Large-power LED lamp heat radiator with fins having functions of heat pipes

An LED lamp, high-power technology, used in lighting and heating equipment, cooling/heating devices for lighting devices, lighting devices, etc. It has the advantages of convenient processing, production and installation, easy operation, simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

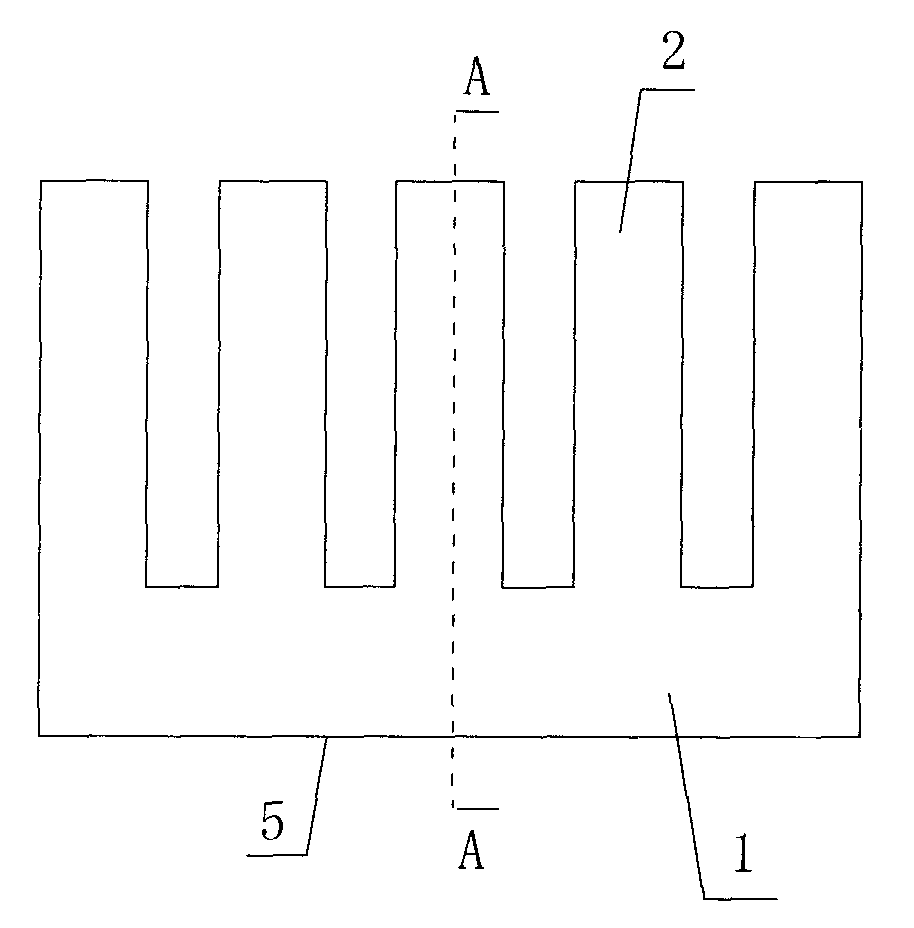

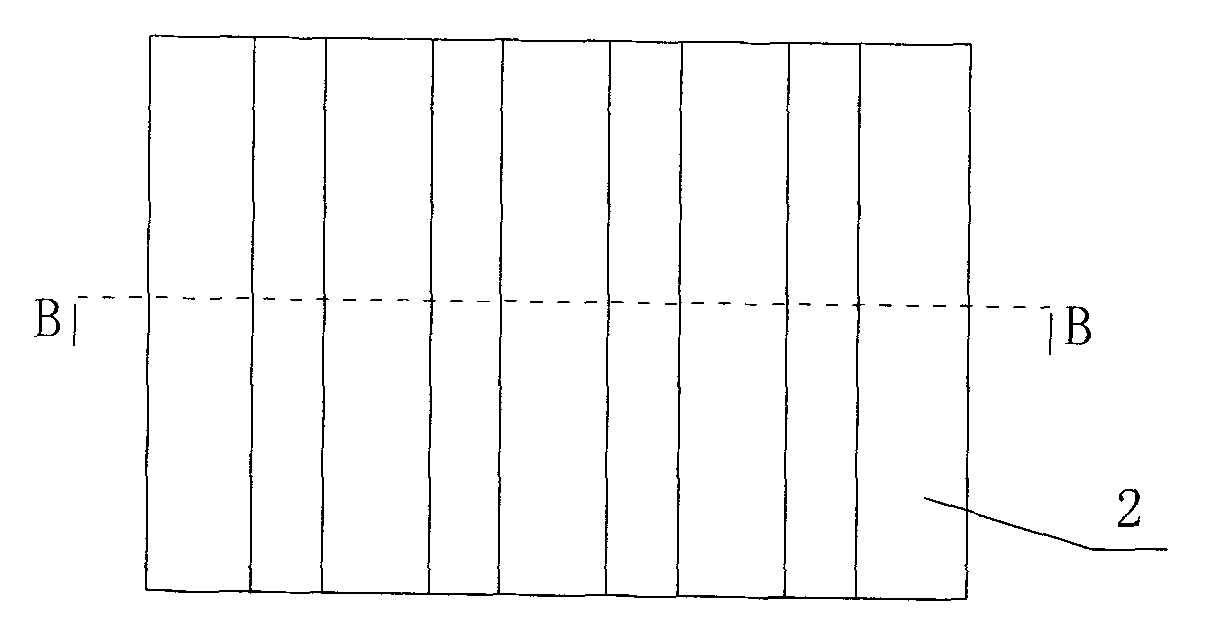

[0032] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the present invention includes a metal heat dissipation body 1 and metal heat dissipation fins 2 arranged on the metal heat dissipation body 1, the number of the metal heat dissipation fins 2 is not less than one piece, and the metal heat dissipation body 1 is provided with There is a fixed installation surface 5 for the fixed installation of the high-power LED light source. Both the metal heat dissipation body 1 and the metal heat dissipation fins 2 are hollow structures. The first hollow cavity inside the metal heat dissipation body 1 communicates with the second hollow cavity inside the metal heat dissipation fin 2 to form a closed inner hollow cavity 3 that communicates with each other.

[0033] A heat pipe liquid-absorbing core 4 is arranged on the inner wall of the closed inner cavity body 3 and a working liquid is housed inside. The heat dissipation body 1 and the metal heat dissipat...

Embodiment 2

[0038] Such as Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 As shown, in this embodiment, the difference from Embodiment 1 is that: the metal heat dissipation body 1 is a cylindrical structure, the number of the metal heat dissipation fins 2 is multiple, and the plurality of metal heat dissipation fins 2. Taking the central axis of the metal heat dissipation body 1 as the center line, it is radially and evenly arranged on the surrounding outer edge of the metal heat dissipation body 1. The fixed installation surface 5 is arranged on the lower end surface of the metal heat dissipation body 1 . Specifically: the number of the metal heat dissipation fins 2 is 12, and the 12 metal heat dissipation fins 2 are all in the shape of a cuboid and have the same structure and size. When actually laid out, the 12 metal heat dissipation fins 2 They are arranged radially and evenly around the outer sides of the cylindrical metal heat dissipation body 1, and the assembled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com