Aluminum-air battery and method for recycling electrolyte of aluminum-air battery

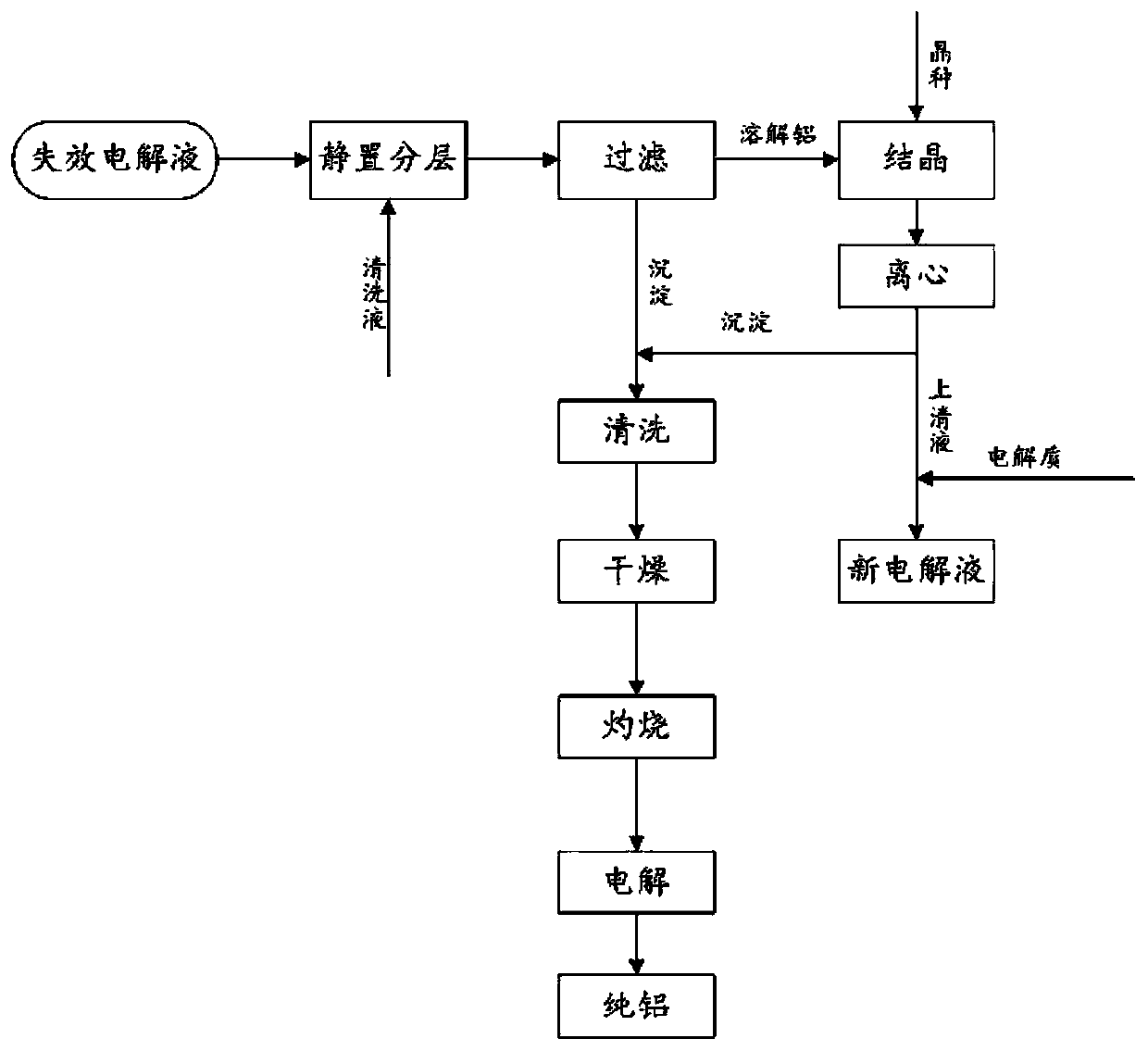

An electrolyte recovery, aluminum-air battery technology, applied in fuel cell type half cells and primary cell type half cells, improvement of process efficiency, etc., can solve the complex process, high cost, difficult recovery of failed electrolyte, etc. problems, to avoid environmental pollution, easy to operate, and improve the effect of resource reuse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Collect the spent electrolyte solution containing dissolved aluminum and aluminum hydroxide into the gravity sedimentation tank, clean the aluminum-air battery with water and inject the cleaning solution together. The volume ratio of the spent electrolyte solution and the cleaning solution is 1:1. Set aside for 2 days, after the aluminum hydroxide precipitate phase is separated from the solution phase, use a pump to roughly filter the supernatant containing dissolved aluminum and inject it into the seed crystal chamber, stir slowly and add aluminum hydroxide crystal seeds, and control the temperature at 30 °C , the stirring speed is 50r / min, and the stirring time is 6 days. Afterwards, centrifuge to obtain the sediment in the seed chamber, put it together with the sediment in the lower layer of the gravity settling tank, wash it repeatedly with deionized water until it is neutral, and dry it at 60°C for 9 hours to obtain alumina powder. Put the alumina powder in a muffl...

Embodiment 2

[0066] Collect the spent electrolyte solution containing dissolved aluminum and aluminum hydroxide into the gravity sedimentation tank, clean the aluminum-air battery with water and inject the cleaning solution together, the volume ratio of the spent electrolyte solution and the cleaning solution is 1:2, cool at 10°C Set aside for 1 day, after the aluminum hydroxide precipitate phase is separated from the solution phase, use a pump to roughly filter the supernatant containing dissolved aluminum and inject it into the seed crystal chamber, stir and pass in excess CO 2 , the control temperature is 15°C, the stirring speed is 200r / min, and the stirring time is 3 days. Afterwards, centrifuge to obtain the sediment in the seed chamber, put it together with the sediment in the lower layer of the gravity settling tank, wash it repeatedly with deionized water until it is neutral, and dry it at 80°C for 5 hours to obtain alumina powder. Put the alumina powder in a muffle furnace and bu...

Embodiment 3

[0068] Collect the spent electrolyte solution containing dissolved aluminum and aluminum hydroxide into the gravity sedimentation tank, clean the aluminum-air battery with water and inject the cleaning solution together, the volume ratio of the spent electrolyte solution and the cleaning solution is 1:2.5, cool at 0°C Set aside for 0.5 days, after the aluminum hydroxide precipitate phase is separated from the solution phase, use a pump to roughly filter the supernatant liquid containing dissolved aluminum and inject it into the seed crystal chamber, stir and add aluminum chloride seed crystals, control the temperature at 15°C, The stirring speed is 100r / min, and the stirring time is 6 days. Afterwards, centrifuge to obtain the sediment in the seed chamber, put it together with the sediment in the lower layer of the gravity settling tank, wash it repeatedly with deionized water until it is neutral, and dry it at 60°C for 3 hours to obtain alumina powder. Put the alumina powder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com