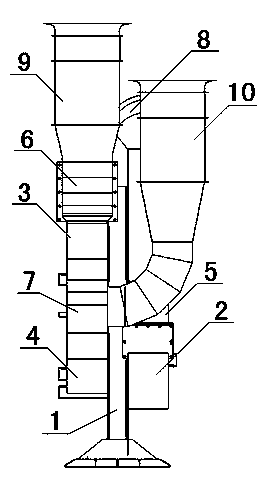

Patents

Literature

30results about How to "Precise control of cooling rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

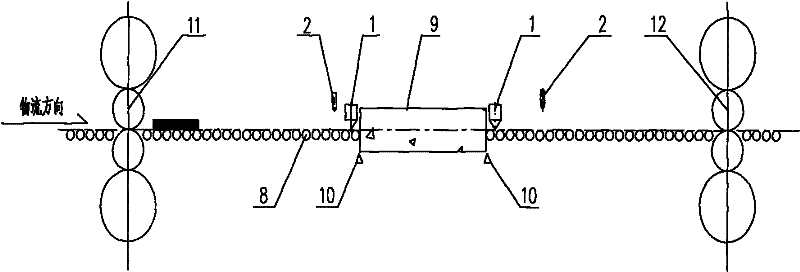

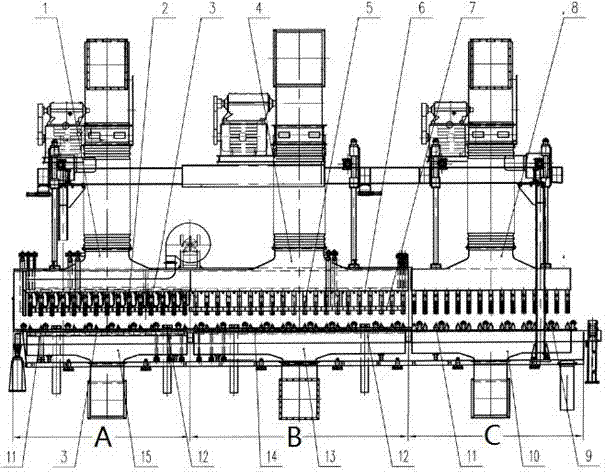

Intermediate blank cooling system and cooling control technology

ActiveCN101642780ADoes not change metal propertiesReduce difficultyTemperature control deviceWork treatment devicesProduction lineEngineering

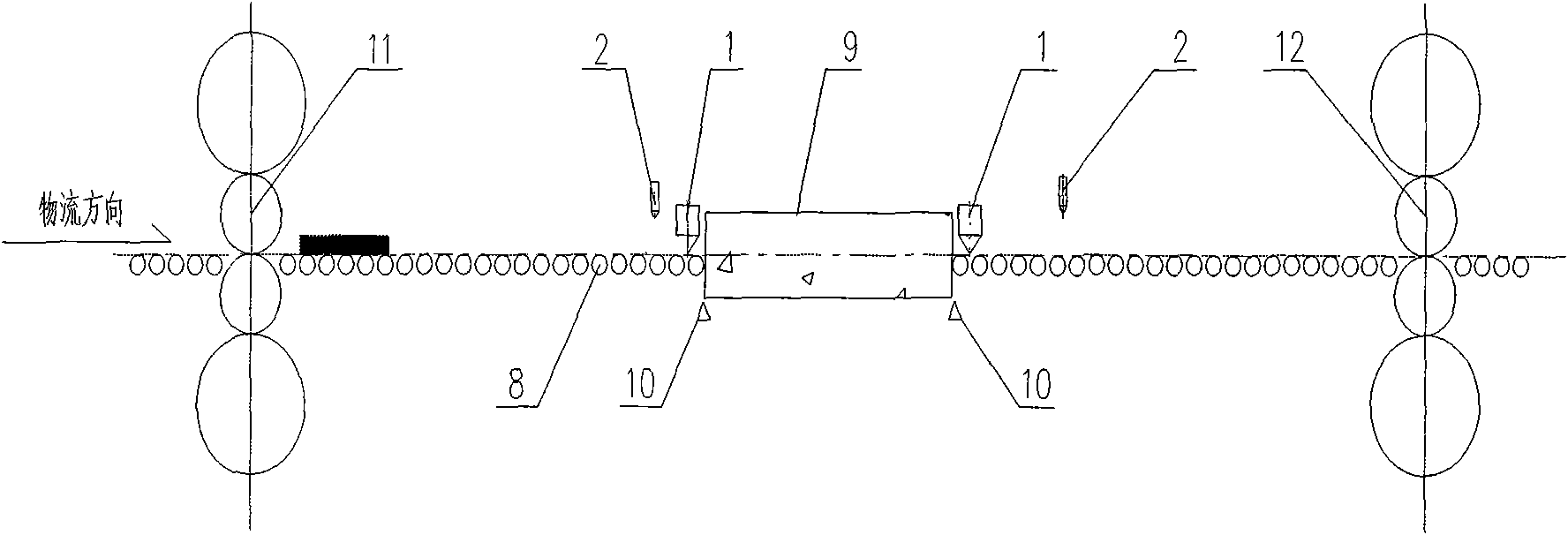

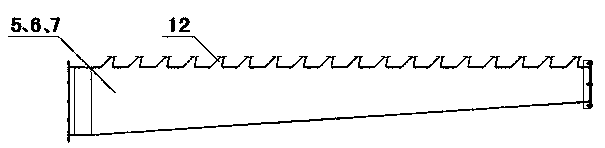

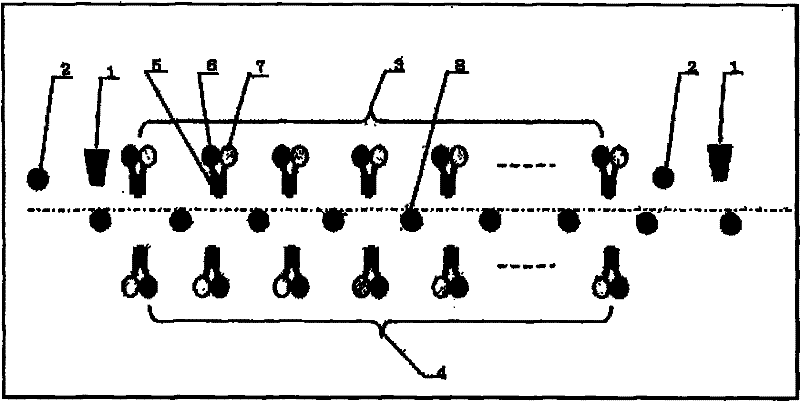

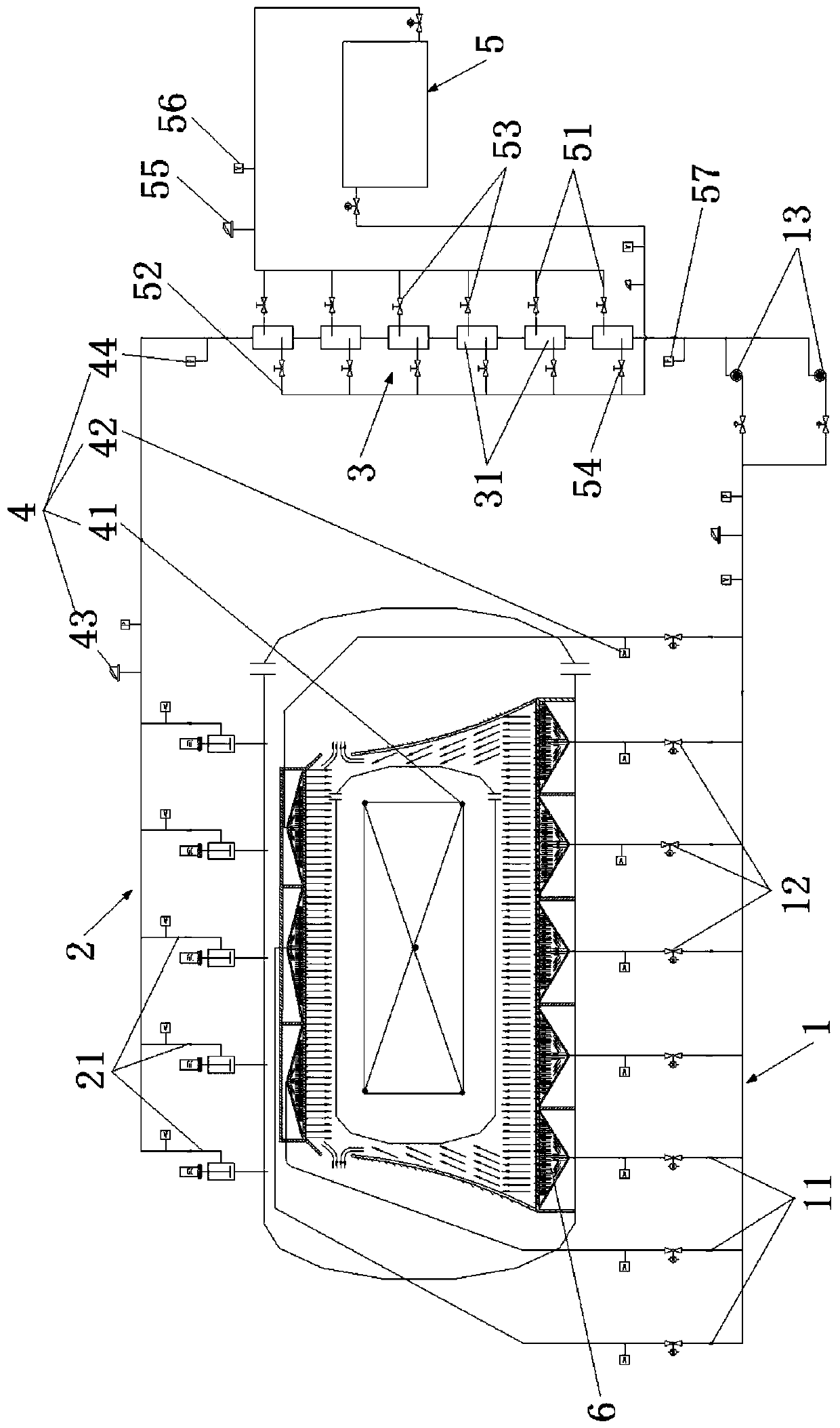

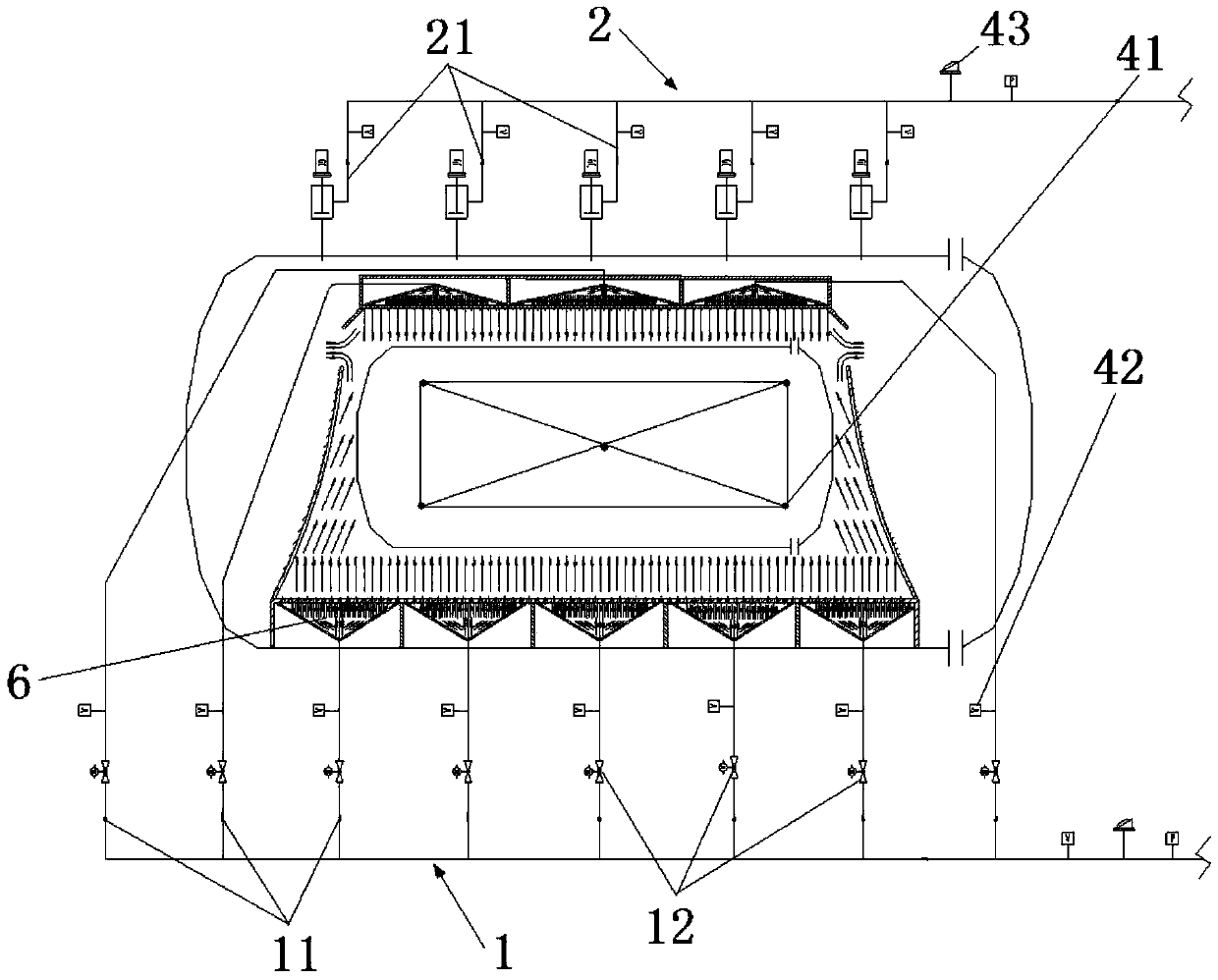

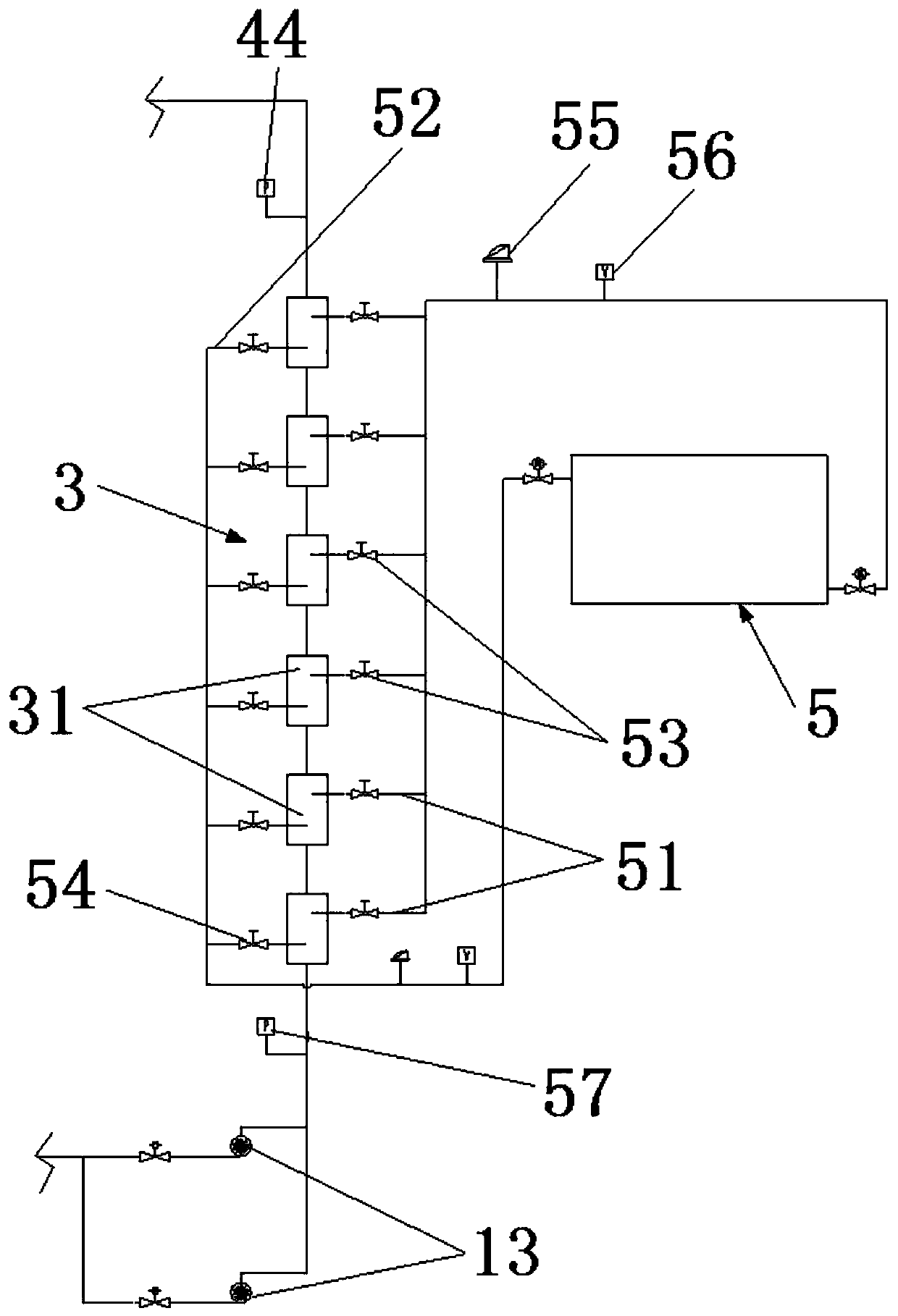

The invention belongs to the metallurgy technical field and in particular relates to an intermediate blank cooling system and cooling control technology. The intermediate blank cooling system is characterized in that an aerial fog cooling device body is arranged between a rough mill and a finishing mill. The aerial fog cooling device body is composed of an upper cooling header and a lower coolingheader, and an aerial fog nozzle and a compression air pipe are arranged on the cooling water pipe of the upper cooling header and the lower cooling header; and the on / off control valve and flow control valve of the cooling water pipe and the compression air pipe are connected with a control valve station. The intermediate blank aerial fog cooling technology is controlled by the aerial fog controltechnology sprayed on the cooling header arranged near roller ways at the front and rear of the mills. The invention has fast cooling speed without changing metal performance, water yield regulatingrange is wide and the water yield can be regulated continuously, the cooling speed of the intermediate blank can be precisely controlled, and the invention can be widely applicable to middle and thickplate production line.

