Technology and system for removing silicon from silicon-containing wastewater

A technology for silicon treatment and waste water, applied in the field of silicon-containing waste water desiliconization treatment process and system, can solve the problems of increasing the cost of treatment process chemicals, reducing the service life of equipment, corrosion damage to operating equipment, etc., to improve resource reuse, avoid Pollution, the effect of effective treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

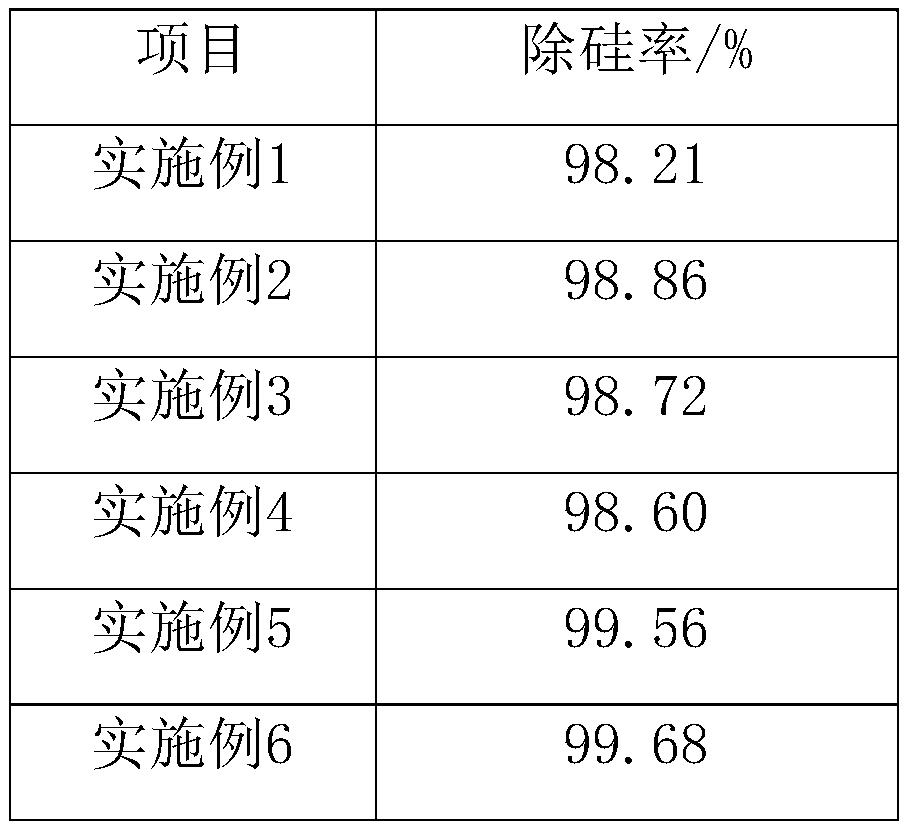

Embodiment 1

[0033] A process for removing silicon from silicon-containing wastewater, comprising the steps of:

[0034](1) Collect the coalification silicon-containing raw water into the raw water collection pool 1, use the lift pump 2 to pump the coalification silicon-containing raw water to the electrolytic tank 3 for electrolytic treatment, and then place the electrolytically treated water body in the sedimentation tank 4, naturally static stratification;

[0035] (2) discharging the lower sediment after the layered treatment in step (1), and reclaiming or waiting to discharge the supernatant after the layered treatment;

[0036] In described step (1), the current density of electrolytic treatment is 40A / m 2 , the voltage is 2V, and the electrolytic treatment time is 60min.

