Preparation method of ZnO nano porous sheet cluster

A nanoporous and cluster technology, applied in the field of nanomaterials, can solve the problems of low concentration and reduce the production efficiency of ZnO, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

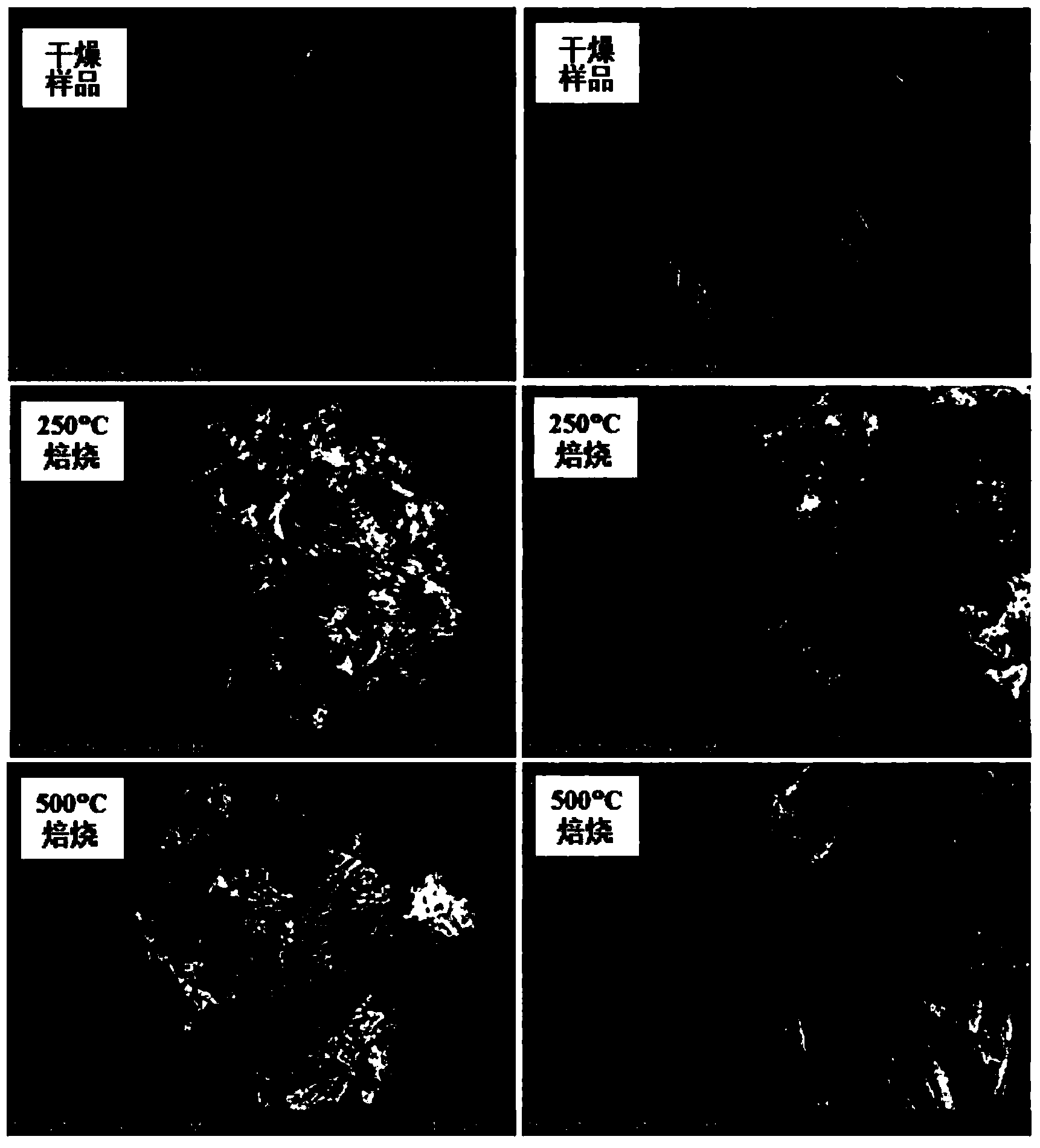

[0030] Weigh zinc nitrate and urea respectively according to the molar ratio of zinc nitrate and urea being 1:3, add deionized water to prepare Zn 2+ 50mL of mixed solution with a concentration of 0.3M; pour the mixed solution into a polytetrafluoroethylene cylindrical bottomed container with an inner diameter of 20mm and a wall thickness of 0.8mm; seal the open end with a plastic film, and heat in a water bath at 85°C for 12h; The resulting white solid was collected by filtration and dried in an oven at 120 °C for 24 h; part of the white solid was roasted at 250 °C and 500 °C for 6 h, respectively. figure 1 It is the scanning electron microscope observation results of the white solid after drying and the ZnO nanoporous sheet clusters calcined at 250°C and 500°C. The calcining treatment did not destroy the shape and size of the ZnO clusters, but it was a smooth sheet before calcining. Afterwards, it turns into a sheet with more transparent holes, and its thickness is about 50n...

