High-hardness domestic drinking water softening device and method

A technology of domestic drinking water and softening device, which is applied in the field of high-hardness drinking water softening device, can solve the problems of appropriate and mature technology for removing hardness of drinking water, achieve good effect of removing hardness, fast response time, and reduce turbidity of effluent water Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

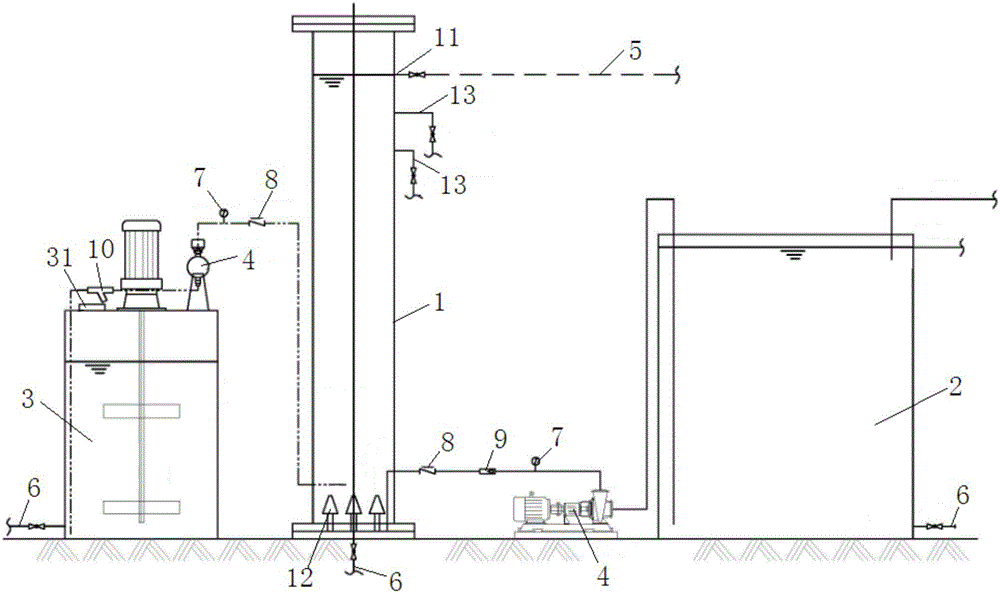

[0041] Laboratory simulated water distribution, using CaCl 2 2H 2 O (calcium chloride dihydrate) formulated as total hardness (as CaCO 3 (calcium carbonate) based on 330 mg / L of CaCl 2 solution. The alkalinity of the distribution water is extremely low, so sodium carbonate is used as a softening agent. Preparation of sodium carbonate solution: Prepare 1%, 2%, 3%, and 5% sodium carbonate solutions respectively. Before softening, wash the quartz sand with deionized water, and stop when the turbidity of the effluent and the turbidity of the influent are close. Fluidize the quartz sand in the reactor by adjusting the water flow rate. Find that when the water inlet flow is 48 liters / hour, when the fluidization height of quartz sand can reach 115 centimetres, adjust the softening dose of the metering pump 4 so that the softening dose is 2.75 mmol / min sodium carbonate, start timing. Samples are taken from sampling ports 13 at different heights of the liquid-solid fluidized bed ...

Embodiment 2

[0043] Laboratory simulated water distribution total hardness (as CaCO 3 (calcium carbonate) 350 mg / liter, total alkalinity as CaCO 3 (calcium carbonate) 250 mg / L, respectively with CaCl 2 2H 2 O (Calcium Chloride Dihydrate) and NaHCO 3 (sodium bicarbonate) preparation. The softening agent is calcium hydroxide emulsion, and the water intake is 48 liters per hour. Regulate metering pump 4, make its feeding amount be 1.5 mmol / min, 1.8 mmol / min, 2.0 mmol / min, 2.3 mmol / min, 2.5 mmol / min, 2.8 mmol / min, 3.0 mmol / min, 3.2mmol / min in a series of fluidized bed hardness removal experiments. The overall operation is basically the same as in Example 1. The study found that with the increase of the dosage of the softening agent, the turbidity of the effluent gradually increased, and the hardness decreased with the increase of the dosage of the softening agent, and finally stabilized at 120 mg / L. The hardness removal rate reaches 67%, but the turbidity of the effluent after calciu...

Embodiment 3

[0045] Laboratory simulated water distribution total hardness (as CaCO 3 (calcium carbonate) 515 mg / L, magnesium hardness (as CaCO 3 (calcium carbonate)) 70 mg / L, total alkalinity (calculated as CaCO 3 (calcium carbonate) 235 mg / L. The medicine used is sodium hydroxide. The treated water volume is 48 liters / hour, and the corresponding fluidized bed height is 115 cm. Regulate metering pump 4 to control the dosage per minute, 1.88 mmol / min, 2.44 mmol / min, 3.008 mmol / min, 3.76 mmol / min, 4.512 mmol / min, 5.076 mmol / min, 5.64 mmol / min, 6.768mmol / min, carried out a series of fluidized bed dehardening experiments with different dosages. Samples are taken every three minutes until the hardness of the water outlet 11 is stable, and then samples are taken every hour, and then samples are taken from the sampling ports 13 at different heights of the liquid-solid fluidized bed reactor 1 . Sampling and analysis of water hardness, continuous operation for 24 hours. Measure the hardness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com