Patents

Literature

43results about How to "Improve resource reuse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for searching and optimizing game resource quotation relationship

InactiveCN108804688AImprove reuseImprove resource reuseSpecial data processing applicationsMonitoring programReuse rate

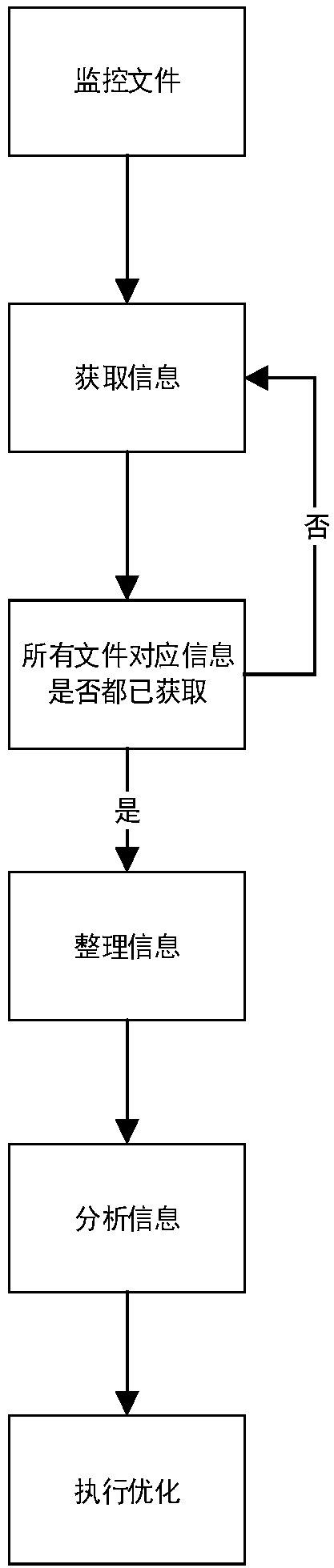

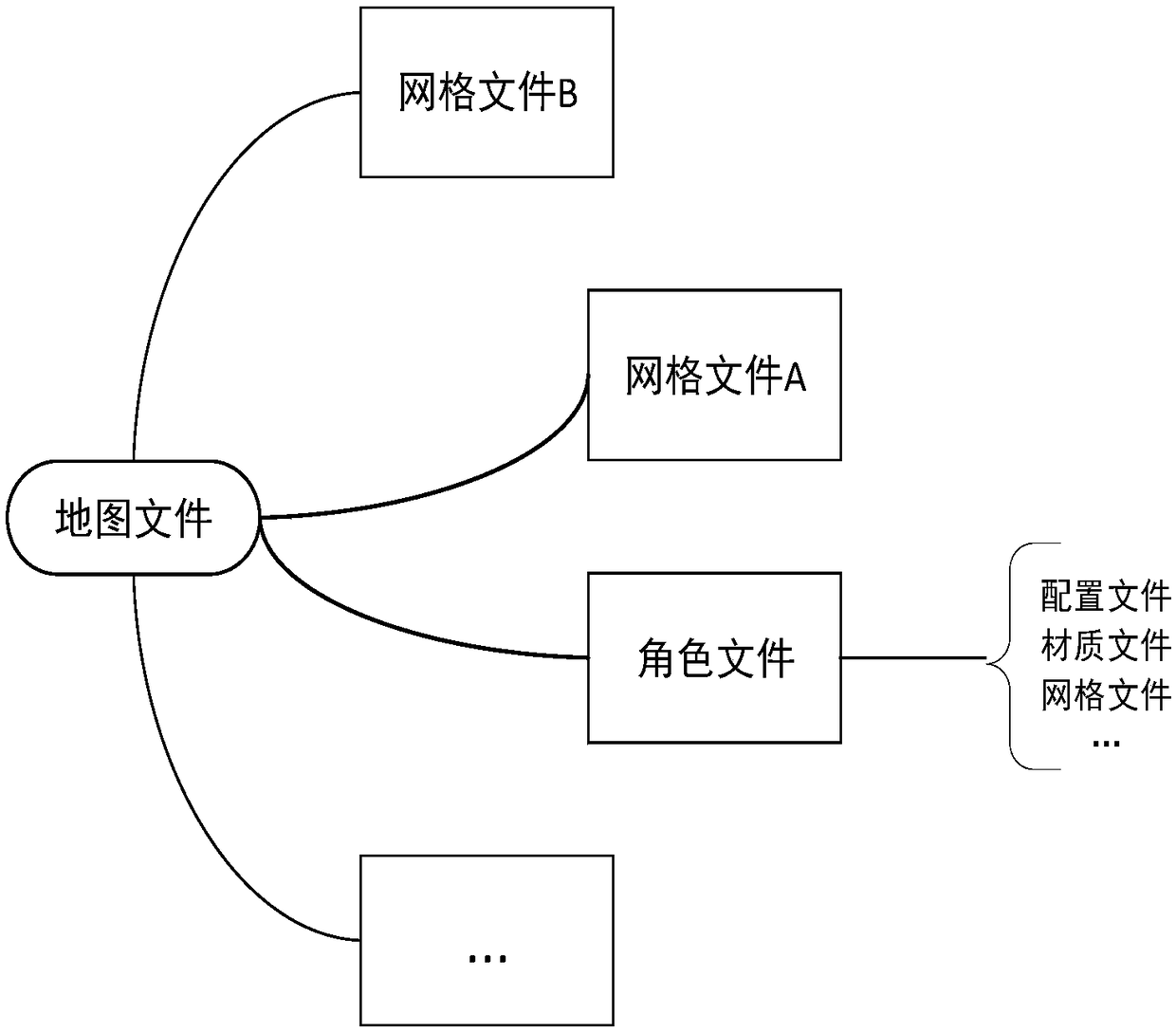

The technical scheme of the invention comprises a method for searching and optimizing a game resource quotation relationship. The method comprises the following steps: injecting a monitoring program into a file opening site, recording a currently opened resource file name, and establishing a resource quotation relationship tree according to the quotation relationship of each file, checking the resource tree to compare the repetition degree and similarity of the underlying resources through a similarity check algorithm, performing marking classification on the resources according to the similarity of the resources, and optimizing a game installation package by using an analysis result according to the multidimensional compressive analysis of space occupation, a use distribution map, similarity and the like of the resources in the resource tee. The method provided by the invention has the beneficial effects of providing an optimized guiding direction for reducing the size of the installation package, deleting redundant files, integrating duplicate files to improve the resource reuse rate, and optimizing the size of the installation package.

Owner:ZHUHAI KINGSOFT ONLINE GAME TECH CO LTD +1

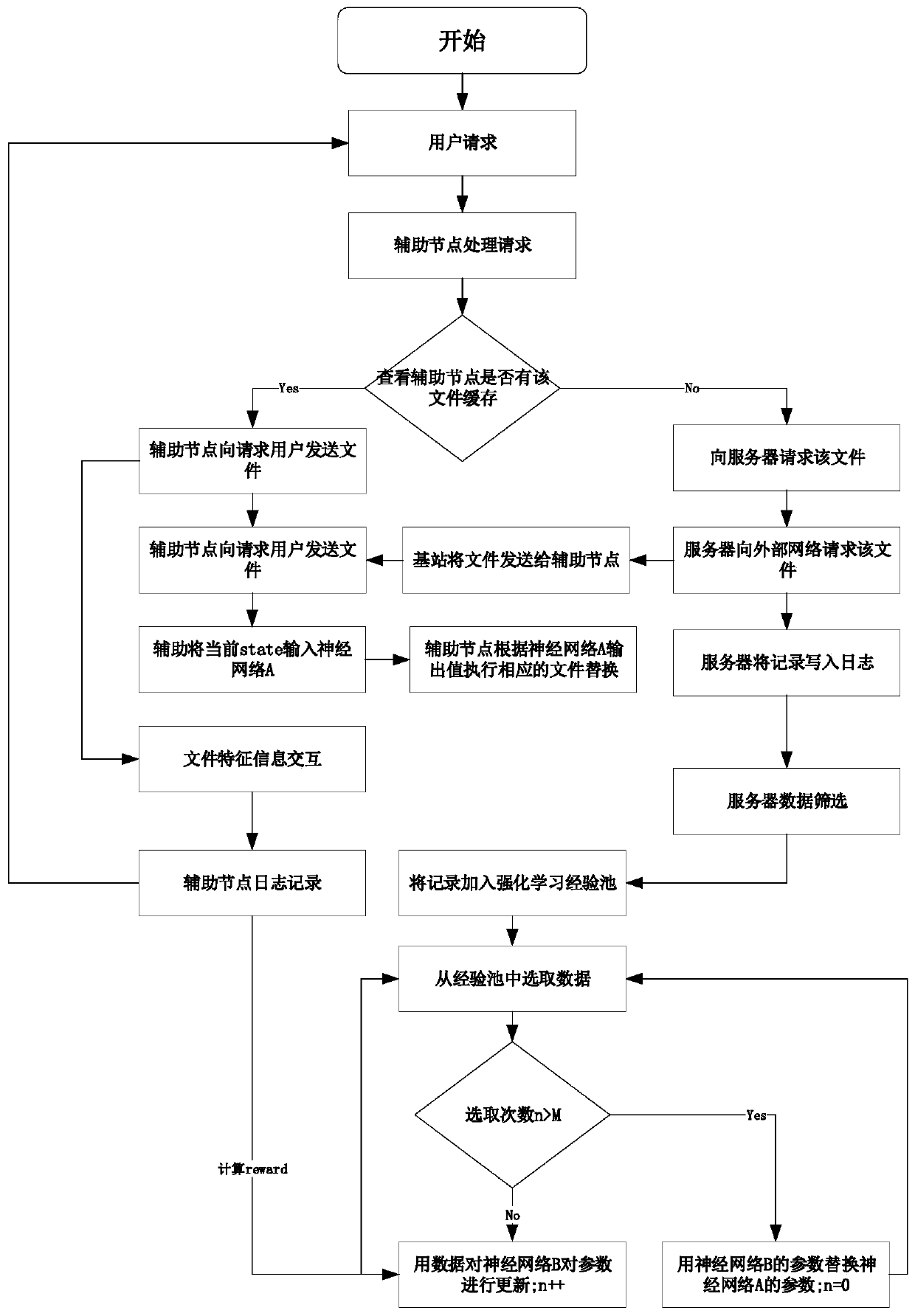

D2D auxiliary equipment caching system and caching method based on reinforcement learning

ActiveCN110062357APrivacy protectionReduce latencyDigital data information retrievalNeural architecturesStatistical analysisComputer science

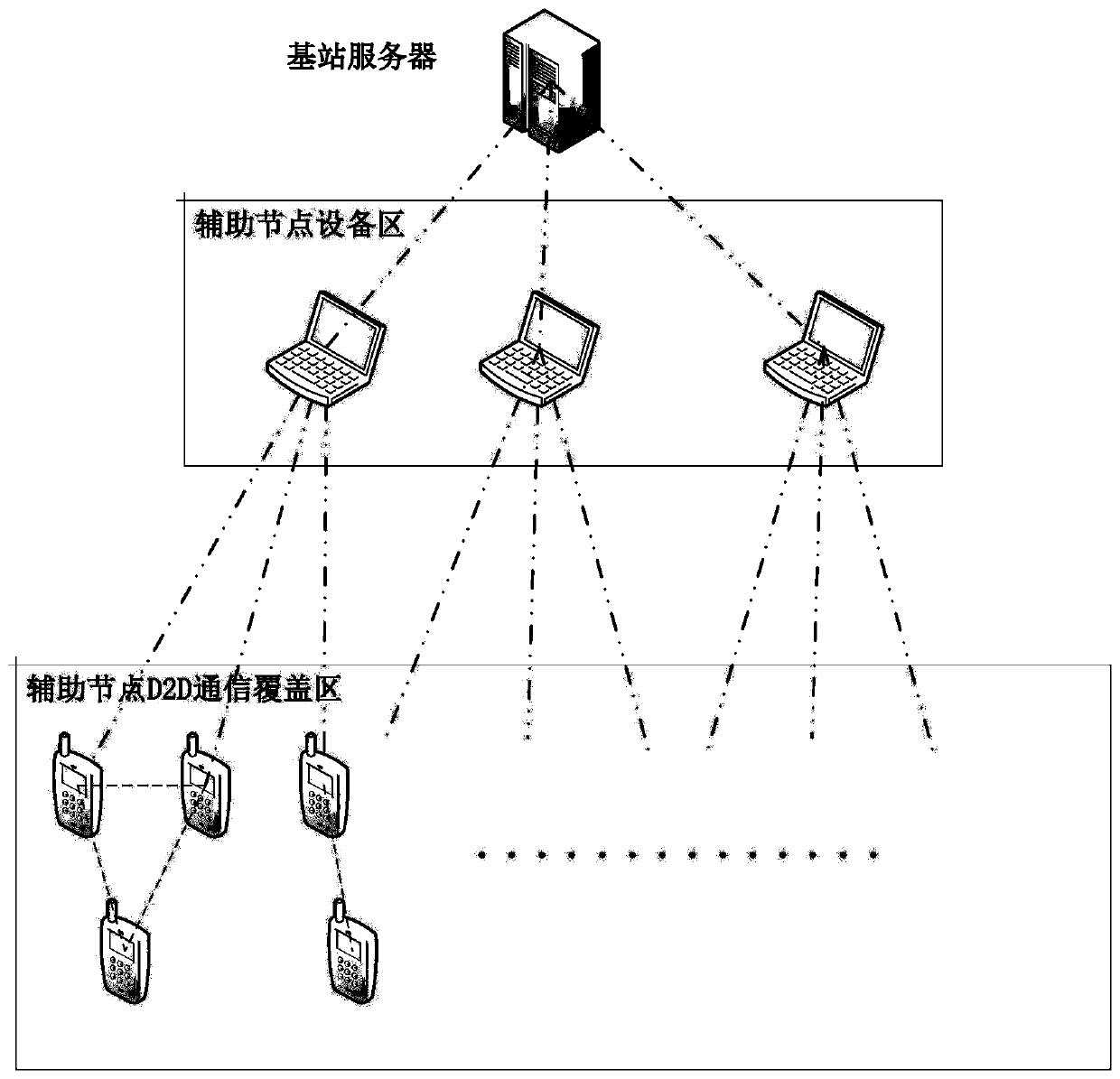

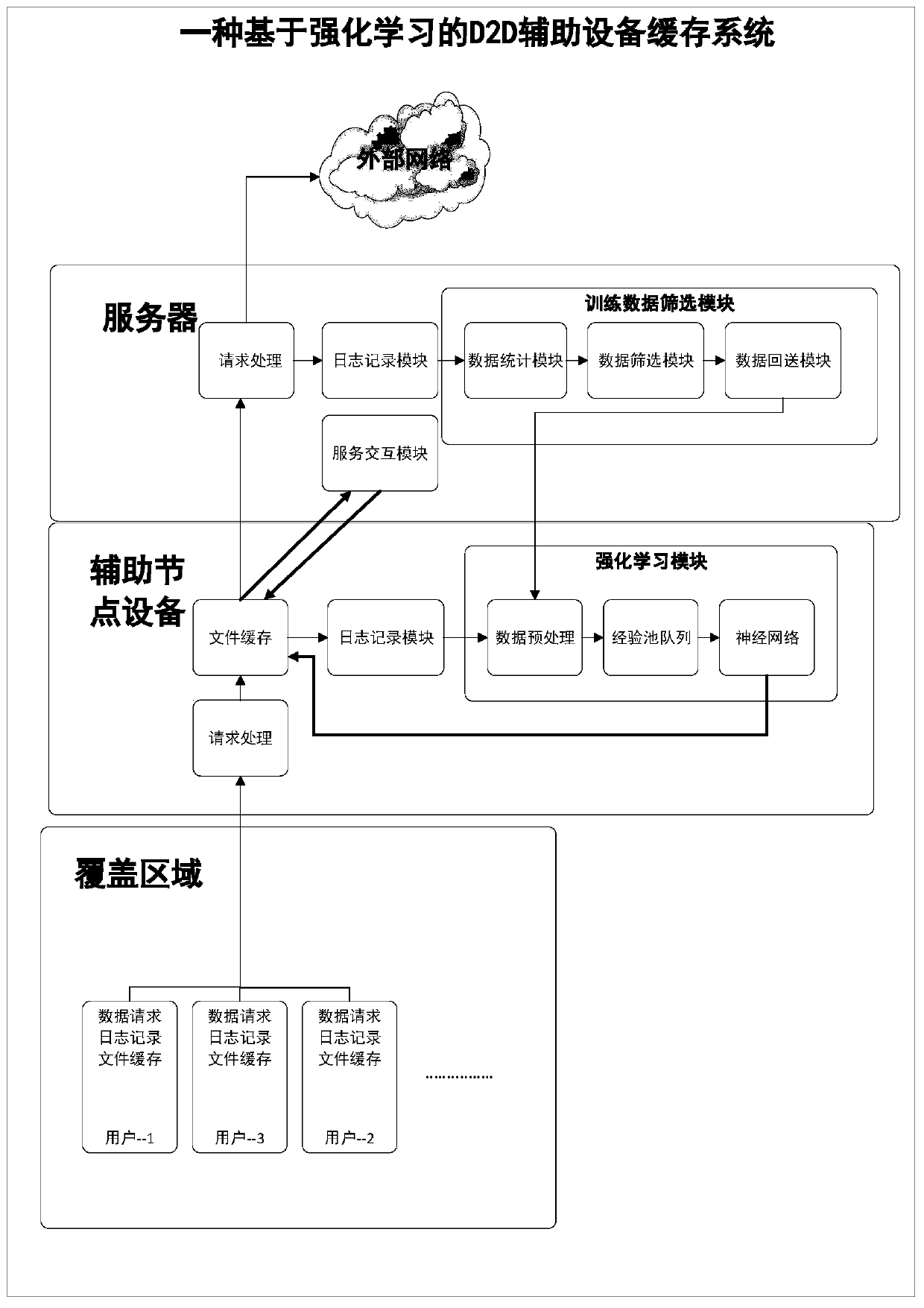

The invention discloses a D2D auxiliary equipment caching system and caching method based on reinforcement learning, and particularly relates to a D2D communication caching optimization system based on a DQN (Deep Q Network) reinforcement learning mode. The system is composed of a training data screening module, a service interaction module, a request processing module and a log recording sub-module of a server side, and a reinforcement learning module, a request processing module, a file caching module, a log recording module of auxiliary node equipment and all users in an auxiliary node D2Dcommunication coverage area where the users are located. The record of a user on a file request is statistically analyzed; the data is screened and then is used for reinforcement learning; a caching strategy adapting to popularity on auxiliary node equipment is obtained through learning by a neural network, so that the hit rate of system D2D auxiliary equipment unloading is improved, the load of abase station is effectively reduced, and the effects of reducing the user delay, saving the network bandwidth, increasing the resource reuse and the like of D2D communication are exerted.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

