Method for flotation of coal from coal-containing casting fly ash

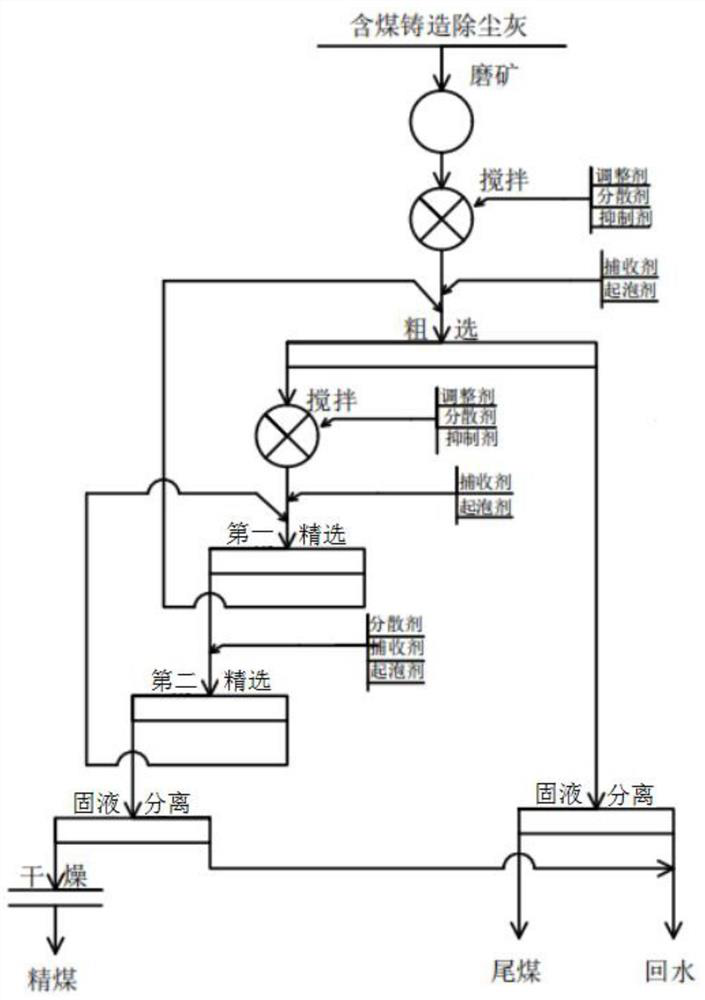

A roughing and clean coal technology, applied in the direction of solid separation, recycling technology, mechanical material recovery, etc., can solve the problems of insufficient dissociation of coal particles, low clean coal yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The coal-containing foundry ash with ash content of 57.63% is subjected to grinding treatment until the dissociation degree of coal particles in the coal-containing foundry ash is ≥75%, and a grinding with a particle size of 200 mesh or less and a material proportion of ≥90wt.% is obtained pink;

[0056] Mixing the ground ore powder with water to obtain an ore slurry with a concentration of 11wt.%.

[0057] Mix the ore pulp, the pH regulator, the first dispersant and the first inhibitor, send the resulting mixed material into the flotation equipment, add the first collector and the first foaming agent, and carry out rough flotation to obtain crude Clean coal and roughing tailings, in which the aeration volume of flotation is 0.25m 3 / m 2 min, the impeller speed of the flotation machine is 1800rpm, and the pH adjuster is calcium oxide, so as to ensure that the pH value of the roughing system is 8.2 to 8.5; the first dispersant is sodium hexametaphosphate. The dosage o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com