Machine for automatically recycling, screening and grading abrasive materials of shot blasting machine

An automatic recovery and shot blasting machine technology, applied in the field of abrasives, can solve problems such as increased factory costs, waste of resources, doping of broken pellets, etc., and achieve the effects of improving resource reuse, reducing labor intensity, and reducing use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

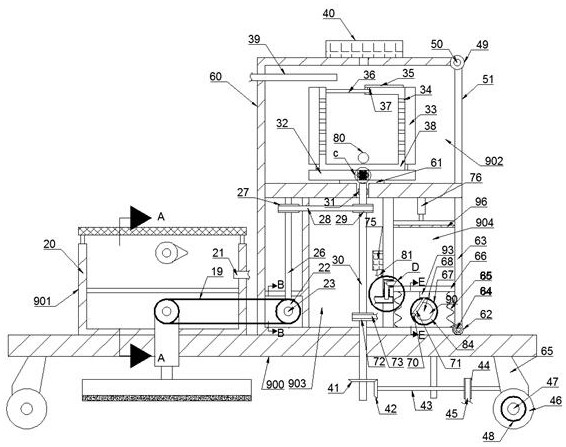

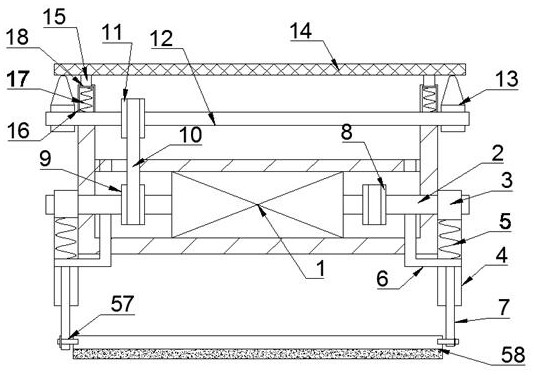

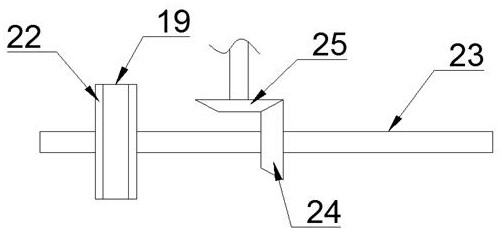

[0022] Combine below Figure 1-6 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0023] combined with Figure 1-6The described machine for automatic recovery, screening and grading of shot blasting machine abrasives includes a main body 900 on which a first screening box 901 is fixed, and a first motor 1 is fixed inside the first screening box 901. The first motor 1 is rotatably provided with a first motor shaft 2 extending symmetrically to the outside of the first screening box, and a first pulley 9 is sleeved on the left first motor shaft 2. The first belt 10 is sleeved on the first pulley 9, and the first rotating shaft 12 with two ends extending to the outside of the first screening box is rotatably provided in the first screening box 901, and the first rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com