Kitchen waste pretreatment device

A pretreatment device, kitchen waste technology, applied in the direction of solid waste removal, etc., can solve problems such as hidden dangers to human life safety, and achieve the effects of high resource reuse rate, low investment and less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

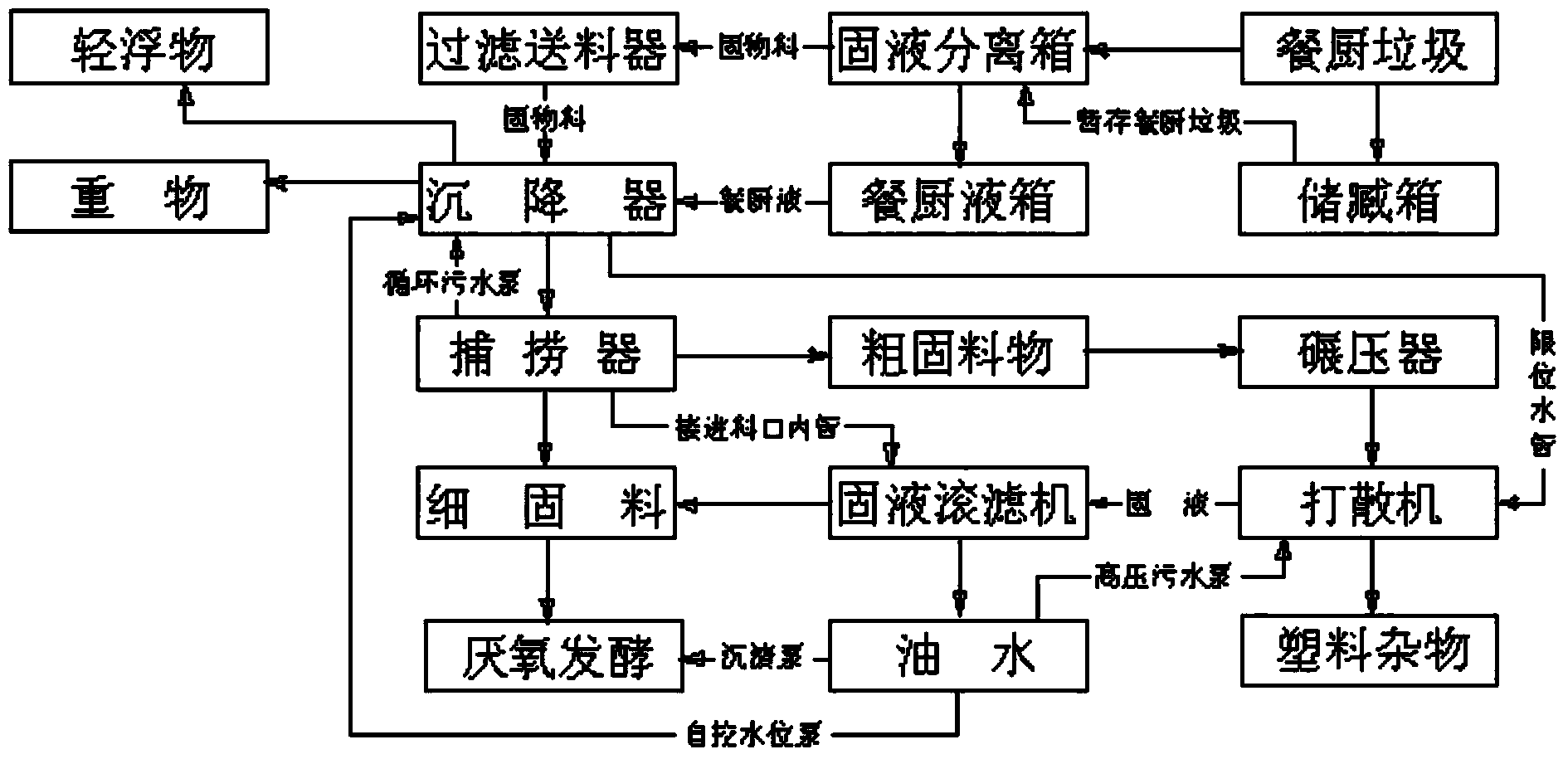