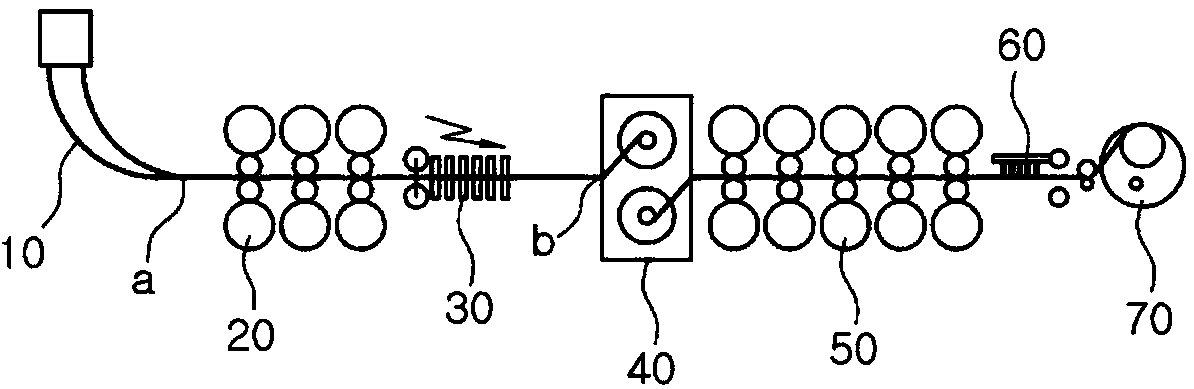

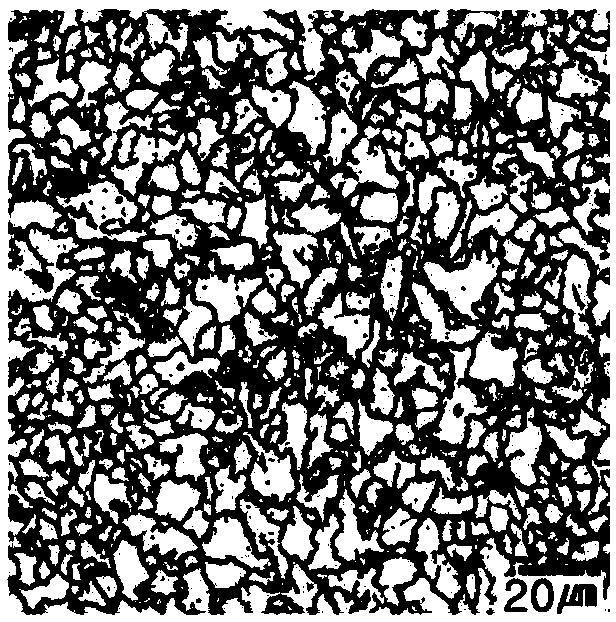

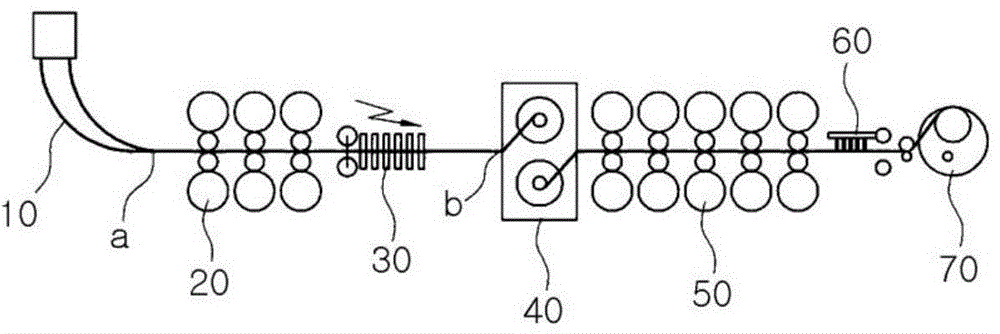

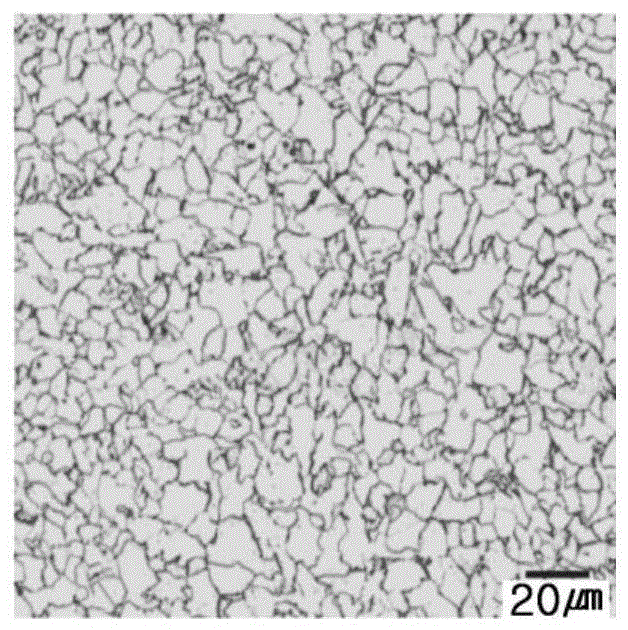

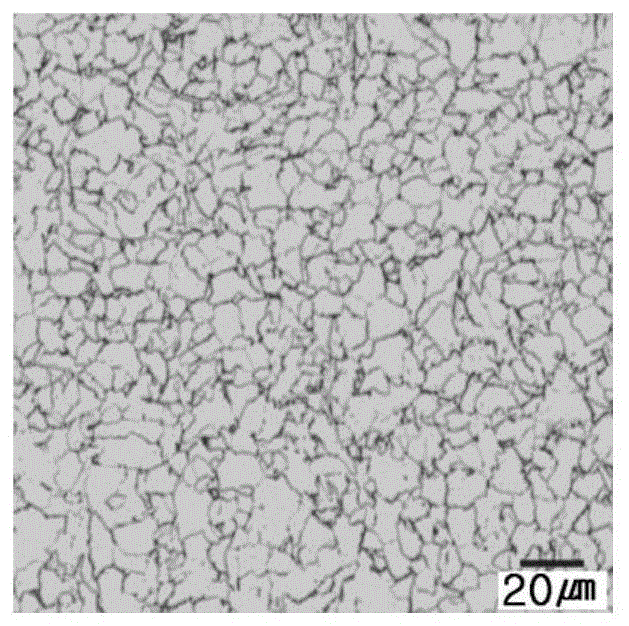

Hot Rolled Steel Plate Which Has Low Errors In Material And Thickness And Has Excellent Resistance Of Electroplating Stripping And The Manufacturing Method Thereof

ActiveCN103882343ASmall materialSmall thicknessHot-dipping/immersion processesFurnace typesProduction rateSheet steel

The present invention relates to a hot rolled steel plate which has low errors in material and thickness and has excellent resistance of electroplating stripping and the manufacturing method thereof. The present invention provides the hot rolled steel plate including the C, Mn, Si, Al, P, S, Cu, Sb, B, N, Ti, Nb foreign element Cr, Ni, Mo, Sn, remainder of Fe and other inevitable impurities, the contents thereof are described in the instruction. The present invention also provides the manufacturing method of the hot rolled steel plate. According to the present invention, scrap iron can be used for making the hot rolled steel plate to improve the reusing resources and to save the energy and productivity, the hot rolled steel plate fused and galvanized can be also used for a molten zinc hot rolled steel plate.

Owner:浦项股份有限公司

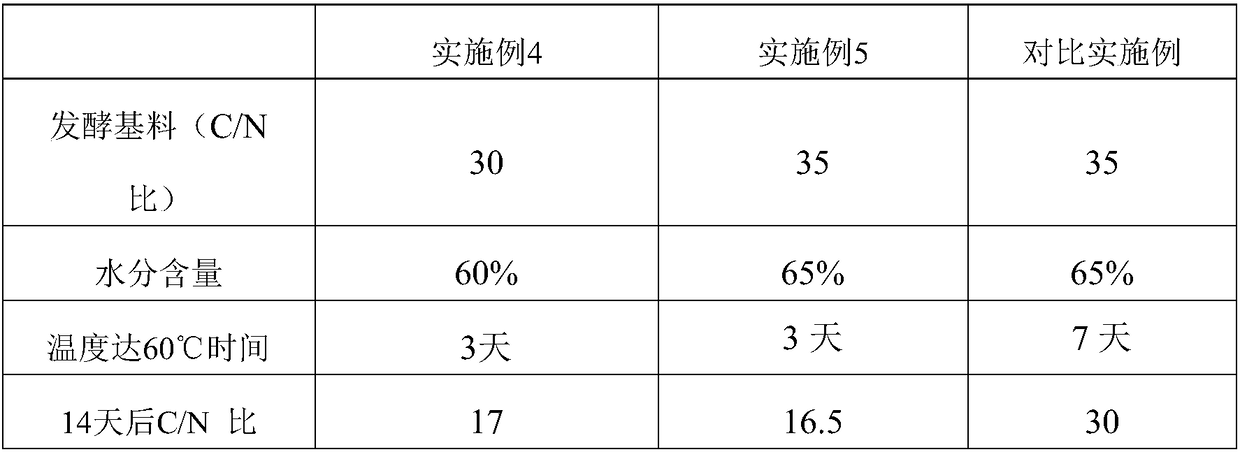

Geobacillus stearothermophilus strain as well as application and application method thereof

InactiveCN108690819AAccelerated destructionQuick breakdownBio-organic fraction processingBacteriaBiotechnologyEngineering

The invention relates to a geobacillus stearothermophilus strain. The geobacillus stearothermophilus R2D2-6. 626069934 is preserved in CGMCC ( China General Microbiological Culture Collection Center)and has the preservation number of CGMCC NO.15478. The strain can be used for maintaining the activity and realizing mass breeding in the compost fermentation high-temperature period; the fast decomposition of organic matters in the compost fermentation can be promoted; the time required by the composting can be greatly reduced; the complete composting degree is improved; the loss of nitrogen elements caused by high temperature or time factors can be reduced; the national NY525-2012 organic fertilizer industry standard can be reached. The organic waste resource reutilization in poultry and livestock culture industry can be favorably improved; the environment damage of the poultry and livestock culture industry can be greatly reduced; the geobacillus stearothermophilus strain also conformsto the operation rule of rural revitalization and green environment agriculture sustainable environment.

Owner:叶荫人

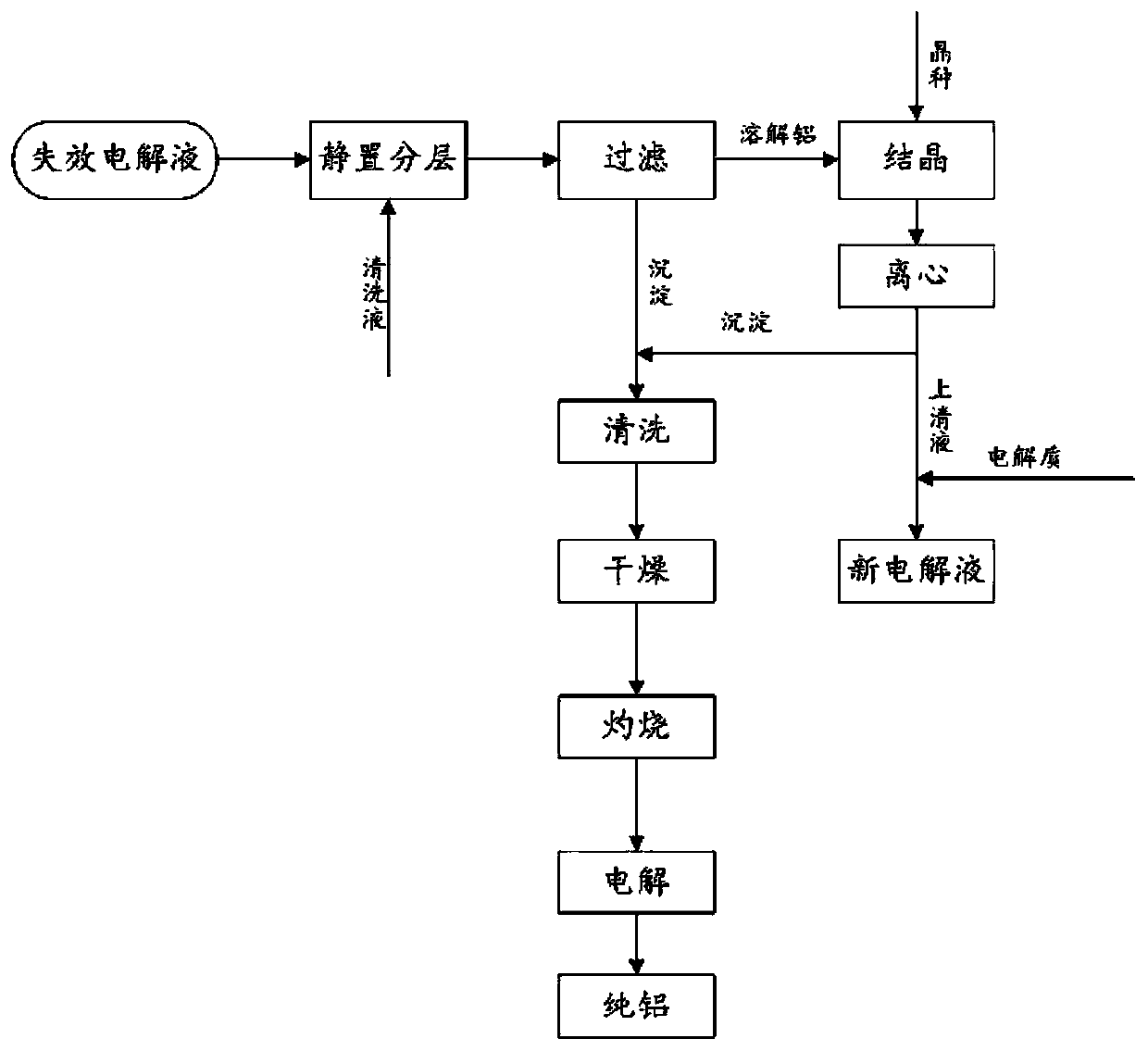

Aluminum-air battery and method for recycling electrolyte of aluminum-air battery

ActiveCN110380159AImprove resource reuseLow costFuel and primary cellsProcess efficiency improvementChemistrySeed crystal

The invention discloses a method for recycling an electrolyte of an aluminum-air battery. The method comprises the steps of: diluting a failed electrolyte, performing cooling, standing and layering, collecting a lower-layer precipitate, adding one or more than one seed crystals into the lower-layer precipitate for crystallization to promote most of dissolved aluminum to precipitate, performing centrifuging, drying, firing to obtain alumina, and electrolyzing the alumina to obtain pure aluminum, wherein the separated supernatant can be added with an electrolyte for repeated use. The invention also discloses an aluminum-air battery with the novel electrolyte prepared by the method. Compared with the prior art, the method can effectively remove the aluminum hydroxide precipitate and most of dissolved aluminum in the electrolyte, and does not introduce impurity phases, so that the centrifuged solution can be used as the electrolyte again after the electrolyte is added, and the resource utilization rate is improved. The method is safe, effective, easy to operate, capable of being performed in a fully-closed environment, capable of purifying the working environment, capable of effectively avoiding environmental pollution, low in requirement on equipment and suitable for large-scale industrialization.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD

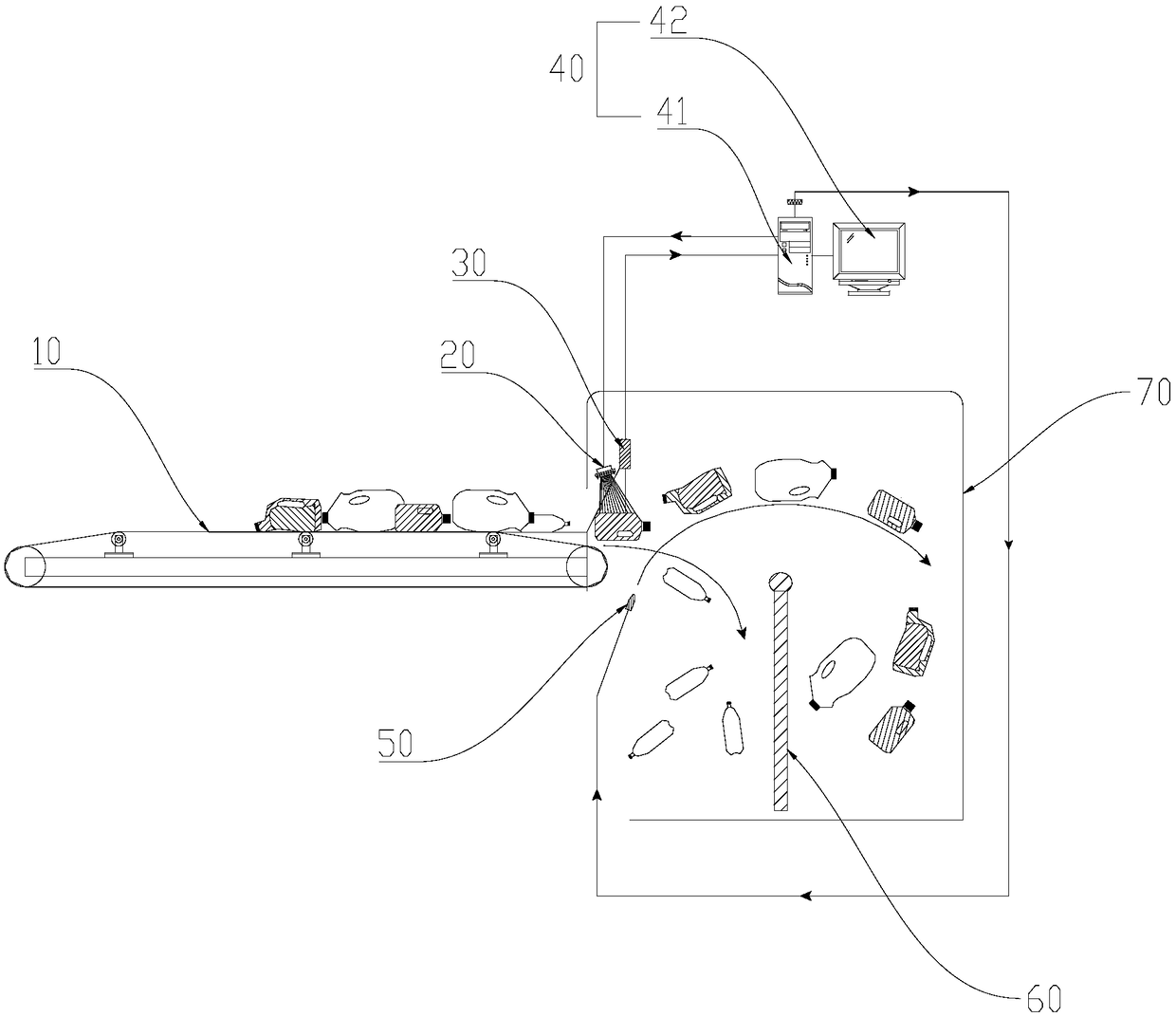

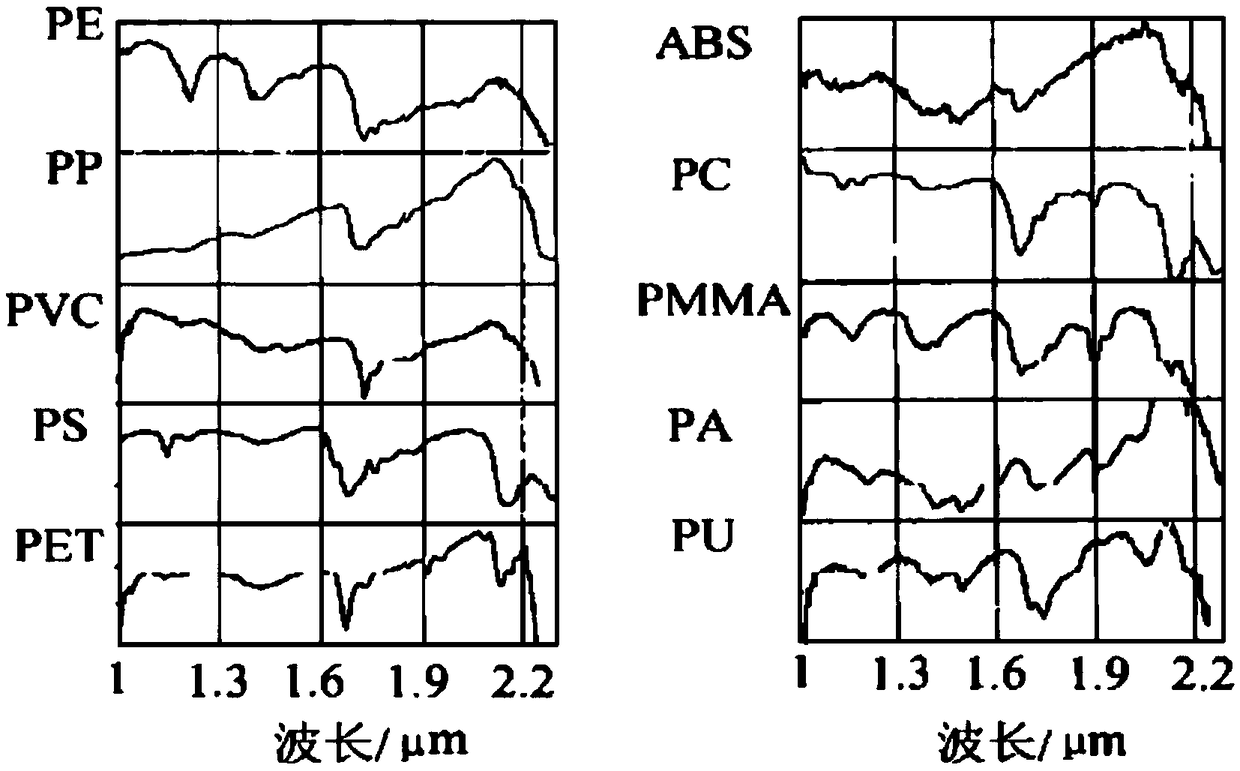

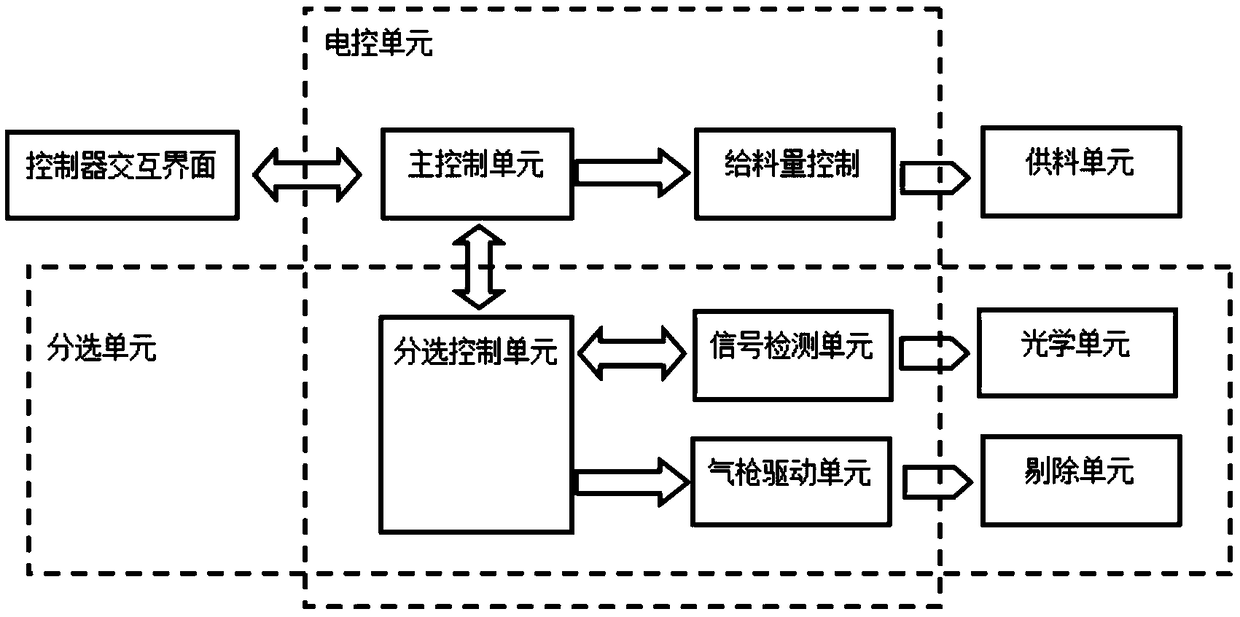

Waste plastic kind sorting device and sorting method thereof

PendingCN108971026AImprove classification efficiencyImprove resource reuseSortingInfraredEngineering

The invention relates to a waste plastic kind sorting device and a sorting method thereof. The waste plastic kind sorting device comprises a conveyor mechanism, a near infrared ray scanning light source arranged above the front edge of the conveyor mechanism, a NIR photoelectric detector located at the front end of the near infrared ray scanning light source, a control mechanism connected with thenear infrared ray scanning light source and the NIR photoelectric detector and a high-pressure air injection mechanism arranged below the front end of the conveyor mechanism; the high-pressure air injection mechanism is connected with the control mechanism, and a classification partition board is arranged at the front end of the high-pressure air injection mechanism. According to the waste plastic kind sorting device and the sorting method thereof, through difference of spectra generated when the near infrared ray scanning light source radiates on different kinds of plastics, the waste plastics with the different kinds are sorted, the efficiency of classifying the waste plastics is greatly improved, the resource reuse rate of municipal solid waste is improved, through more accurate classification, values of products are improved, meanwhile, the environment is protected better, and the practicability is high.

