Electric flocculation silicon removal process and system for silicon-containing wastewater

A technology of electrocoagulation and waste water, which is applied in the field of electrocoagulation and silicon removal process and system, can solve the problems of electrode plate scaling, etc., achieve strong adsorption capacity, simple process operation, and solve the effect of electrode plate scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

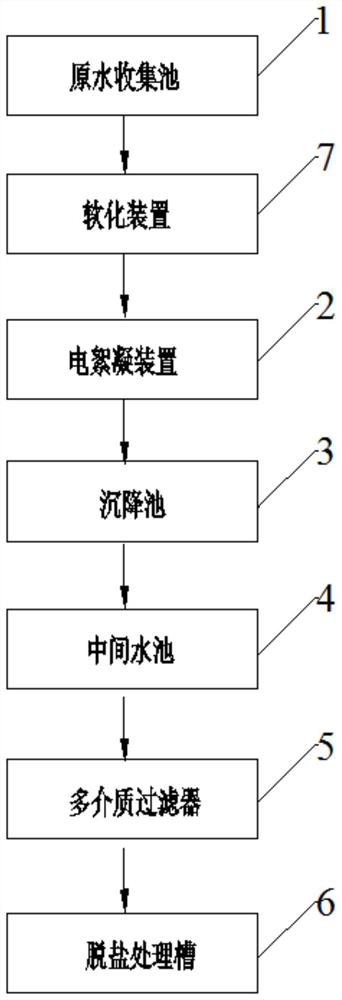

[0032] 1) Collect the silicon-containing raw water into the raw water collection tank 1, and then pump the silicon-containing raw water in the raw water collection tank 1 into the softening device 7 to first remove the hardness, so as to ensure that the hardness of the silicon-containing raw water is not higher than 100mg / L;

[0033] 2) Send the water body that has been removed from the hardness in step 1) into the electroflocculation device 2 for electrolytic treatment, and then send the water body after the electrolytic treatment into the sedimentation tank 3 for static stratification; the voltage during the electrolytic treatment is 22v, and the current Density at 55A / m 2 , the electrolytic treatment time is 20min;

[0034] 3) Discharging the lower layer sediment after sedimentation and stratification in the sedimentation tank 3 in step 2), and then sending the supernatant liquid after sedimentation and stratification in the sedimentation tank 3 into the intermediate pool 4...

Embodiment 2

[0043] A process for removing silicon by electrocoagulation of silicon-containing wastewater, comprising the steps of:

[0044] 1) Collect the silicon-containing raw water into the raw water collection tank 1, and then pump the silicon-containing raw water in the raw water collection tank 1 into the softening device 7 to first remove the hardness, so as to ensure that the hardness of the silicon-containing raw water is not higher than 100mg / L;

[0045] 2) Send the water body that has undergone hardness removal in step 1) into the electroflocculation device 2 for electrolytic treatment, and then send the water body after the electrolytic treatment into the sedimentation tank 3 for static stratification; the voltage during the electrolytic treatment is 23v, and the current Density at 58A / m 2 , the electrolytic treatment time is 25min;

[0046] 3) Discharging the lower layer sediment after sedimentation and stratification in the sedimentation tank 3 in step 2), and then sending ...

Embodiment 3

[0056] A process for removing silicon by electrocoagulation of silicon-containing wastewater, comprising the steps of:

[0057] 1) Collect the silicon-containing raw water into the raw water collection tank 1, and then pump the silicon-containing raw water in the raw water collection tank 1 into the softening device 7 to first remove the hardness, so as to ensure that the hardness of the silicon-containing raw water is not higher than 100mg / L;

[0058] 2) Send the water body that has been removed from the hardness in step 1) into the electroflocculation device 2 for electrolytic treatment, and then send the water body after the electrolytic treatment into the sedimentation tank 3 for static stratification; the voltage during the electrolytic treatment is 24v, and the current Density at 605A / m 2 , the electrolytic treatment time is 30min;

[0059] 3) Discharging the lower layer sediment after sedimentation and stratification in the sedimentation tank 3 in step 2), and then sen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com