Owner:CISDI ENG CO LTD

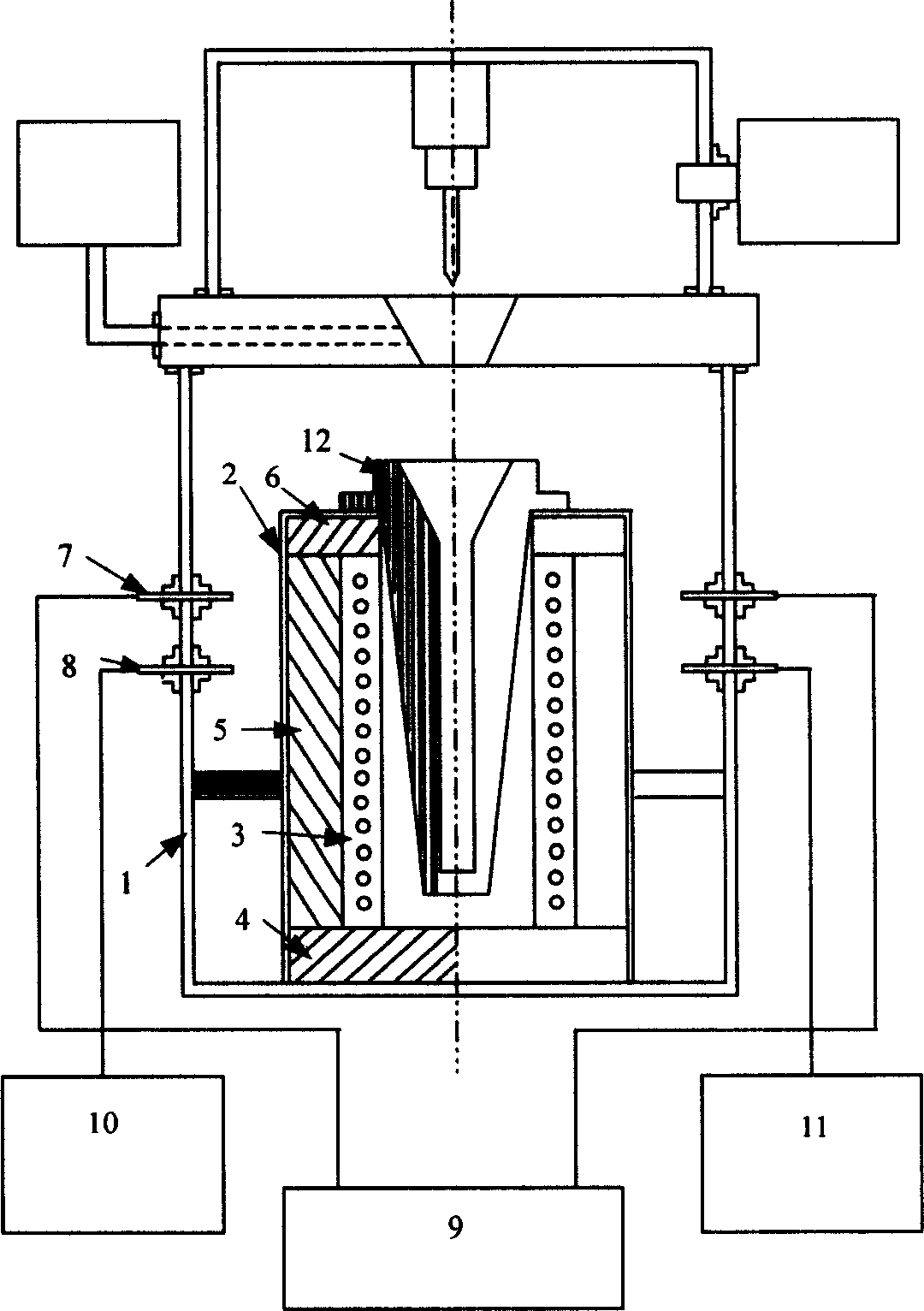

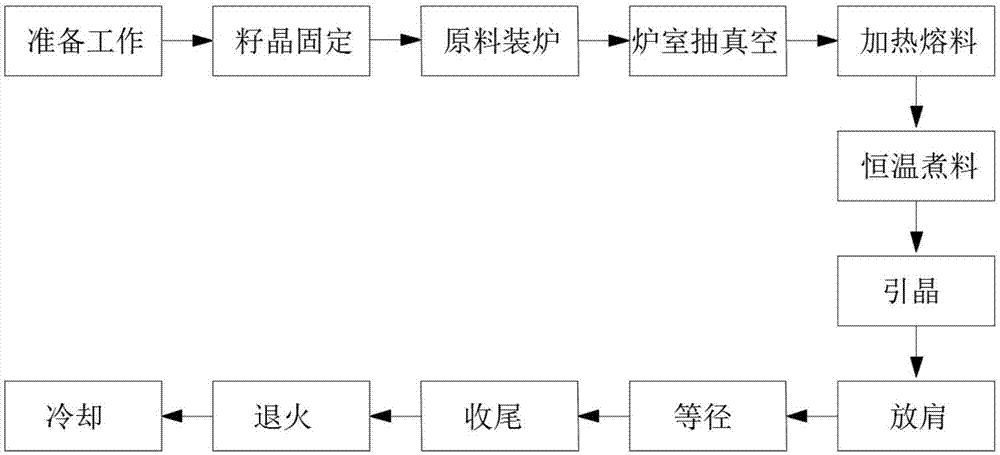

Improved kyropoulos method for sapphire crystal growth

InactiveCN102978694APrecise control of cooling rateReduce thermal stressPolycrystalline material growthUsing seed in meltHot zoneHeat stress

The invention relates to an improved kyropoulos method for sapphire crystal growth. The method comprises the following steps: raw material preparation, furnace body vacuumizing, furnace body heating, seed welding, monocrystal growth, crystal growth, separation and annealing, and crystal taking. In the whole crystal growth process, crystals are not taken out of a crucible and are still in a hot zone, so the cooling speed of the crystals can be accurately controlled to reduce the heat stress; a solid-liquid interface is bounded by a melt when the crystals grow, so the temperature disturbance and the mechanical disturbance of the melt surface can be reduced or eliminated by the melt before reaching the solid-liquid interface; if the crystals move or rotate in the crystal growth process, the crystal growth process is easily influenced by the mechanical vibration, so the improved kyropoulos method allows the pulling of a crystal seed rod in a rotary manner to be stopped after the monocrystal formation in order to effectively avoid the influence of the crystals by the mechanical vibration; and the utilization rate of the sane alumina raw material is high.

