Hot-rolled steel sheet with small variation in material and thickness and excellent plating peeling resistance, and manufacturing method thereof

A technology of hot-rolled steel sheets and manufacturing methods, which is applied in the direction of manufacturing tools, heat treatment furnaces, hot-dip coating processes, etc., can solve problems such as difficulty in ensuring yield strength and cracks, and achieve improved resource reuse and small deviations in material and thickness , energy saving and productivity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

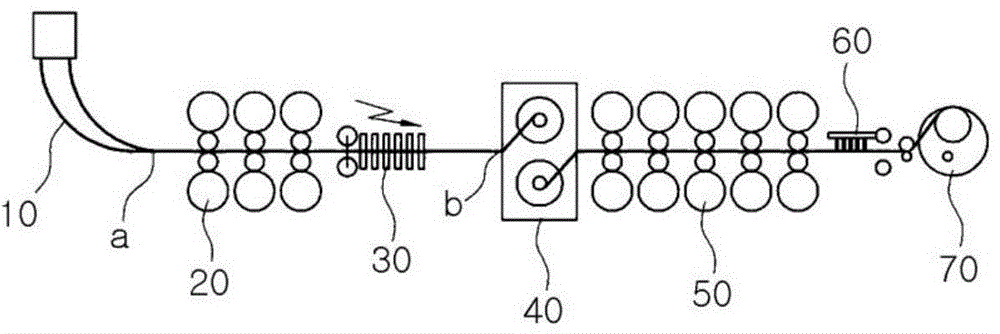

[0025] When the inventors of the present invention studied to produce high-strength hot-rolled steel sheets with small variations in material and thickness and excellent plating peeling resistance, they completed the present invention with the aim of appropriately controlling the alloy components and adopting a small-scale rolling process. (mini-mill process) open continuous rolling method (open continuous rolling method), while performing finish rolling and uniform rolling at a temperature lower than the existing rolling process, thereby not adding expensive alloy elements such as Ni , It is also possible to provide a hot-rolled steel sheet that has a uniform material and a small variation in thickness, and is excellent in plating peeling resistance.

[0026] Next, the present invention will be described. First, the selection of alloy components and composition ranges will be described. However, unless % is specifically stated below, it should be considered as % by weight. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com