Device and method for treating landfill leachate membrane separation concentrated solution through surface photo-thermal evaporation

A technology for landfill leachate and membrane separation, which can be applied in illumination water/sewage treatment, heating water/sewage treatment, water/sewage treatment, etc. problem, to achieve the effect of increasing the light intensity, accelerating the surface evaporation rate, and enhancing the surface evaporation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

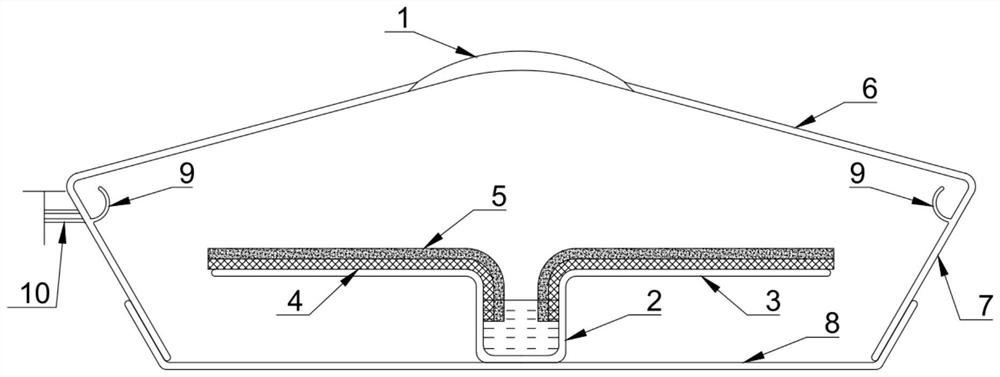

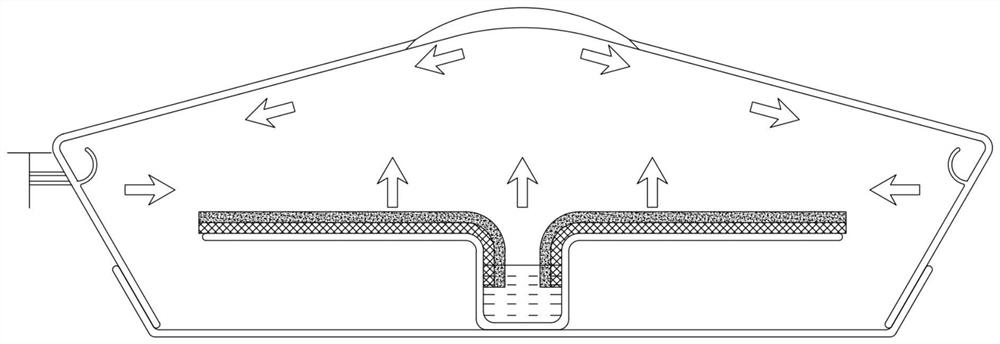

[0037] The present invention is a device for treating landfill leachate film concentrate by surface photothermal evaporation, such as figure 1 As shown, it includes a condenser 1, a reaction pool 2, an evaporation table 3, a hydrophilic porous material layer 4, a photothermal porous material layer 5, an inclined transparent condensation top cover 6, a transparent side wall 7, a crystal salt collection box 8, and a condensation water collection Groove 9, condensed water outlet 10.

[0038] The condenser lens 1 is embedded in the inclined transparent condensation top cover 6; the inclined transparent condensation top cover 6 and the transparent side wall 7 are placed above the crystallization salt collection box 8; the reaction pool 2 is placed in the crystallization salt collection box 8; The evaporation table 3 is located on the edge of the reaction pool 2, and the evaporation table 3 is sequentially attached with a hydrophilic porous material layer 4 and a photothermal porous...

Embodiment 2

[0042] The present invention is a device for treating landfill leachate film concentrate by surface photothermal evaporation, such as figure 1 As shown, it includes a condenser 1, a reaction pool 2, an evaporation table 3, a hydrophilic porous material layer 4, a photothermal porous material layer 5, an inclined transparent condensation top cover 6, a transparent side wall 7, a crystal salt collection box 8, and a condensation water collection Groove 9, condensed water outlet 10.

[0043] The condenser lens 1 is embedded in the inclined transparent condensation top cover 6; the inclined transparent condensation top cover 6 and the transparent side wall 7 are placed above the crystallization salt collection box 8; the reaction pool 2 is placed in the crystallization salt collection box 8; The evaporation table 3 is located on the edge of the reaction pool 2, and the evaporation table 3 is sequentially attached with a hydrophilic porous material layer 4 and a photothermal porous...

Embodiment 3

[0050] The present invention is a device for treating landfill leachate film concentrate by surface photothermal evaporation, such as figure 1 As shown, it includes a condenser 1, a reaction pool 2, an evaporation table 3, a hydrophilic porous material layer 4, a photothermal porous material layer 5, an inclined transparent condensation top cover 6, a transparent side wall 7, a crystal salt collection box 8, and a condensation water collection Groove 9, condensed water outlet 10.

[0051] The condenser lens 1 is embedded in the inclined transparent condensation top cover 6; the inclined transparent condensation top cover 6 and the transparent side wall 7 are placed above the crystallization salt collection box 8; the reaction pool 2 is placed in the crystallization salt collection box 8; The evaporation table 3 is located on the edge of the reaction pool 2, and the evaporation table 3 is sequentially attached with a hydrophilic porous material layer 4 and a photothermal porous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com