Owner:浙江东海蓝玉光电科技有限公司

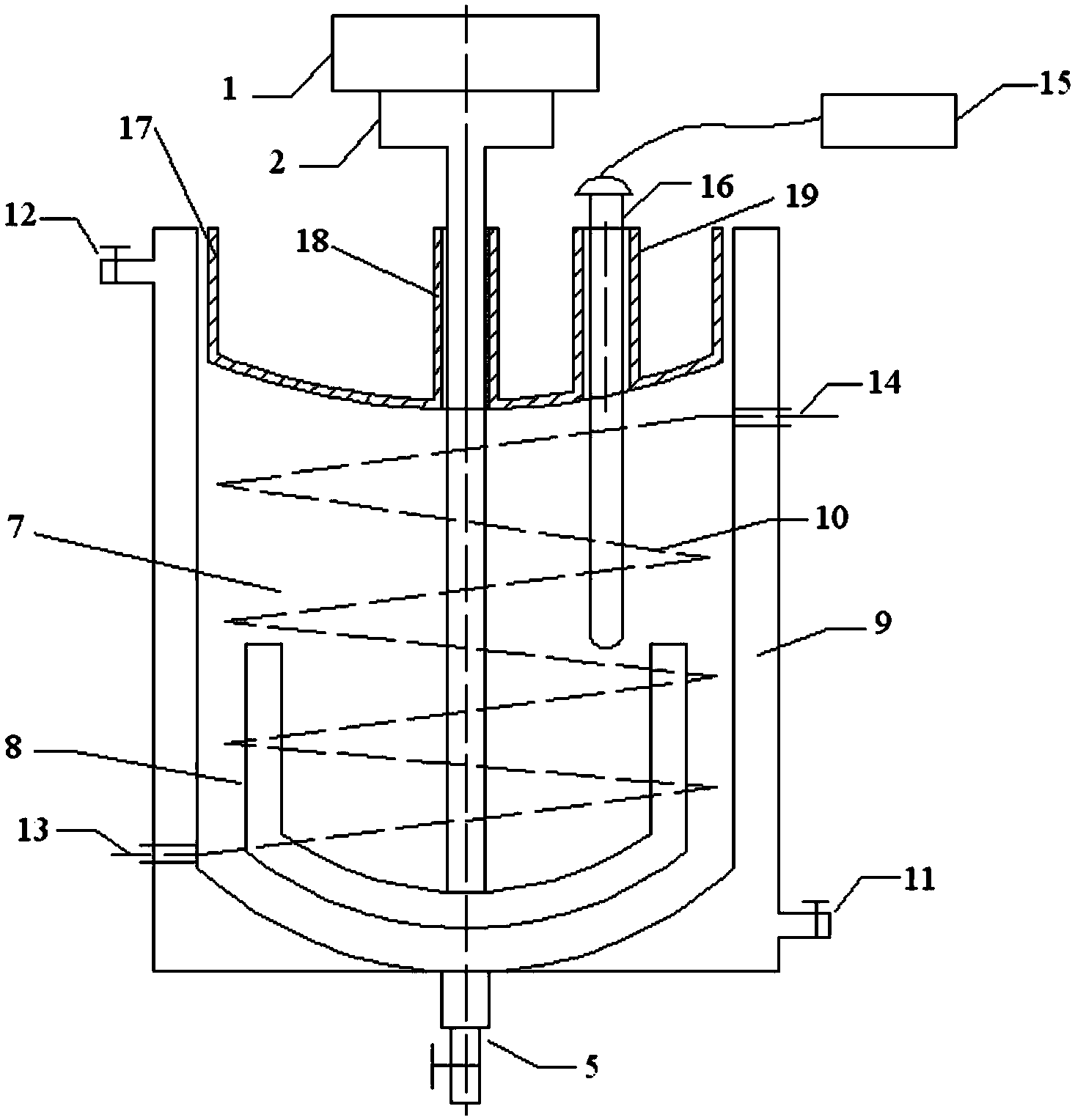

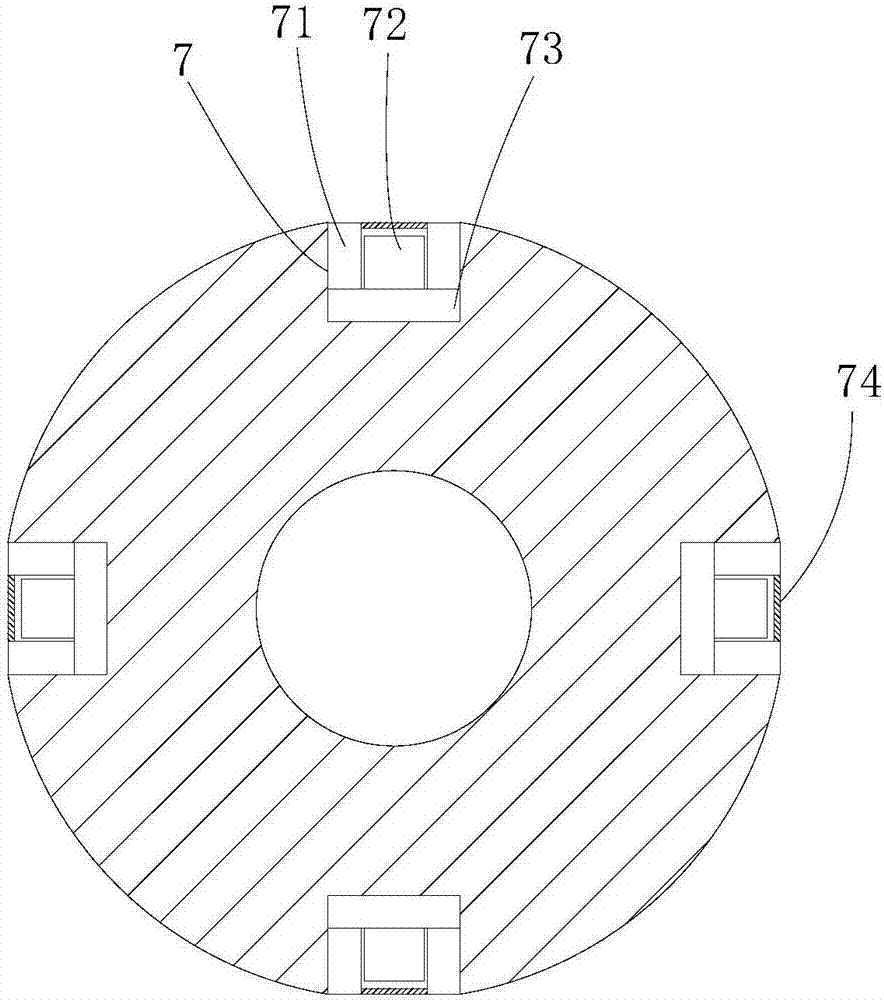

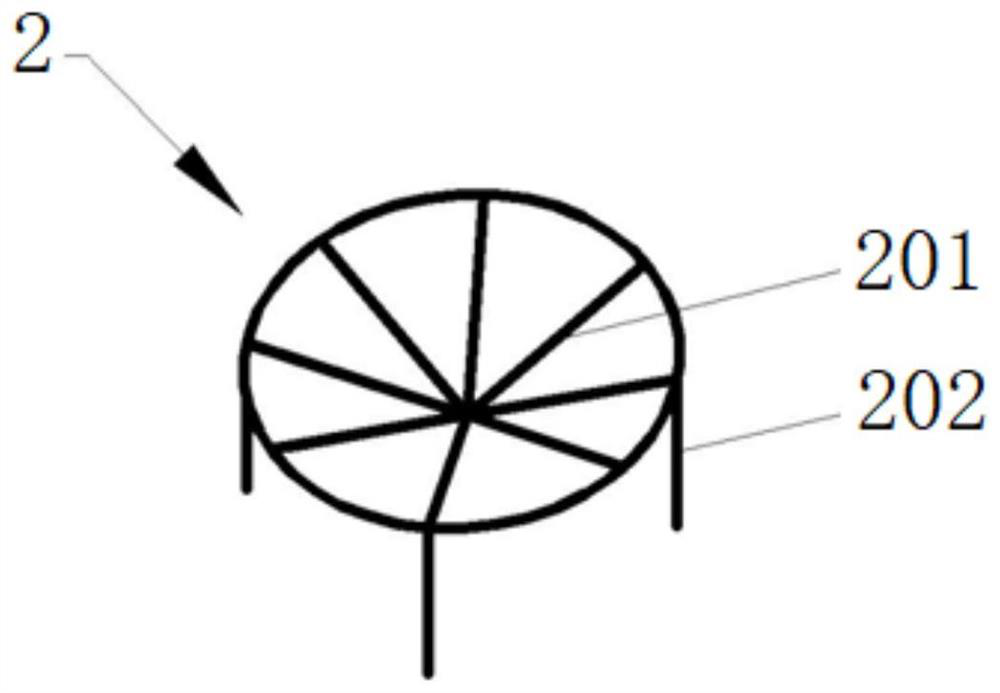

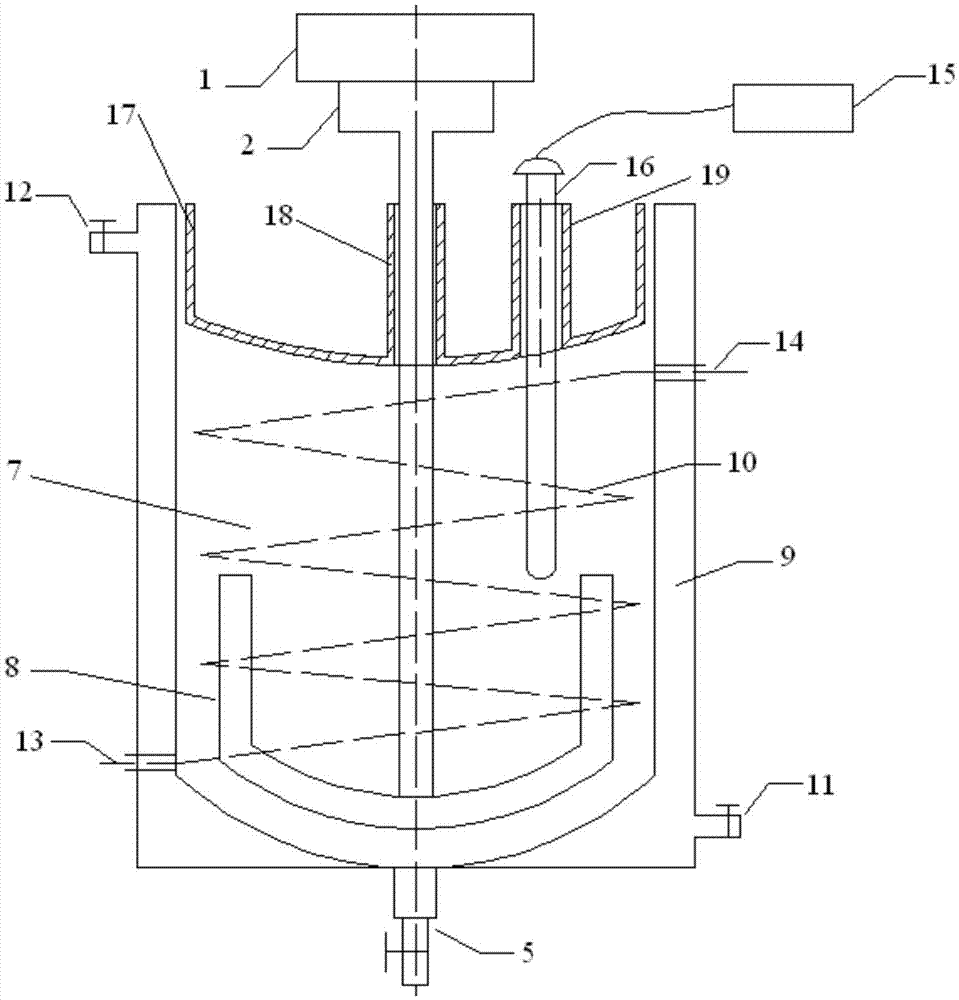

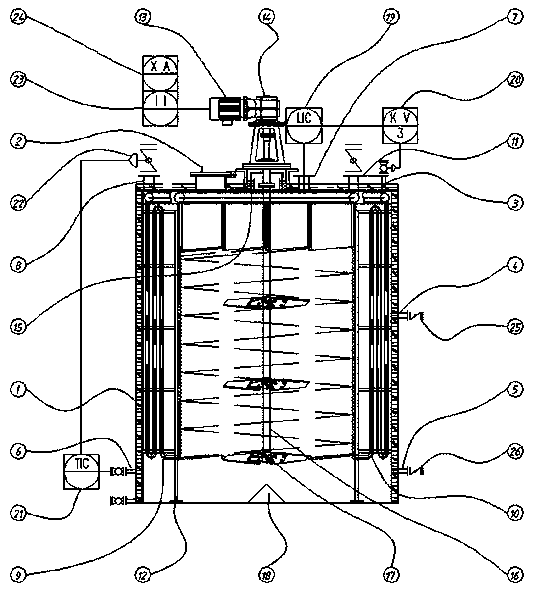

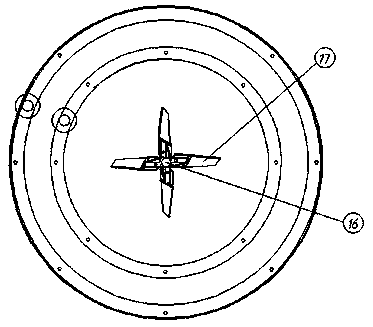

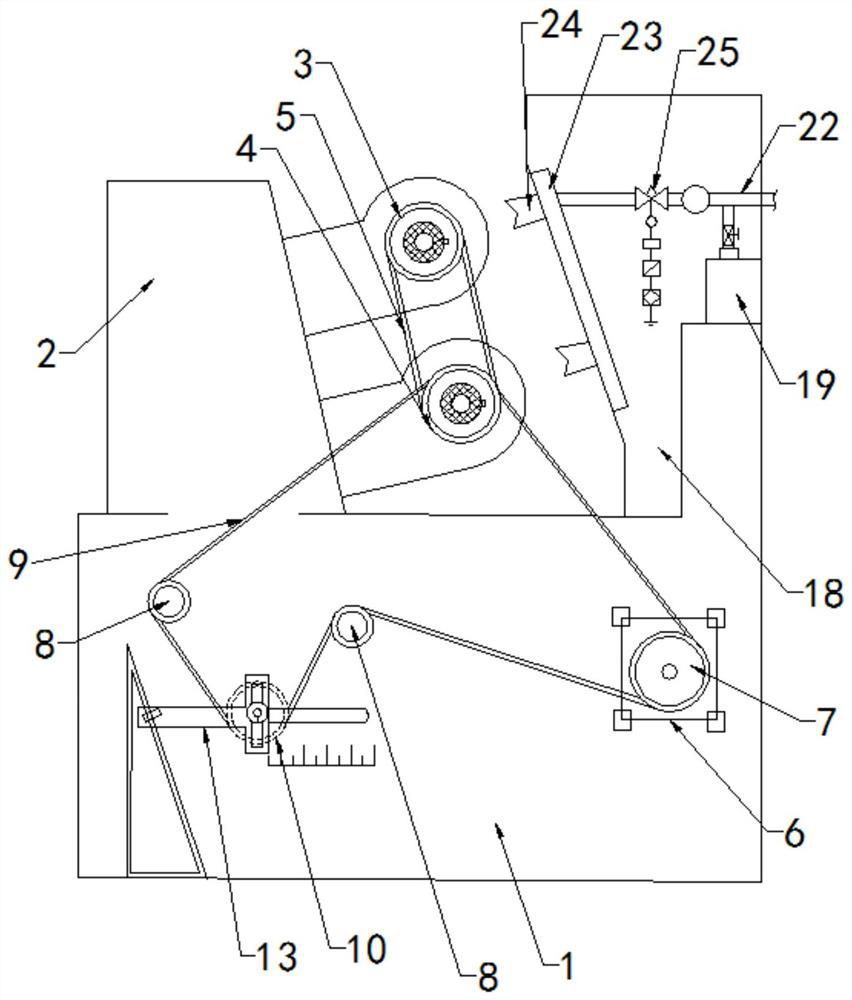

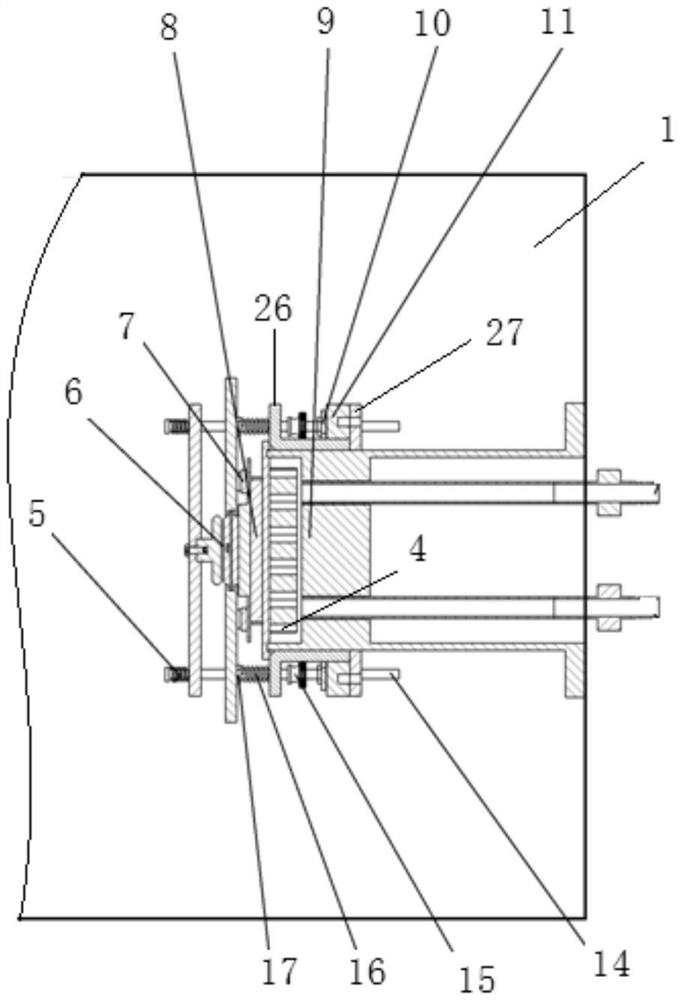

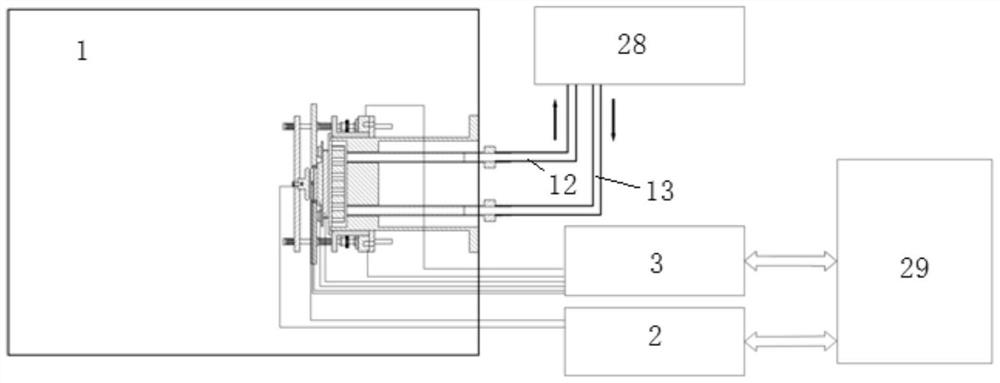

Shear history simulation experiment device and method for non-Newtonian crude oil

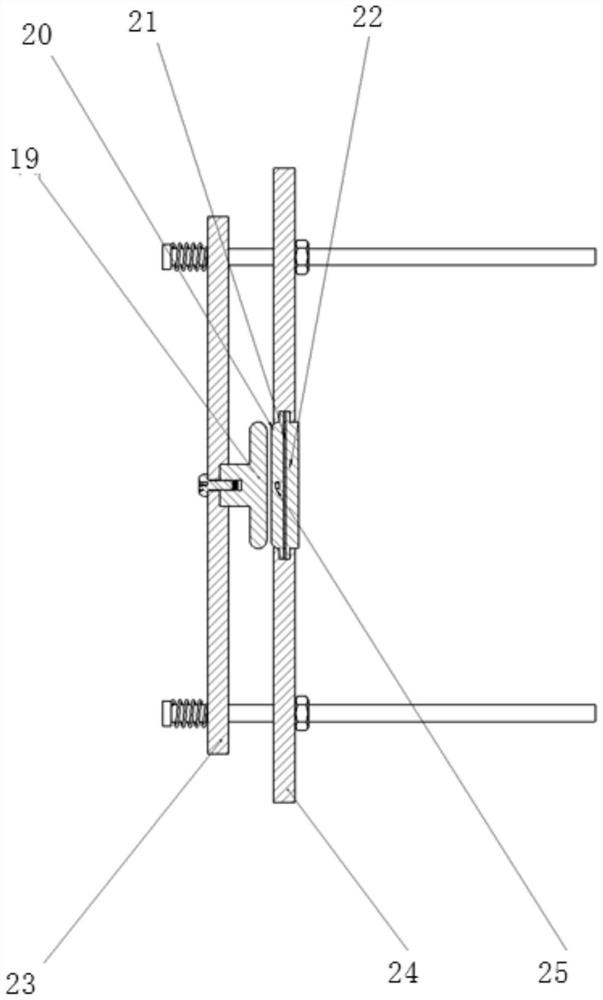

InactiveCN103728439AAvoid two-phase flowReduce the amount of adhesionMaterial testing goodsWater bathsDrive shaft

The invention discloses shear history simulation experiment device and method for non-Newtonian crude oil. The device comprises a motor, an infinitely variable transmission, a computer, a temperature measurement collection device and a stirring device, wherein the stirring device comprises a stirring tank, a stirrer, a hot bath heating coil and an arc double-hole floating cover; the stirring tank comprises a water bath jacket; the stirrer is inserted into the stirring tank; the hot bath heating coil encircles around the inner wall of the stirring tank; the arc double-hole floating cover is arranged at the top of the stirring tank; a hole I and a hole II are formed in the floating cover; the motor is connected with a driving shaft of the infinitely variable transmission; a driven shaft of the infinitely variable transmission is connected with the stirrer through the hole I; the computer is respectively connected with the infinitely variable transmission and a temperature collection device; the temperature collection device is connected with the stirring device. The shear history simulation experiment device and method have the beneficial effects that the shearing action of in-line flow shear and pump high-speed shear under a turbulence state on the rheological property of the non-Newtonian crude oil can be measured by using the device, and a whole transportation process of a crude oil pipeline is simulated.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

