Method of recycling cyclohexanone waste lye

A technology of waste lye and cyclohexanone, applied in chemical instruments and methods, natural water treatment, neutralized water/sewage treatment, etc., can solve environmental secondary pollution and other problems, achieve radical cure of secondary pollution, and significantly improve social environment Benefits and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The waste caustic lye basic substance component and weight percentage that the inventive method radically cures are:

[0015] Inorganic matter: sodium carbonate (Na 2 CO 3 ) about 7%

[0016] Sodium hydroxide (NaOH) about 8%

[0017] Organic matter: about 35% organic acid alcohol ketone ester

[0018] Water about 50%

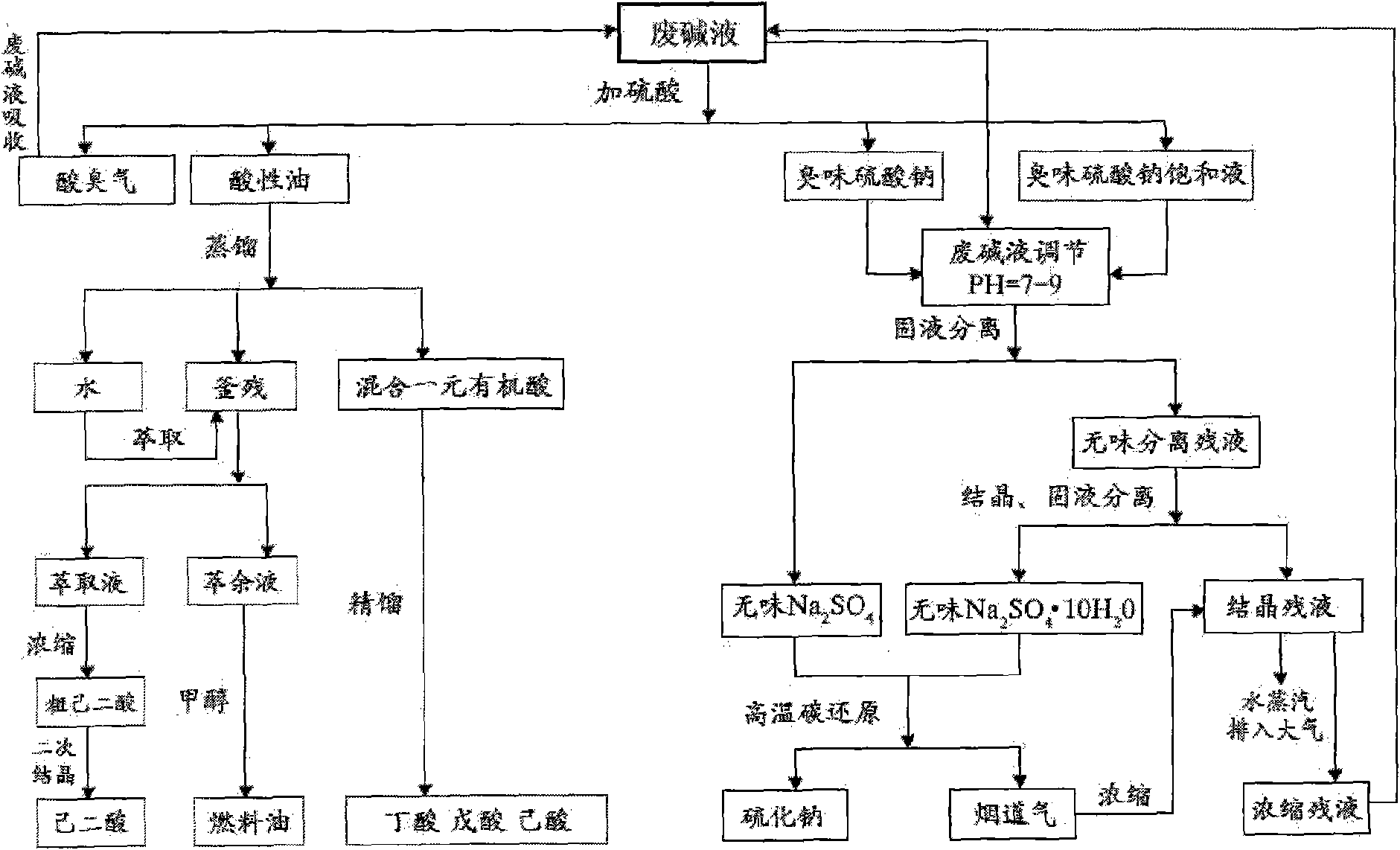

[0019] Below in conjunction with technological process block diagram, briefly describe the implementation process of the inventive method:

[0020] (1) Acid neutralization to extract acid oil, anhydrous sodium sulfate (Na 2 SO 4 ) and sodium sulfate containing crystal water (Na 2 SO 4 10H 2 O); and simultaneously treat the acidified sewage generated during the acid neutralization process.

[0021] (1) Acid neutralization to extract acid oil, anhydrous sodium sulfate (Na 2 SO 4 ) and sodium sulfate containing crystal water (Na 2 SO 4 10H 2 O):

[0022] Add industrial sulfuric acid or waste sulfuric acid into the waste caustic so tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com