Owner:深圳市朗坤生物科技有限公司

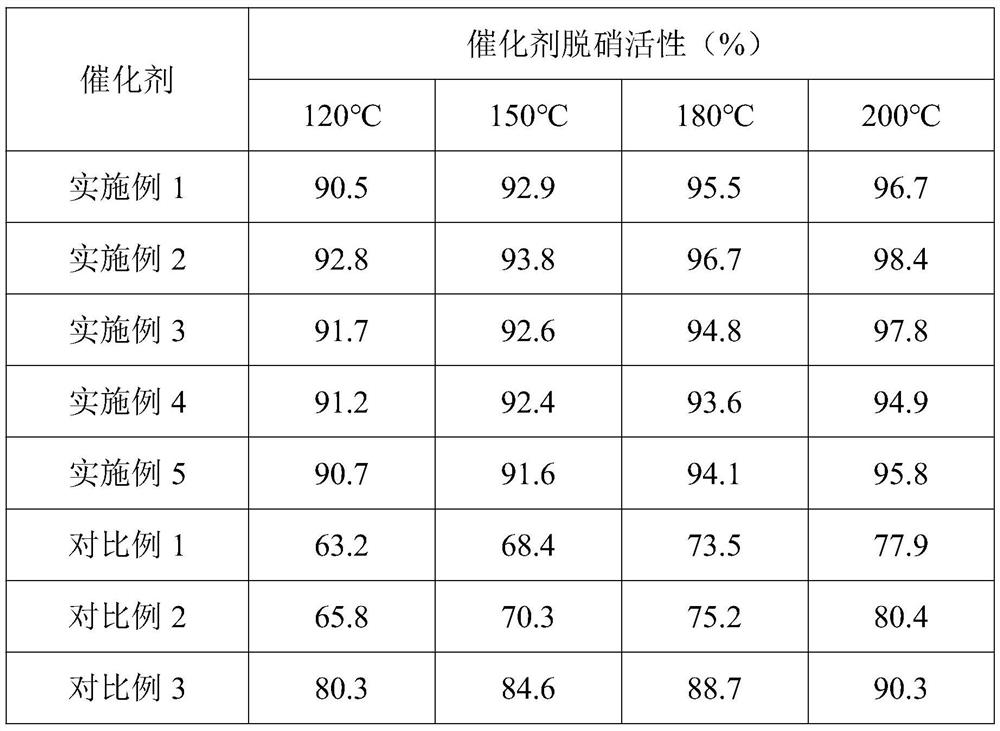

Sulfur-resistant and water-resistant manganese low-temperature denitration catalyst and preparation method thereof

InactiveCN111659364AImprove sulfur resistanceSolution areaDispersed particle separationPerfluorocarbons/hydrofluorocarbons capturePtru catalystPhysical chemistry

The invention discloses a sulfur-resistant and water-resistant manganese low-temperature denitration catalyst and a preparation method thereof, and relates to the technical field of catalyst preparation. The catalyst comprises a sulfur-resistant auxiliary agent, an active component and a hydrophobic substance, and a carrier of the catalyst is a titanium dioxide nanotube synthesized by using a waste SCR catalyst as a raw material through a hydrothermal method. A titanium dioxide nanotube precursor is prepared from the waste SCR low-temperature denitration catalyst through a closed hydrothermalreaction, and is used as a raw material for preparing the honeycomb low-temperature denitration catalyst, and the prepared manganese-based low-temperature denitration catalyst with high sulfur resistance, water resistance and low cost has the following advantages: the production cost is greatly reduced, the sulfur resistance and water resistance are enhanced, and the denitration efficiency is obviously higher than that of the low-temperature denitration catalyst applied in the industry at present. The resource saving is easily achieved, the resource reutilization is improved, the problems of low specific surface area and small pore volume of the existing titanium dioxide are solved, and the industrial application and promotion of the manganese-based low-temperature denitration catalyst areachieved.

Owner:JIANGSU LONGKING COALOGIX CATALYST REGENERATION CO LTD

Microbial organic fertilizer for preventing and treating apple tree canker and preparation method thereof

InactiveCN106348861AWith qi supplementDiureticBiocideBio-organic fraction processingEcological environmentOfficinalis

The invention discloses a microbial organic fertilizer for preventing and treating apple tree canker. The fertilizer is prepared from peanut press pulp, molasses, yeast waste liquor, rice bran, radix astragali, self-heal, Herba Patriniae, taraxacum, Mangnolia officinalis, garlic, a composite fermentation strain and a composite fermenting enzyme. The invention also discloses a preparation method of a microbial organic fertilizer for preventing and treating apple tree canker. The preparation method comprises the steps of multistage fermentation, aging and the like. The microbial organic fertilizer for preventing and treating apple tree canker can effectively treat apple tree canker, effectively inhibit harmful pathogenic bacteria and has certain prevention effects on disease incidence of healthy apple trees. Besides, the fertilizer is capable of promoting growth and development of apple trees and reducing the consumptions of the pesticide and chemical fertilizer, has the advantages of protecting the ecological environment and enhancing the resource reutilization rate, and has favorable economic benefits and social benefits.

Owner:谭仁燕

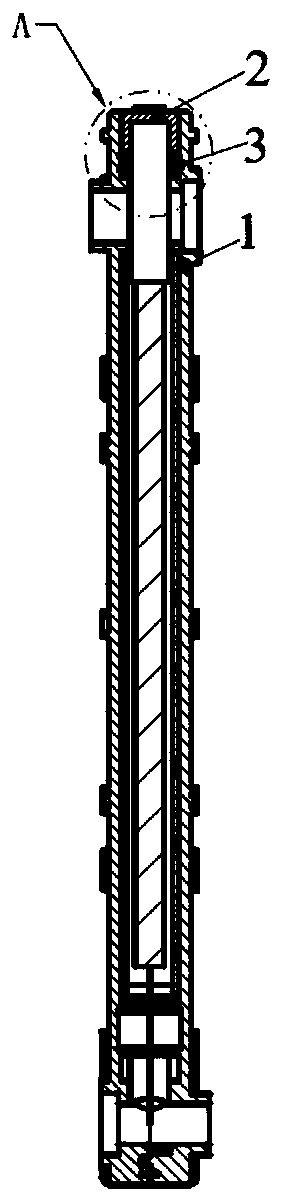

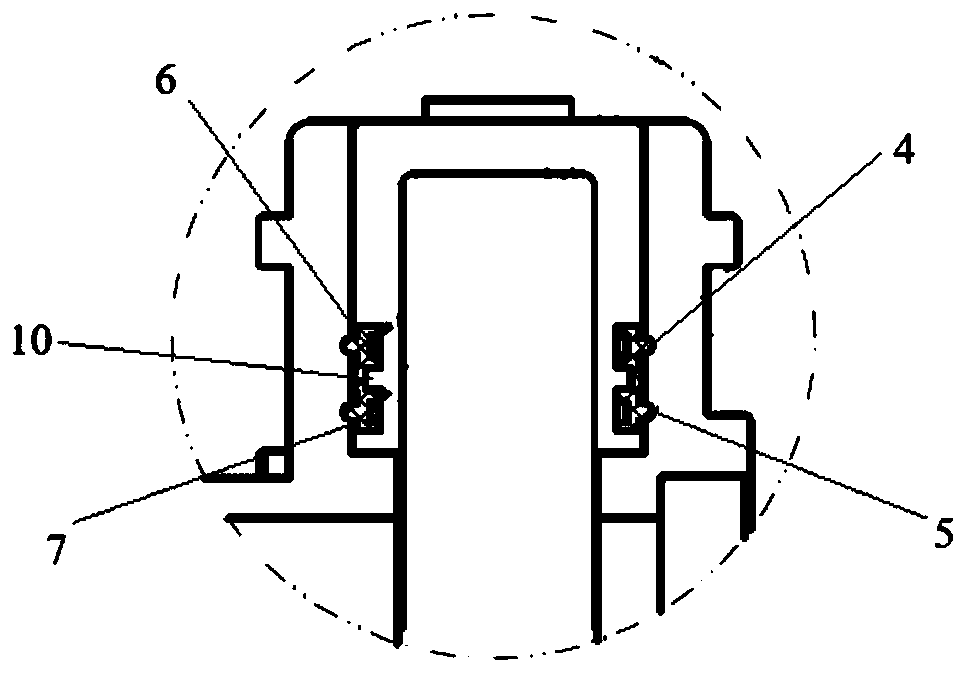

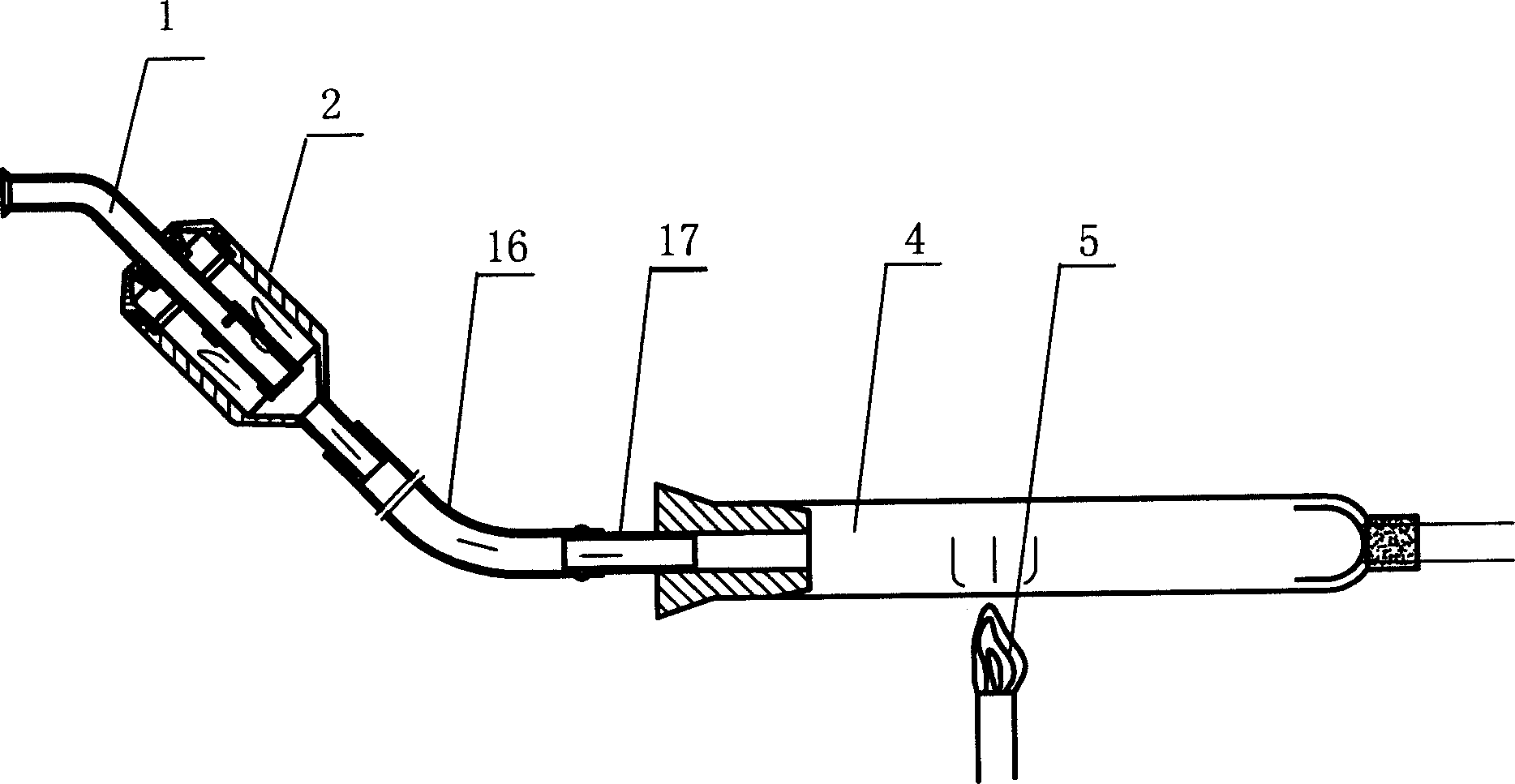

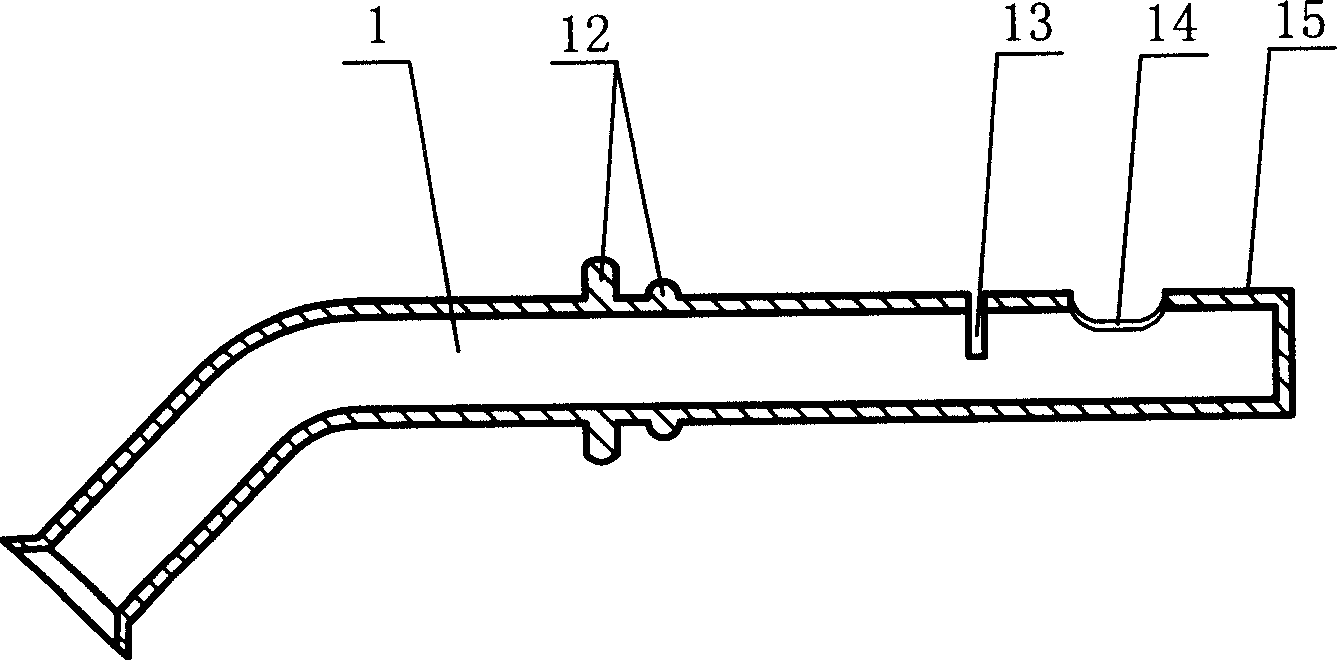

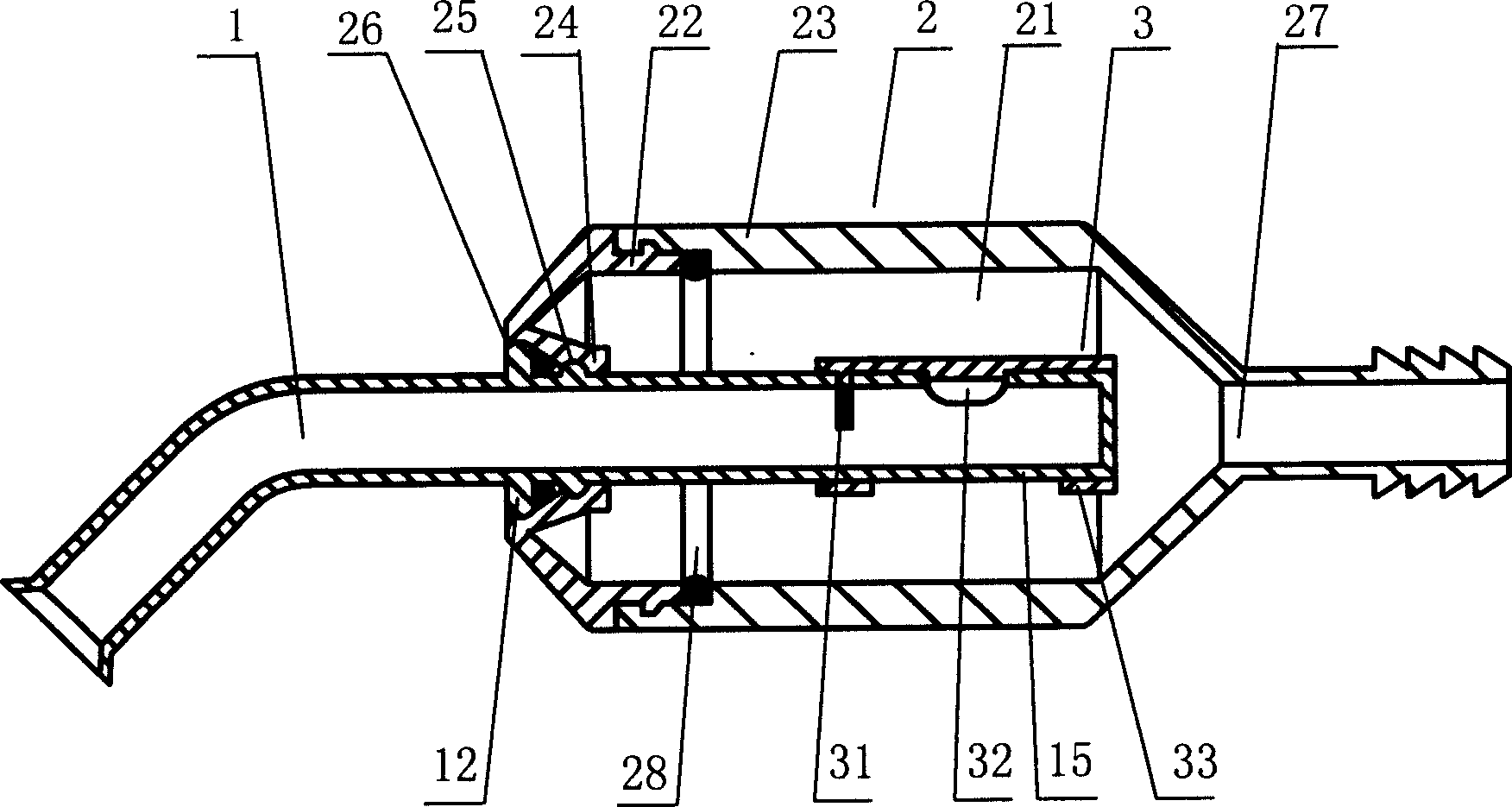

Guarding device for manualy blowing lighting fixture

InactiveCN1736911ASolve the inability to prevent the backflow of harmful gas in the lampSolve resource problemsGlass reforming apparatusBlow pipesCouplingEffect light

The sevurity protection device for manual blast-produced lamp comprises a tube-type gas mouth, a coupling hose, connection pipe fixed between the said hose and lamp seal, and an air draft device between the said mouth and hose with gas storage room, connection end for said mouth with fixed valve membrane device. This invention solves the problems that existing device can not stop the reflow of harmful gas and resources recycle.