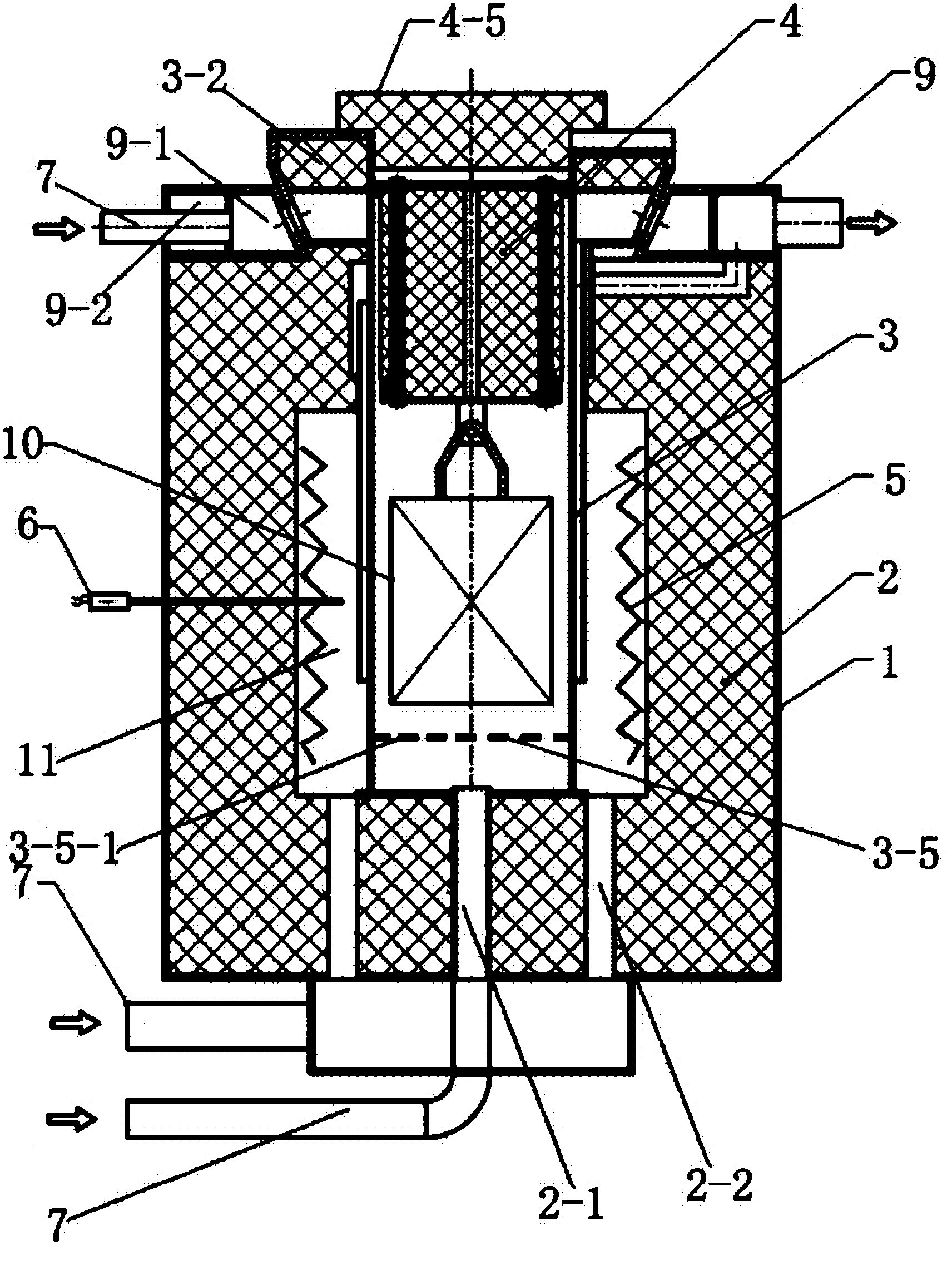

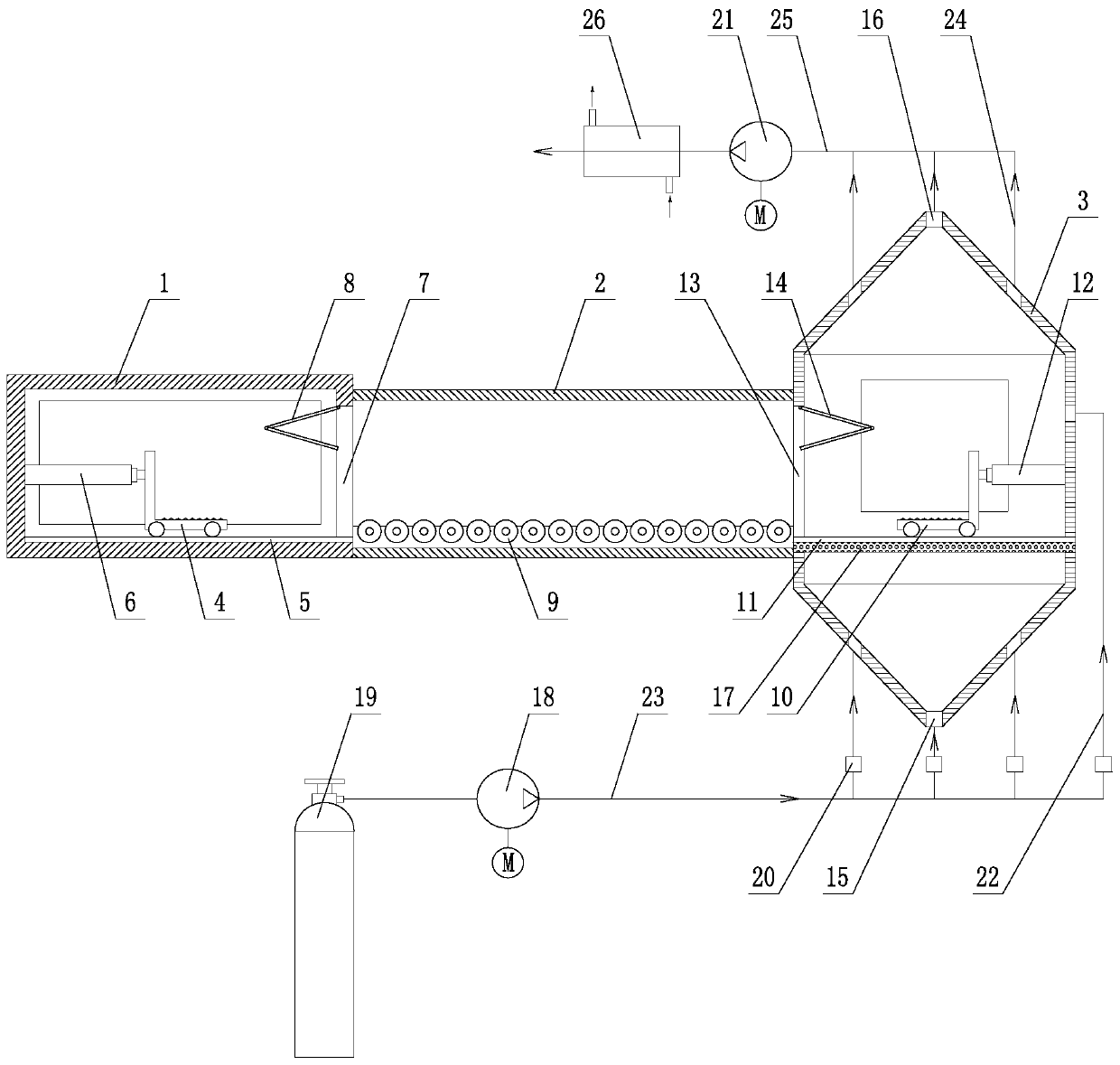

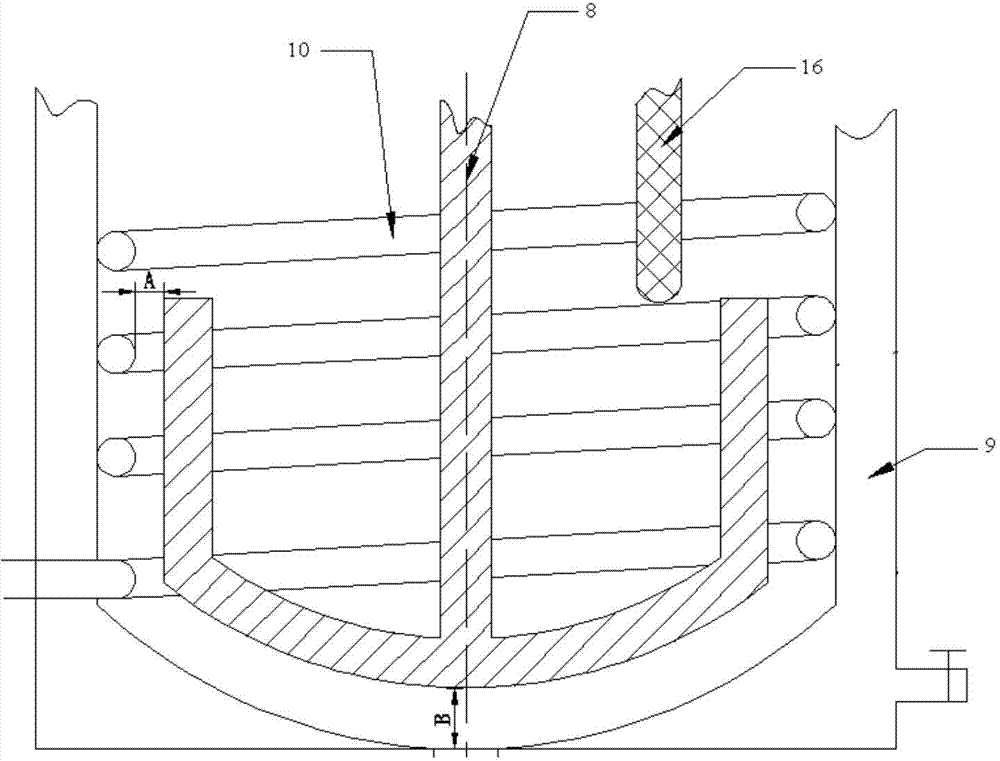

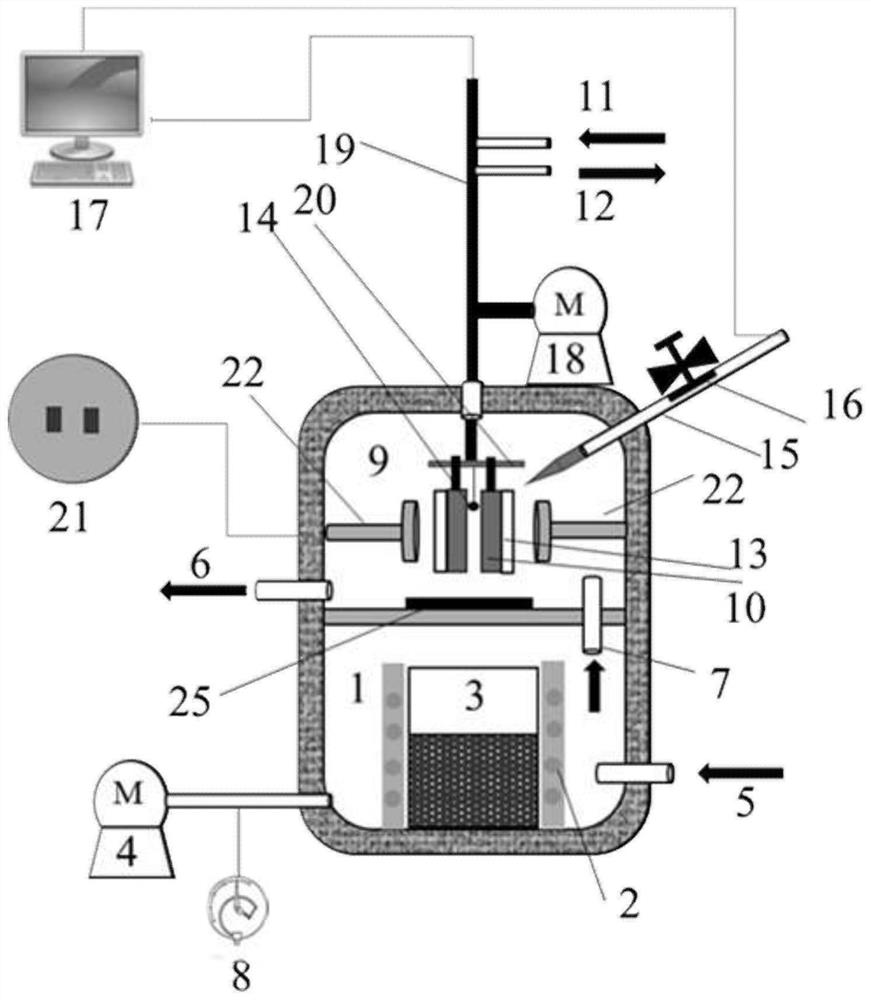

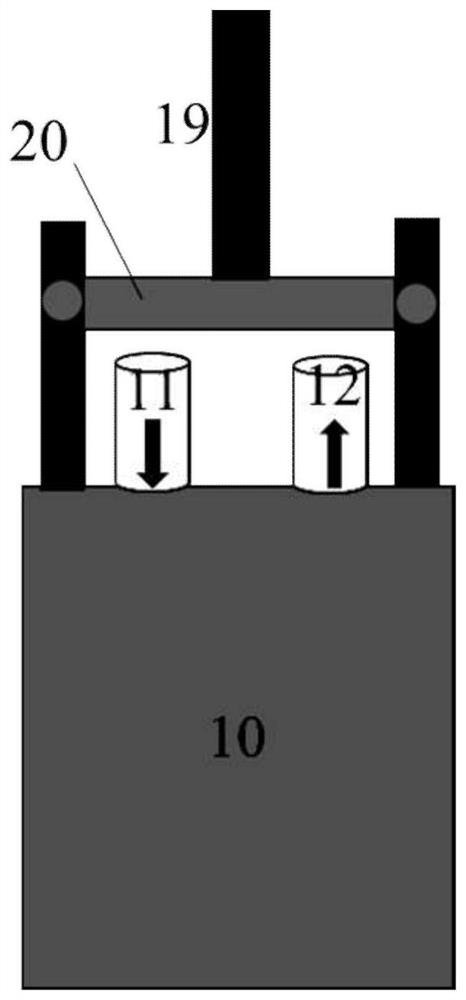

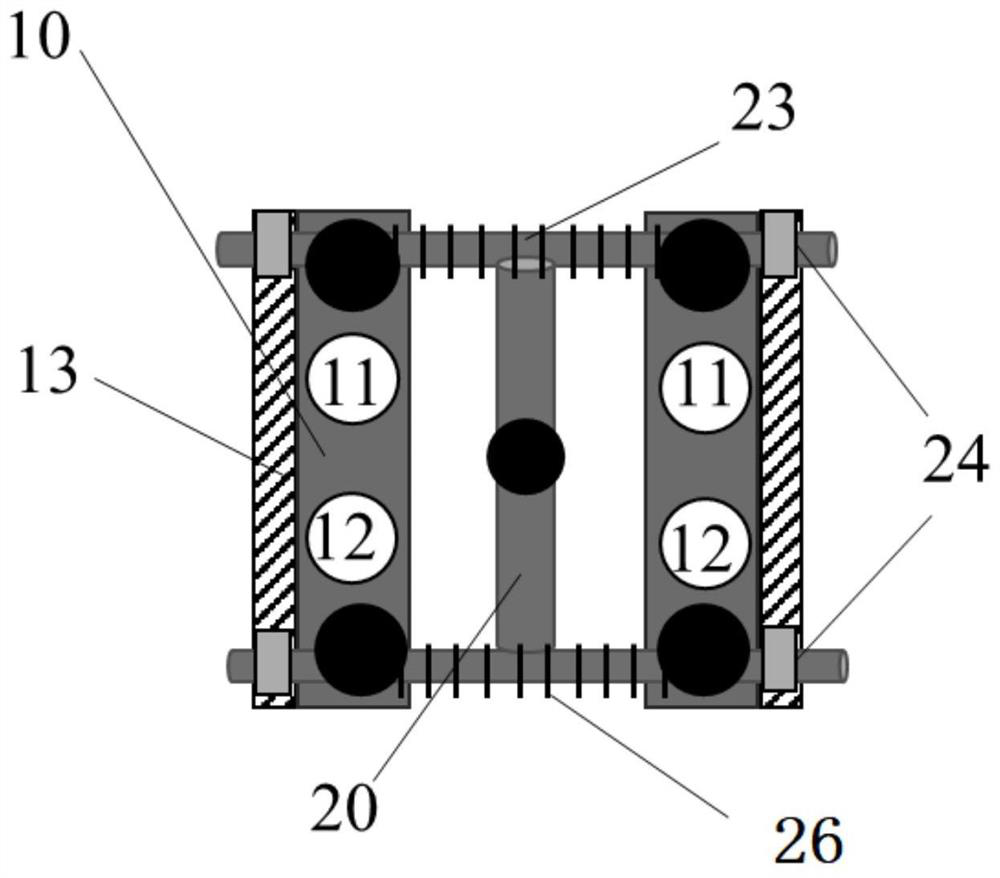

Thermal simulation furnace with heating/cooling controllable structure and capable of sampling halfway

InactiveCN102305539ARealize the cooling control functionRealize heating control functionFurnace typesEngineeringThermocouple

The invention relates to a thermal simulation furnace with heating / cooling controllable structure and capable of sampling halfway, comprising a furnace shell, a furnace lining arranged in the furnace shell, a soaking screen arranged at the inner cavity of the furnace lining, a radial sampling device arranged at the opening on the top of the soaking screen, a heating element, a thermocouple, a cooling pipe, and a control device, wherein a plurality of soaking screen cooling paths distributed uniformly are arranged on the outer wall of the soaking screen to form the soaking screen with a cooling structure. The furnace provided by the invention comprises a furnace plug with a crossing sampling structure and the soaking screen with hollow flanges and the cooling paths, and is characterized in that the furnace can be used with a computer for numerical simulation production, the heating efficiency can be accurately controlled, the cooling efficiency can be accurately controlled, the adjusting range of the cooling speed is large, the furnace can be used in each period for sampling for test, the amount of sample is large, the temperature field in the furnace is not influenced, the uniformity of temperature in the furnace is good, and the surface of the workpiece and the internal temperature can be monitored when the temperature is raising and lowering.

