Titanium-alloy-plate tandem-rolling temperature controlling device and temperature controlling tandem-rolling method

A technology of a titanium alloy plate and a temperature control device is applied in the field of continuous plate rolling, which can solve the problems of long distance and temperature difference on the surface of the slab, and achieve the effect of avoiding warpage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

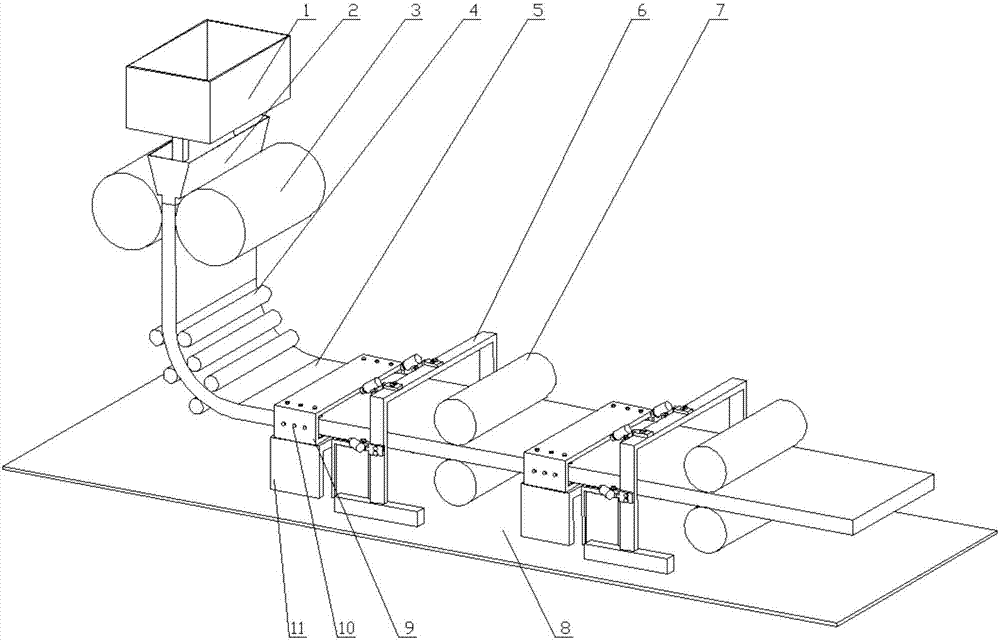

[0013] In order to better understand the technical solutions of the present invention, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. A 3500mm plate rolling mill is now used to carry out steel plate rolling, and the method of the present invention is used to realize temperature feedback control during continuous rolling of titanium alloy plates.

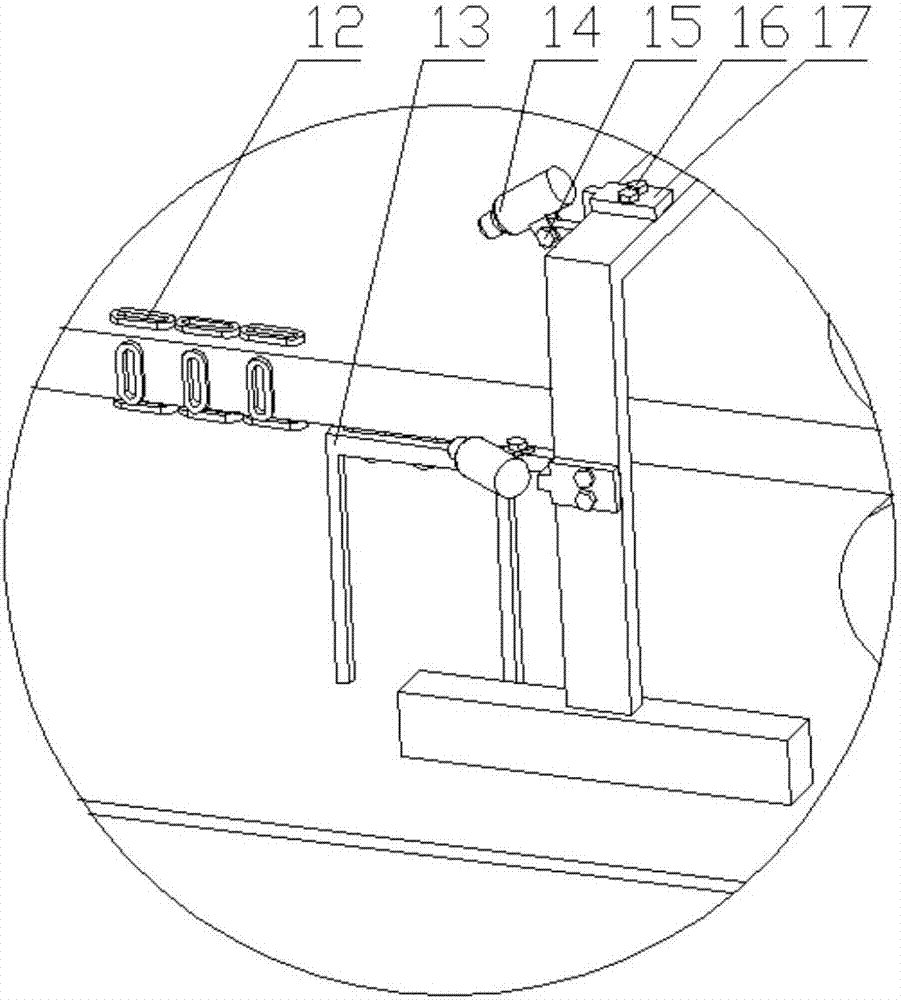

[0014] exist figure 1 and figure 2 In the schematic diagram of the temperature control device for continuous rolling of titanium alloy plates, where the titanium alloy plate 5 enters the horizontal rolling, a truss 8 fixed on the ground is arranged in front of each rolled roll, and two colorimetric thermometers 14 is fixed on the beam of the truss through the bracket 17 and screws, and another colorimetric thermometer is also fixed on the vertical beam on one side of the truss through the bracket and screws. The angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com