A method for enriching and purifying tannic acid from papermaking waste liquid

A technology for papermaking waste liquid and tannic acid, applied in chemical instruments and methods, organic chemistry, sugar derivatives, etc., can solve the problems of high cost, high production cost, low product purity, etc. The effect of resource reuse and high resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

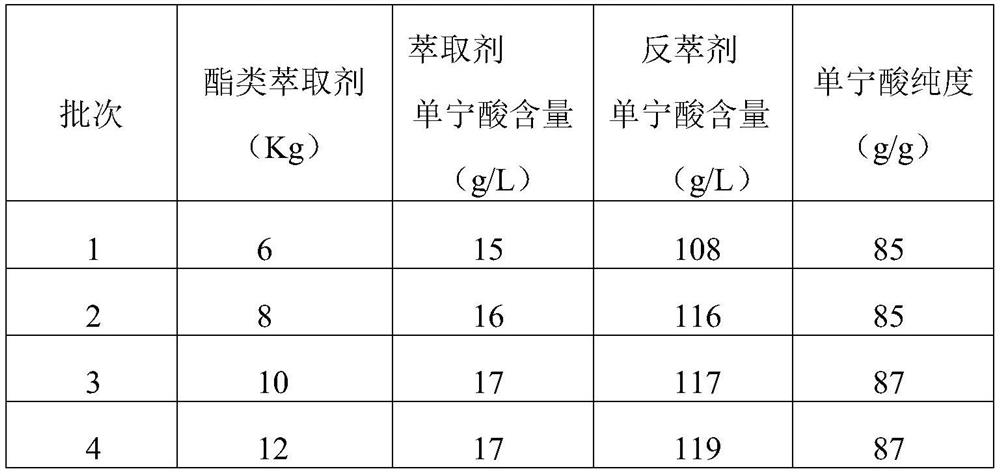

Embodiment 1

[0029] (1) the coniferous wood soda process waste liquid that 400kg paper mill provides (wherein solid matter accounts for 5% of papermaking waste liquid gross mass, and pH value is 3.5, and hemicellulose content is 1.65%, and lignin content is 1.75%, Cellulose waste liquid total sugar is 0.1kg) is placed in the separation container, removes insoluble suspended solids with 50 mesh sieves, settles after stirring for 3 hours, discharges the lower layer of fine fibers and silt, and uses a molecular weight cut-off of 140 Daltons The flat polyamide nanofiltration membrane assembly is concentrated to 20% of the total volume, and the concentrated solution (wherein the concentration of hemicellulose is 49.38g / L, the concentration of lignin is 10.28g / L, and the concentration of tannic acid is 124g / L) Concentration is 1.58g / L), 20kg concentrated solution adds 500g n-butanol and reclaims the mass ratio of hemicellulose to be 91%;

[0030] (2) Perform multi-stage countercurrent extraction...

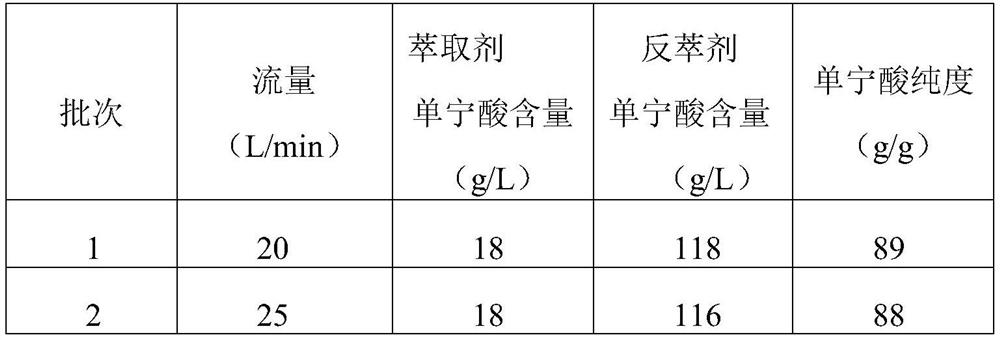

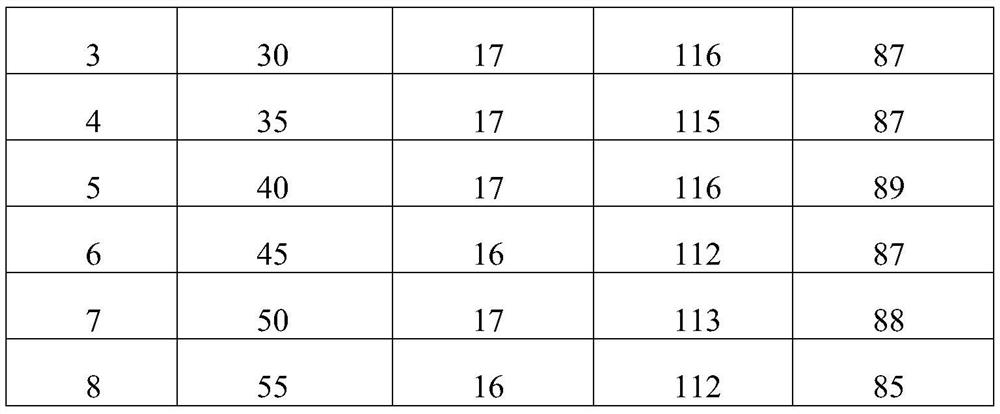

Embodiment 2

[0037] (1) the coniferous wood and broad-leaved wood alkali process waste liquid that 8000kg paper mill provides (wherein solid matter accounts for 5% of papermaking waste liquid total mass, and pH value is 3.5, and hemicellulose content is 1.65%, and lignin content is 1.75%, the total sugar of cellulose waste liquid is 0.1kg) is placed in the separation container, removes insoluble suspended matter with 50 mesh sieves, settles after stirring for 3 hours, discharges the lower layer of fine fibers and silt, and uses a molecular weight cut-off of 140 Dalton's flat-panel polyamide nanofiltration membrane assembly is concentrated to 20% of the total volume to obtain a concentrated solution of 125g / L (wherein the hemicellulose concentration is 48.82g / L, and the lignin concentration is 10.44g / L, Tannic acid concentration is 1.68g / L), 200kg concentrated solution adds 500g n-butanol and reclaims the mass ratio of hemicellulose to be 90%;

[0038] (2) Perform multi-stage countercurrent...

Embodiment 3

[0046] (1) the coniferous wood and broad-leaved wood alkali process waste liquid that 7600kg paper mill provides (wherein solid matter accounts for 5% of papermaking waste liquid total mass, and pH value is 3.5, and hemicellulose content is 1.65%, and lignin content is 1.75%, the total sugar of cellulose waste liquid is 0.1kg) is placed in the separation container, removes insoluble suspended matter with 50 mesh screens, settles after stirring for 3 hours, discharges the fine fiber and silt of the lower layer, and uses a molecular weight cut-off of 140 Dalton's flat-panel polyamide nanofiltration membrane assembly is concentrated to 20% of the total volume to obtain a concentrated solution with a concentration of 125g / L (wherein the hemicellulose concentration is 48.82g / L, and the lignin concentration is 10.44g / L, Tannic acid concentration is 1.68g / L), 1520kg concentrated solution adds 500g n-butanol and reclaims the mass ratio of hemicellulose to be 92%;

[0047] (2) Perform ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com