Integrated device for removing water hardness

A technology for removing water and hardness, applied in descaling and water softening, chemical instruments and methods, water/sludge/sewage treatment, etc. and other problems, to achieve the effect of short residence time, convenient transportation and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

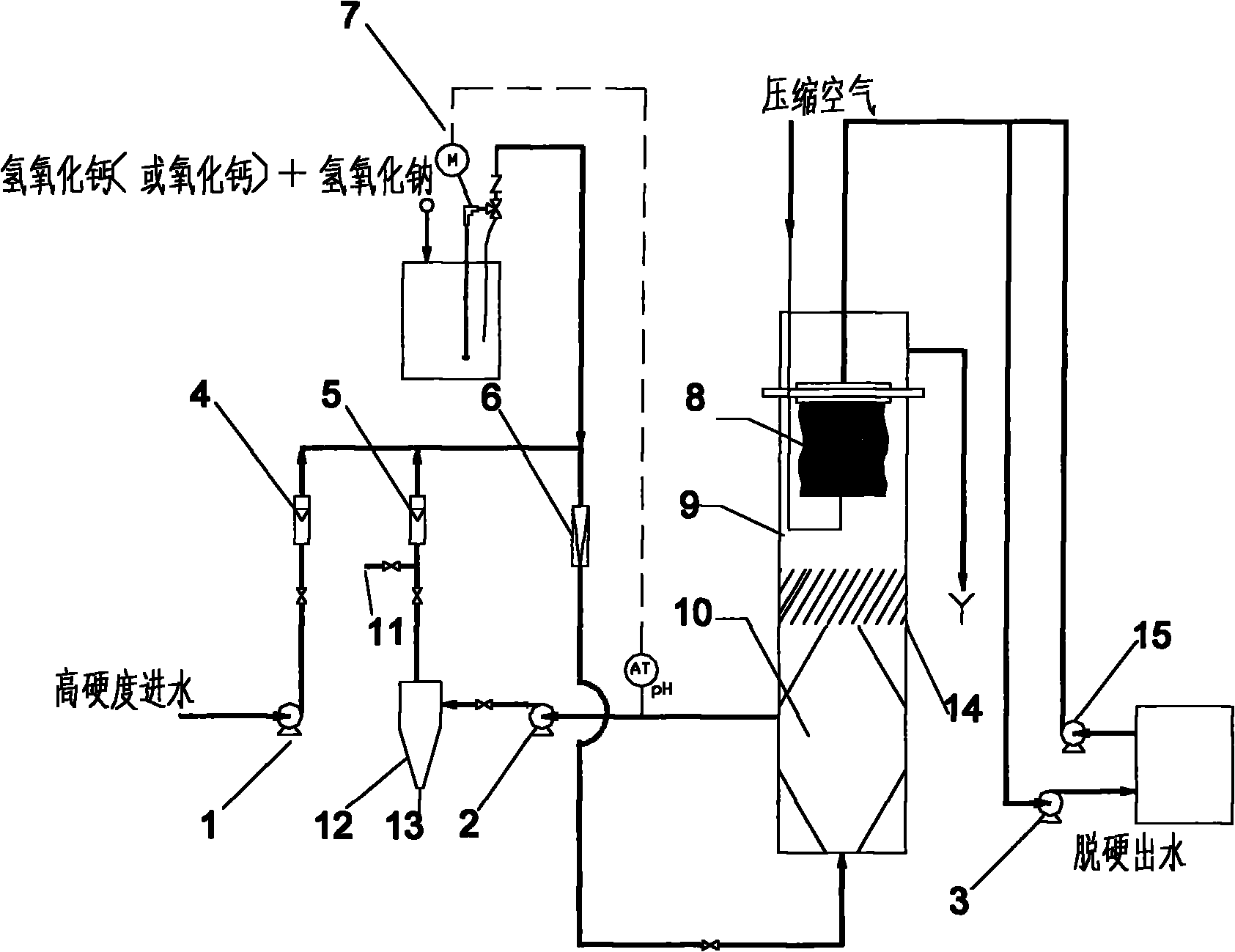

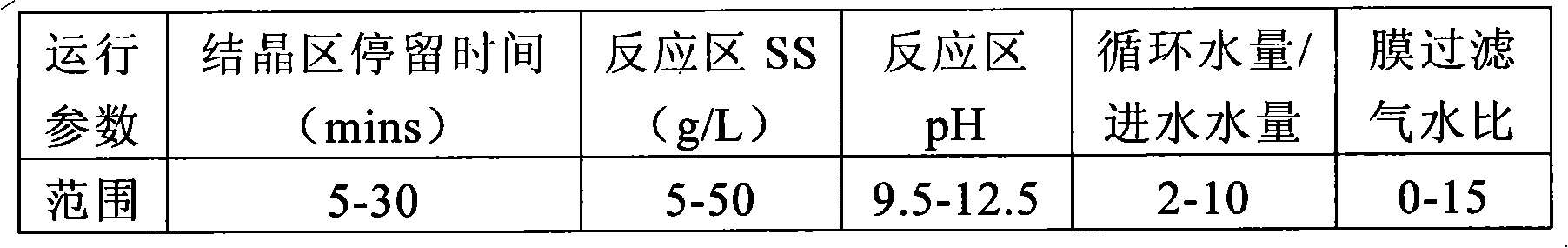

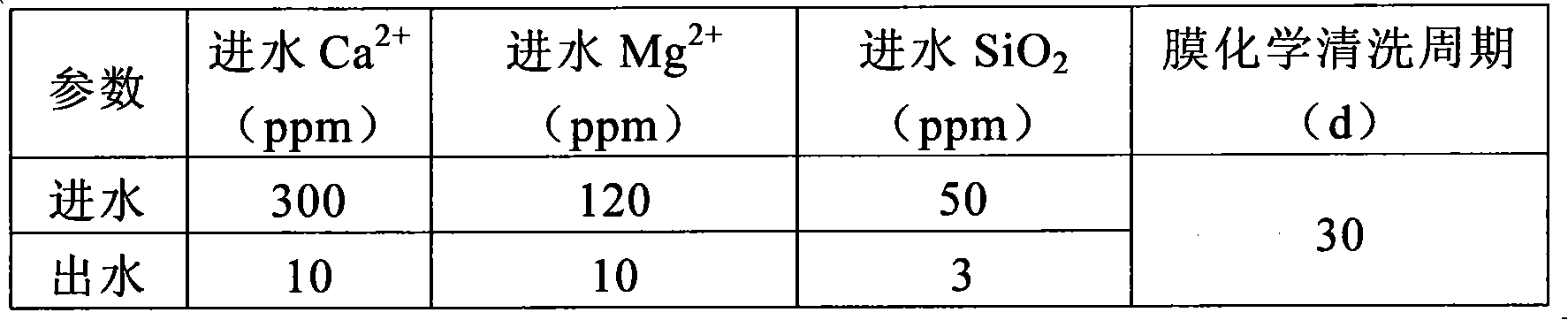

[0022] exist figure 1 The preferred embodiment of the invention shown shows that a high Ca 2+ , Mg 2+ An integrated device for removing hardness in water for ionized water bodies. The equipment includes integrated: hard removal system, pH adjustment system, hydrocyclone separation system, suspension removal (membrane filtration) system, and automatic control system for suspension removal (membrane filtration) control and pH adjustment control, hydrocyclone separation control, slag discharge control, etc.

[0023] According to a preferred embodiment of the present invention, the hard removal system includes: water inlet pump 1, circulation pump 2, water inlet flow meter 4, circulation flow meter 5, pipeline mixer 6, automatic dosing system 7, crystallization area 10, crystallization area row Slag mouth 11. The water inlet pipeline is connected to the inlet of the water inlet pump 1 and the pipeline mixer 6, the automatic dosing system 7 is connected to the inlet of the pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com