Preparation method of composite substrate, composite film and electronic component

A composite substrate and composite film technology, which is applied in the manufacturing of electrical components, piezoelectric devices/electrostrictive devices, semiconductor/solid-state devices, etc. Rough interface, increased substrate dielectric loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

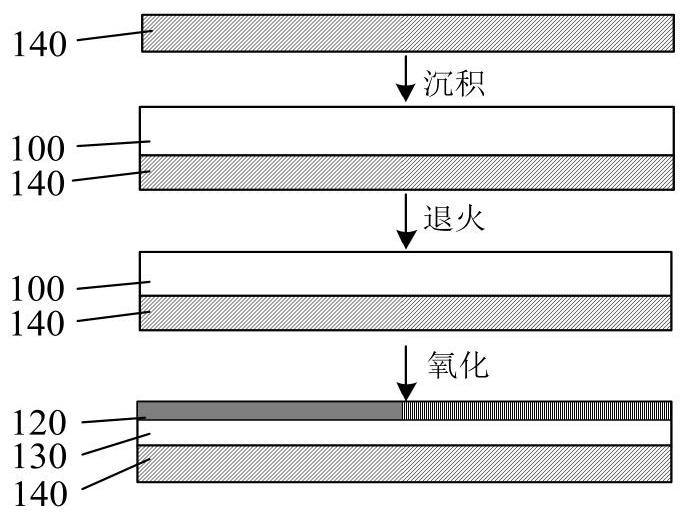

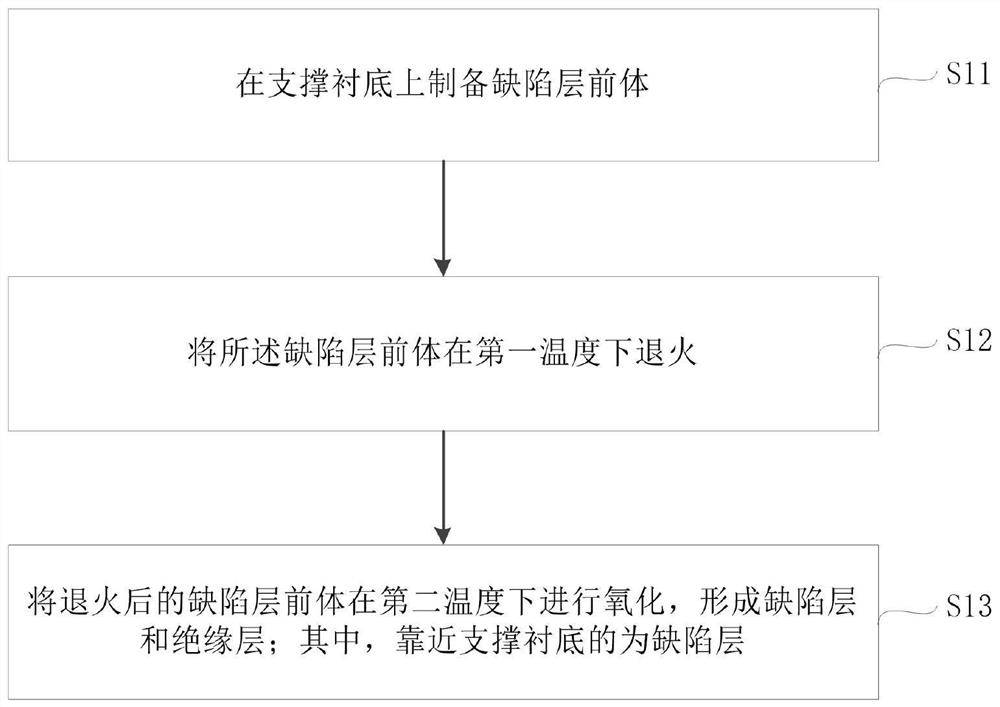

[0039] Specifically, refer to figure 2 , the preparation method comprises:

[0040] S11 , preparing a defect layer precursor 100 on the supporting substrate 140 .