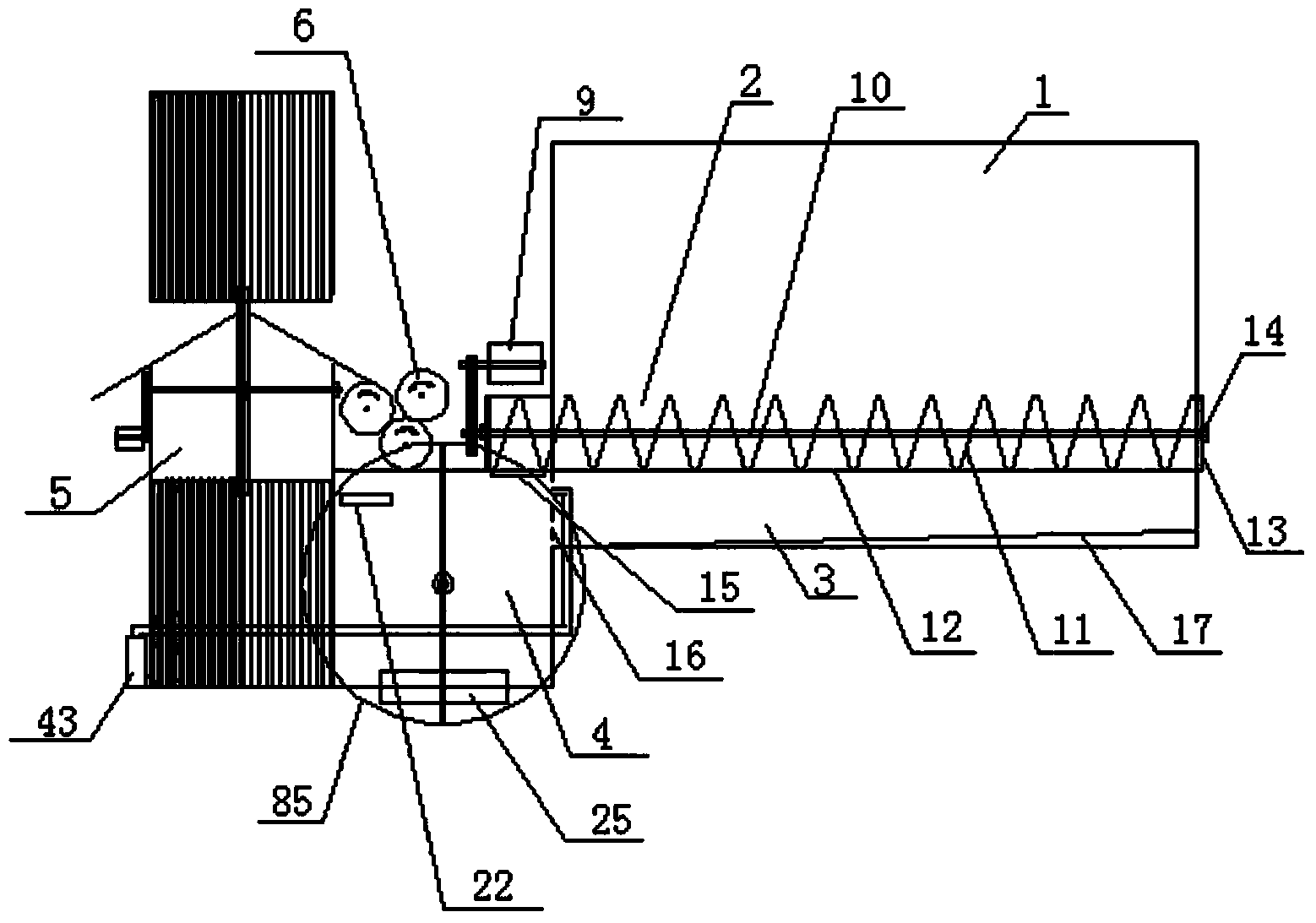

[0036] Such as Figure 1-Figure 12 As shown, a food waste pretreatment device includes a food waste storage box, a filter feeder 2, a washing and breaking machine 7, a rolling machine 6, and also includes a solid-liquid separation box 1, a kitchen liquid tank 3, a settling device 4, catcher 5 and solid-liquid rolling filter 8.