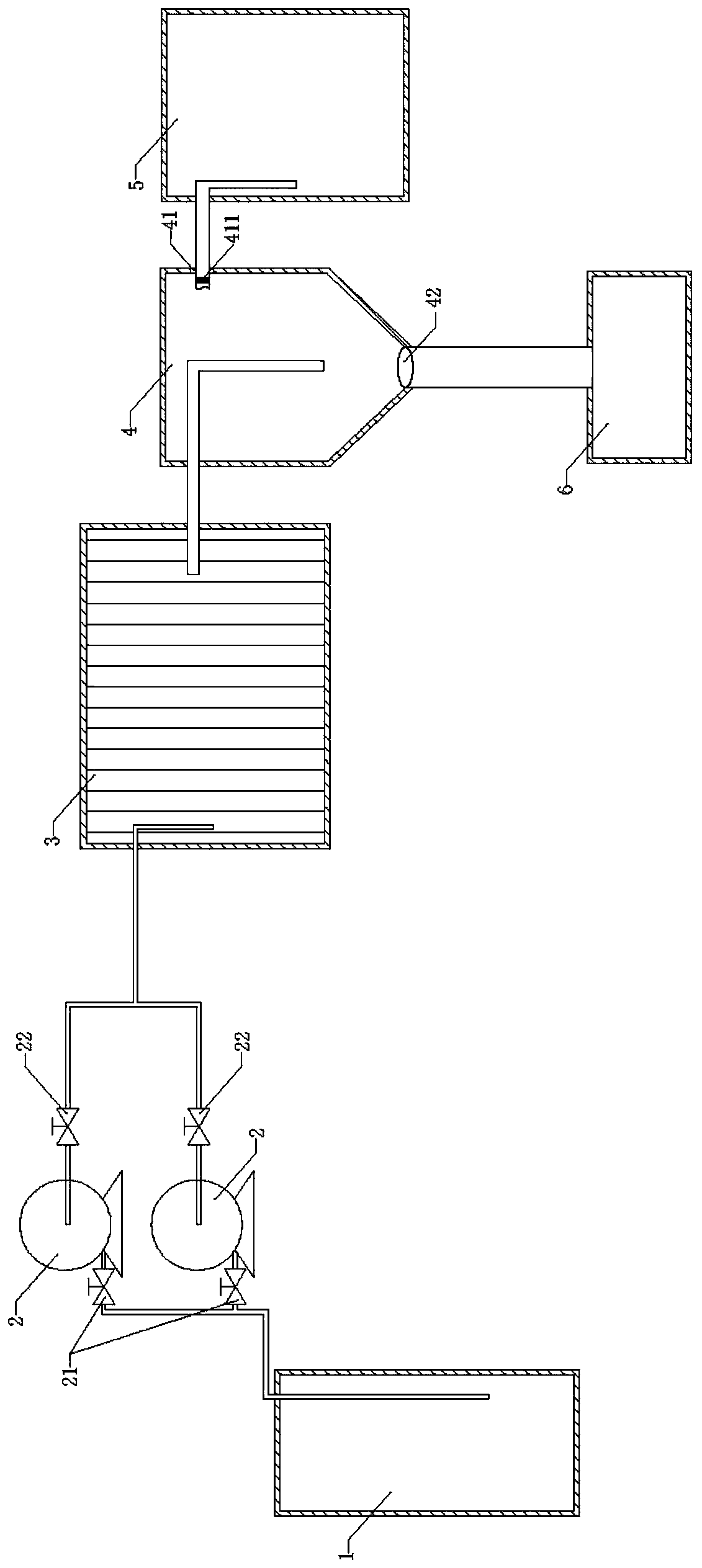

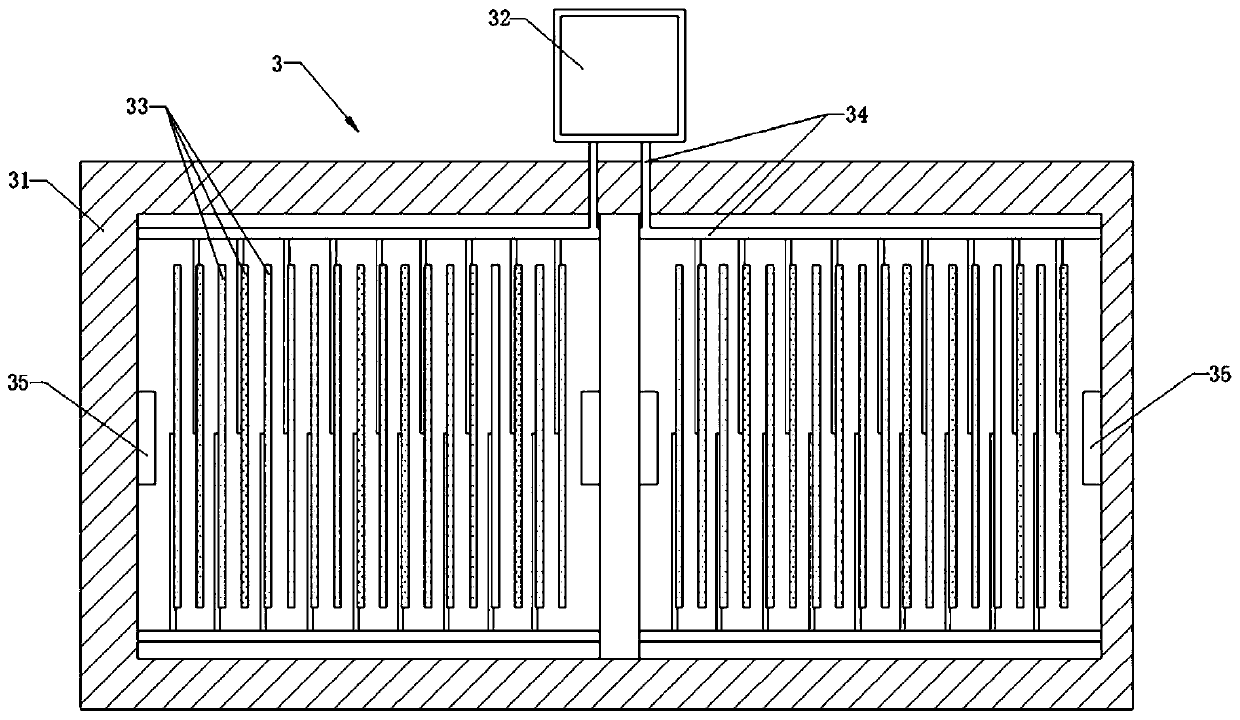

[0037] See attached Figure 1-2 , a treatment system for removing silicon from silicon-containing wastewater, used to implement the above-mentioned silicon-containing wastewater treatment process for removing s...

Embodiment 2

[0043] The difference between this embodiment and above-mentioned embodiment 1 is:

[0044] In described step (1), the current density of electrolytic treatment is 45A / m 2 , the voltage is 3V, and the electrolytic treatment time is 50min.

Embodiment 3

[0046] The difference between this embodiment and above-mentioned embodiment 1 is:

[0047] In described step (1), the current density of electrolytic treatment is 50A / m 2 , the voltage is 4V, and the electrolytic treatment time is 40min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com