High-speed sludge treating system

A sludge treatment and sludge technology, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of unsuitable for large-scale treatment, low treatment efficiency, slow speed, etc., and achieve fast treatment speed, high treatment efficiency, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

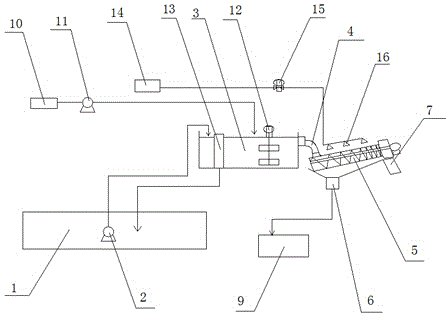

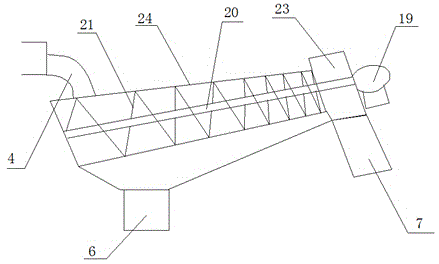

[0026] Such as figure 1 As shown, a high-speed sludge treatment system, the system includes a sludge tank 1, and the sludge delivery pump 2 arranged in the sludge tank 1 is transported to the sludge mixing tank 3 through a pipeline, and the sludge mixing tank 3 passes the sludge The mud input port 4 is connected to a sludge filter press 5 provided with a filtrate outlet 6 for delivering the filtrate to a filtrate pool 9 and a mud cake outlet 7 for discharging the mud cake.

Embodiment 2

[0028] On the basis of Embodiment 1, the sludge agitation tank 3 in this embodiment is provided with a return pipe 13 leading to the sludge tank 1 . When the sludge pumped into the mixing tank exceeds the limit, the excess can flow back to the sludge tank through the return pipe.

Embodiment 3

[0030] On the basis of Embodiment 1 or 2, the system described in this embodiment is provided with flocculant addition equipment leading to the sludge stirring tank 3, including a flocculant addition pump 11, a flocculant injection port 10 and corresponding pipelines; corresponding sludge A mixing and stirring device 12 is arranged in the stirring tank 3 . After adding flocculant to the sludge mixing tank, the particles in the sludge can be concentrated, which is convenient for the next step of treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com