Fuel cell stack device

A technology of fuel cell stacks and fuel cells, which is applied in the direction of fuel cells, circuits, electrical components, etc., can solve the problems of large differences in the working state of single-chip batteries, the service performance and life of the stack, and eliminate the excessive difference in working states , Simple processing and manufacturing, and the effect of eliminating temperature and humidity differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

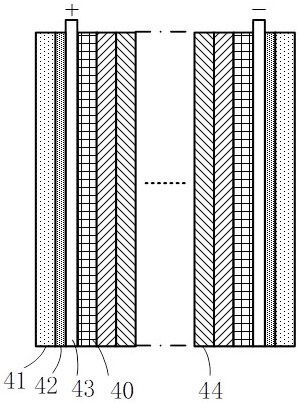

[0055] An embodiment of the present invention discloses a fuel cell stack device, such as Figure 1~2 As shown, it includes a plurality of monolithic cells 44 stacked in one, and dummy cells 40, current collectors 43, insulating plates 42 and end plates 41 which are respectively arranged on the outside of the first cell and the last cell and are stacked in sequence.

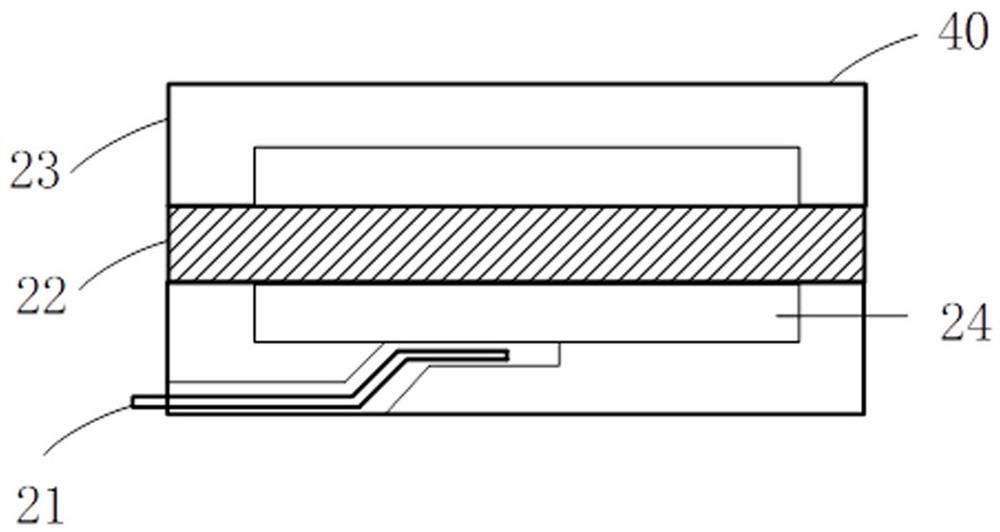

[0056] The dummy battery 40 adopts a sheet-like structure, and further includes a bipolar plate 23, a membrane electrode 22 without catalyst, a cathode gas flow channel and an anode gas flow channel. Inside the dummy battery 40, the membrane electrode 22 is arranged in the middle of the bipolar plate 23 to isolate the cathode gas flow channel and the anode gas flow channel on both sides thereof. In addition, the single cell 44 , the current collecting plate 43 , the insulating plate 42 and the end plate 41 can all adopt the structure in the existing stack.

[0057] The inside of the bipolar plate 23 in the dummy...

Embodiment 2

[0062] Improvements are made on the basis of Example 1. The temperature sensor includes a fiber optic temperature sensor. The optical fiber temperature sensor is installed in the water channel 24 of the dummy battery, and is used to collect the temperature data of the bipolar plate 23 in the dummy battery 40 in real time; the inlet and outlet of the water channel 24 of the dummy battery are sealed.

[0063] Preferably, the fuel cell stack device further includes a heating mechanism.