[0041] Optionally, the preparation method of the defect layer precursor 100 is LPCVD or PECVD, and its thickness may be 200nm-20um, as long as it can realize the support function, which is not specifically limited.

[0042] Wherein, the LPCVD or PECVD is an existing method, for details, reference may be made to the implementation of an existing method, and no further description is given here.

[0043] S12, annealing the defect layer precursor 100 at a first temperature.

[0044] Optionally, in this step, the support substrate 140 containing the defect layer precursor 100 obtained in step S11 is placed in a high-temperature annealing furnace, and nitrogen annealing is performed at 900° C. to 1100° C. (first temperature), and the annealing time is 3h~24h.

[0045] Before the annealing, the wafer prepared in ste...

Embodiment 1

[0083] 1) A Si single wafer is selected as the support substrate, and a polysilicon layer with a thickness of 1.8um is grown on the support substrate by LPCVD as a defect layer precursor, and then the surface of the polysilicon layer is cleaned.

[0084] 2) Place the supporting substrate with the polysilicon layer in step 1) for annealing in a high-temperature annealing furnace, the annealing temperature is 1000°C, the annealing time is 8h, and it is cleaned.

[0085] 3) Perform thermal oxidation treatment on the annealed and cleaned polysilicon layer in step 2), the thermal oxidation temperature is 900°C, and the thermal oxidation time is 10h, and the part of the polysilicon layer far away from the supporting substrate is oxidized into silicon dioxide (insulating layer) , the part of the polysilicon close to the supporting substrate is not oxidized to form a defect layer. The surface of the silicon dioxide layer is planarized, and the planarized silicon dioxide surface is cle...

Embodiment 2

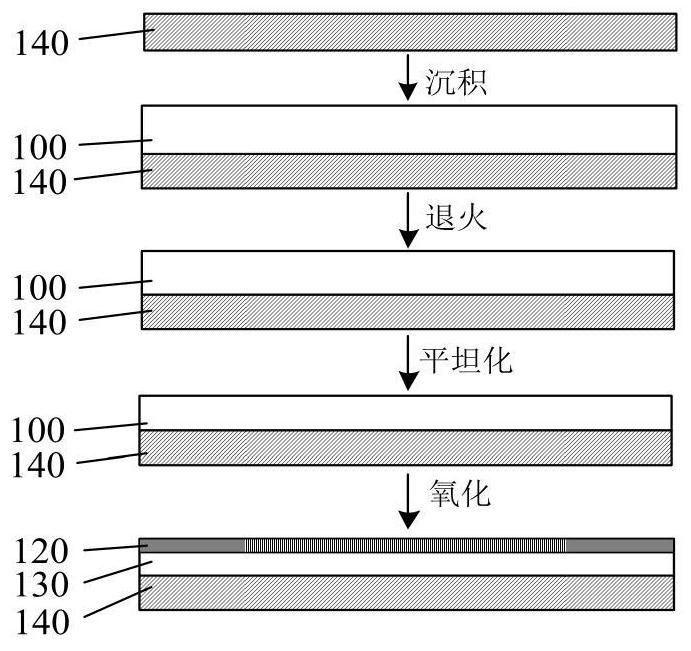

[0089] 1) A Si single wafer is selected as the support substrate, and a polysilicon layer with a thickness of 1.8um is grown on the support substrate by LPCVD as a defect layer precursor, and then the surface of the polysilicon layer is cleaned.

[0090] 2) Place the supporting substrate with the polysilicon layer in step 1) for annealing in a high-temperature annealing furnace, the annealing temperature is 1000°C, the annealing time is 8h, and it is cleaned.

[0091] 3) Polishing the annealed polysilicon layer in step 2), removing a thickness of 300 nm, and cleaning the surface of the polished polysilicon layer again.

[0092] 4) Perform thermal oxidation treatment on the polished and cleaned polysilicon layer in step 3), the thermal oxidation temperature is 900°C, the thermal oxidation time is 10h, and the part of the polysilicon layer far away from the supporting substrate is oxidized into silicon dioxide (insulating layer) , the part of the polysilicon close to the support...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com