Owner:GUANGDONG STRONG METAL TECH

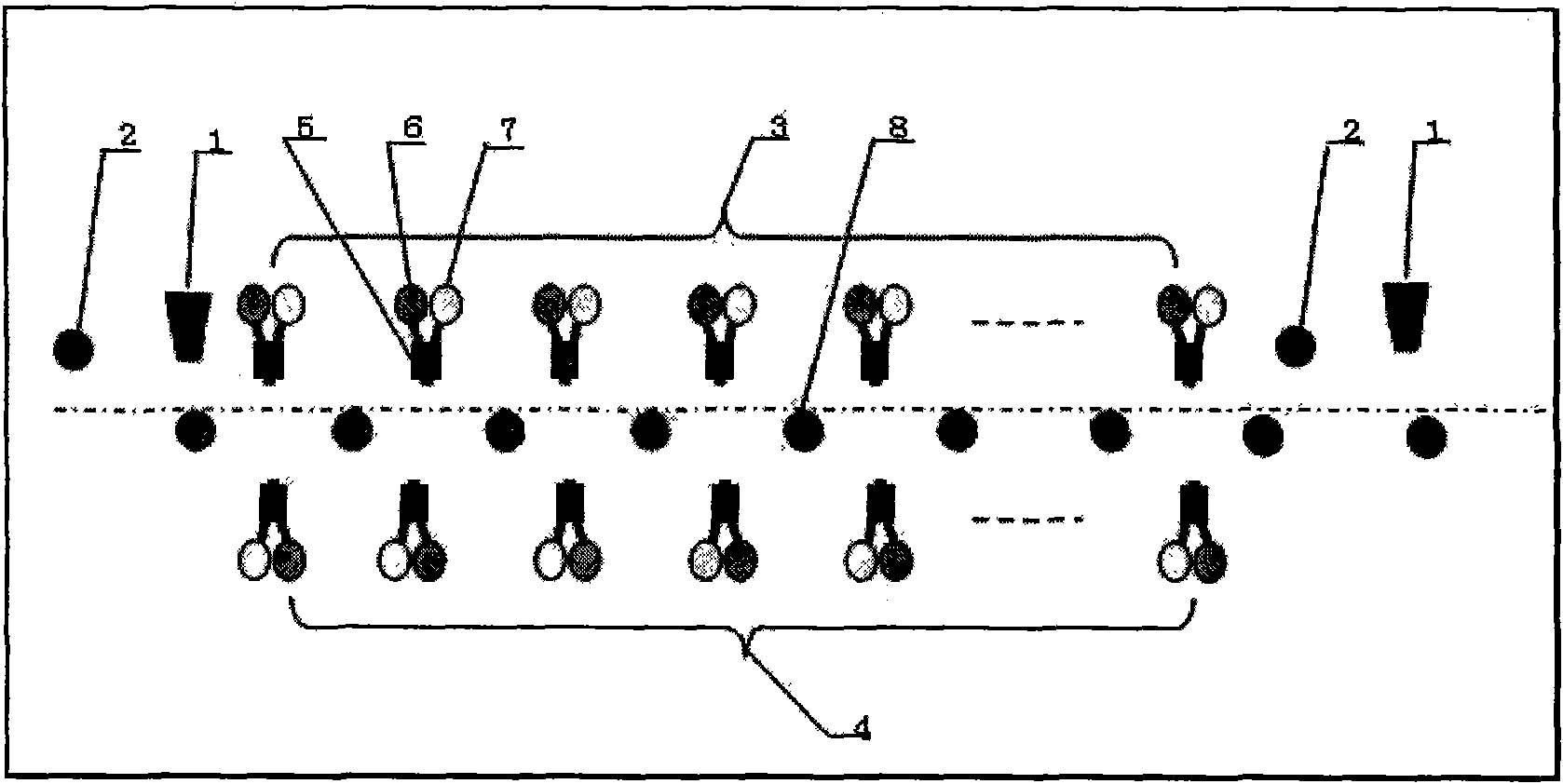

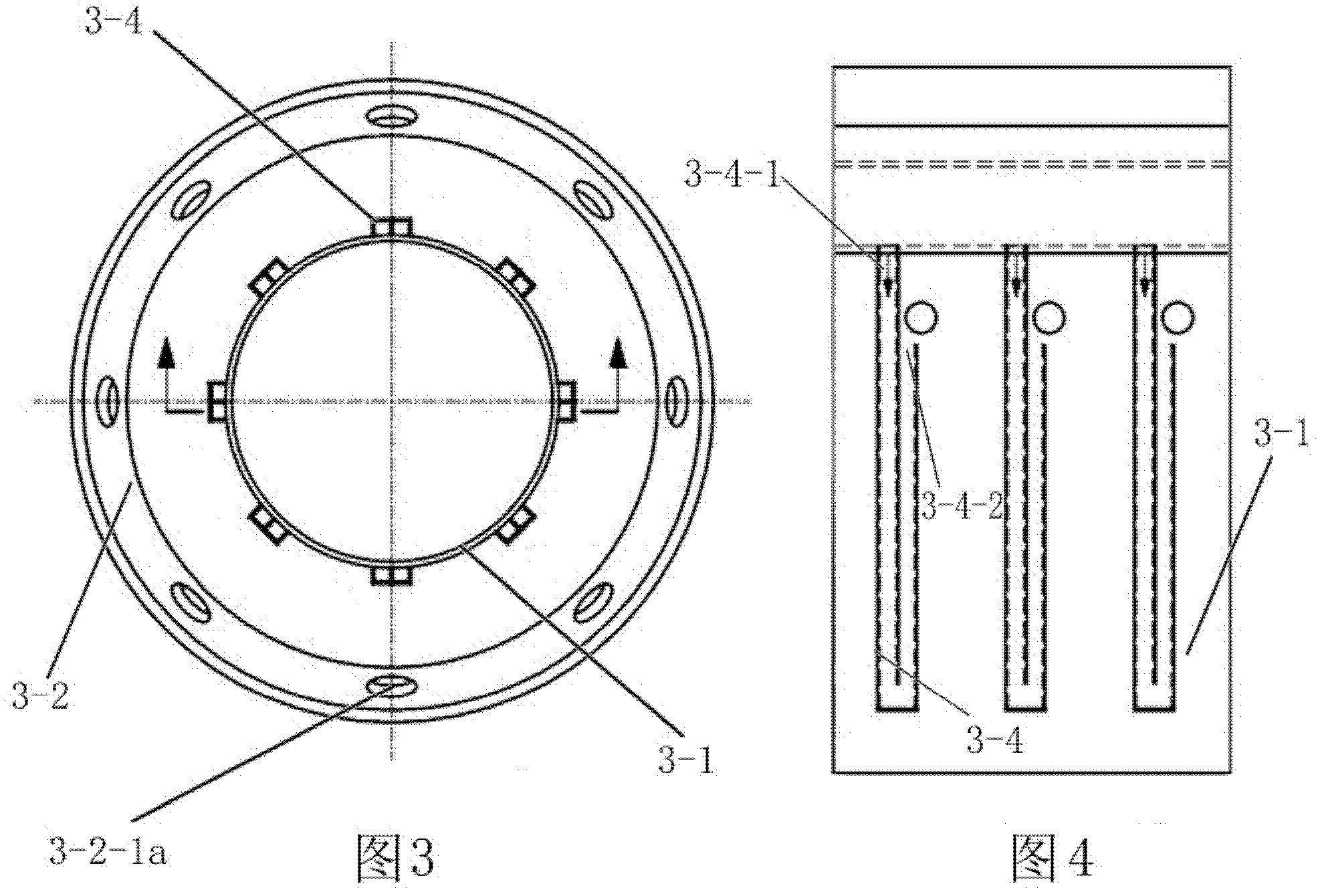

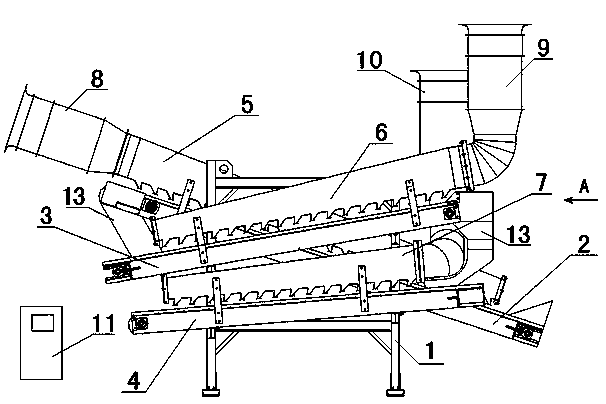

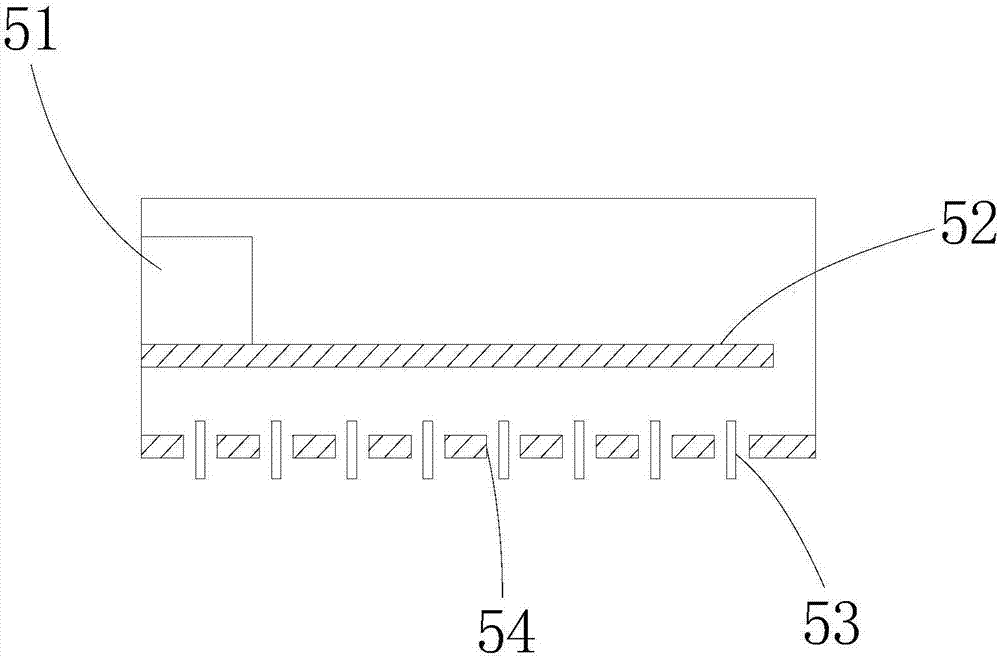

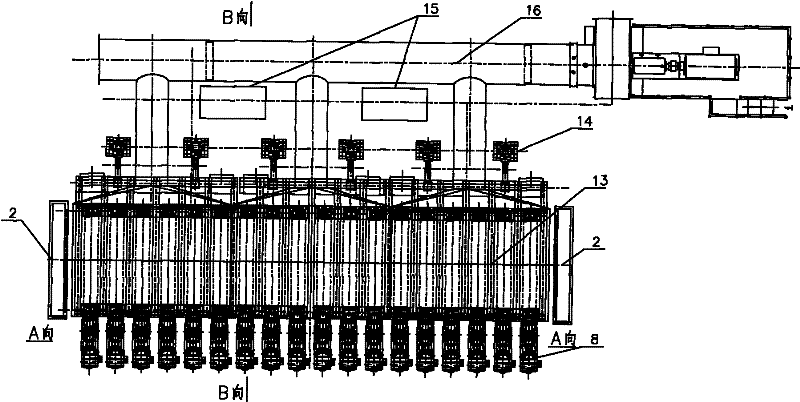

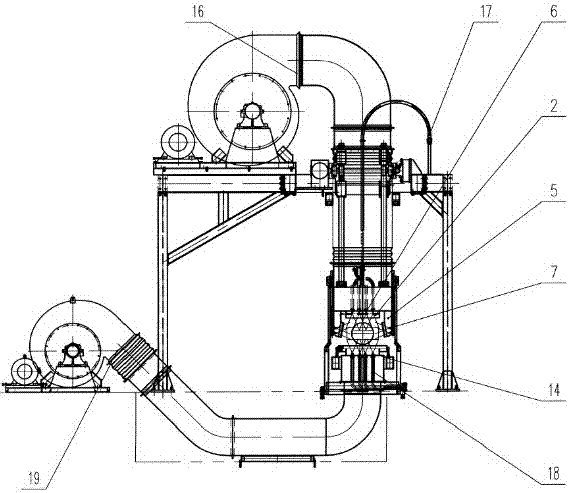

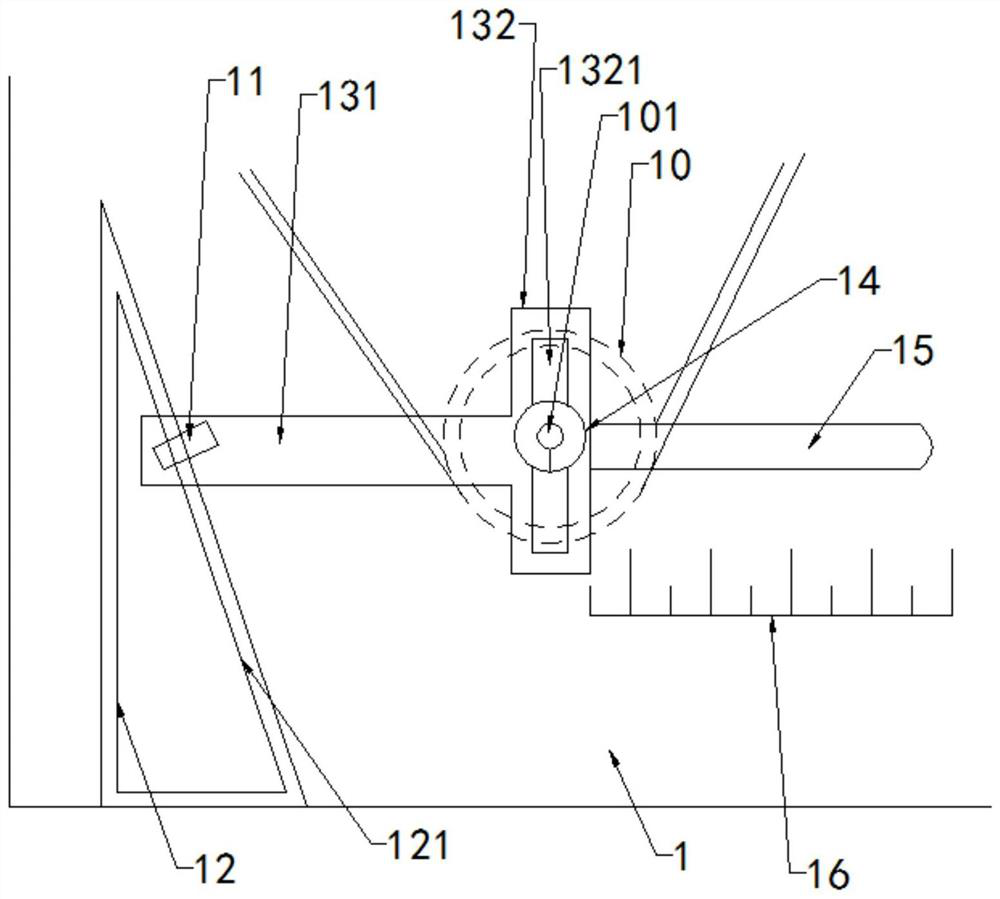

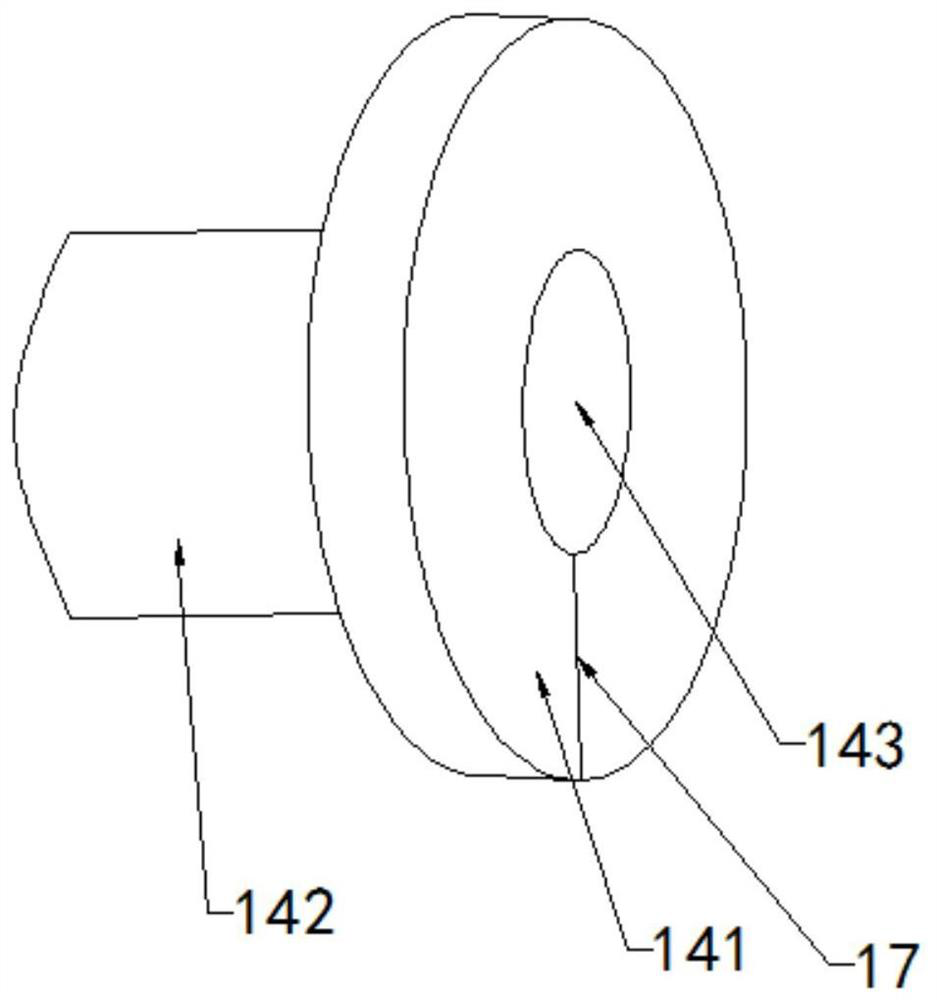

Workblank forging air cooling process for automobile engine connecting rod and air cooling equipment of workblank forging air cooling process