Owner:关美银

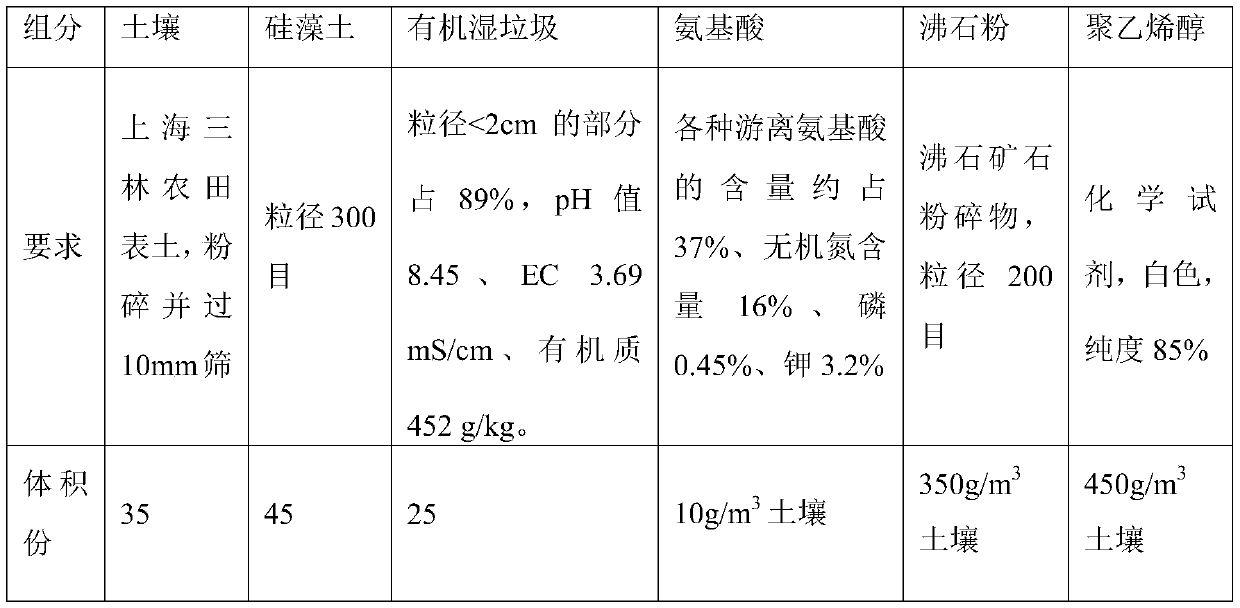

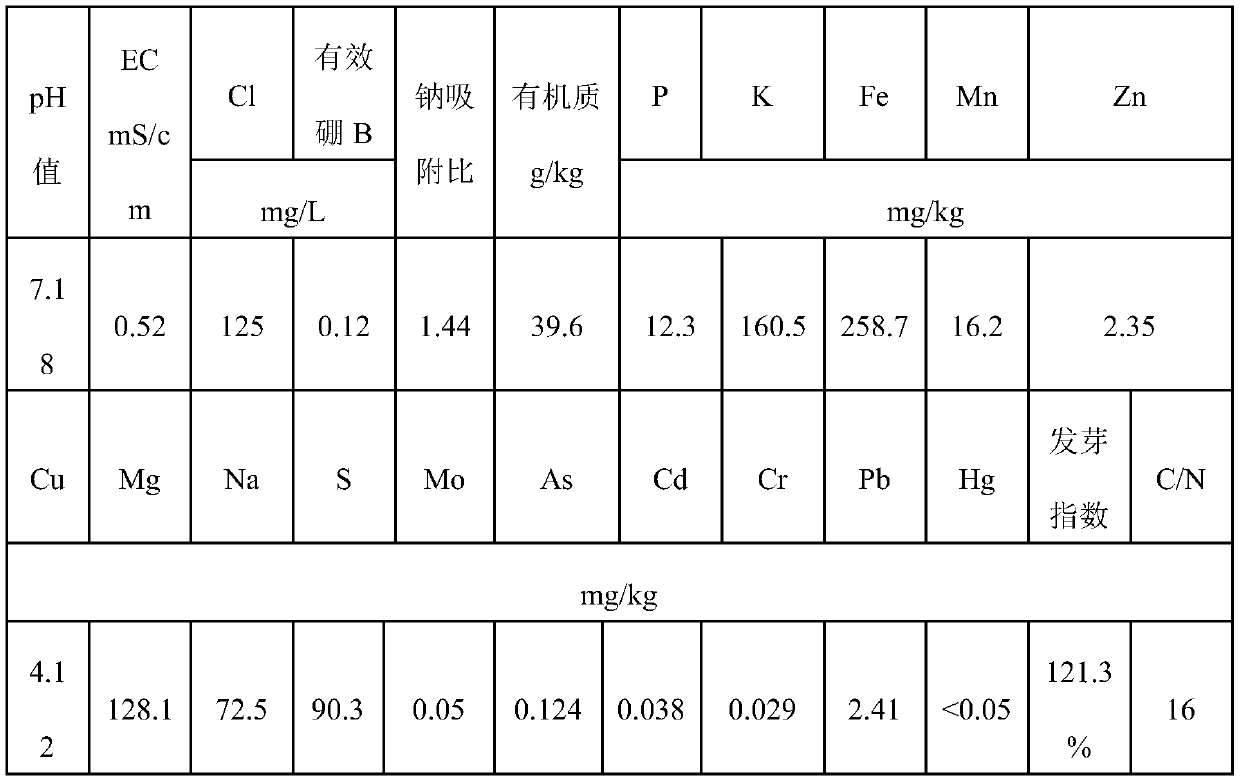

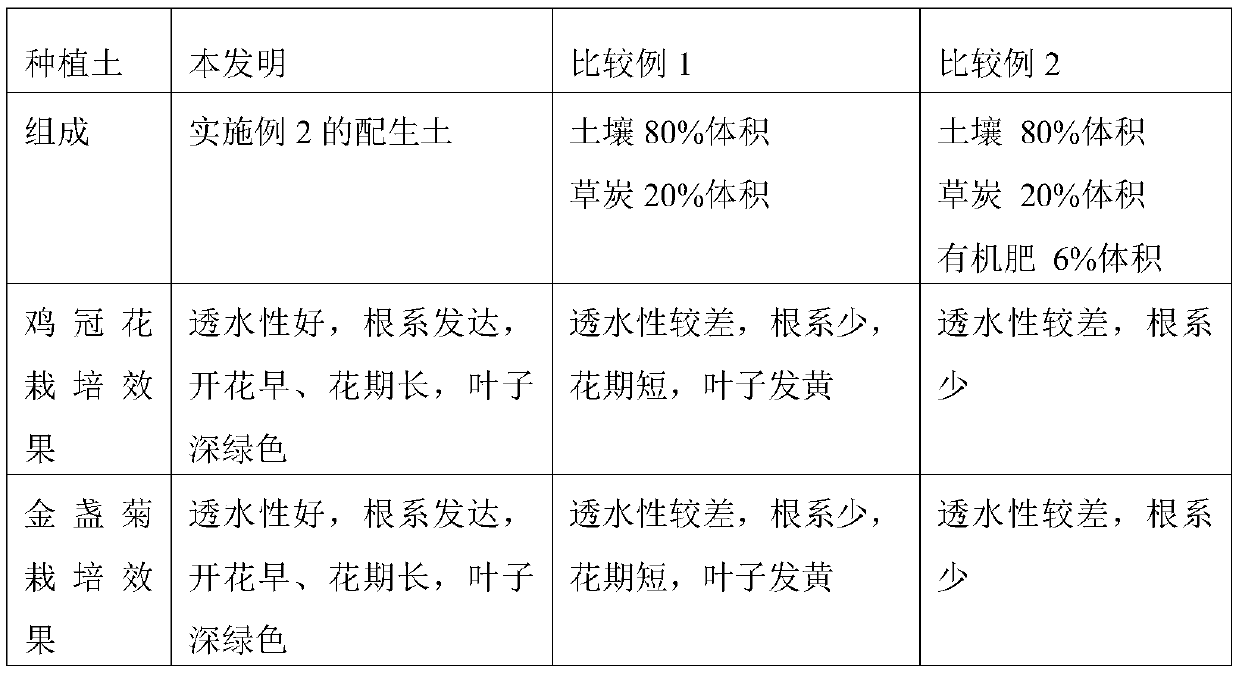

Prepared raw soil prepared with organic wet garbage

InactiveCN109819866AImprove ventilationImprove soil structureGrowth substratesCulture mediaFertilizerChemistry

The invention relates to prepared raw soil prepared with organic wet garbage. The prepared raw soil is basically prepared from, by volume, 30-40 parts of soil, 30-40 parts of organic wet garbage compost and 20-40 parts of kieselguhr, and is formed by mixing the raw materials, wherein 20 g-50 g of amino acid, 300 g-600 g of zeolite powder, 400 g-500 g of polyvinyl alcohol and the like are added corresponding to soil of per cubic meter. Optionally, a proper amount of is added in the component mixing process to promote adsorption between all components and homogenization of a product. The prepared raw soil has the better broad spectrum, is suitable for planting of most landscape plants, and has the better hydrophobicity, water-retaining property and fertilizer maintenance property, nutrientsare comprehensive, the proportion is moderate, growth of plants can be promoted, and compared with a traditional medium and planting oil, the aspects of the plant growth vigor, the flowering phase, the plant adverse resistance, the roots and the like are obviously improved through the prepared raw soil.

Owner:SHANGHAI ACADEMY OF LANDSCAPE ARCHITECTURE SCI & PLANNING

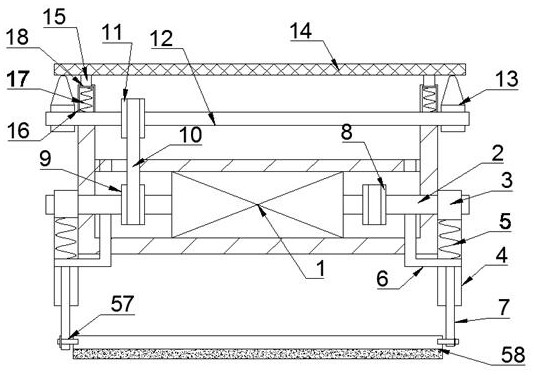

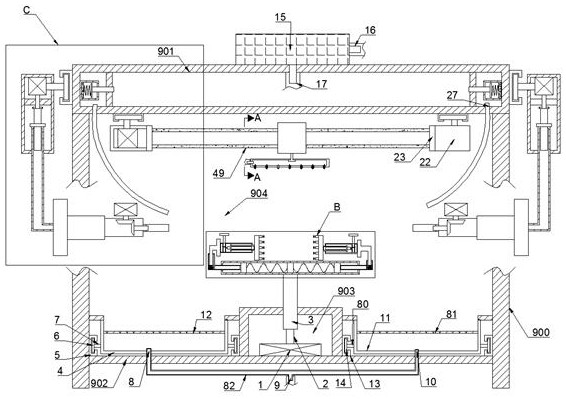

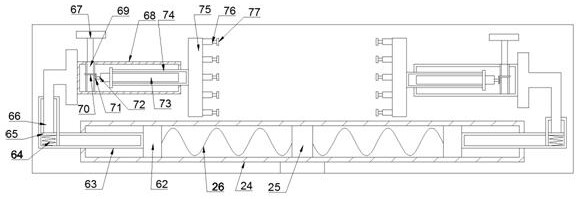

Machine for automatically recycling, screening and grading abrasive materials of shot blasting machine

InactiveCN112474350AEasy to collectQuality is easy to controlSievingGas current separationElectric machineryBilateral symmetry

The invention discloses a machine for automatically recycling, screening and grading abrasive materials of a shot blasting machine. The machine comprises a main body, wherein a first screening box isfixedly arranged on the main body; a first motor is fixedly arranged in the first screening box; and first motor shafts which extend out of the first screening box in a bilateral symmetry mode are rotatably arranged on the first motor. According to the machine, steel shots on the ground can be automatically collected through automatic collecting equipment, so that the steel shots are simple and convenient to collect; impurities are separated from the steel shots through a screening mechanism, and then the complete steel shots are separated from small broken shots and dust of the small broken shots, so that the steel shots are recycled and screened in one step; the abrasive materials are classified through recycled abrasive material grading equipment, so that the quality of the recycled abrasive materials is controllable; and moreover, the utilization is convenient, the labor intensity of people is reduced, the recycling efficiency is improved, the use cost of the shot blasting machineis reduced, and the resource reutilization rate is increased.

Owner:宁海艾雅机械设备有限公司

Microbial organic fertilizer for preventing and treating peach leaf curl and preparation method thereof

InactiveCN106045735AImprove anti-inflammatory and bactericidal effectGrowth inhibitionBioloigcal waste fertilisersNitrogenous fertilisersEcological environmentFermentation

The invention discloses a microbial organic fertilizer for preventing and treating peach leaf curl, made from the following materials: tea leaf dregs, rice bran, soybean meal, straw, humic acid, Radix Astragali, Spica Prunellae, Flos Lonicerae, dandelion, complex trace elements, composite fermenting bacteria and composite fermentation enzymes. The invention also discloses a preparation method of the microbial organic fertilizer for preventing and treating peach leaf curl, comprising the steps such as multistage fermenting and aging. The microbial fertilizer for preventing and treating peach leaf curl according to the invention can effectively prevent and treat peach leaf curl, effectively inhibit germs and can also prevent healthy peach trees from infecting peach leaf curl; in addition, the fertilizer can also promote growth and development of peach trees, enables reduced usage of pesticides and chemical fertilizers, has the advantages of protection of ecological environment and increased reutilization rate of resources, and has good economic and social benefits.