[0037] An electromagnetic valve is installed at the bottom of the food waste storage box, and the electromagnetic valve is connected to the top of the solid-liquid separation box 1; Unload the food waste into the food waste storage box for temporary storage; when the food waste in the solid-liquid separation box 1 falls to the lower fixed position, the electromagnetic valve of the food waste storage box will automatically open and the food waste will be added to the solid-liquid separation box 1 Inside, the electromagnetic valve closes automatically when it reaches the upper fixed position.

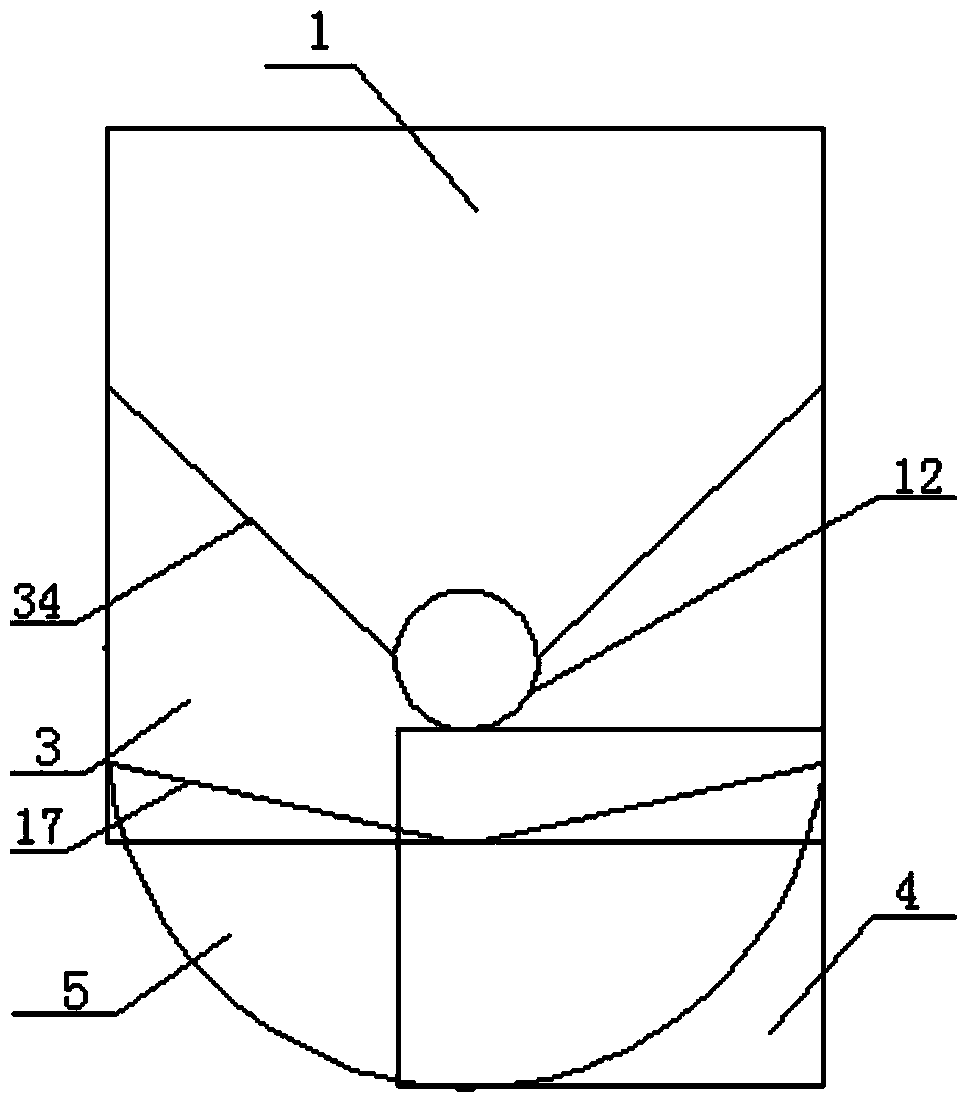

[0038] Such as image 3 As shown, the solid-liquid separati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com