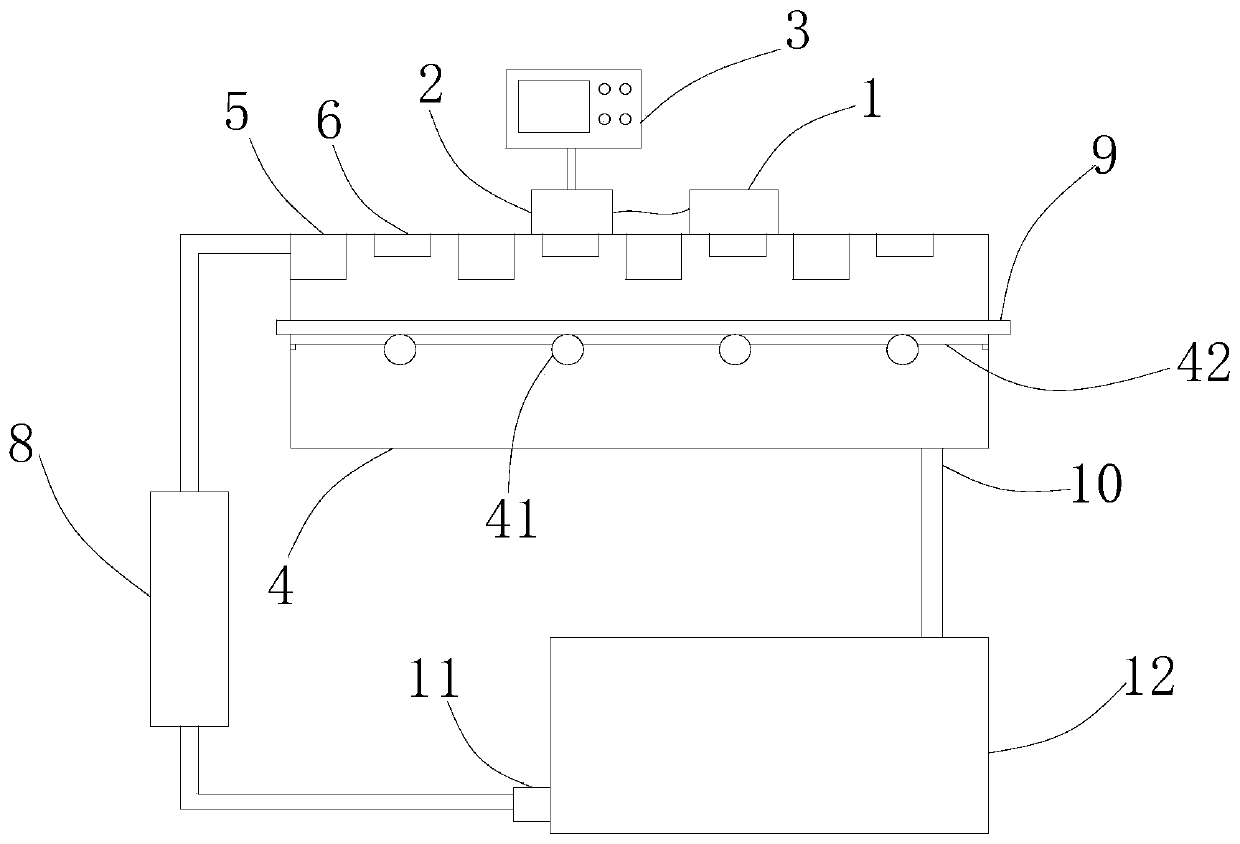

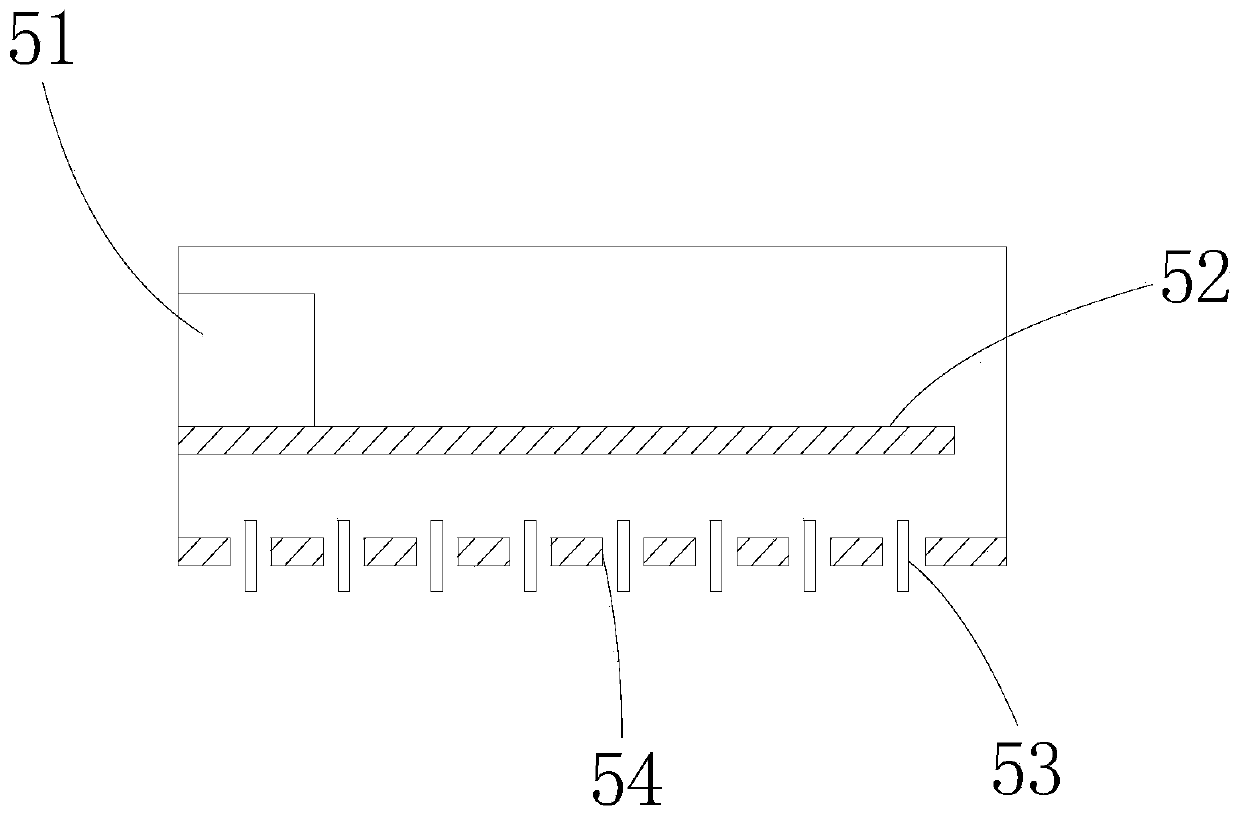

The invention relates to a workblank forging air cooling process, in particular to a workblank forging air cooling process for a non-quenched and tempered automobile engine connecting rod. The invention also relates to air cooling equipment adopted for implementing the air cooling process. The air cooling equipment comprises a system machine frame, a transmission chain, an air tube, a blast blower and a computer control device. The forge element cooling speed is precisely controlled through the air cooling equipment, the equipment can realize the computer automatic programming control, and the chain speed and the air outlet quantity of each air cooling passage can be regulated according to different air cooling requirements of the forge elements, so the hardness and the metallographic structure of the forge elements reach the standard requirements. The process and the equipment provided by the invention belong to the workblank forging air cooling process for the automobile engine connecting rod and the air cooling equipment with the advantages that the structure is simple and reasonable, the operation is convenient, the cooling speed of the forge elements can be effectively controlled, and meanwhile, the quality of the forge elements can be ensured.

Owner:BAICHENG ZHONGYI PRECISION FORGING

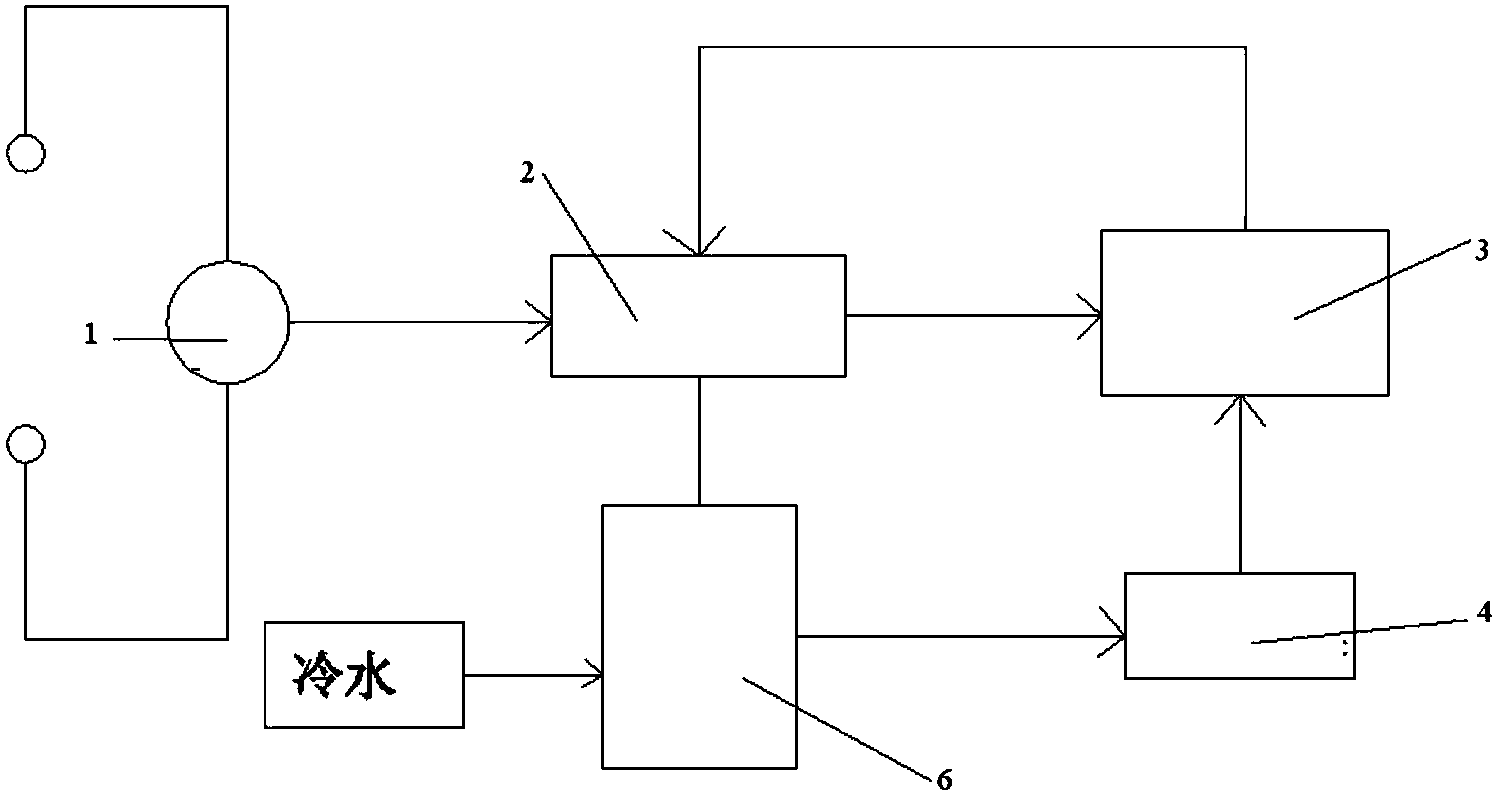

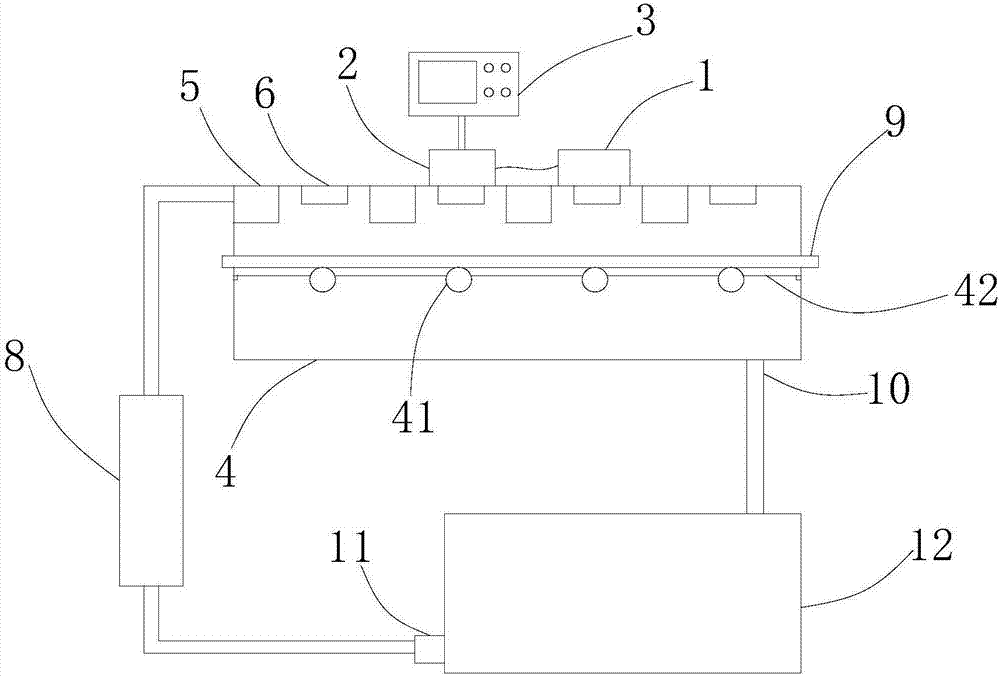

Measurement and control type cooling equipment for screw extruder

Measurement and control type cooling equipment for a screw extruder comprises three cooling modes, namely, the water cooling mode, the air cooling mode and the water cooling and air cooling mixed mode. The cooling equipment is composed of a detection device, a cooling device, a controller, a controllable display device and a trough structure. The cooling device comprises a water spraying device, an air supply device and a refrigeration device. The controller is electrically connected with the controllable display device. A water tank is arranged on the lower portion of the trough structure. According to the measurement and control type cooling equipment, the limitation that existing cooling equipment is singular in cooling mode is fundamentally overcome, thus, the cooling mode can be selected according to properties of polymers, the cooling equipment can accurately measure the temperature and adjust the cooling speed in real time in the cooling process, the effect that the cooling speed of the different polymers can be adjusted in time according to the properties and the extrusion conditions of the polymers, and accordingly, the stably and reliable quality is achieved; and through the mode that the temperature is precisely measured, and differentiated cooling is conduced according to different areas, energy source consumption and resource consumption are effectively reduced.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Temperature cooling regulator for self-consumable electrode arc furnace

A cooling temp controller for the electric arc furnace with non-consumable electrode to control the cooling speed of alloy and eliminate the defects is composed of air-tight stainless steel jacket, stainless steel casing with circular top opening, electric resistance wire furnace, and the refractory insulating material between said electric resistance wire furnace and stainless steel casing. The heater, temp controller and temp measurer are linked with said electric resistance wire furnace via the terminals on said stainless steel jacket.

Owner:SHANGHAI JIAO TONG UNIV

Method for preparing synthetic sapphire by micro-pulling and shoulder-expanding at cooled center

PendingCN106987902AGood genetic characteristics of crystal orientationGuaranteed growth qualityPolycrystalline material growthAfter-treatment detailsSingle crystalOxygen

The invention relates to the technical field of sapphire processing, in particular to a method for preparing artificial sapphire with cold heart shouldering and lifting. Good genetic characteristics can ensure the quality of sapphire single crystal growth; through the cleaning process in the furnace, it can reduce the pollution during the crystal growth process, ensure the purity of the crystal, and reduce crystal defects; on the other hand, it is convenient to accurately control the cooling rate and reduce heat. At the same time, through the micro-lifting method of the lifting rod, it can reduce the disturbance of the temperature field and the probability of defects, thereby improving the quality of the crystal; on the other hand, during the cooling process, the crystal can be annealed in situ to reduce the occurrence of oxygen vacancies. defects, while simplifying procedures and saving energy, thereby further reducing the growth cost of sapphire crystals; the invention can also prevent crystal cracks and ensure crystal quality through reasonable control of the temperature in the furnace.

Owner:NINGXIA PROCRYSTAL TECH CO LTD

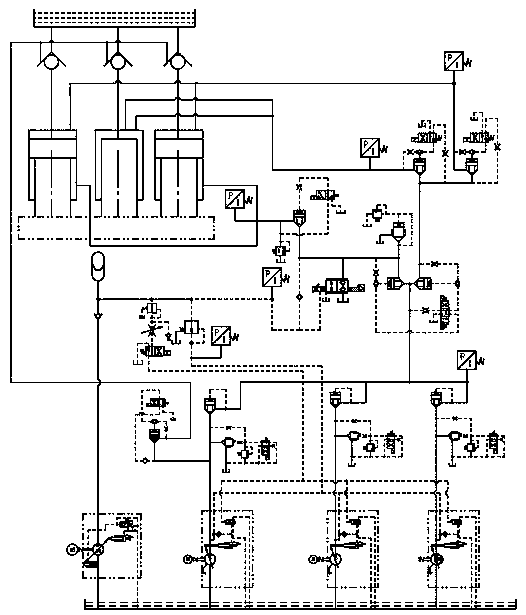

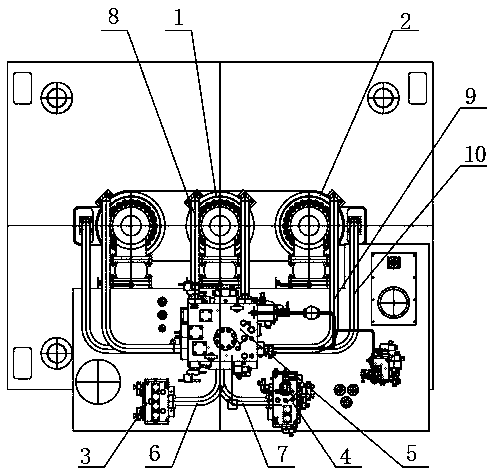

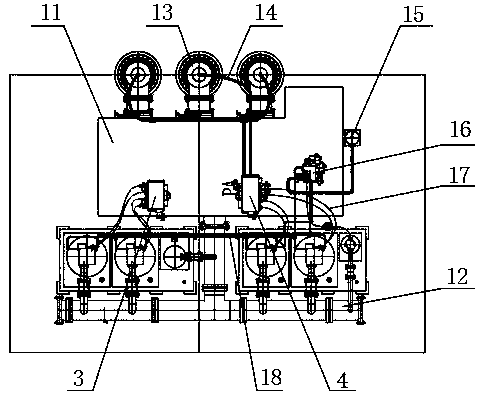

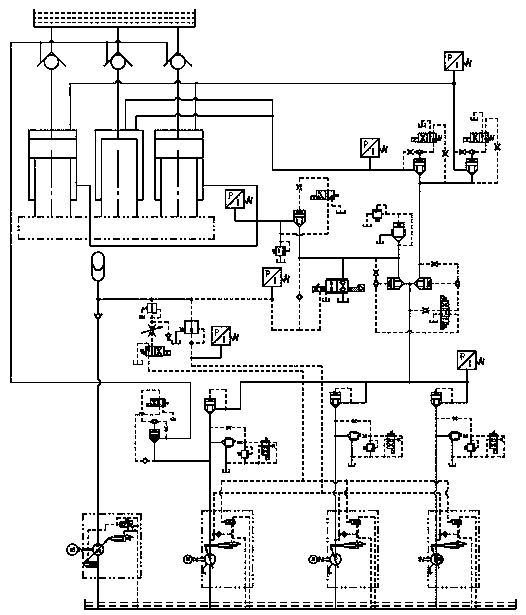

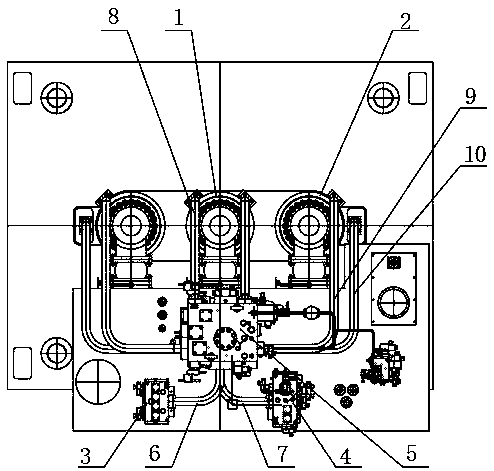

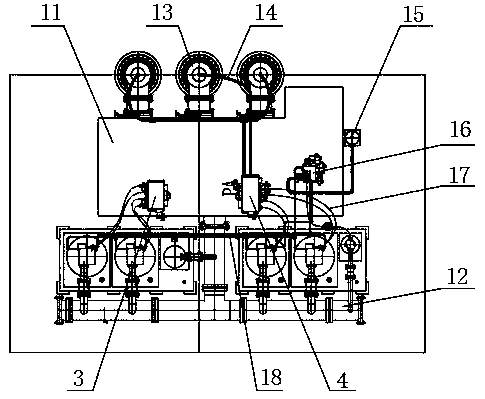

Hot stamping forming hydraulic machine system

ActiveCN109622776ASolve the problem of suppressionSolving Heat Balance ProblemsShaping toolsServomotor componentsProduction lineHot stamping

The invention discloses a hot stamping forming hydraulic machine system and belongs to the field of hot stamping forming hydraulic machine systems. By means of the hot stamping forming hydraulic machine system, stable operation of the system can still be ensured when the press speed is increased to 1000 mm / s, workpieces can be rapidly and evenly cooled, and the die temperature yield is made to tend to be constant always. In order to solve the problem of pressing of a press on the conditions of the high speed and the high takt, the production takt is effectively improved, and therefore the yield is improved. By using the hot stamping production time, the takt is improved to 6-7 times / minute, the output is increased by 30% or more on average, the problem of insufficient cooling or uneven cooling during forming of workpieces is effectively solved, the workpieces have high strength and good appearance after molding, the die heat balance problem is effectively solved, as long as the power is continuously supplied, the production line can achieve production always, the press energy consumption is effectively reduced, the purposes of energy conservation and environment protection are achieved, pipe appearance is attractive, and maintenance is easy.

