Cement water-replenishing shrink-proof agent and preparation method and application thereof

A technology of anti-shrinkage agent and cement, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of reduced bond strength, difficulty in implementation, reduction of cement stone compressive strength and interface bond strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 A kind of oil well cement replenishment anti-shrinkage agent

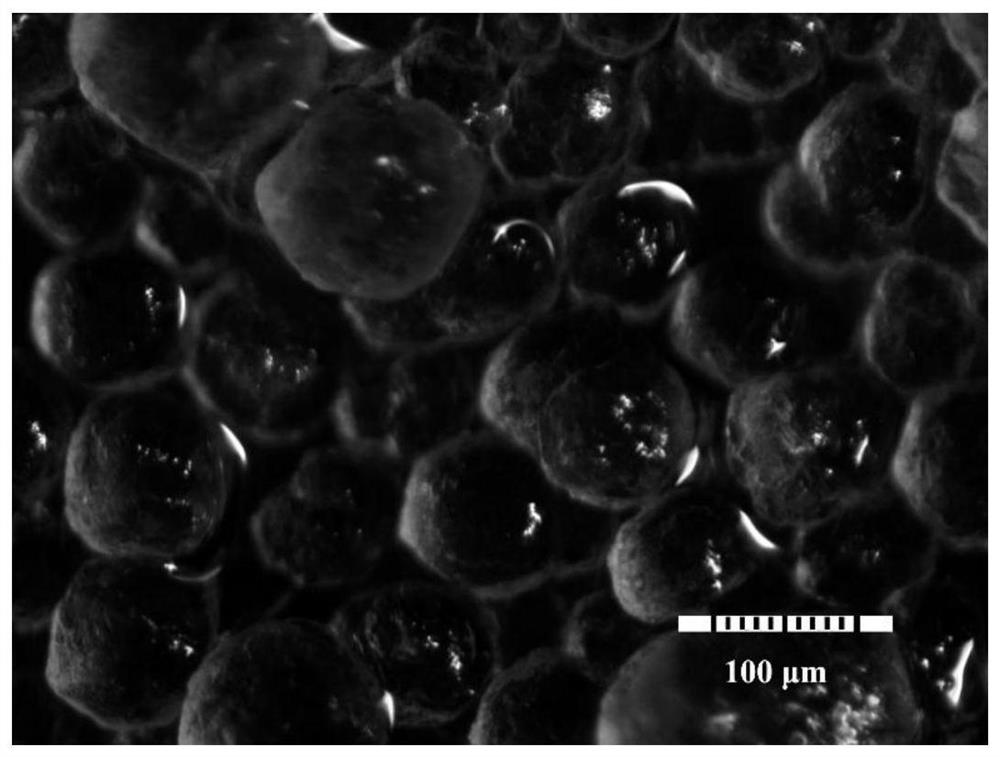

[0027] Dissolve 100 parts of 2-acrylamide-2-methylpropanesulfonic acid (AMPS), 0.5 part of NN-methylenebisacrylamide in 200 parts of water, and then add 1 part of ammonium persulfate to form a reaction system. The reaction system was prepared into a spherical hydrogel using a bidisperse reversed-phase suspension polymerization method (ZL201310073224.0). Mix hydrogel and ultra-fine silica sand (1250 mesh) at a ratio of 20:3 and stir evenly, then dry to obtain moisturizing and anti-shrinkage agent S1. The particle size of the spherical hydrogel is 100-300 μm, and the particle size of the cement water replenishing anti-shrinkage agent is 50-100 μm.

