Coal ash/magnetic straw composite material as well as preparation method and application thereof

A technology of composite materials and fly ash, which is applied in the field of fly ash/magnetic straw composite materials and its preparation, can solve the problems of poor adsorption efficiency and achieve the effects of reducing crystallinity, improving negative effects, and good adsorption and flocculation capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

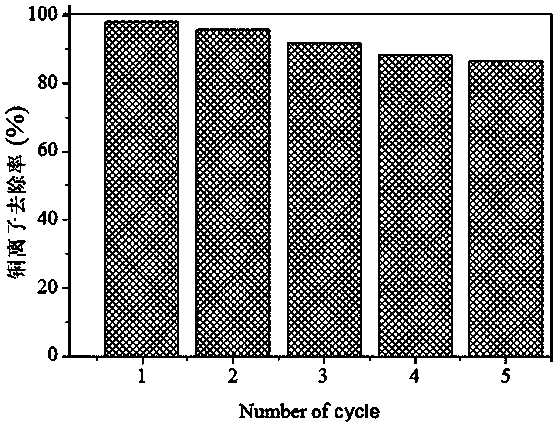

Examples

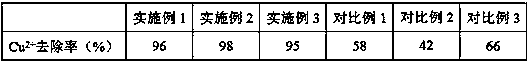

Embodiment 1

[0022] A kind of fly ash / magnetic straw composite material, its preparation method comprises the following steps:

[0023] 1) Pretreatment of rapeseed stalks: wash the collected rapeseed stalks with water to remove surface dust, cut them into pieces, dry them, crush them with a pulverizer, soak them in an appropriate amount of water for 24 hours, filter to remove impurities, and obtain pretreated rapeseed Straw powder, spare;

[0024] 2) Modification of rape straw: Weigh 5 g of pretreated rape straw powder into a 250 mL three-neck flask, add 100 mL of 10 wt% sodium hydroxide solution, and stir in a water bath at 50 °C with electric stirring Stir at a constant temperature and at a constant speed for 24 hours until the rapeseed straw powder is completely melted, then place it to cool, then adjust its pH to neutral with 0.5 wt% hydrochloric acid solution, add an appropriate amount of absolute ethanol to make it precipitate, filter it with a vacuum pump, and place it again Dry in...

Embodiment 2

[0030] A kind of fly ash / magnetic straw composite material, its preparation method comprises the following steps:

[0031] 1) Pretreatment of rapeseed stalks: Wash the collected rapeseed stalks with water to remove surface dust, cut them into pieces, dry them, crush them with a grinder, soak them in an appropriate amount of water for 24 hours, filter to remove impurities, and obtain the pretreated Rapeseed straw powder, spare;

[0032] 2) Modification of rape straw: Weigh 5 g of pretreated rape straw powder into a 250 mL three-neck flask, add 100 mL of 15 wt% sodium hydroxide solution, and stir in a water bath at 55 °C with electric stirring Stir at a constant temperature and at a constant speed for 24 hours until the rapeseed straw powder is completely melted, then place it to cool, then adjust its pH to neutral with 1.0 wt% hydrochloric acid solution, add an appropriate amount of absolute ethanol to make it precipitate, filter it with a vacuum water pump, and place it again ...

Embodiment 3

[0038] A kind of fly ash / magnetic straw composite material, its preparation method comprises the following steps:

[0039] 1) Pretreatment of rapeseed stalks: Wash the collected rapeseed stalks with water to remove surface dust, cut them into pieces, dry them, crush them with a grinder, soak them in an appropriate amount of water for 24 hours, filter to remove impurities, and obtain the pretreated Rapeseed straw powder, spare;

[0040] 2) Modification of rape straw: Weigh 5 g of pretreated rape straw powder into a 250 mL three-neck flask, add 100 mL of 20 wt% sodium hydroxide solution, and place in a water bath at 60 °C with an electric stirrer Stir at constant temperature and constant speed for 24 h, let the rape straw powder melt completely and let it cool down, then adjust its pH to neutral with 1.5 wt% hydrochloric acid solution, add an appropriate amount of absolute ethanol to make it precipitate, filter it with a vacuum pump, and place it in Dry in an oven at 60°C for 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com