Owner:谭仁燕

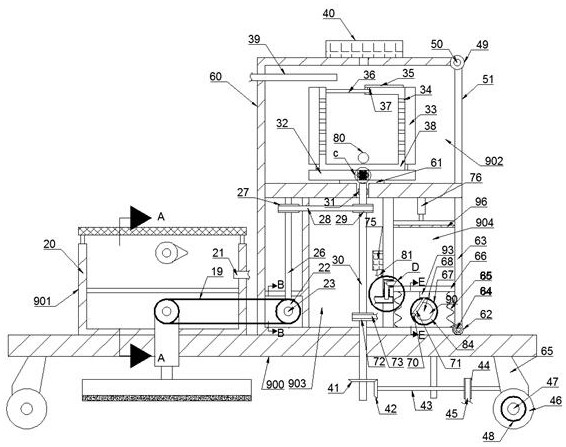

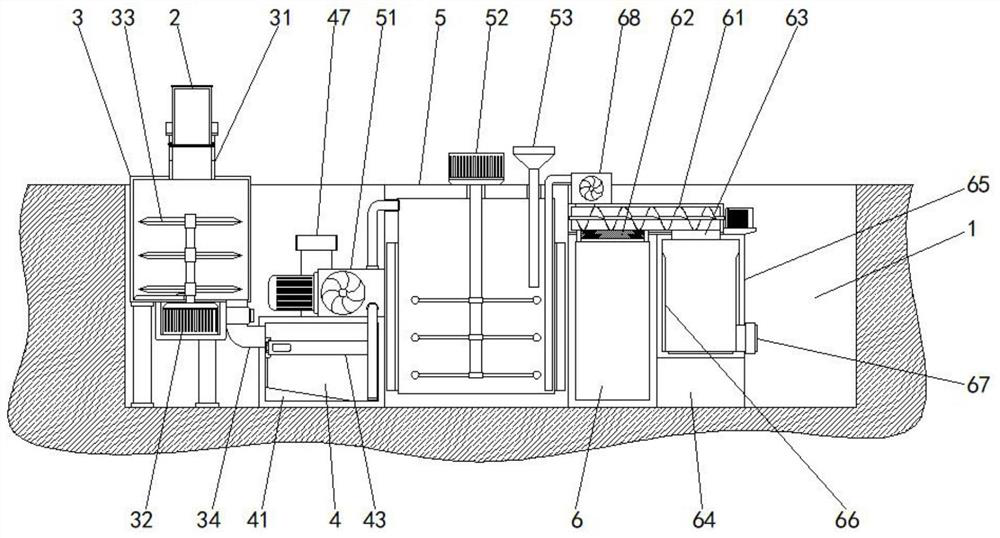

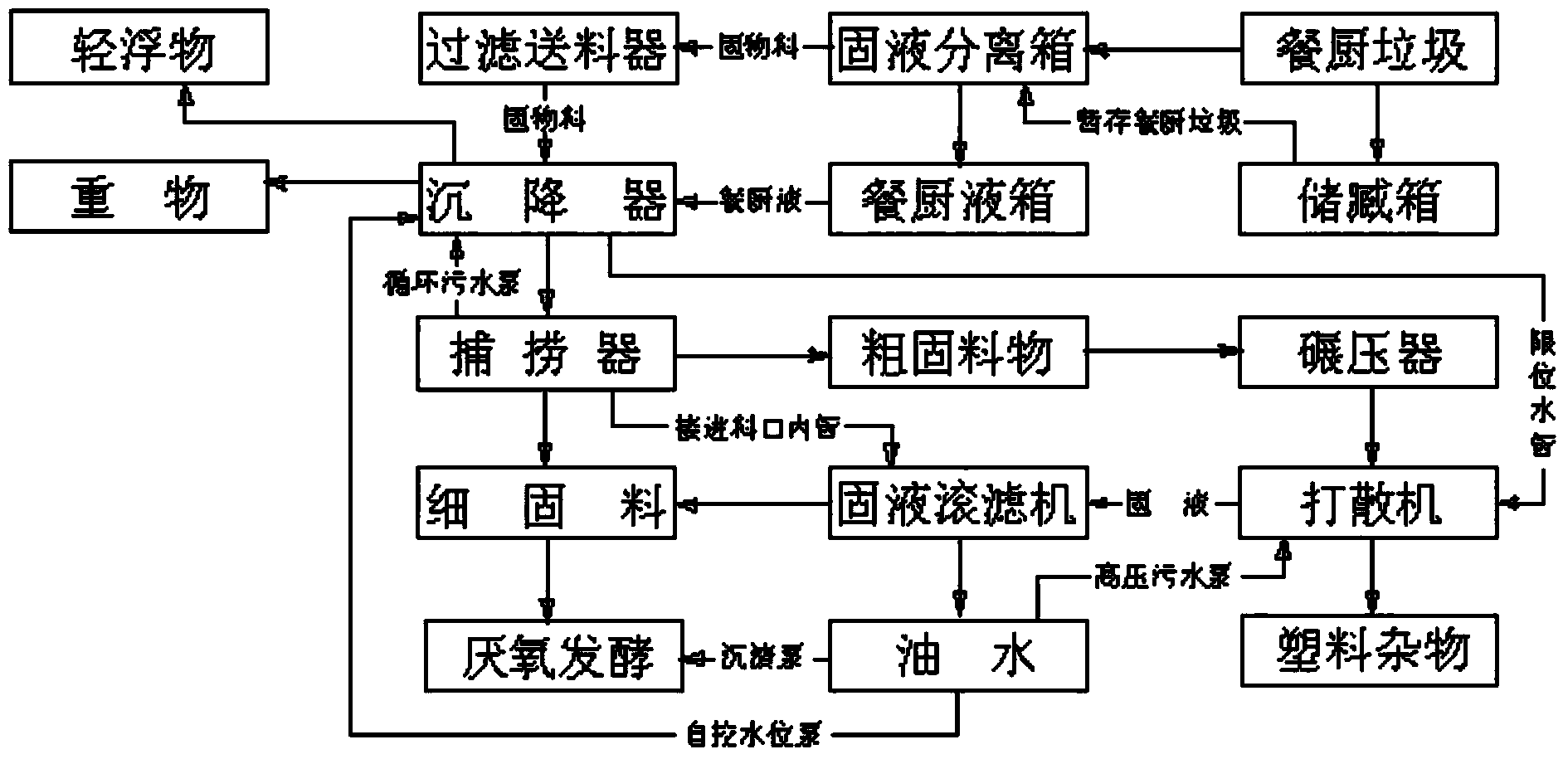

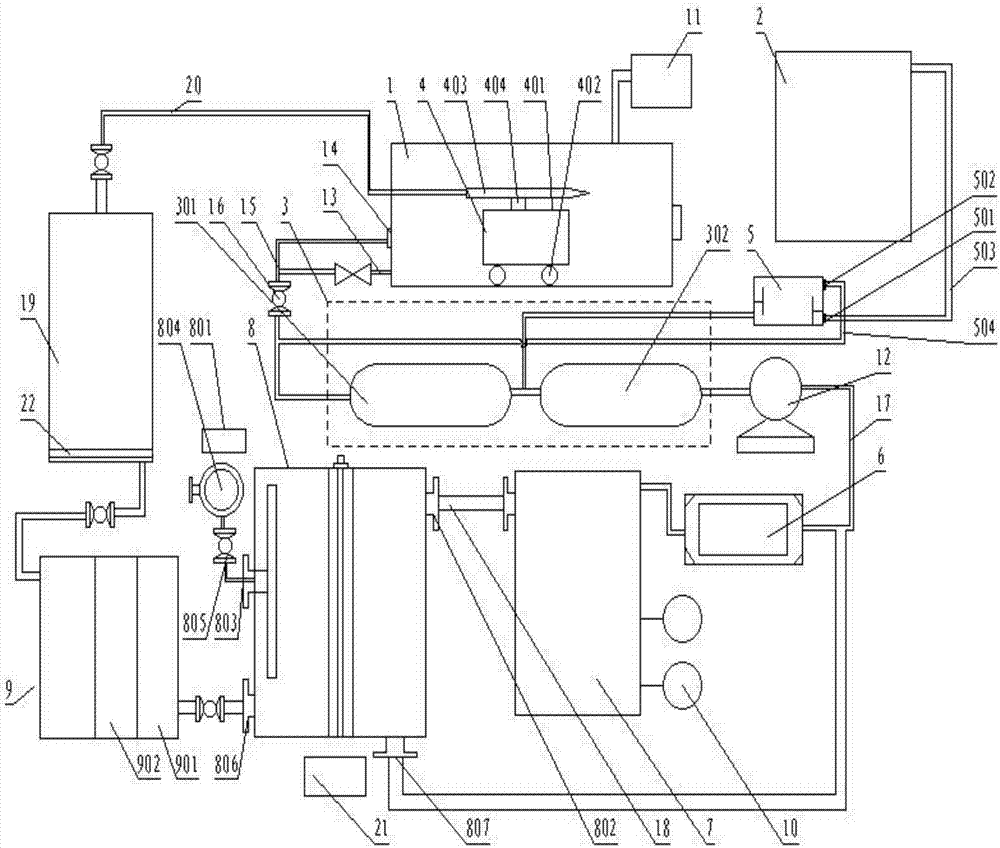

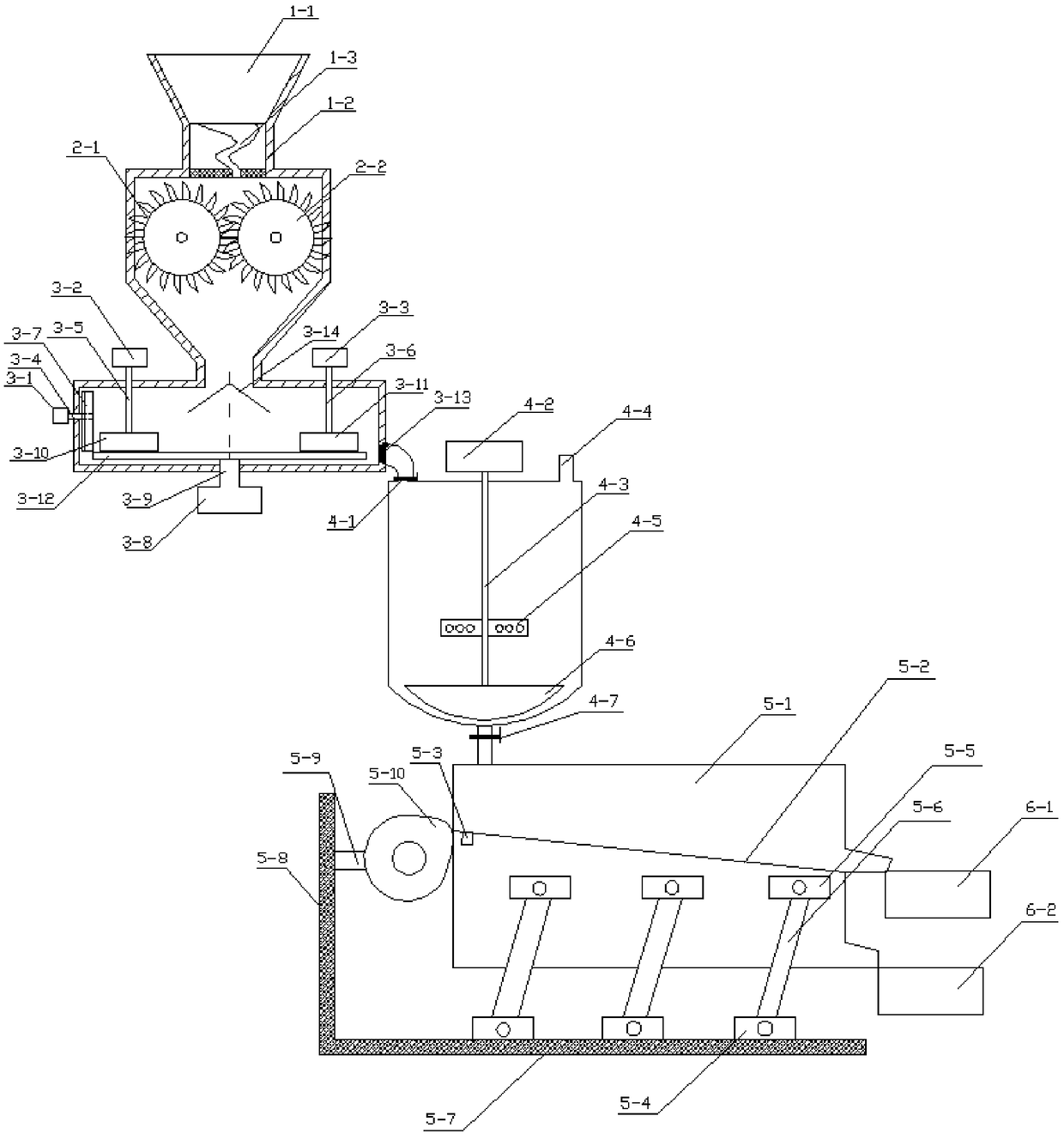

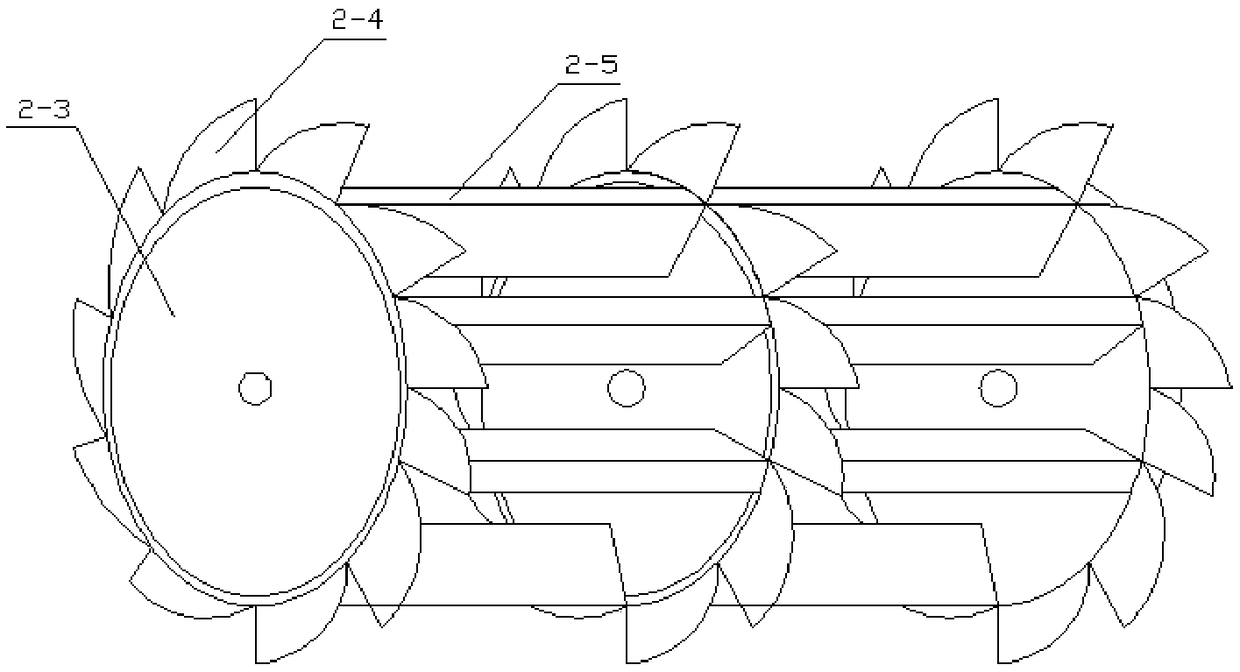

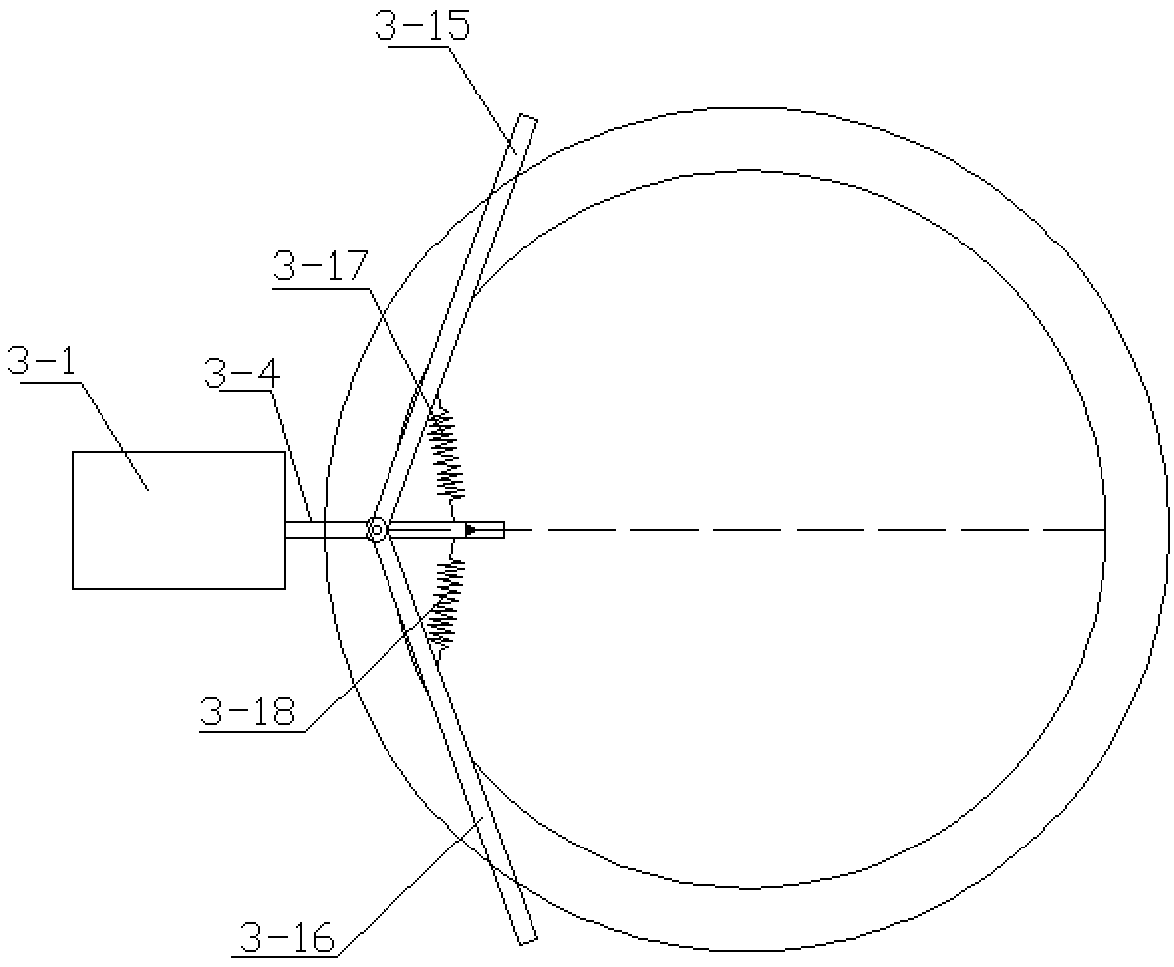

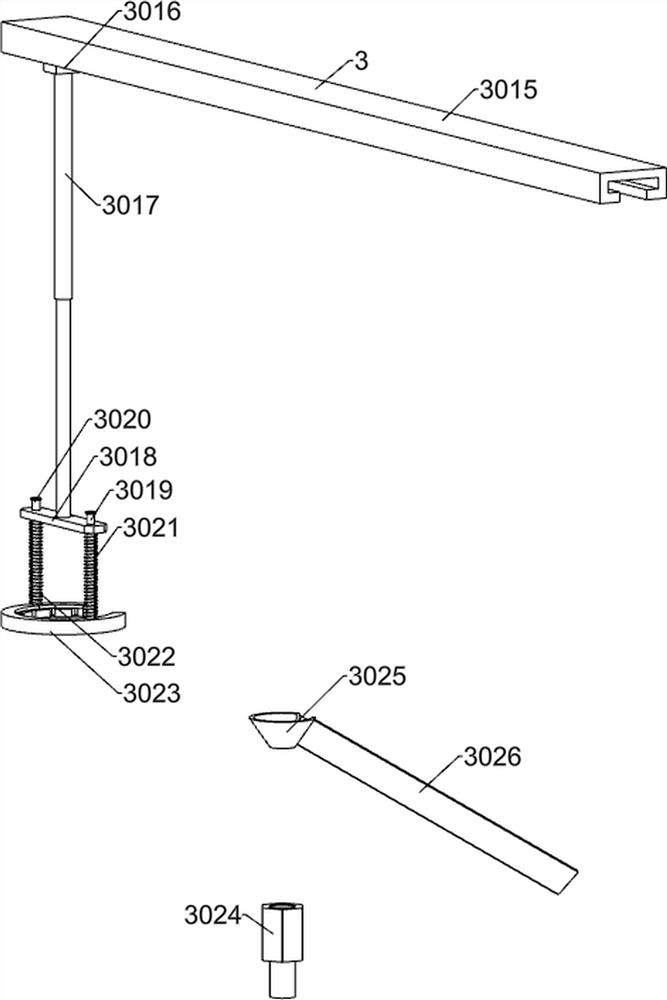

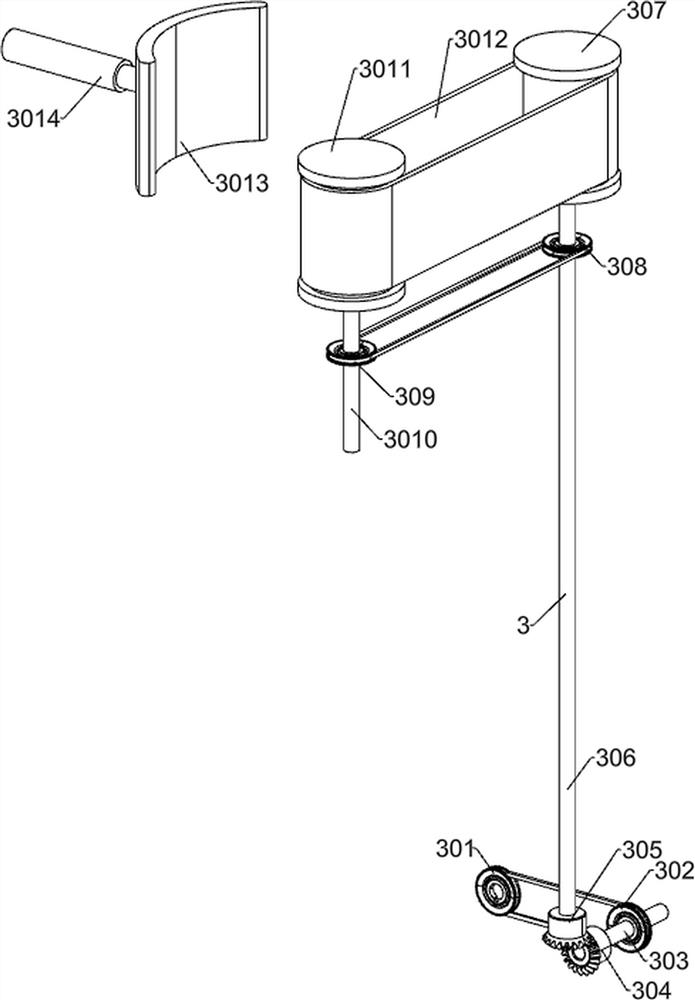

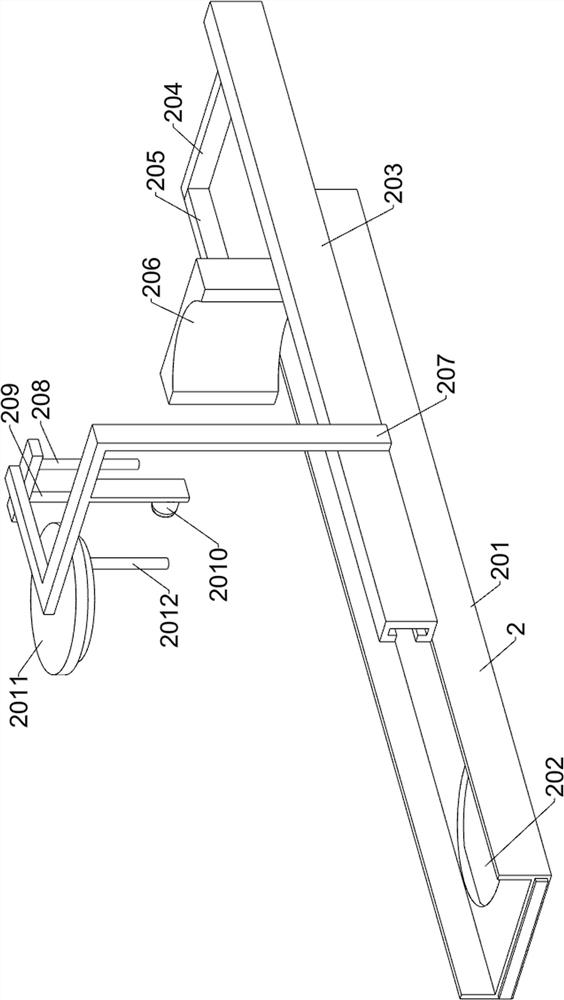

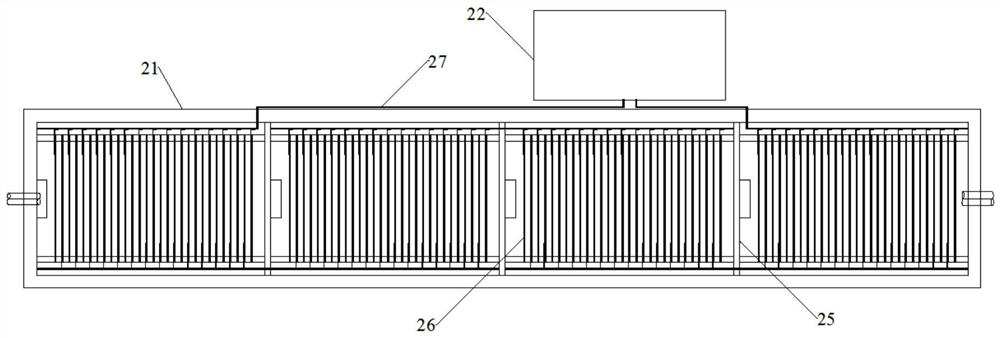

Kitchen waste heating and filtering treatment device and treatment method

PendingCN113426812AAvoid getting dirtyAvoid divergenceSolid waste disposalProcess engineeringEnergy consumption

The invention relates to a kitchen waste heating and filtering treatment device. The device comprises a pit used for containing equipment, a smashing mechanism is arranged in the pit and used for smashing kitchen waste, an oil-water separation mechanism is arranged on the right side of the smashing mechanism and used for separating oil, water and residues, and a fermentation mechanism is arranged on the right side of the oil-water separation mechanism and used for fermenting the residues, wherein a solid-liquid separation treatment mechanism is arranged on the right side of the fermentation mechanism and used for filtering the residues. The kitchen waste heating and filtering treatment device and method have the advantages of being simple in process route, low in energy consumption, high in automation degree and high in resource reutilization rate, and are particularly suitable for centralized resourceful treatment of small-scale kitchen waste; and therefore, the problem of protein homology does not exist at the same time, compared with landfill treatment, the method is safer, and the pollution to the environment can be reduced to the minimum.

