Non-Newtonian crude oil shear history simulation experiment device and method

A simulation experiment device, non-Newton technology, applied in the direction of material inspection products, etc., can solve the problem of large difference between pipes, and achieve the effect of reducing the volatilization area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

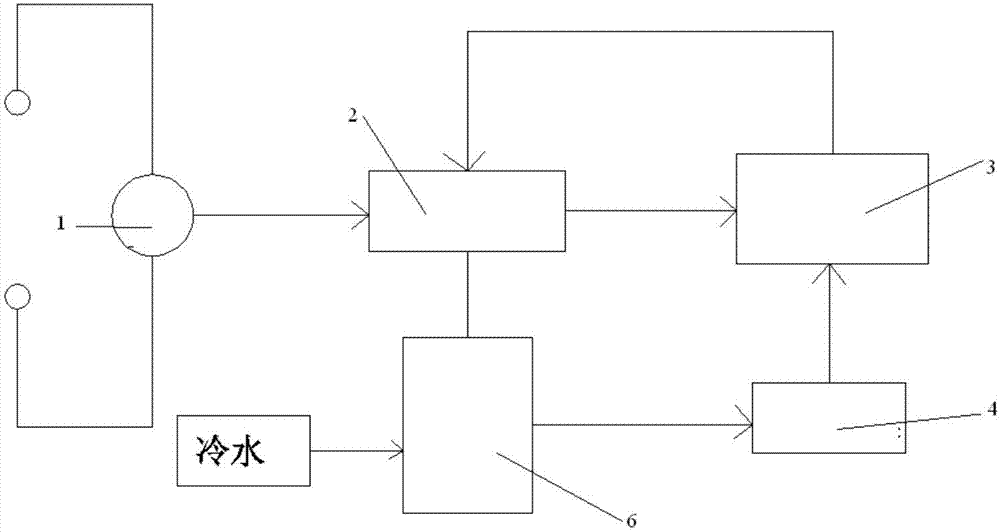

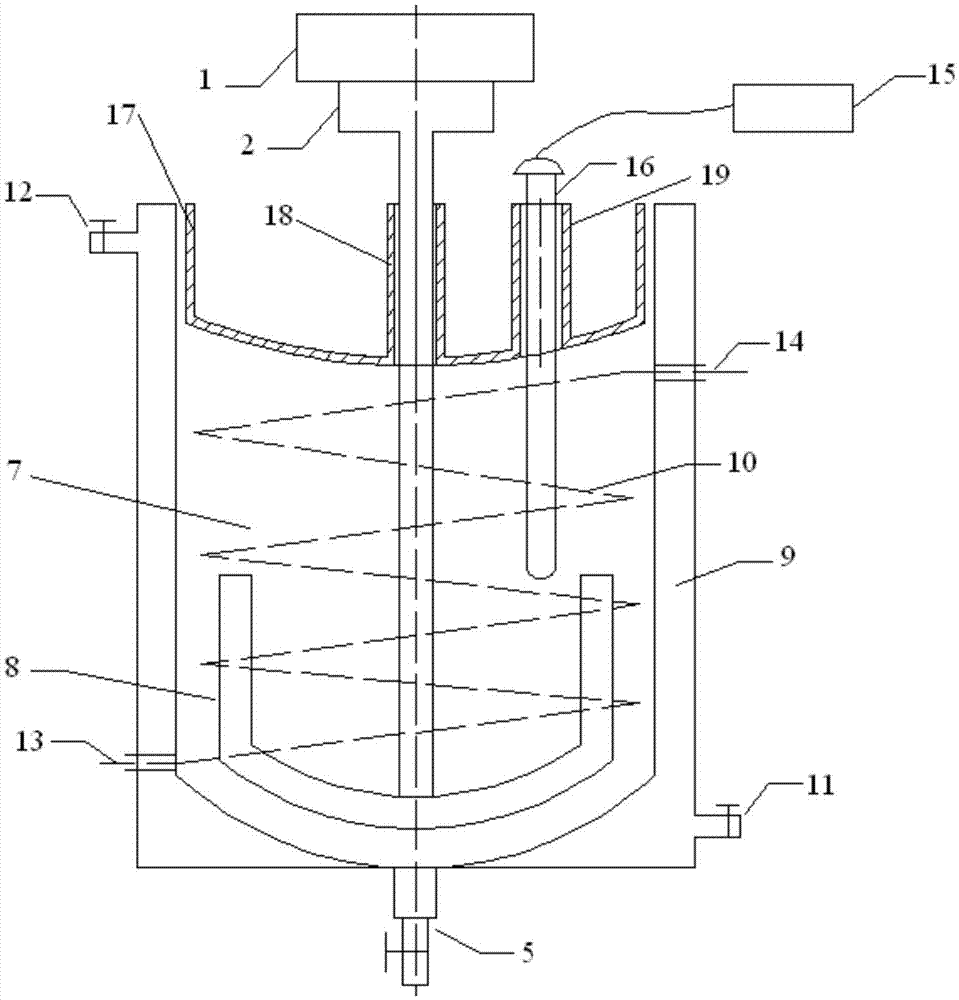

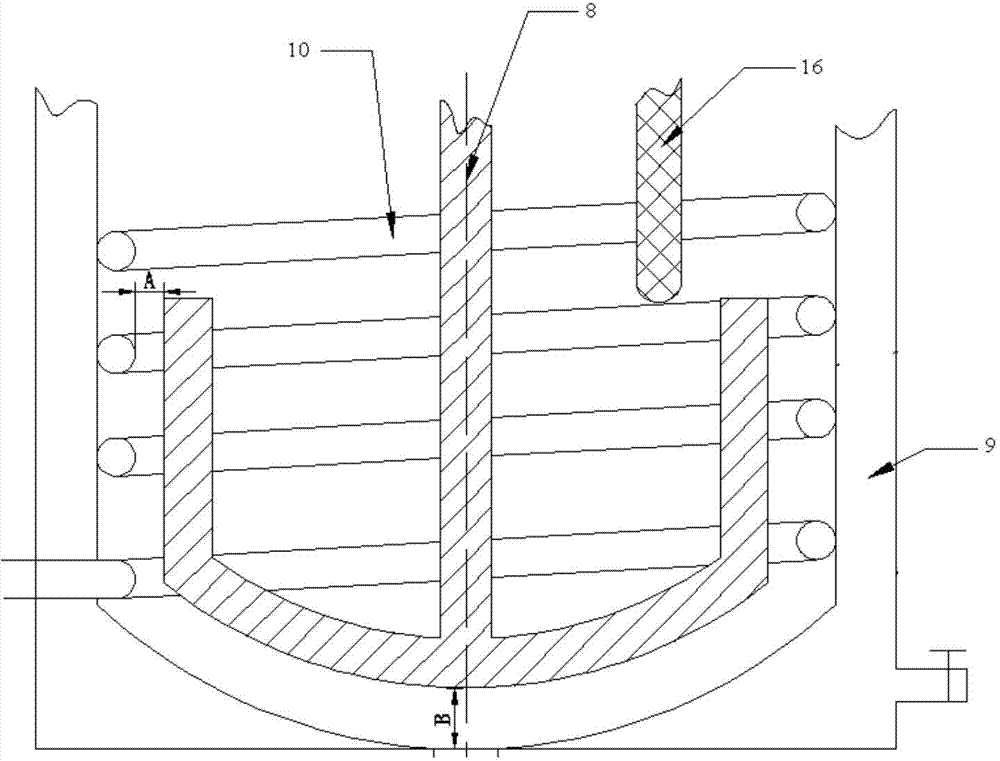

[0035] A non-Newtonian crude oil shear history simulation experiment device, such as Figure 1-4 As shown, it consists of a motor 1, a continuously variable transmission 2, a computer 3, a temperature measurement acquisition device 4 and a stirring device 6, and the stirring device 6 includes a stirring tank 7 with a water bath jacket 9 and an agitator 8 inserted therein, surrounding The hot water bath heating coil 10 around the inner wall of the stirring tank 7 and the arc-shaped double-hole floating roof 17 on the top of the stirring tank 7, the motor 1 is connected to the driving shaft of the continuously variable transmission 2, and the driven shaft of the continuously variable transmission 2 passes through the The hole of the floating roof 17 is connected to the agitator 8 , the computer 3 is respectively connected to the continuously variable tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com