Method and system for sewage treatment

A treatment method and technology of a treatment system are applied in the field of sewage treatment method and treatment system, which can solve the problem of high cost of sewage removal hardening process, achieve good hard removal effect, improve economic benefit and reduce process cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] In the above step of adding a coagulant, the coagulant includes a flocculant. More preferably, after obtaining the first sediment, the preparation method includes: adding a flocculant to the second treated sewage to obtain a flocculant containing For the third sewage treatment of sediment, the flocculant can be selected from polyacrylamide (PAM), polyiron (PE), etc.; then, the third sewage treatment is subjected to solid-liquid separation treatment to obtain hard wastewater and flocculated sediment .

[0045] More preferably, the above-mentioned coagulant also includes a coagulant, and before the step of adding calcium carbide slag to the sewage, the treatment method also includes the step of adding a coagulant to the sewage, and the above-mentioned coagulant can be selected from ferric chloride , alum and ferrous sulfate.

[0046] The above contains Ca 2+ , Mg 2+ The precipitate and colloid further react with the coagulant containing coagulant and flocculant to dest...

Embodiment 1

[0065] The present embodiment provides a kind of treatment method of sewage, comprises the following steps:

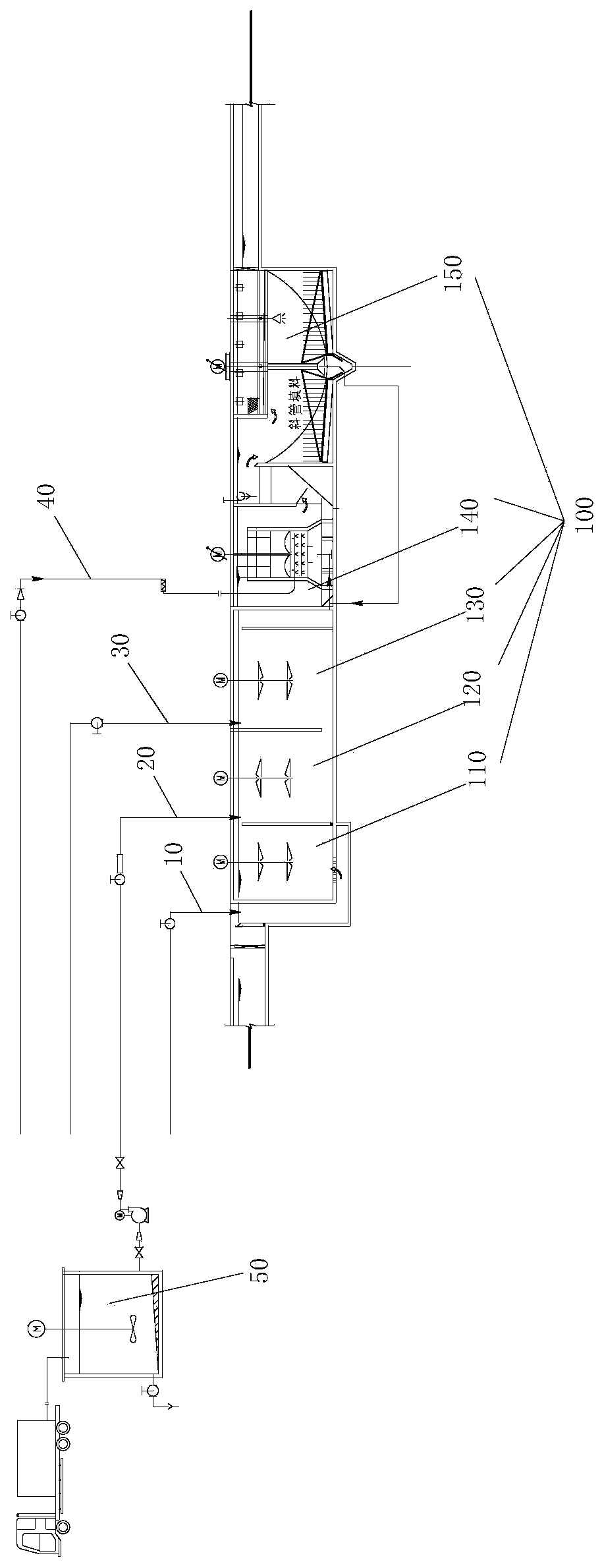

[0066] Feed sewage with a total hardness of 900mg / l into the coagulation reaction zone 110 of the sedimentation tank 100, and simultaneously add ferric chloride;

[0067] Make the sewage flow from the coagulation reaction zone 110 to the carbide slag reaction zone 120, and add carbide slag at the same time, and the reaction time is 100s;

[0068] Make the sewage flow from the calcium carbide slag reaction zone 120 to the carbonate reaction zone 130, and add sodium carbonate at the same time, and the reaction time is 90s;

[0069] Make the sewage flow from the carbonate reaction zone 130 to the flocculation reaction zone 140, and add polyacrylamide (PAM) at the same time, and the reaction time is 90s;

[0070] The sewage flows from the flocculation reaction zone 140 to the sedimentation zone 150, and the sedimentation time is 1800s.

[0071] Among them, the weight rat...

Embodiment 2

[0073] The difference between this embodiment and embodiment 1 is:

[0074] The weight ratio of calcium carbide slag to sodium carbonate is 2:1, the weight ratio of hard removing agent to coagulant is 8:1, and the weight ratio of coagulant to flocculant is 3:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com