Owner:HEFEI METALFORMING MACHINE TOOL

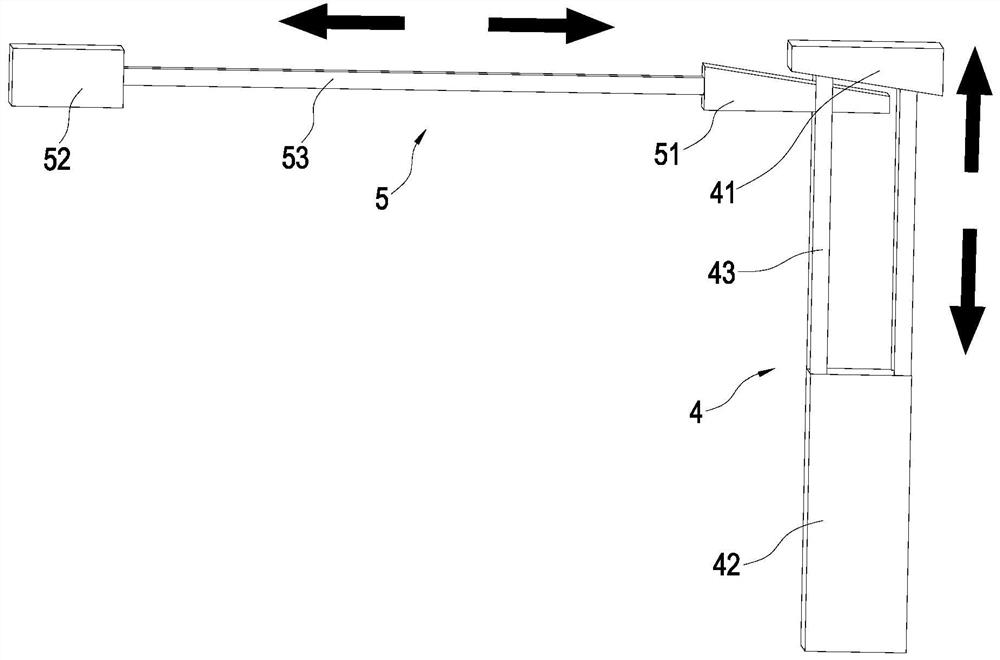

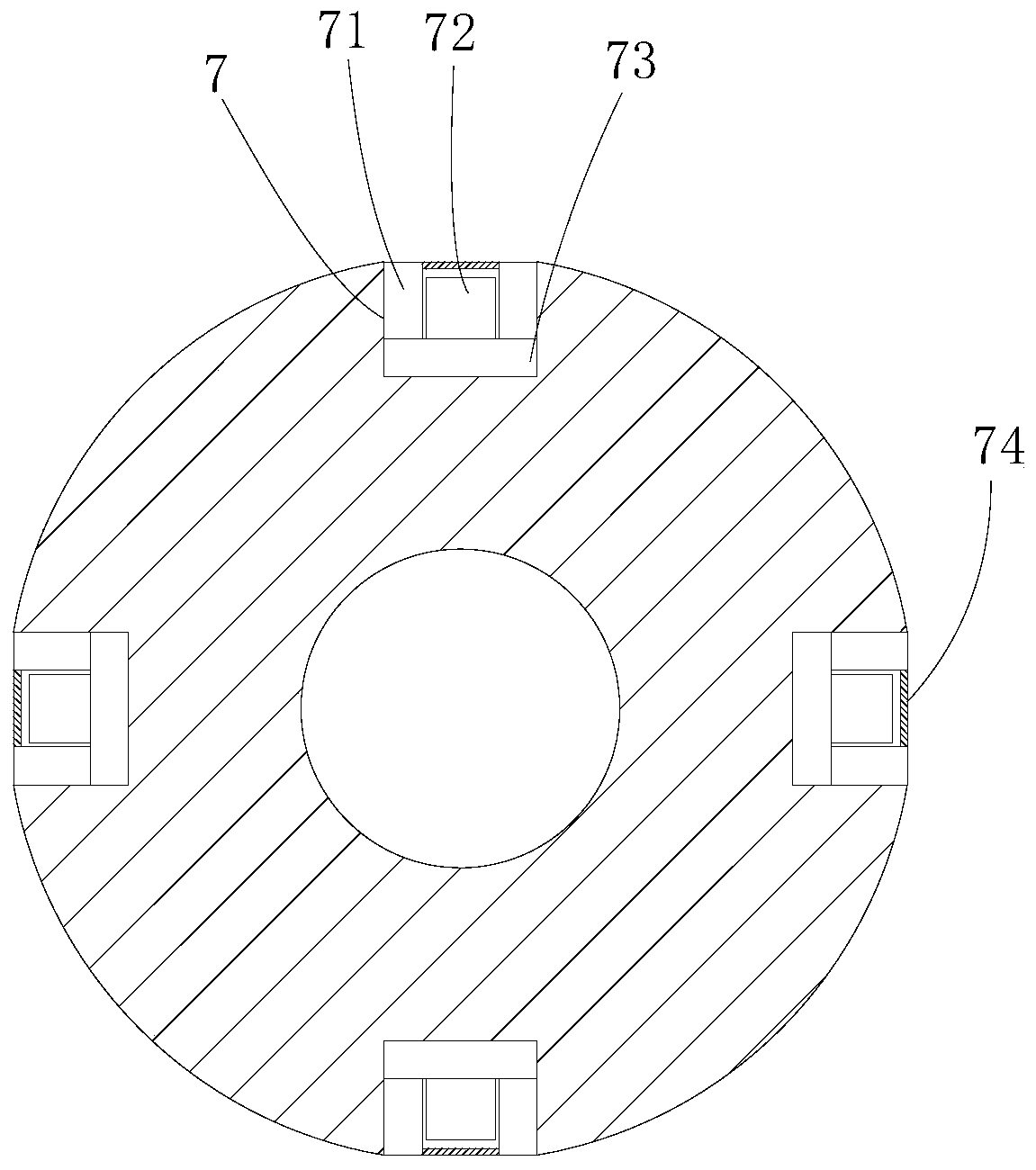

Cooling system for friction stir welding and using method thereof

ActiveCN112935645ARapid coolingUniform temperature distributionWelding/cutting auxillary devicesAuxillary welding devicesFriction weldingEngineering

The invention discloses a cooling system for friction stir welding. The cooling system comprises a fixing table, a first liquid spraying part, a second liquid spraying part and a adjusting and controlling device, wherein the fixing table is used for fixing a workpiece to be welded; each of the first liquid spraying part and the second liquid spraying part is provided with a plurality of nozzles capable of being connected with a cooling liquid source on the upper side and the lower side of the fixing table, and the liquid spraying directions of the nozzles located on the upper side and the lower side of the fixing table are vertically opposite; the nozzles of the first liquid spraying part are single-hole nozzles, and the nozzles of the second liquid spraying part are multi-hole nozzles; and the adjusting and controlling device comprises an angle adjusting and controlling part and a height adjusting and controlling part, the angle adjusting and controlling part can adjust and control the angles of the nozzles of the first liquid spraying part and / or the second liquid spraying part, and the angle adjusting and controlling part can adjust and control the heights of the nozzles of the first liquid spraying part and / or the second liquid spraying part. The invention further provides a using method of the cooling system, the cooling speed can be accurately controlled, the medium-thickness workpiece can be rapidly cooled in the thickness direction during friction stir welding, temperature distribution is uniform, and therefore the good mechanical property is obtained.

Owner:CHINA-UKRAINE INST OF WELDING GUANGDONG ACAD OF SCI

Method for preparing carrier resin for high-temperature-resistant molding process coloring materials

InactiveCN109575258AAccurate control of heating ratePrecise control of cooling rateAlcoholLiquid state

The invention discloses a method for preparing carrier resin for high-temperature-resistant molding process coloring materials. The method includes steps of 1, uniformly mixing and stirring, by weight, 70-100 parts of dihydric alcohol, 60-100 parts of polyacid and 15-25 parts of diacid anhydride with one another to obtain first mixtures in nitrogen atmosphere, gradually heating the first mixturesuntil the temperatures of the first mixtures reach 195-235 DEG C, carrying out condensation reaction, preserving heat after reaction systems become uniform and transparent, and continuing to carry outreaction; 2, cooling products obtained at the step 1 until the temperatures of the products reach 175-185 DEG C, adding 7-8 parts of p-dihydroxybenzene into the products, uniformly stirring the p-dihydroxybenzene and the products to obtain second mixtures, then cooling the second mixtures until the temperatures of the second mixtures are lower than 45 DEG C, and filtering the second mixtures to obtain the carrier resin. The method for preparing the carrier resin for the high-temperature-resistant molding process coloring materials has the advantages that the dihydric alcohol, the polyacid anddiacid are mixed with one another to obtain the first mixtures in the nitrogen atmosphere, the first mixtures are heated until the temperatures of the first mixtures reach 195-235 DEG C, the condensation reaction is carried out, the heating rates can be accurately controlled, accordingly, products only contain few small molecules and are in excellent liquid states, and the high-temperature resistance of the products can be improved.

Owner:镇江利德尔复合材料有限公司

Intermediate blank cooling system and cooling control technology

ActiveCN101642780BDoes not change metal propertiesReduce difficultyTemperature control deviceWork treatment devicesProduction lineThick plate

The invention belongs to the metallurgy technical field and in particular relates to an intermediate blank cooling system and cooling control technology. The intermediate blank cooling system is characterized in that an aerial fog cooling device body is arranged between a rough mill and a finishing mill. The aerial fog cooling device body is composed of an upper cooling header and a lower coolingheader, and an aerial fog nozzle and a compression air pipe are arranged on the cooling water pipe of the upper cooling header and the lower cooling header; and the on / off control valve and flow control valve of the cooling water pipe and the compression air pipe are connected with a control valve station. The intermediate blank aerial fog cooling technology is controlled by the aerial fog control technology sprayed on the cooling header arranged near roller ways at the front and rear of the mills. The invention has fast cooling speed without changing metal performance, water yield regulatingrange is wide and the water yield can be regulated continuously, the cooling speed of the intermediate blank can be precisely controlled, and the invention can be widely applicable to middle and thick plate production line.

Owner:CISDI ENG CO LTD

Cryoprotectant and ultralow-temperature cryopreservation method for stichopus japonicus sperms

ActiveCN112075415AShort operating timeAvoid greater loss of sperm motilityDead animal preservationSolventChemistry

The invention relates to the technical field of ultralow-temperature cryopreservation of sea cucumber germplasm resources, in particular to a cryoprotectant, an activator formula and an ultralow-temperature cryopreservation for apostichopus japonicus sperm method based on a program cooling instrument and CASA. The cryoprotectant is composed of a diluent, an antifreeze agent and an additive. The diluent is natural seawater, the antifreeze agent is one or more of aprotic polar solvents, and the additive is glucose. According to the method, the freezing stock is large (more than 200 mL of fresh stichopus japonicus seminal fluid can be frozen in one batch), the cooling process can be precisely controlled, the application effect is good after thawing, and the problems of asynchronous maturationof male and female sea cucumbers in south and north and a series of stichopus japonicus germplasm degradation in actual production can be solved.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