Owner:浙江永尔佳环保科技有限公司

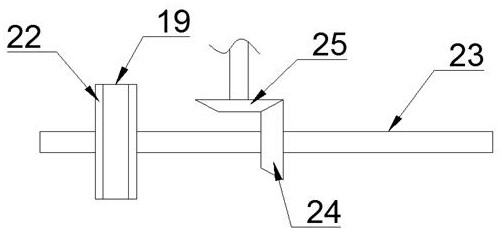

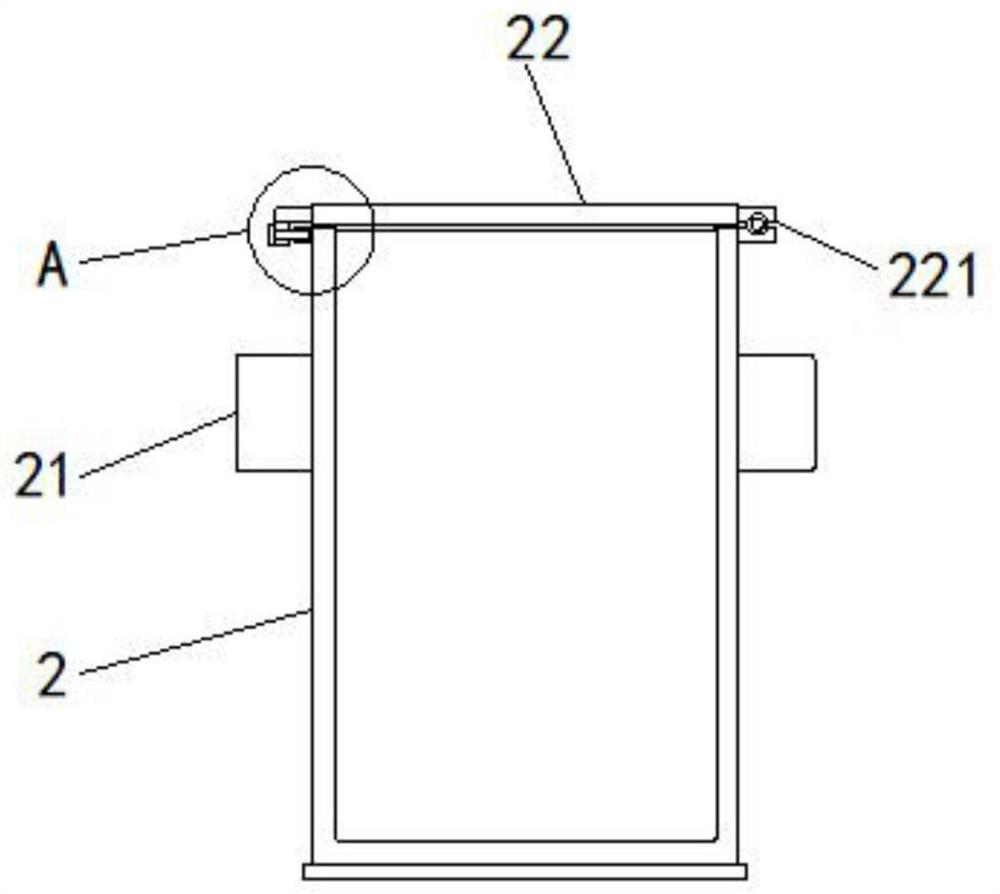

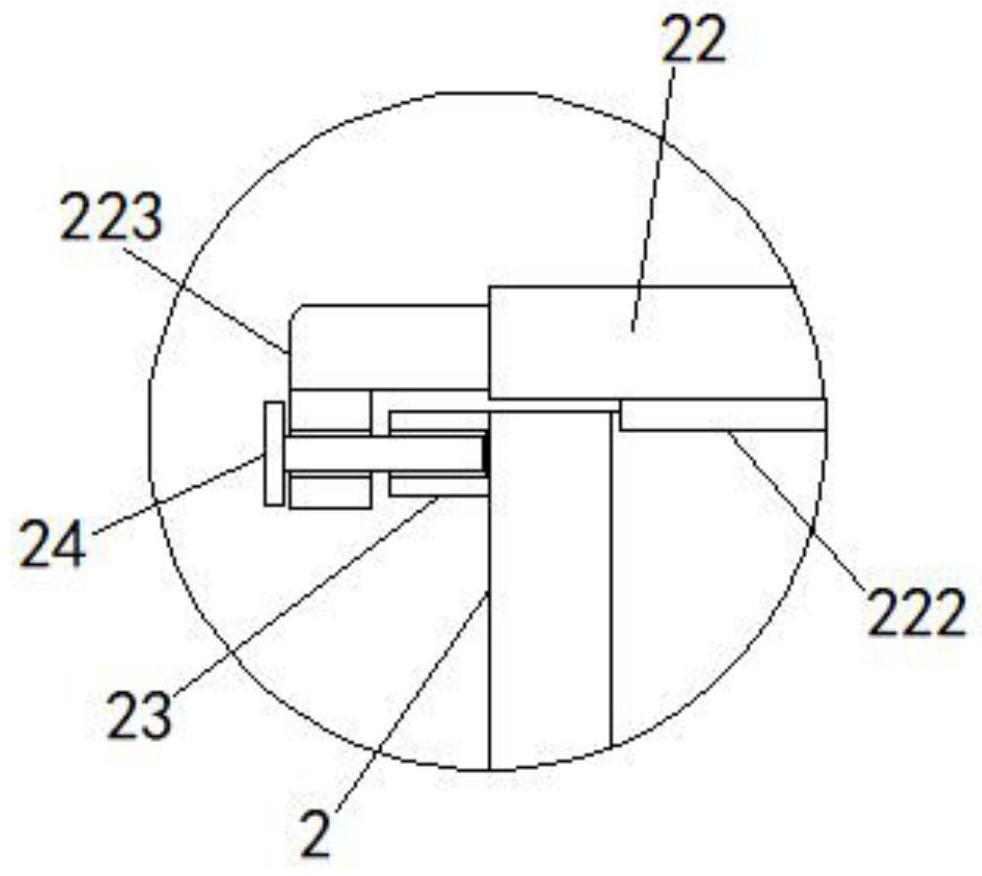

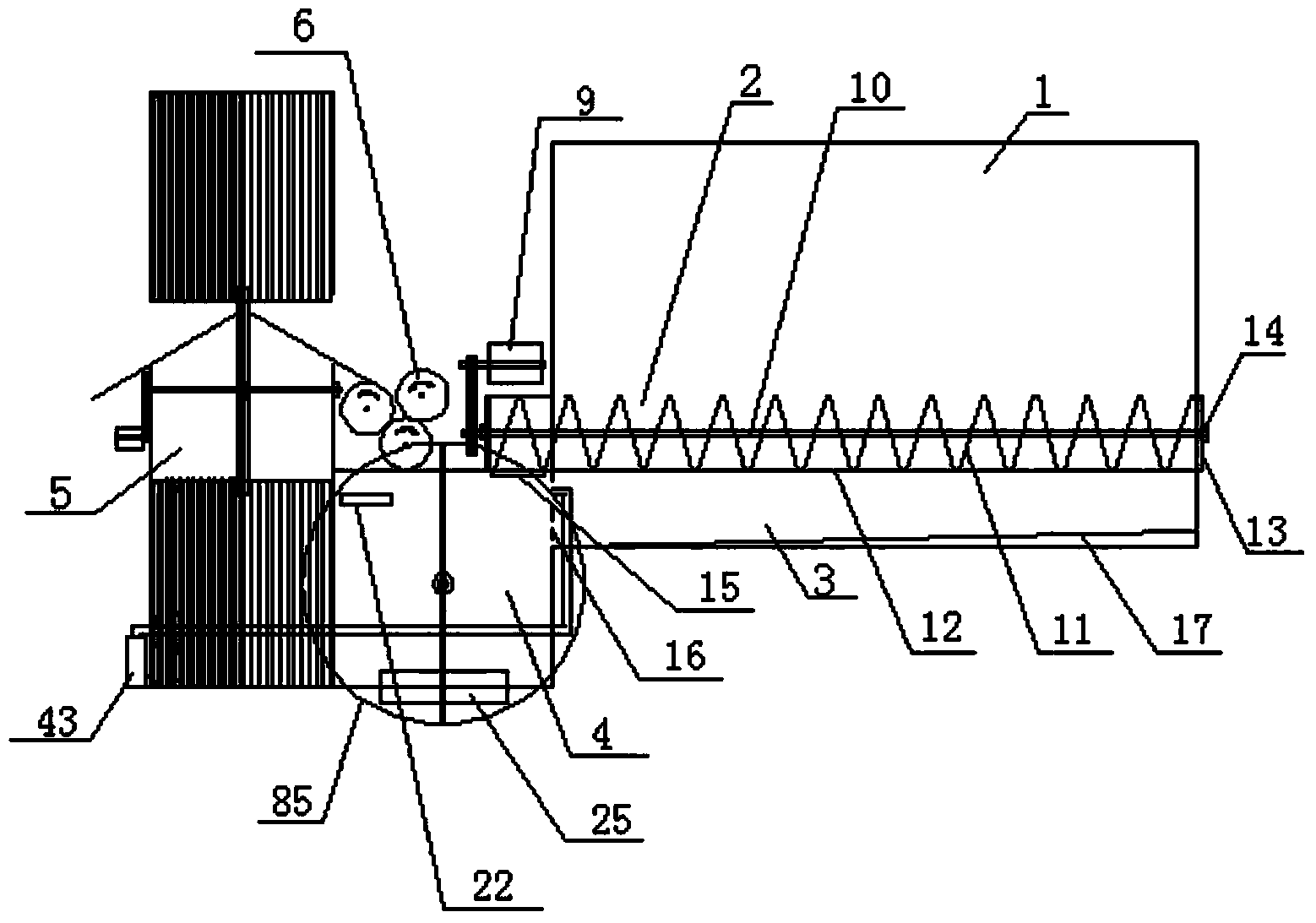

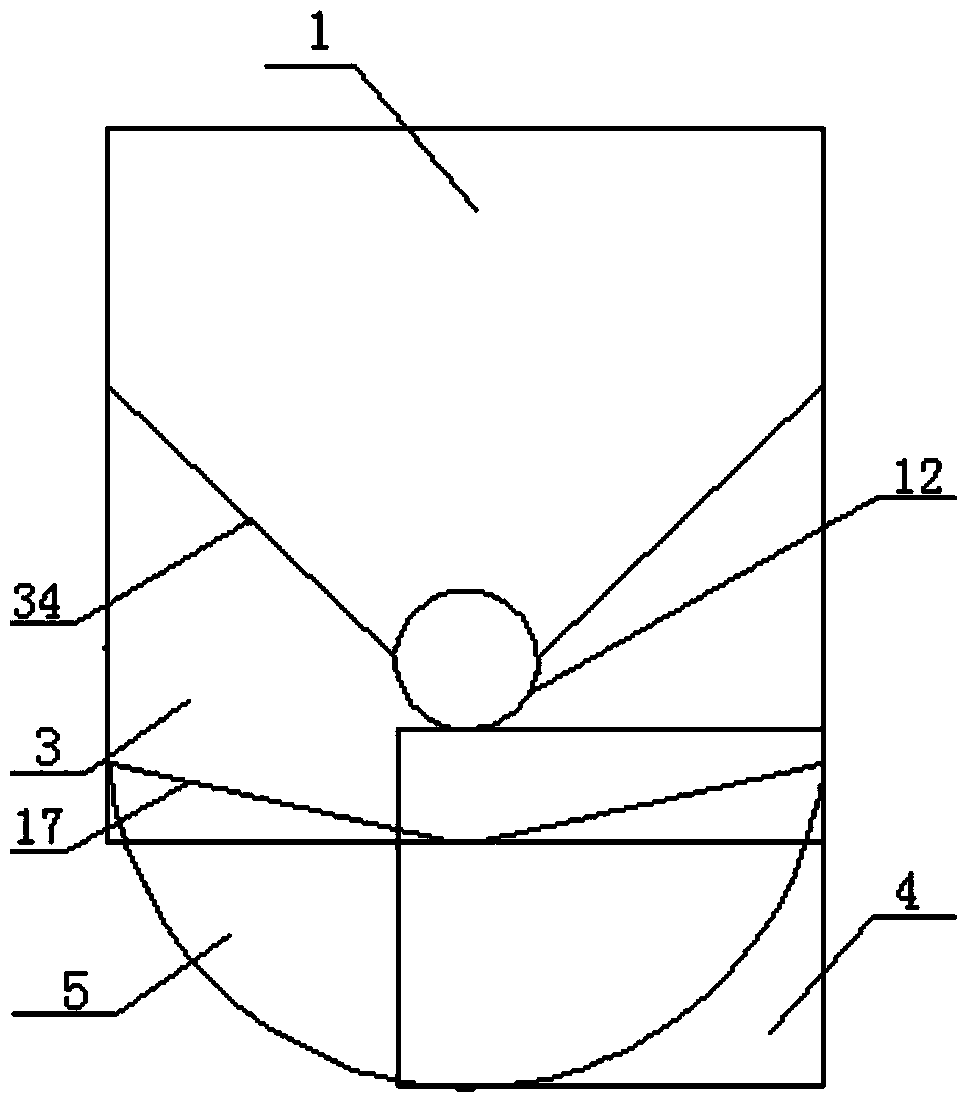

Kitchen waste pretreatment device

The invention discloses a kitchen waste pretreatment device, and aims to provide a kitchen waste pretreatment device with high resource recycling rate and without secondary pollution. The device comprises a kitchen waste storage box, a filtration feeder (2), a flushing and scattering machine and a rolling machine (6), and also comprises a solid-liquid separation box (1), a kitchen liquid box (3), a settlement device (4), a catching device (5) and solid-liquid rolling filtration machine. The kitchen waste storage box is connected the solid-liquid separation box (1) through an electromagnetic valve at the bottom. The filtration feeder (2) goes through circular holes at two sides of the solid-liquid separation box (1). The kitchen liquid box (3) is arranged under the solid-liquid separation box (1). The kitchen liquid inlet of the settlement device (4) is welded at the outlet of the kitchen liquid box (3). The feed inlet of the catching device (5) is welded at the feed outlet of the settlement device (4). The device has high resource recycling rate, low production cost and minimal pollution.

Owner:JIANGSU XINZHONGHENG WATER IND EQUIP

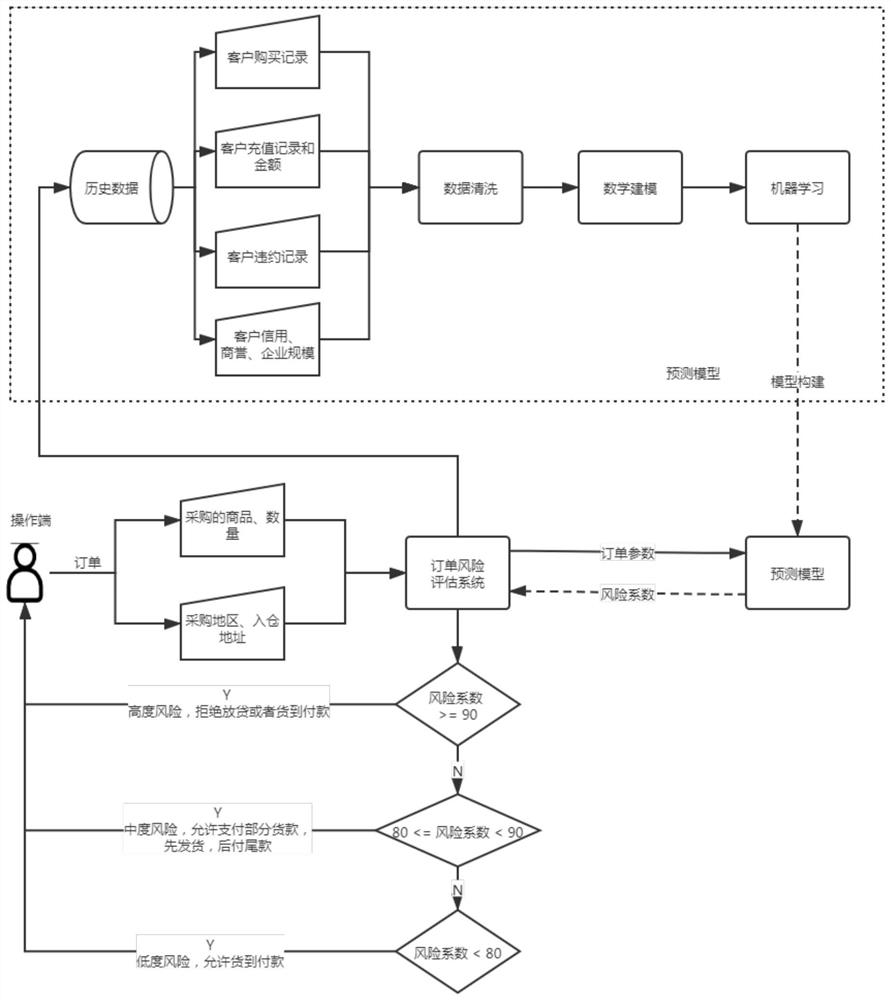

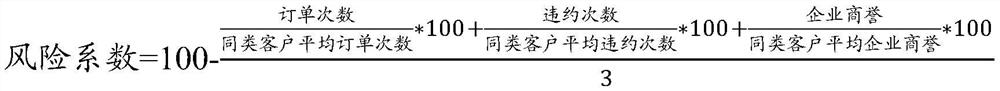

Chemical transaction risk assessment method and system

PendingCN113657904AReduce transaction riskReduce bad debtsFinanceBuying/selling/leasing transactionsData setFinancial transaction

The invention relates to the technical field of computers, in particular to a chemical transaction risk assessment method and system, and the method comprises the steps: carrying out the mathematical modeling of data in a historical data set, building a prediction model through machine learning, inputting order parameters into the prediction model, and calculating a risk coefficient; and selecting different transaction modes for transaction according to the risk coefficient. According to the invention, risk assessment is carried out on transaction records based on a machine learning means, so that transaction risks and bad debts can be effectively reduced, the risk assessment is upgraded from the original manual experience operation to historical data-based assessment prediction, so that the risk assessment is more objective, efficient and accurate; through the prediction model, the competitive advantage can be effectively improved, and the service expansion and resource reuse are improved.

Owner:厦门汇银通达数字科技有限公司

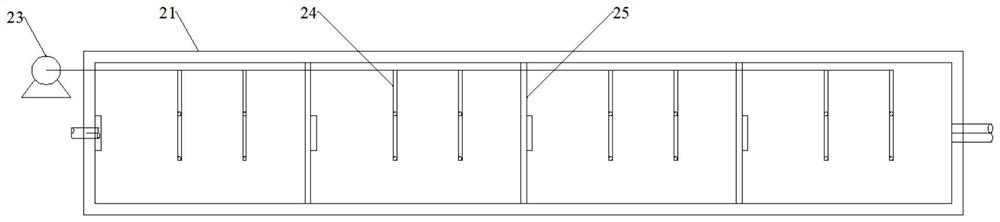

Method for cooling reduction crystallization of As2O3

InactiveCN109607611AReduce cleaning timesAvoid rapid foulingArsenic oxides/hydroxides/oxyacidsSolution crystallizationLiquid temperatureCentrifugation

The invention provides a method for cooling reduction crystallization of As2O3. The method comprises the steps: sending a high temperature liquid containing arsenic into a No. 1 cooling trough provided with a water-cooling coil, introducing cooling water into the water-cooling coil for first-stage cooling, sending the cooled liquid obtained after first-stage cooling to a No. 2 cooling trough provided with a water-cooling coil, introducing cooling water into the water-cooling coil for second-stage cooling until the liquid temperature is lower than 40 DEG C, transferring the cooled liquid into aNo. 1 reaction trough, introducing sulfur dioxide gas into the No. 1 reaction trough for reduction for a reduction period of 2-3 hours, then transferring the reduced liquid into a No. 2 reaction trough, performing still standing for 3 hours or above, introducing air into the reduced solution, performing stirring for 20-30 minutes, and performing centrifugation on the aerated solution so as to obtain a centrifuge mother liquor and the As2O3 crystal. Through the method, the scaling phenomenon caused by adhesion of As2O3 to the cooling coils can be avoided, and the purity of the prepared As2O3 crystal is more than 98%.