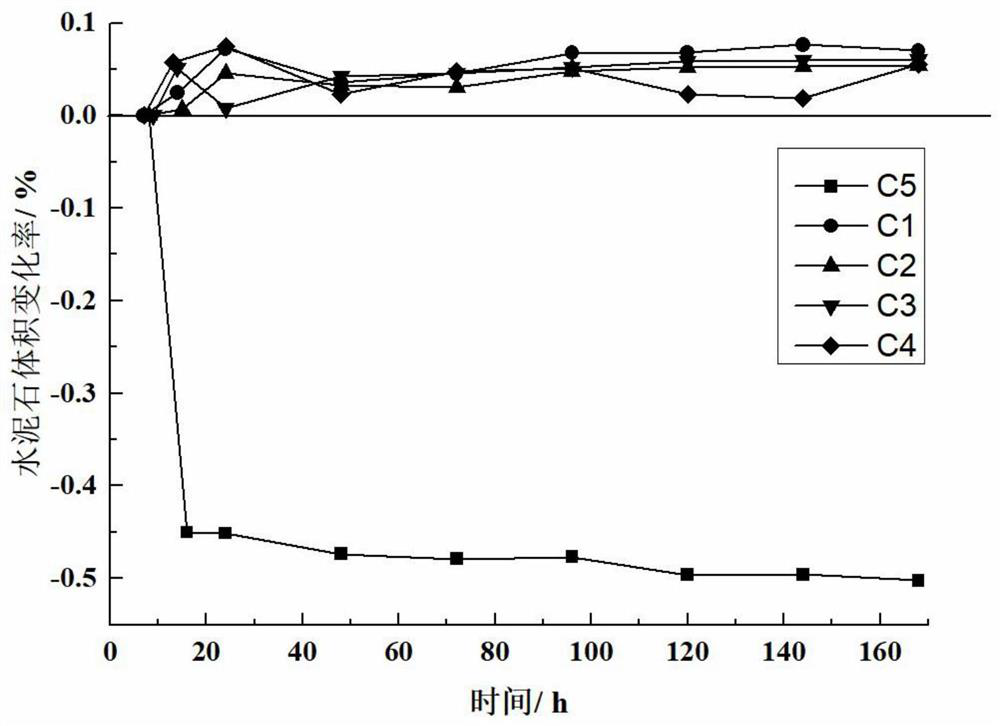

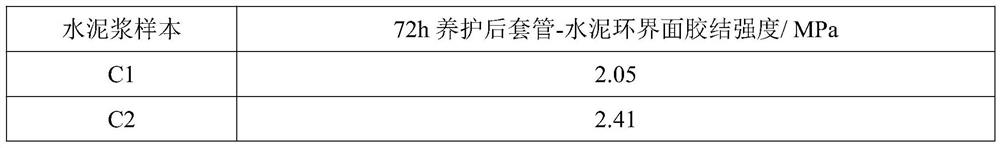

[0028] Dry mix the cement water-replenishing anti-shrinkage agent with oil well cement and add admixtures and water, that is, G grade oil well cement + 2.5% sulfonic acid group and carboxylic acid group copolymerization fluid loss reducer + 1.5% sulfo...

Embodiment 2

[0029] Embodiment 2 A kind of oil well cement replenishment anti-shrinkage agent

[0030] Dissolve 100 parts of 2-acrylamide-2-methylpropanesulfonic acid (AMPS), 1 part of NN-methylenebisacrylamide in 250 parts of water, and then add 2 parts of ammonium persulfate to form a reaction system. The reaction system was prepared into a spherical hydrogel using a bidisperse reversed-phase suspension polymerization method (ZL201310073224.0). Mix hydrogel and ultra-fine silica sand (6000 mesh) at a ratio of 10:1, stir evenly, and then dry to obtain moisturizing and anti-shrinkage agent S2. The particle size of the spherical hydrogel is 100-300 μm, and the particle size of the cement water replenishing anti-shrinkage agent is 50-100 μm.

[0031] Dry mix the cement water-replenishing anti-shrinkage agent with oil well cement and add admixtures and water, that is, G grade oil well cement + 2.5% sulfonic acid group and carboxylic acid group copolymerization fluid loss reducer + 1.5% sulfo...

Embodiment 3

[0032] Embodiment 3 A kind of oil well cement replenishment anti-shrinkage agent

[0033] Dissolve 100 parts of 2-acrylamide-2-methylpropanesulfonic acid (AMPS), 1.5 parts of NN-methylenebisacrylamide in 300 parts of water, and then add 3 parts of ammonium persulfate to form a reaction system. The reaction system was prepared into a spherical hydrogel using a bidisperse reversed-phase suspension polymerization method (ZL201310073224.0). Mix the hydrogel and superfine calcium carbonate (1250 mesh) at a ratio of 20:3 and stir evenly, then dry to obtain the moisturizing anti-shrinkage agent S3. The particle size of the spherical hydrogel is 100-300 μm, and the particle size of the cement water replenishing anti-shrinkage agent is 50-100 μm.

[0034] Dry mix the cement water-replenishing anti-shrinkage agent with oil well cement and add admixtures and water, that is, G grade oil well cement + 2.5% sulfonic acid group and carboxylic acid group copolymerization fluid loss reducer +...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com