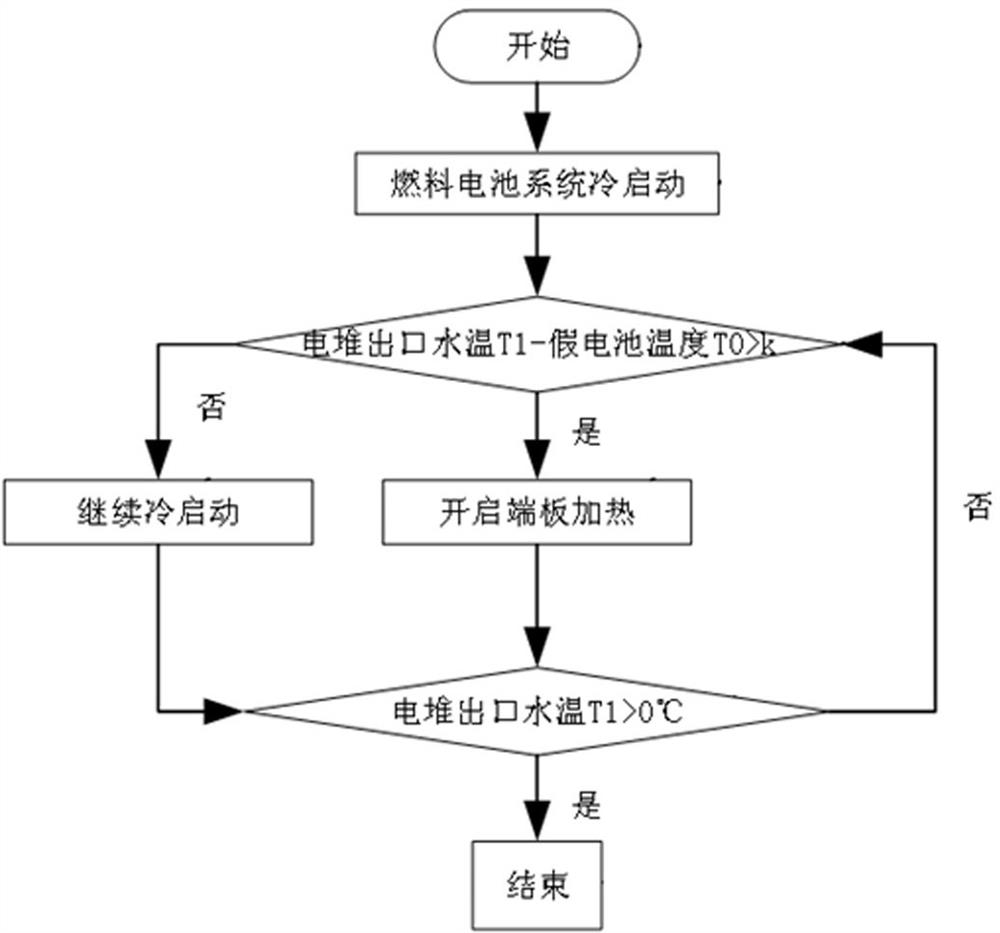

[0064] The electrodes of the heating mechanism are arranged between the current collecting plate 43 and the insulating plate 42 for heating the dummy battery 40 and the single battery 44 . Optionally, the heating mechanism may be a heating sheet. The end plate 41 is heated by the heating sheet 41, thereby heating the single cell 44 close to the dummy battery 40 to increase its temperature.

[0065] Preferably, the fuel cell stack device further includes a controller (also referred to as a temp...

Embodiment 3

[0084] Based on the improvement of Embodiment 1 or 2, an integrated temperature and humidity sensor or a temperature sensor and a humidity sensor can be used respectively.

[0085] Optionally, the humidity sensor is an ordinary gas humidity sensor or an optical fiber humidity sensor.

[0086] For the common gas humidity sensor, it can be installed on the inner wall of the cathode gas flow channel or the anode gas flow channel. Existing common gas humidity sensors include semiconductor gas sensors, electrochemical gas sensors, catalytic combustion gas sensors, thermal conductivity gas sensors, infrared gas sensors, solid electrolyte gas sensors, and the like.

[0087] For the use of fiber optic humidity sensors, it can be installed in the cathode gas flow channel or the anode gas flow channel.

[0088] Preferably, the fuel cell stack device further includes a controller (also called a humidity controller, which can be shared with Embodiment 2). The input end of the controller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com