Embodiment 2

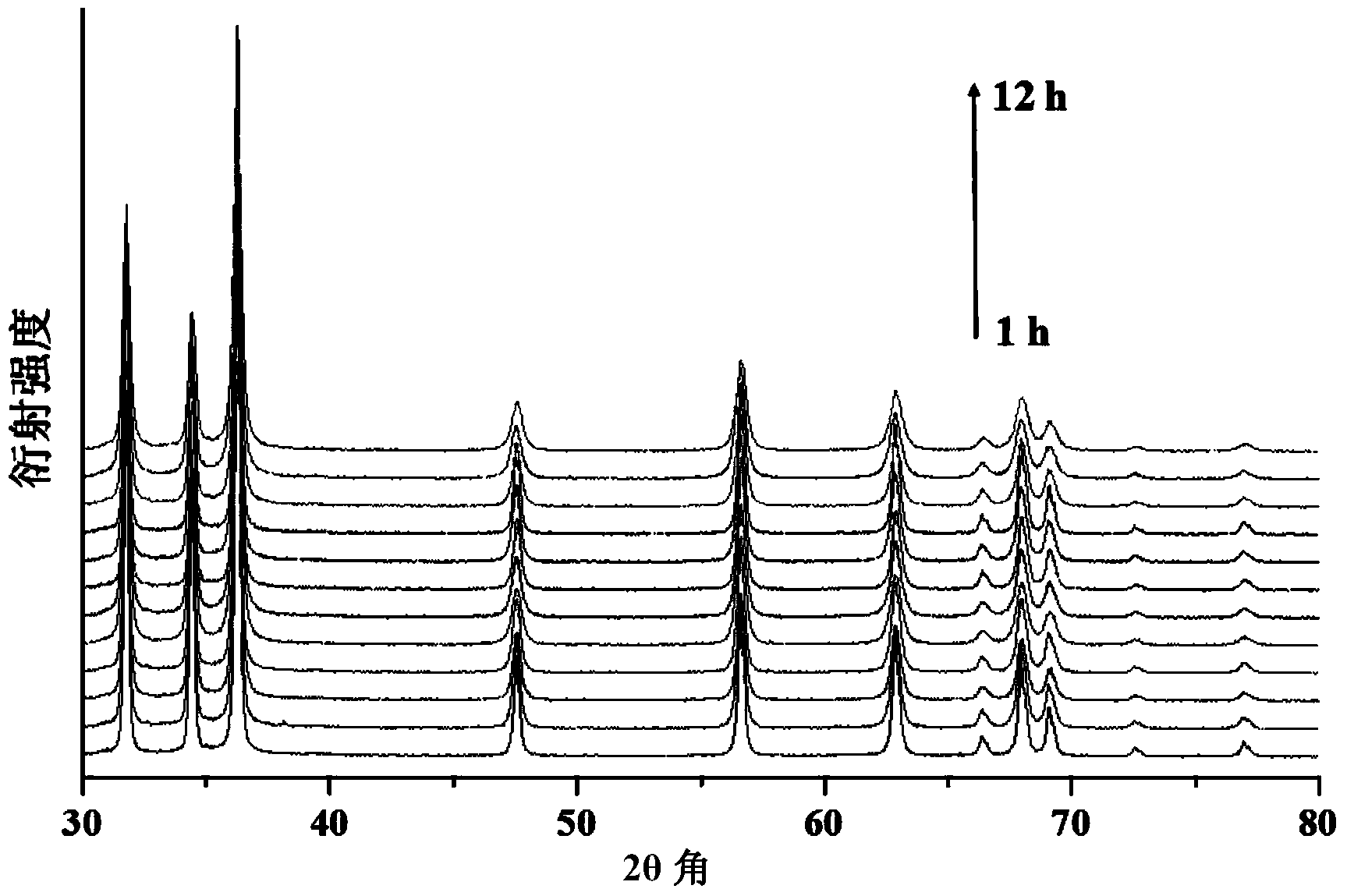

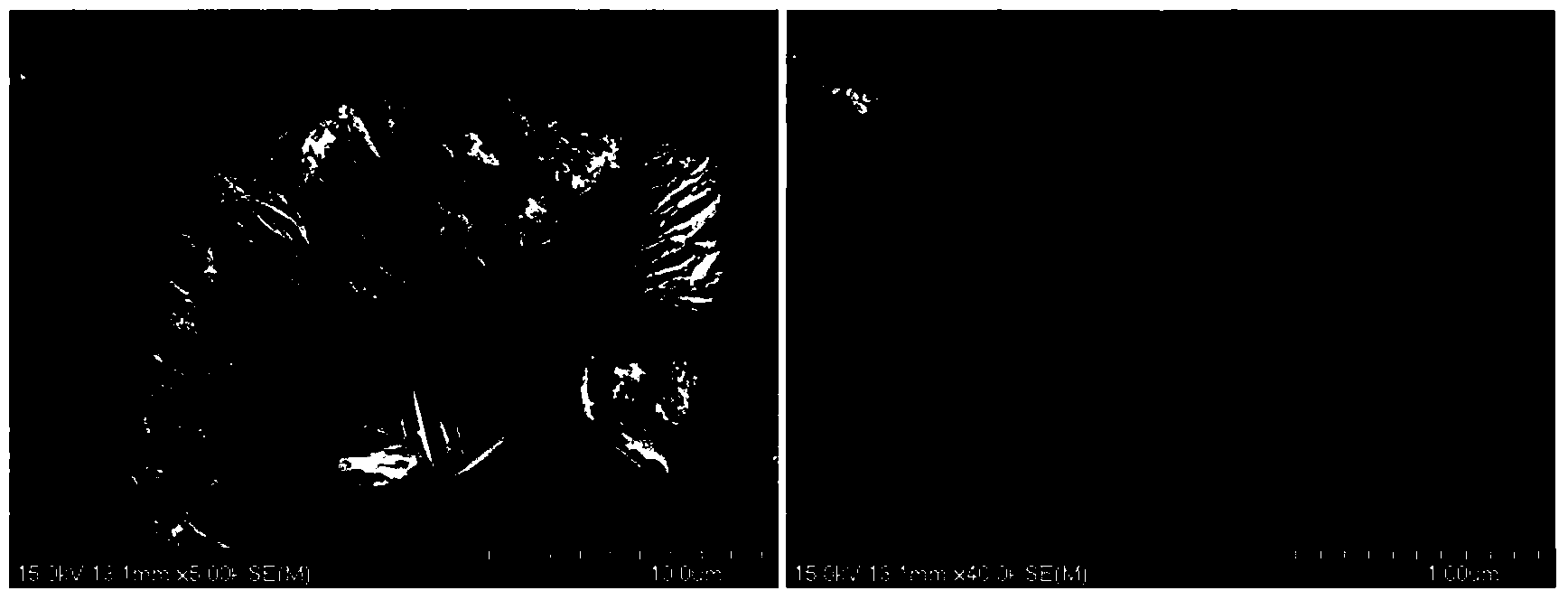

[0032] Weigh zinc nitrate and urea respectively according to the molar ratio of zinc nitrate and urea being 1:4, add deionized water to prepare Zn 2+ 1800mL of solution with a concentration of 0.3M; pour these solutions into 12 glass cylindrical bottomed containers with an inner diameter of 40mm and a wall thickness of 2.0mm; seal the open end with a plastic film, and heat it in an oil bath at 95°C. Take out a container every hour; collect the white solid formed by filtration, dry it in an oven at 120°C for 24h, and then bake it at 500°C for 6h. figure 2 It is the crystal form analysis result of the samples after roasting with different synthesis times. They are all ZnO with high crystallinity, and the length of synthesis time does not affect the ZnO crystal form. image 3 It is the scanning electron microscope observation result of the ZnO nanoporous sheet cluster obtained by roasting the white solid formed after 12 hours of reaction at 500°C. The thickness of the sheet is a...

Embodiment 3

[0034] Weigh zinc nitrate and urea respectively according to the molar ratio of zinc nitrate and urea being 1:3, add deionized water to prepare Zn 2+ 90 mL of a solution with a concentration of 0.5 M; pour these solutions into a glass cylindrical bottomed container with an inner diameter of 30 mm and a wall thickness of 1.5 mm; after sealing the open end with a plastic film, put it in a 90°C water bath and heat for 12 hours; collect by filtration The resulting white solid was dried in an oven at 120°C for 24 hours, and then calcined at 500°C for 6 hours. Figure 4 It is the scanning electron microscope observation result of the ZnO nanoporous sheet cluster obtained by roasting, the thickness of the sheet is about 50nm, and there are many through holes in it.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com