Owner:郴州金铖环保科技有限公司

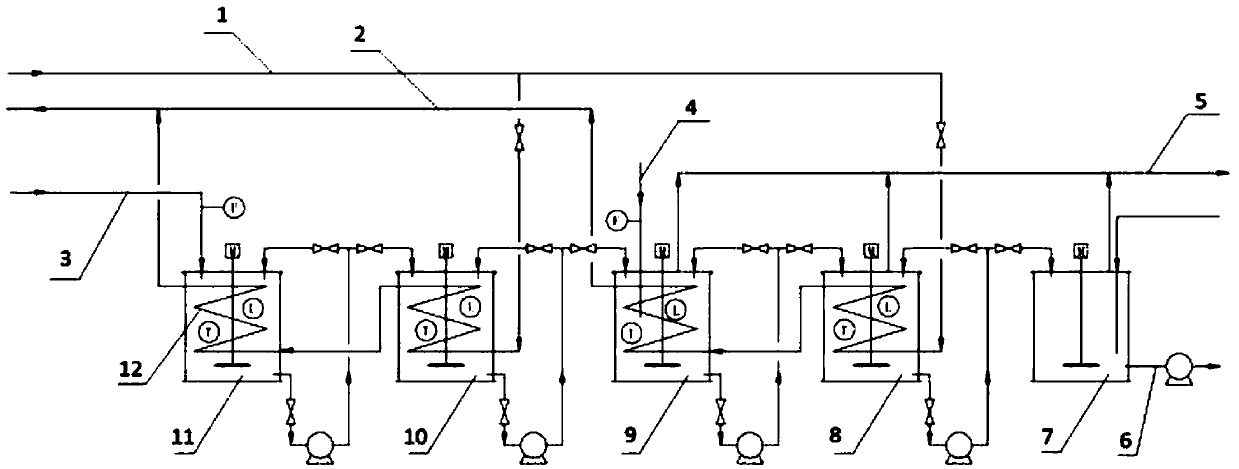

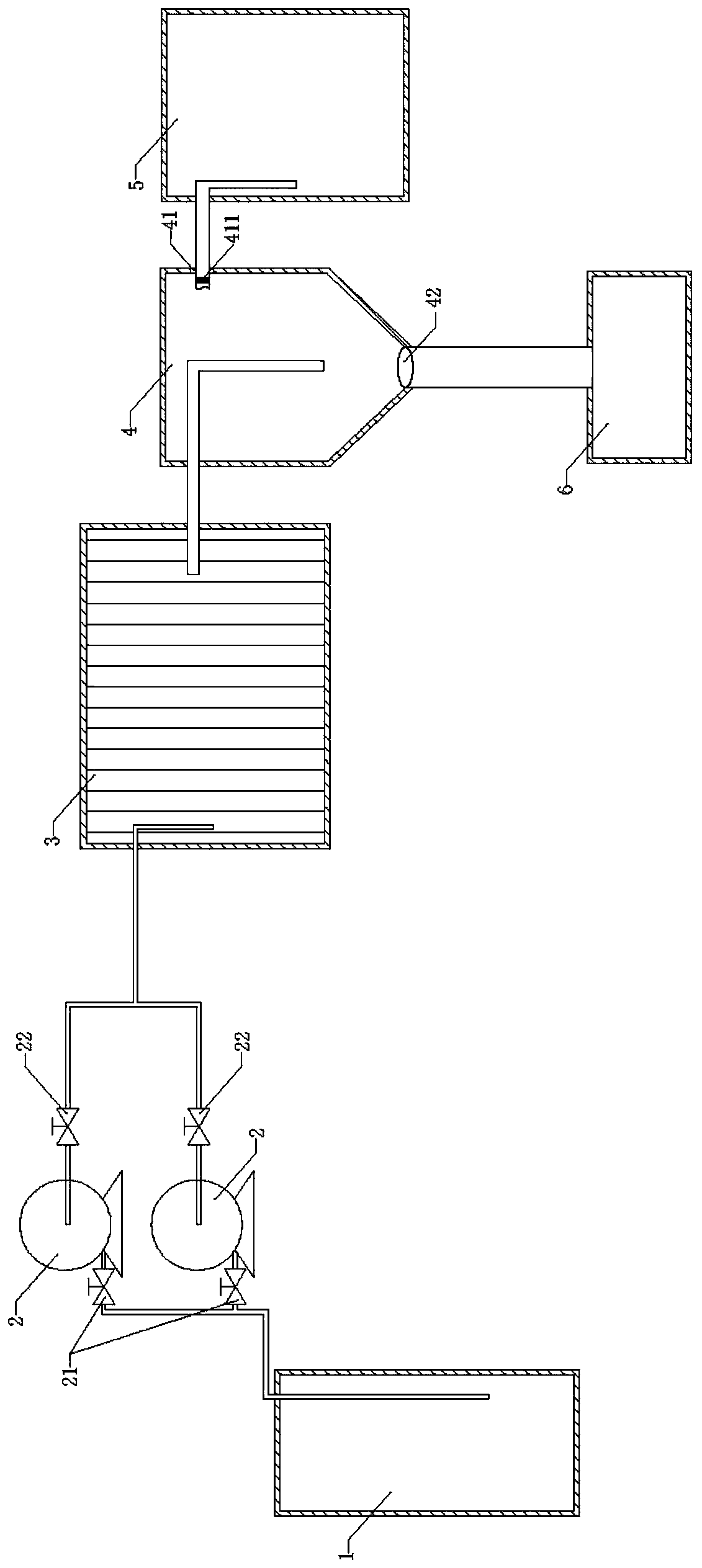

Petrol station buried tank cleaning system

PendingCN106944443AAvoid wastingReduce consumptionSludge treatment by de-watering/drying/thickeningHollow article cleaningProcess engineeringSewage

The invention discloses a petrol station buried tank cleaning system. The petrol station buried tank cleaning system comprises a buried tank, a cleaning recycling device, a cleaning machine, an oil-water separation device, a sludge dewatering machine, a reaction tank, an air flotation machine, a filtering device, a cleanser adding device, an inert gas generator and a vacuum pump, wherein the lower portion of the buried tank is provided with a water discharging valve and an outlet which are connected in the cleaning recycling device through recycling pipelines. According to the petrol station buried tank cleaning system, cleaned oil products can be reused, waste of oil products is prevented, and the resource reutilization rate is greatly improved. Sewage is recycled, the whole cleaning system becomes a closed cycle system, consumption of cleaning water is reduced, cleaning efficiency is high, and the environment is protected.

Owner:成都佳辉蓉达环保科技有限公司

A waste battery treatment device

The invention provides a waste battery treating device. The device comprises a feeding device, a first-stage crushing device, a second-stage crushing device, a water washing device, a screening device, a recovering device and a control system. According to the device, a waste battery is subjected to two-stage crushing and then is treated by water washing, screening and recovering, and thus the battery components can be classified and recycled; the device is environmentally friendly, efficient, outstanding in treating effect, and high in automation degree; and the battery recovering treatment capacity is improved.

Owner:鉴奕霖 +1

Wash-free hand sanitizer recovery device capable of fully recycling

ActiveCN112742812AImprove resource reuseLow efficiencyHollow article cleaningLavatory sanitoryHand sanitizerProcess engineering

The invention relates to the field of wash-free hand sanitizers, in particular to a wash-free hand sanitizer recovery device capable of fully recycling. The technical problem to be solved by the invention is to provide the wash-free hand sanitizer recovery device capable of fully recycling. According to the technical scheme, the wash-free hand sanitizer recovery device capable of fully recycling comprises a feeding assembly, a splitting and cleaning assembly, a recycling assembly, a bottle body treatment assembly and the like, wherein a bottom frame is connected with the bottle body treatment assembly; the splitting and cleaning assembly is connected with the recycling assembly; and the splitting and cleaning assembly is connected with the bottle body treatment assembly. When the wash-free hand sanitizer recovery device is used, a pressing pump and a volume bottle of a wash-free hand sanitizer empty bottle are automatically separated, then hand sanitizer on the outer surface of a conduit is automatically cleaned, meanwhile, the hand sanitizer in the volume bottle, the pressing pump and the conduit is automatically cleaned through wind power, the collected hand sanitizer is automatically used for preliminarily disinfecting a mouse pad, and the resource reutilization rate is greatly improved.

Owner:北京亿刻科技有限公司

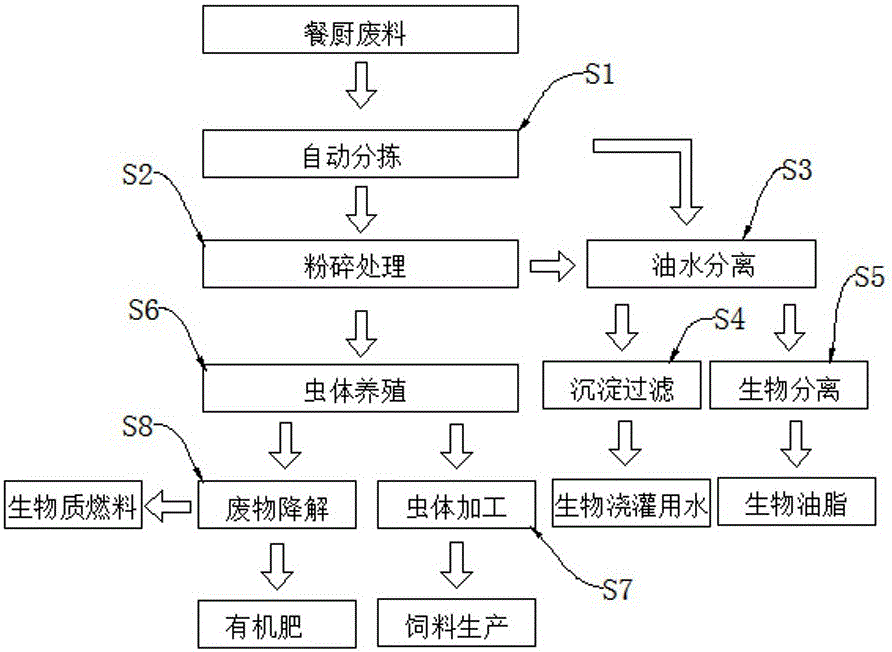

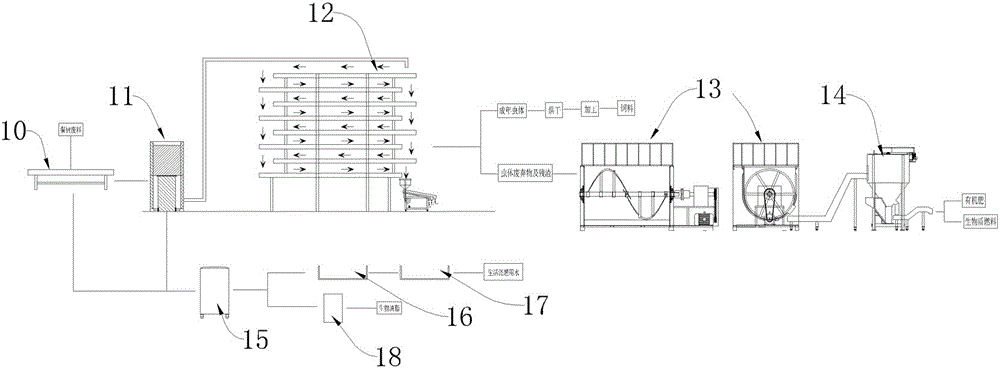

Kitchen and kitchen waste treatment process and its treatment system

The invention discloses a kitchen waste and food waste treatment process and a kitchen waste and food waste treatment system. The process comprises steps as follows: mixtures of kitchen waste and food waste are sorted by an automatic sorting table and put into a pre-treatment pulverizer for pulverizing; a liquid-phase mixture obtained through the automatic sorting table and an oil-water mixture separated from the pulverizer enter oil-water separating equipment for oil-water separation; a water phase separated from the oil-water separating equipment is filtered and is discharged as life irrigating water finally; an oil phase enters biological separating equipment for biological separation, and biological oil is prepared finally. The kitchen waste and the food waste pulverized by the pre-treatment pulverizer are taken as nutrition sources and are put into a polypide cultivation production line for saprophagous polypide cultivation, adult polypides enter a dryer for drying treatment and are processed and produced into feedstuff for poultry, fish and the like, polypide waste and residues are degraded, a part of a degraded material is used for generating electricity in a biomass fuel mode, and the other part is packed and transported outwards in an organic fertilizer mode for use.

Owner:深圳市德力骏塑胶机械有限公司

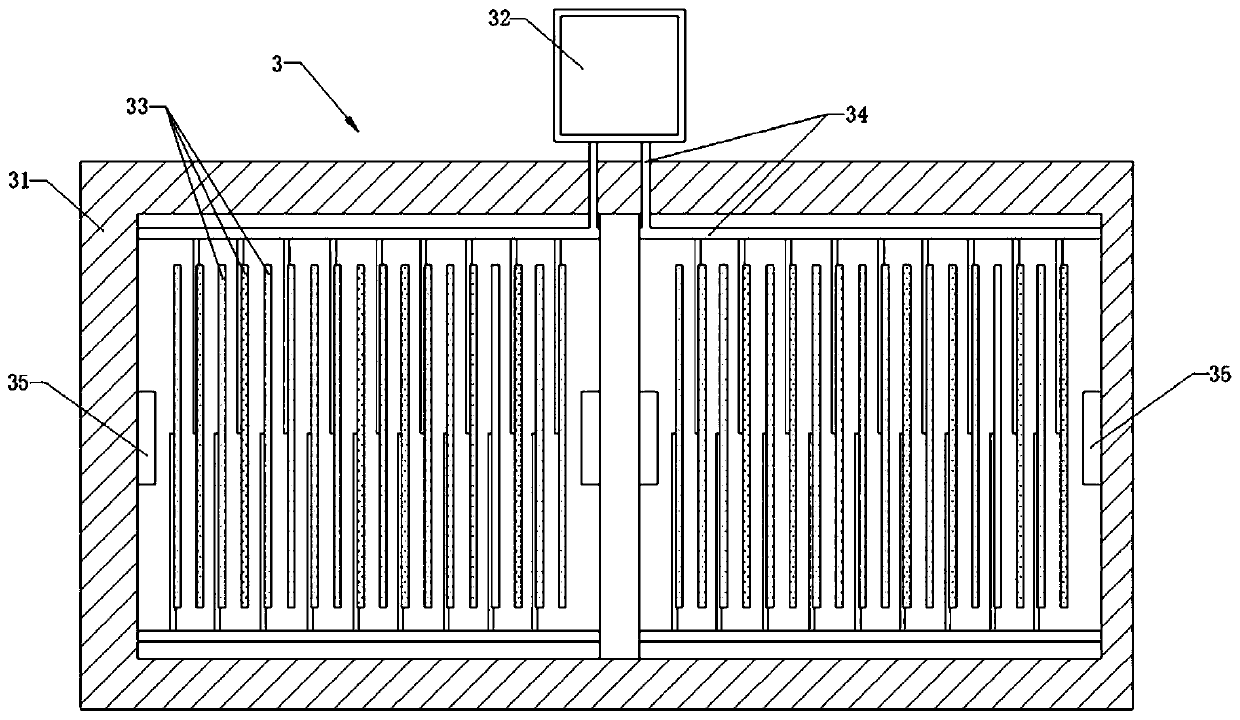

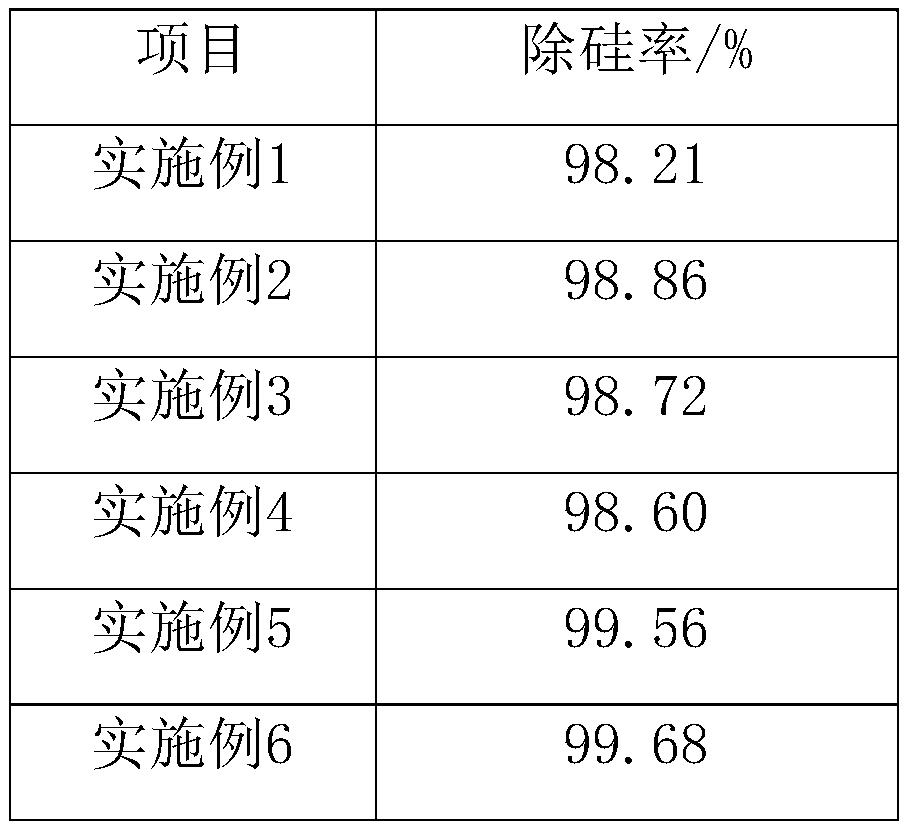

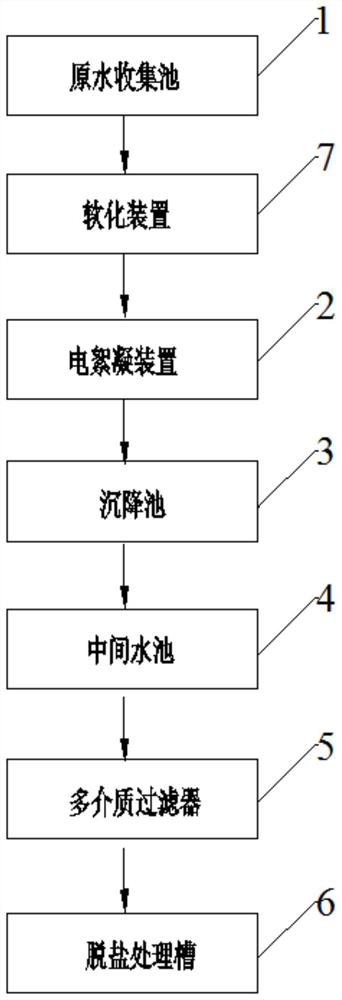

Technology and system for removing silicon from silicon-containing wastewater

ActiveCN110723849AEvenly dispersedQuality improvementSemi-permeable membranesSpecific water treatment objectivesElectrolysisPhysical chemistry

The invention relates to the technical field of water treatment, and concretely relates to a technology and a system for removing silicon from silicon-containing wastewater. The technology for removing silicon from silicon-containing wastewater comprises the following steps: (1) collecting coalified silicon-containing raw water into a raw water collection tank, pumping the coalified silicon-containing raw water into an electrolytic tank by using a lifting pump, electrolyzing the raw water, then putting the electrolyzed water into a sedimentation tank, and naturally standing for layering; and (2) discharging layered lower-layer sediments obtained in step (1), and recovering or waiting for discharging a supernatant obtained after the layering treatment. In the step (1), the current density of the electrolysis treatment is 40-60 A / m<2>, the voltage is 2-5 V, and the electrolysis treatment time is 30-60 min. The technology for removing silicon from silicon-containing wastewater has the advantages of simplicity in operation, no addition of chemical agents in the treatment process, and avoiding of secondary pollution to the environment, makes the silicon removal treatment rate reach up to 99% or above, and is suitable for large-scale treatment.

