gas phase dispersion of carbon nanotubes;

[0026] Specifically, the high-voltage DC power supply adopts a voltage of 20000V and a maximum power of 100W; the pulse parameters are: frequenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com