Owner:DONGGUAN SANRENXING ENVIRONMENTAL TECH CO LTD

Energy-saving recycling treatment method for soluble organic matters in kelp blanching water

InactiveCN107382667AImprove extraction efficiencyImprove resource reuseChemical industryHydroxy compound separation/purificationUltrafiltrationChemistry

The invention relates to an energy-saving recycling treatment method for soluble organic matters in kelp blanching water. The energy-saving recycling treatment method comprises six main steps as follows: sprinkling in the conveying process of a fresh kelp raw material, blanching the raw material in a blanching pot after sprinkling, performing high-temperature nanofiltration on a sprinkling liquid after purification of the sprinkling liquid, performing three-section extraction on the sprinkling liquid, salting the kelp raw material after the three-section extraction to obtain a salted finished kelp product, performing ultrafiltration purification separation on multi-stage sprinkling liquid and the like. By the treatment method provided by the invention, a one-time blanching water heating and multi-stage heat recovering process is adopted, heat obtained during one-time heating is successively utilized through multi-stage blanching, and the extracting process is speeded up. Therefore, the efficiency is improved and the energy is saved.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

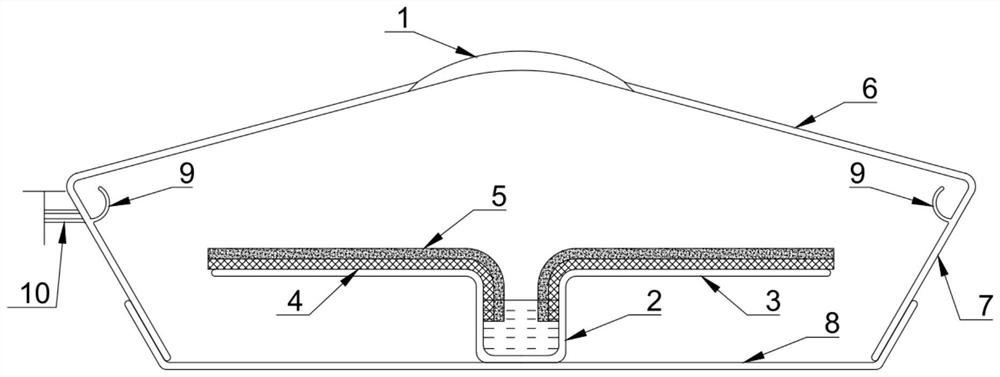

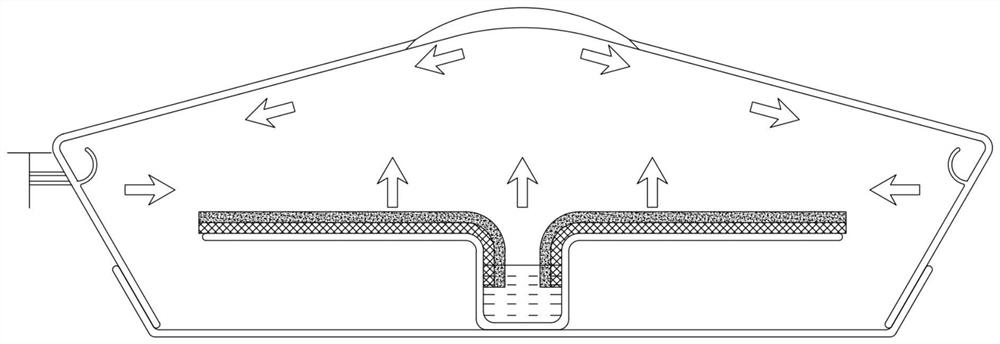

Device and method for treating landfill leachate membrane separation concentrated solution through surface photo-thermal evaporation

PendingCN113149312ACondensation collection achievedEnhanced convectionWater/sewage treatment by irradiationGeneral water supply conservationSolution treatmentPhysical chemistry

The invention relates to a device and a method for treating a landfill leachate membrane separation concentrated solution through surface photo-thermal evaporation, and belongs to the technical field of landfill leachate membrane concentrated solution treatment. The device comprises a condensing lens, a reaction tank, an evaporation table, a hydrophilic porous material layer, a photo-thermal porous material layer, an inclined transparent condensation top cover, a transparent side wall, a crystal salt collection box, a condensate water collection tank and a condensate water outlet, the condensing lens is embedded into the inclined transparent condensing top cover; the inclined transparent condensation top cover and the transparent side wall are arranged above the crystal salt collecting box in a covering mode; the reaction tank is arranged in the crystal salt collecting box; the evaporation table is located at the edge of the reaction tank, the hydrophilic porous material layer and a photo-thermal porous material layer are sequentially attached to the evaporation table from bottom to top, and the hydrophilic porous material layer extends to the side wall of the reaction tank; the condensate water collection tank is located around the inner wall of the transparent side wall. Air internal circulation exists in the reactor, air convection on the surface of the photo-thermal material is promoted, and the surface evaporation rate of the photo-thermal material is increased.

Owner:HUAZHONG UNIV OF SCI & TECH

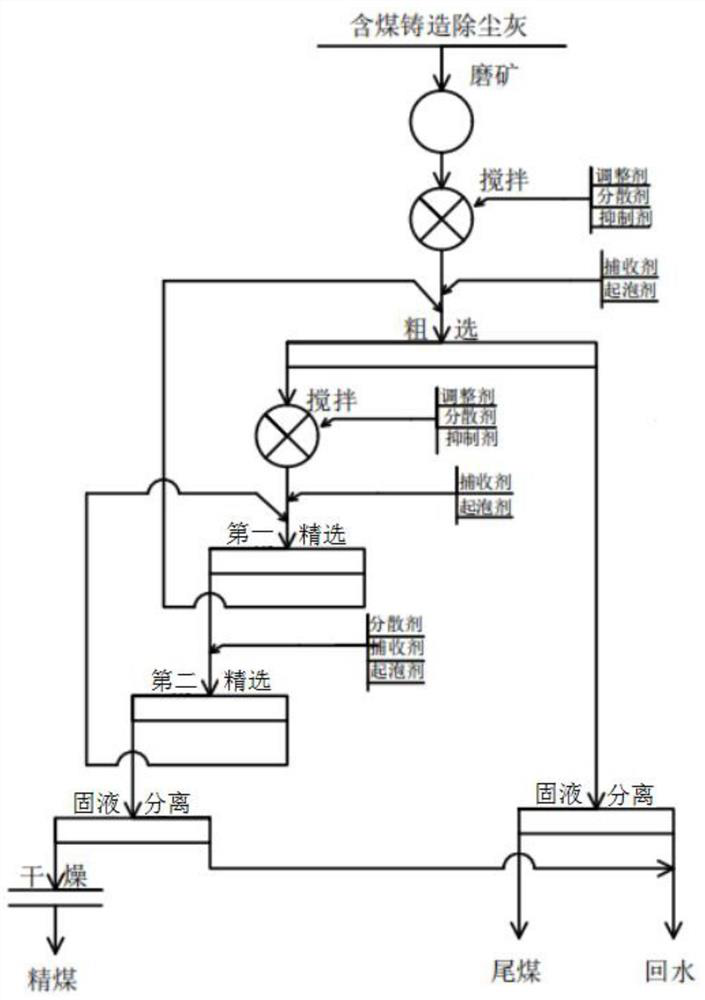

Method for flotation of coal from coal-containing casting fly ash

PendingCN112958275AImprove resource reuseLow ashGlass recyclingSolid separationAluminiteMining engineering

The invention belongs to the technical field of solid waste resource recycling treatment, and particularly relates to a method for flotation of coal from coal-containing casting fly ash. The method for flotation of the coal from the coal-containing casting fly ash comprises the following steps that the coal-containing casting fly ash is subjected to ore grinding treatment to obtain ore grinding powder; the ore grinding powder is mixed with water to obtain ore pulp; the ore pulp is subjected to roughing to obtain roughed clean coal; and the roughed clean coal is sequentially subjected to first concentration and second concentration to obtain clean coal, specifically, the ash content of the clean coal is less than or equal to 14wt.%. According to the method, the purpose of stripping ettringite on the surfaces of coal particles in the coal-containing casting fly ash is achieved in an ore grinding mode, the separation degree of the coal particles and gangue minerals in the coal-containing casting fly ash can be improved, the clean coal yield of the coal-containing casting fly ash is improved, and the ash content of the clean coal is reduced. A test result shows that by adopting the method provided by the invention, the ash content of the obtained clean coal is less than or equal to 14wt.%, and the ash content of tailings is more than or equal to 63wt.%.

Owner:许泽胜

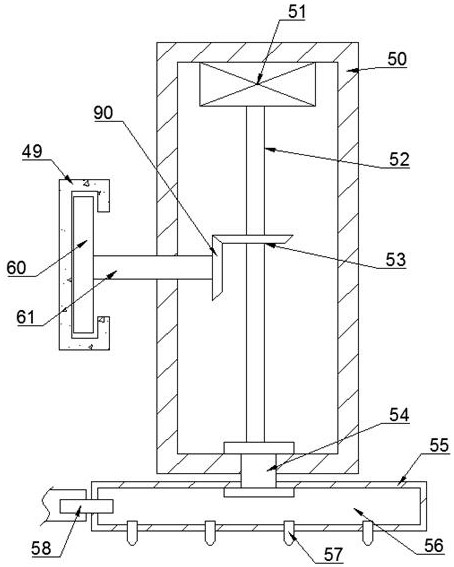

Double-sided drilling machine capable of automatically cleaning scraps

InactiveCN112170888AEasy to adjustReduce labor intensityCleaning using liquidsPositioning apparatusElectric machineEngineering

The invention discloses a double-sided drilling machine capable of automatically cleaning scraps, comprising a main body, wherein a base is arranged in the main body; a power cavity is arranged in thebase; a first motor is fixedly arranged in the power cavity; a first motor shaft is rotatably arranged on the first motor; the first motor shaft is connected to a first rotary shaft extending to theoutside of the power cavity; and a working cavity is arranged in the main body. Double-sided operation can be independently carried out through two drill bits, and the X-axis position and the Y-axis position of the drill bits relative to a die can be conveniently adjusted at the same time, so that a position needing to be punched is rapidly positioned, punching efficiency is improved, and an equipment clamp can meet machining requirements of most objects without replacing the clamp by many times, and thus, application limitation and use cost of the equipment are reduced, the equipment can be automatically cleaned, waste liquid after cleaning can be recycled, a resource reutilization rate is increased, and labor intensity of workers is reduced.

Owner:天津勇刚锁具销售有限公司

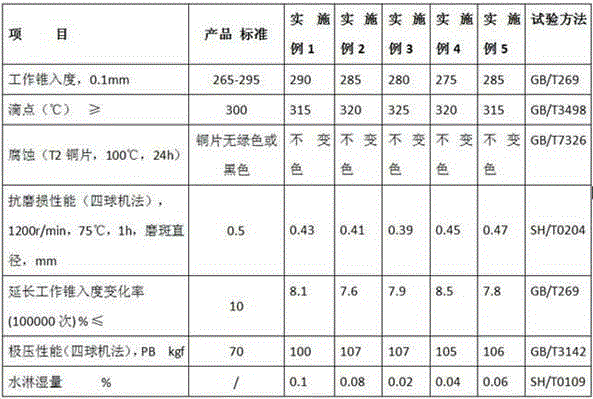

Lubricating grease prepared by using waste gear oil and method for preparing lubricating grease

ActiveCN104450082AHarm reductionIndex of recovery lossLubricant compositionHigh energyHazardous substance

The invention discloses multifunctional lubricating grease prepared by using waste gear oil. The multifunctional lubricating grease is prepared by using the following materials in weight percent: 32-45 percent of deeply-treated waste gear oil, 30-44 percent of overbased calcium sulphonate, 4-8 percent of 12-hydroxystearic acid / alkyl benzene sulphonate, 6-10 percent of conversion agent, 6-13 percent of water, 0.8-3.2 percent of boric acid, 0.5-1.5 percent of extreme pressure antiwear agent, 0.6-1.5 percent of calcium hydroxide, 0.1-1.6 percent of antioxidant and 0.2-1.2 percent of ethylene-propylene copolymer / random polypropylene. The qualified lubricating grease product is produced according to an improved method for producing the lubricating grease by converting harmful materials into saponifiable materials through heating and catalyzing, so that the regeneration of resources is achieved, the harm of waste gear oil to the environments is reduced, and the reutilization rate of the sources is improved; and the method can be used for solving the problems of high energy consumption, high difficulty in treating waste water and waste residues and severe environment pollution during treatment of waste oil in China.

Owner:LUOHE BEIJIA BILL SCI & TECH CHEM

Electric flocculation silicon removal process and system for silicon-containing wastewater

PendingCN112499848AAvoid pollutionFacilitated DiffusionWater contaminantsScale removal and water softeningElectrolysisChemical agent

The invention relates to the technical field of silicon-containing wastewater treatment, in particular to an electric flocculation silicon removal process for silicon-containing wastewater. The process comprises the following steps: 1) collecting silicon-containing raw water into a raw water collecting tank, and pumping the silicon-containing raw water in the raw water collecting tank into an electric flocculation device through a gas-liquid mixing pump for electrolytic treatment, then feeding the electrolyzed water body into a sedimentation tank, and conducting standing for layering; (2) discharging lower-layer sediment settled and layered by the sedimentation tank in the step (1), and feeding supernatant liquid settled and layered by the sedimentation tank into a middle water pond for secondary settling; and (3) feeding the supernatant subjected to secondary sedimentation in the middle water pond in the step (2) into a multi-medium filter for filtering, and finally desalting the filtered filtrate for recycling. The electric flocculation silicon removal process for the silicon-containing wastewater is simple to operate, does not need to add chemical agents in the treatment process, avoids secondary pollution to the environment, can be suitable for large-scale treatment, and is high in practicability, and the silicon removal treatment rate is up to 99% or above.

Owner:DONGGUAN SANRENXING ENVIRONMENTAL TECH CO LTD

Microbial organic fertilizer for preventing and controlling grape downy mildew and preparation method thereof

InactiveCN106348854AGrowth inhibitionEffective control of rotCalcareous fertilisersExcrement fertilisersPatriniaEcological environment

The invention discloses a microbial organic fertilizer for preventing and controlling grape downy mildew. The microbial organic fertilizer is prepared from the following raw materials: chicken manure, mushroom dreg, yeast waste liquor, saw dust, rice husk, astragalus, selfheal, patrinia, dandelion, mangnolia officinalis, compound fermentation strain, compound fermenting enzyme and a compound trace element. The invention also discloses a preparation method of the microbial organic fertilizer for preventing and controlling the grape downy mildew. The preparation method comprises the steps of multistage fermentation, ageing, and the like. The microbial organic fertilizer for preventing and controlling the grape downy mildew can effectively control pseudoperonospora cubensis of grape plants and fruits, effectively inhibit harmful bacteria and also has certain prevention effect on healthy grape plants in avoidance of infection of downy mildew; besides, usage amounts of pesticide and chemical fertilizer also can be reduced, so that the microbial organic fertilizer disclosed by the invention has the advantages of preserving the ecological environment and improving resource re-utilization rate and has good economic benefit and social benefit.

Owner:谭仁燕

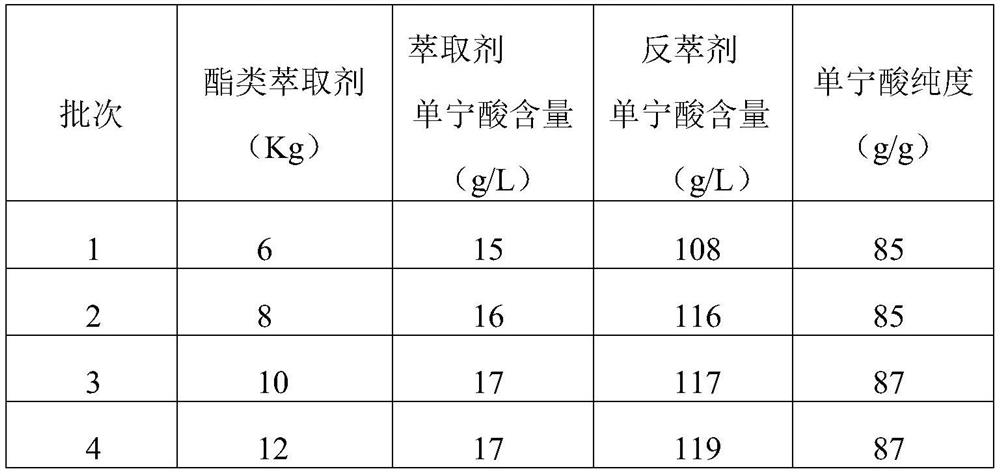

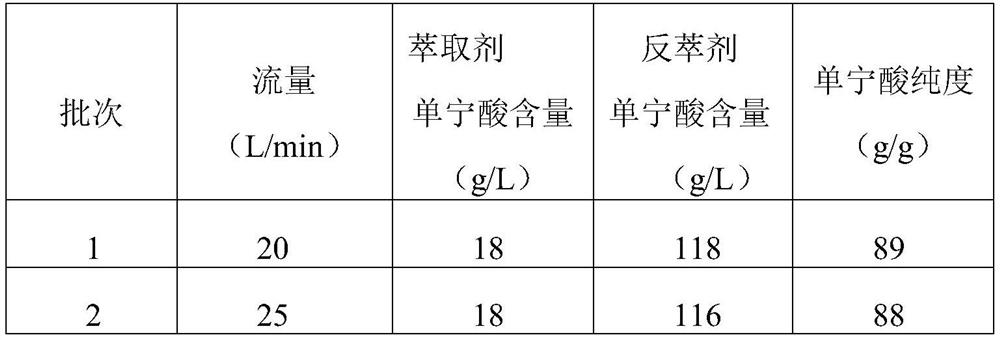

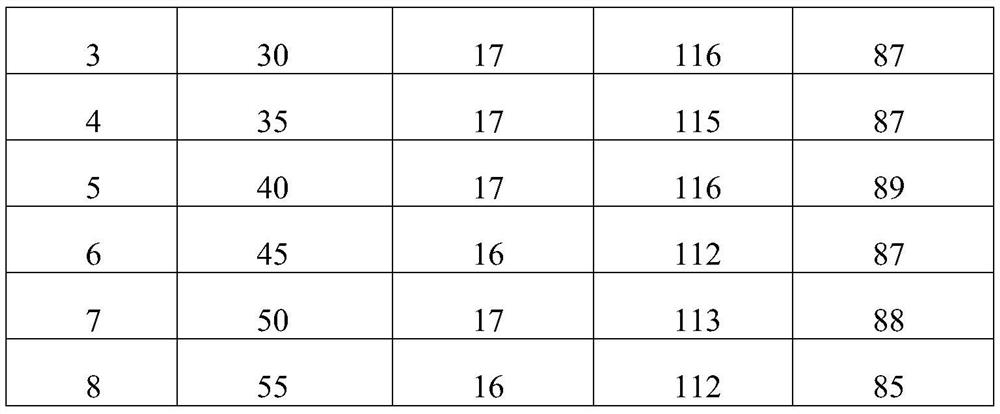

A method for enriching and purifying tannic acid from papermaking waste liquid

ActiveCN111072733BImprove resource reuseReduce contentEsterified saccharide compoundsSugar derivativesOrganic solventEnvironmental engineering

The invention discloses a method for enriching and purifying tannic acid from papermaking waste liquid, which comprises the following steps: (1) purifying the papermaking waste liquid, and concentrating the purified papermaking waste liquid through a nanofiltration membrane module to obtain tannin-containing A concentrated solution of acid; (2) carrying out multistage countercurrent extraction to the concentrated solution prepared in step (1), using an organic solvent group as an extractant to obtain an extract containing tannic acid; (3) extracting the concentrated solution in step (2) The obtained extraction liquid containing tannic acid is carried out multi-stage countercurrent back extraction, adopts NaOH solution as back extraction liquid, obtains the back extraction liquid containing tannic acid; (4) after the back extraction liquid that step (3) obtains is cooled , add acid to adjust the pH value, place it in a storage tank, then filter, concentrate in vacuum, and spray dry to obtain industrial grade tannic acid. The invention not only improves the resource reuse of papermaking waste liquid, but also significantly reduces the content of tannic acid, lignin and the like as pollutants; and embodies the characteristics of resource utilization and environmental protection.

Owner:SHANGHAI CHANGFA NEW MATERIAL CO LTD

Hot-rolled steel sheet with small variation in material and thickness and excellent plating peeling resistance, and manufacturing method thereof

ActiveCN103882343BExcellent plating stripping resistanceImprove resource reuseHot-dipping/immersion processesFurnace typesProduction rateSheet steel

The present invention relates to a hot rolled steel plate which has low errors in material and thickness and has excellent resistance of electroplating stripping and the manufacturing method thereof. The present invention provides the hot rolled steel plate including the C, Mn, Si, Al, P, S, Cu, Sb, B, N, Ti, Nb foreign element Cr, Ni, Mo, Sn, remainder of Fe and other inevitable impurities, the contents thereof are described in the instruction. The present invention also provides the manufacturing method of the hot rolled steel plate. According to the present invention, scrap iron can be used for making the hot rolled steel plate to improve the reusing resources and to save the energy and productivity, the hot rolled steel plate fused and galvanized can be also used for a molten zinc hot rolled steel plate.

Owner:浦项股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com