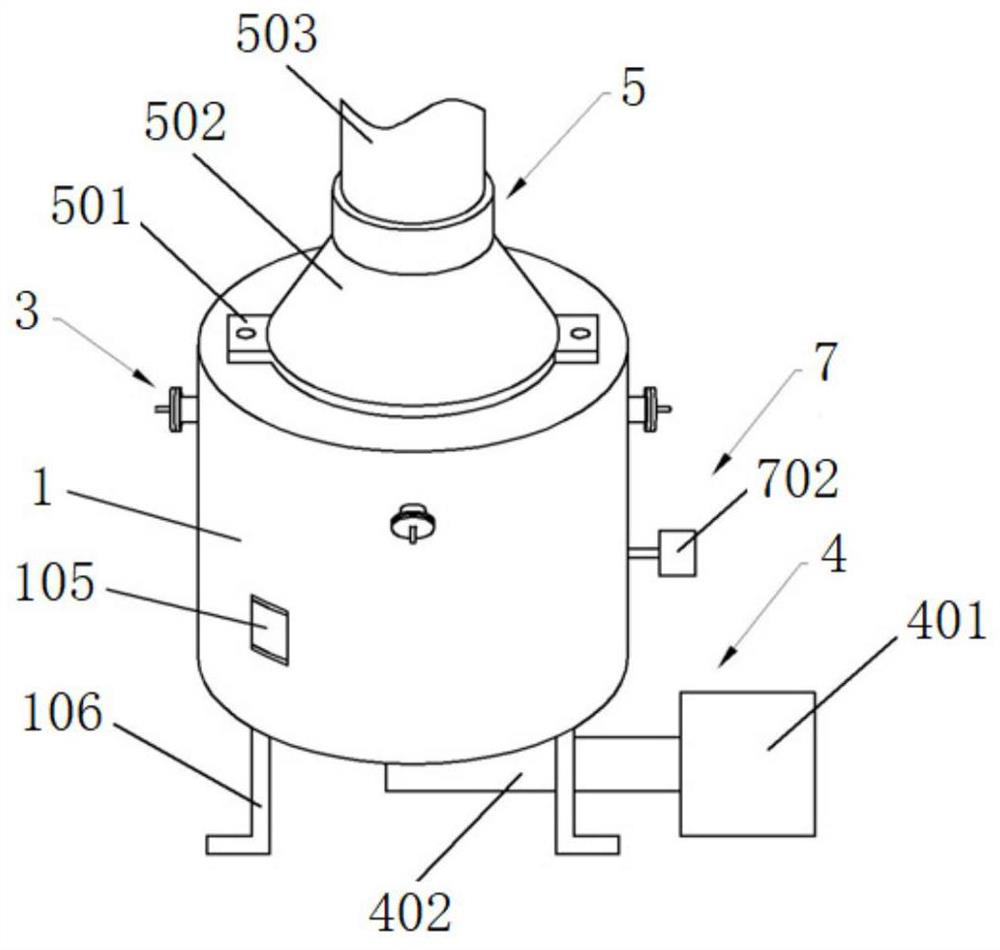

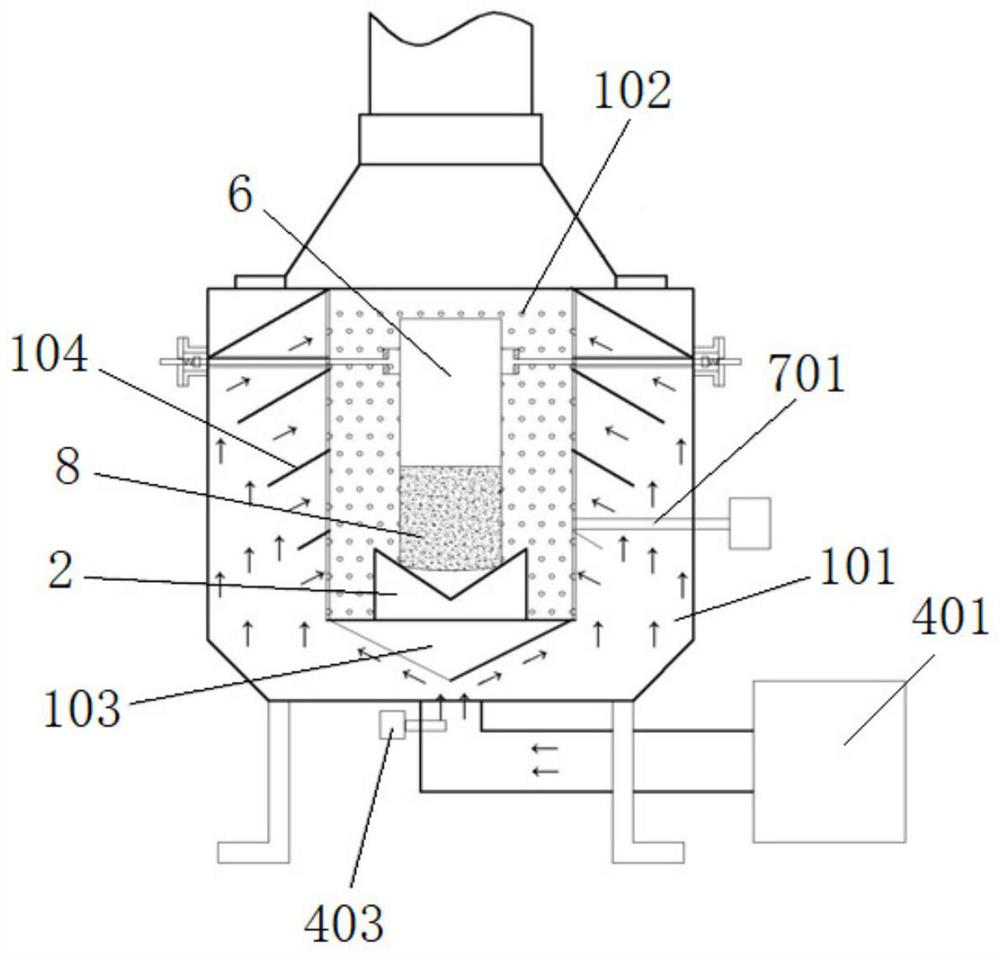

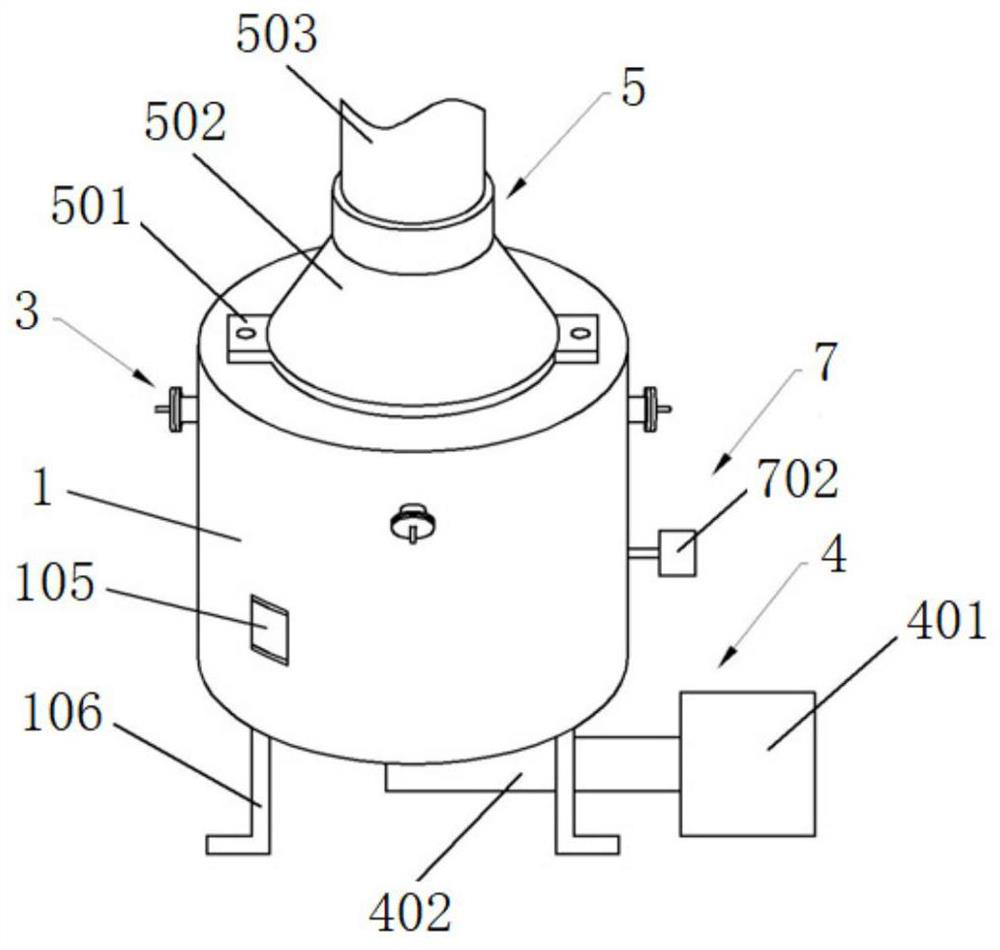

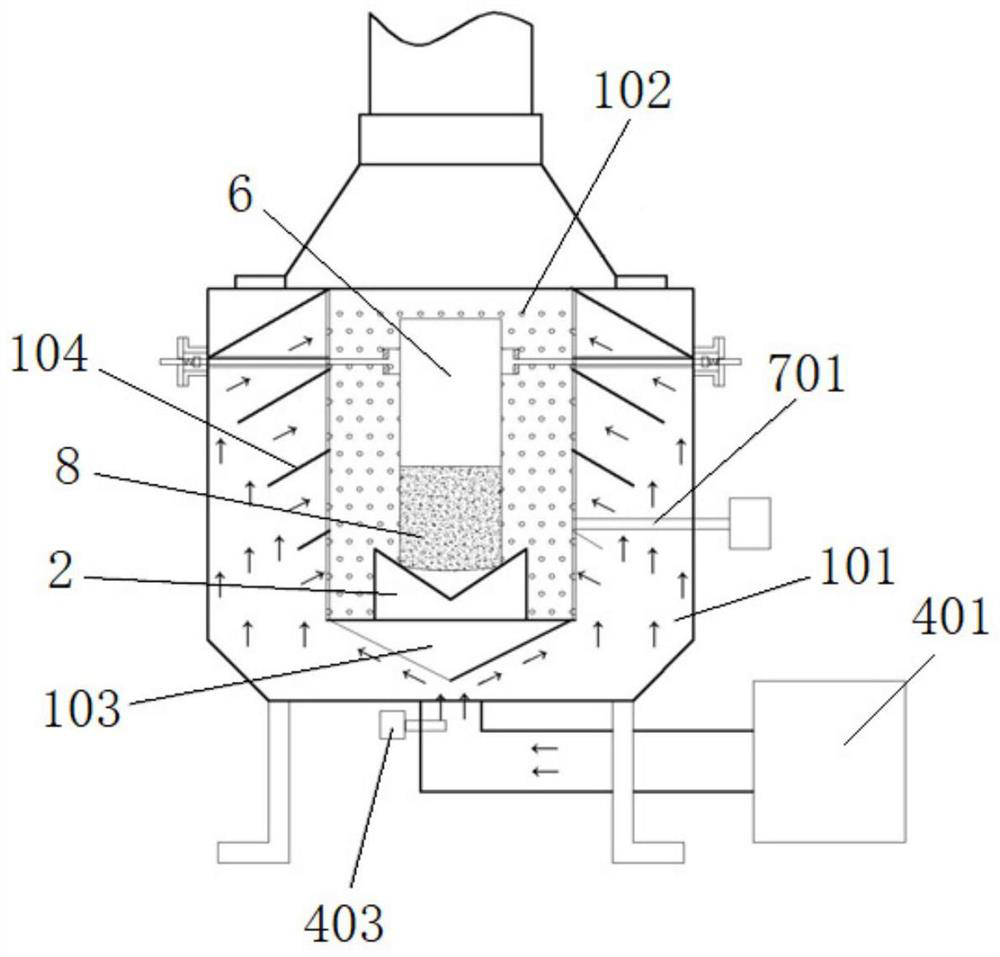

Chalcogenide glass air cooling device and air cooling control method of chalcogenide glass

ActiveCN112710122AEasy to fixAvoid breakingLighting and heating apparatusCooling fluid circulationChalcogenide glassCooling chamber

The invention provides a chalcogenide glass air cooling device and an air cooling control method of chalcogenide glass. The chalcogenide glass air cooling device comprises a device body, a center positioning device, a synthesis container, a guide mechanism and an air cooling system; the device body includes an inner barrel body and an outer barrel body arranged on the outer side of the inner barrel body in a sleeving manner, and a closed and communicating air cooling cavity is formed between the outer side wall of the inner barrel body and the inner side wall of the outer barrel body; an air cooling chamber is formed in the inner barrel body, and the air cooling cavity communicates with the air cooling chamber; an air inlet communicating with the air cooling cavity is formed in the outer barrel body; the air cooling system communicates with the air cooling cavity through the air inlet; and the synthesis container is vertically arranged in the center of the air cooling chamber through the center positioning device and a fixing device. According to the chalcogenide glass air cooling device, the synthesis container is stably and safely fixed to the center of the air cooling chamber through the center positioning device and the fixing device, and uniform flowing of airflow is achieved by installing the guide mechanism, so that the uniformity of the temperature of all parts in the melt cooling process is guaranteed.

Owner:GRINM GUOJINGHUI NEW MATERIALS CO LTD

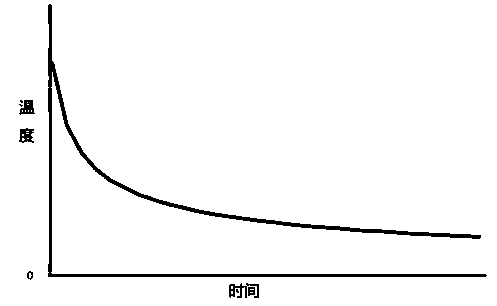

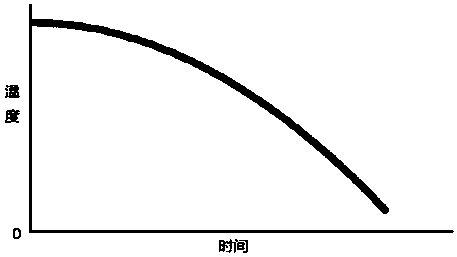

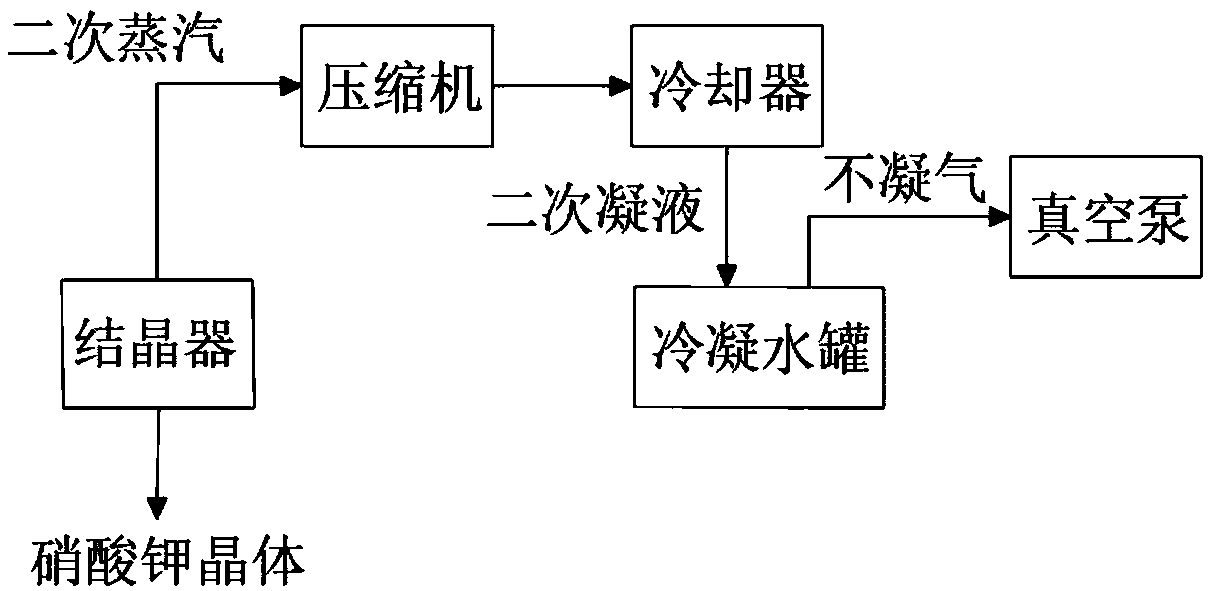

Vacuum cooling crystallization method

InactiveCN109675336AReduce cooling water usageReduce processing costsSolution crystallizationIron sulfatesVacuum coolingMoisture

The invention discloses a vacuum cooling crystallization method. The vacuum cooling crystallization method comprises the following steps: 1) adding a to-be-crystallized liquid into a crystallizer, turning on a compressor and a vacuum pump, enabling the compressor to suck steam in the crystallizer so that moisture in the crystallizer is vaporized and flash-evaporated, wherein the compressor is controlled by using variable frequency; 2) enabling the secondary steam formed by flash-evaporation to enter the compressor for compression and heating, then enabling the heated steam to enter a condenserfor condensation, discharging a condensate that forms secondary steam into a condensation water tank, discharging a non-condensable gas in the system out of the system through the vacuum pump; and 3)turning off the compressor and the vacuum pump after the crystallization process is completed. According to the vacuum cooling crystallization method disclosed by the invention, the variable frequency speed control technology is adopted by the compressor, the cooling rate of the feed liquid can be accurately controlled, the burst nucleation is prevented, the crystal size is uniform and the product quality is stable. The steam jet pump cooling crystallization method is only suitable for crystallization of substances with rapid nucleation rate and less strict requirement for crystal grain size,and the method disclosed by the invention is stronger in adaptability and wider in application range.

Owner:天津乐科节能科技有限公司

A cryoprotectant solution and ultra-low temperature cryopreservation method for japonicus japonicus sperm

ActiveCN112075415BAvoid problems with large vitality lossLow costDead animal preservationStichopusGermplasm

The invention relates to the technical field of ultra-low temperature cryopreservation of sea cucumber germplasm resources, in particular to a cryoprotectant solution, an activator formula, and a method for ultra-low temperature cryopreservation of imitation japonicus japonicus sperm based on a programmed cooling instrument and CASA. The cryoprotective solution is composed of diluent, antifreeze and additives; wherein, the diluent is natural seawater, the antifreeze is one or more of aprotic polar solvents, and the additive is glucose. This method has a large amount of frozen storage (more than 200mL of fresh japonicus semen can be frozen in one batch), can precisely control the cooling process, and has a good application effect after thawing. quality degradation problem.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

A kind of screw extruder measurement and control cooling equipment

Measurement and control type cooling equipment for a screw extruder comprises three cooling modes, namely, the water cooling mode, the air cooling mode and the water cooling and air cooling mixed mode. The cooling equipment is composed of a detection device, a cooling device, a controller, a controllable display device and a trough structure. The cooling device comprises a water spraying device, an air supply device and a refrigeration device. The controller is electrically connected with the controllable display device. A water tank is arranged on the lower portion of the trough structure. According to the measurement and control type cooling equipment, the limitation that existing cooling equipment is singular in cooling mode is fundamentally overcome, thus, the cooling mode can be selected according to properties of polymers, the cooling equipment can accurately measure the temperature and adjust the cooling speed in real time in the cooling process, the effect that the cooling speed of the different polymers can be adjusted in time according to the properties and the extrusion conditions of the polymers, and accordingly, the stably and reliable quality is achieved; and through the mode that the temperature is precisely measured, and differentiated cooling is conduced according to different areas, energy source consumption and resource consumption are effectively reduced.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

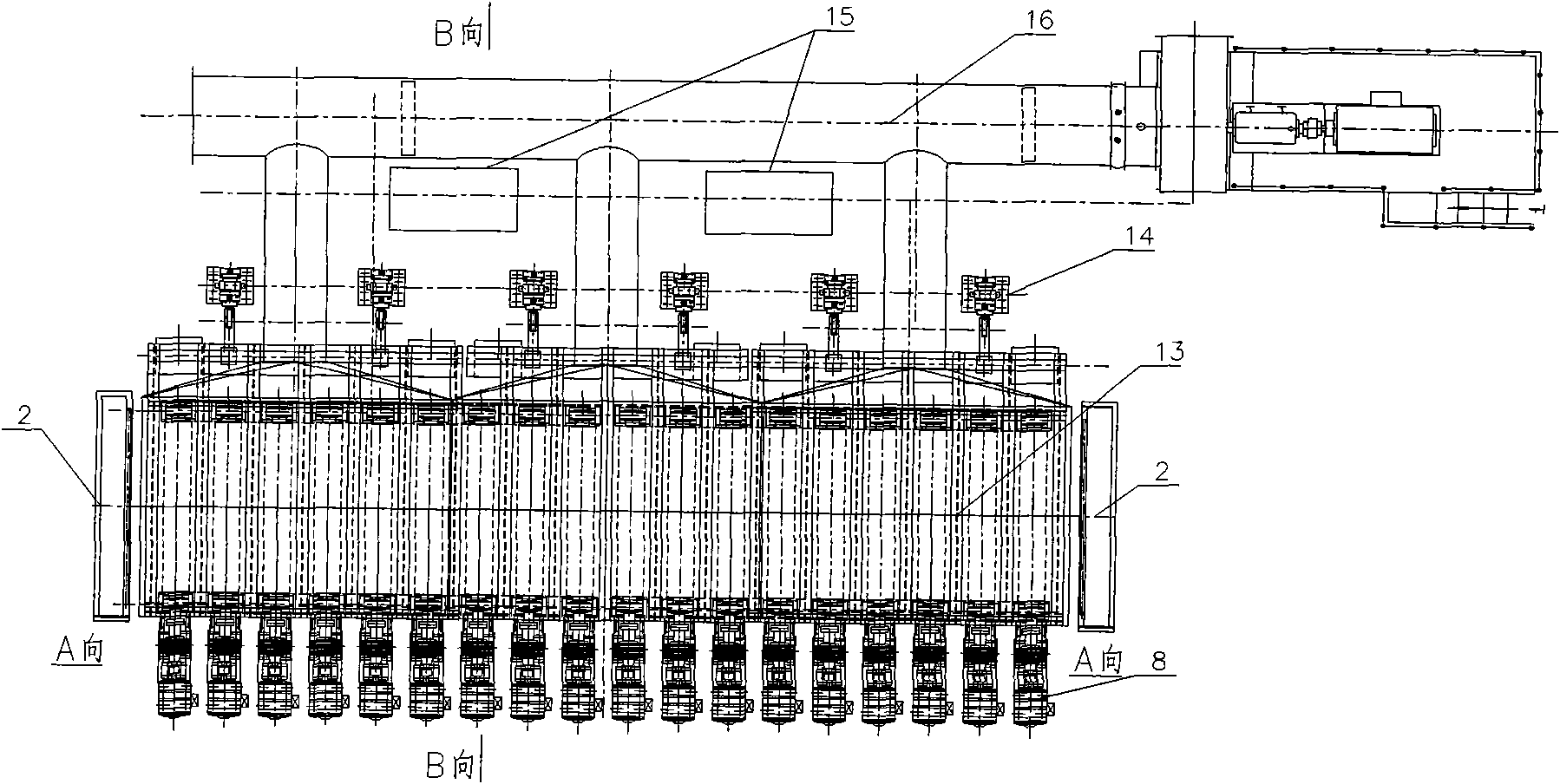

A three-stage aluminum profile quenching cooling device and cooling method

ActiveCN105567921BLarge cooling rate rangePrecise control of cooling rateFurnace typesHeat treatment furnacesAir volumeWater flow

The invention provides a three-section type aluminum profile quenching and cooling device and method. Three sections are combined, the first section is cooled in a strong air and water mist manner, the second section is cooled in a strong water mist manner, and the third section is cooled in a strong air manner. In nozzles in different positions in each section, the flow of air and the flow of water can be proportionally adjusted; the different air cooling and water cooling nozzles are arranged on the periphery of the section of an aluminum profile, the flow of each nozzle can be adjusted in a stepless manner to be suitable for quenching and cooling of aluminum alloy profiles with different sections and of different specifications and materials, and the air volume and the water flow of each nozzle on each section can be adjusted according to the practical condition. By the adoption of the three-section type aluminum profile quenching and cooling device, the cooling speed range large enough can be provided, the cooling speed of different positions of each aluminum profile can be accurately controlled, and different quenching and cooling processes of the aluminum profiles with different sections and of different specifications and materials can be achieved.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

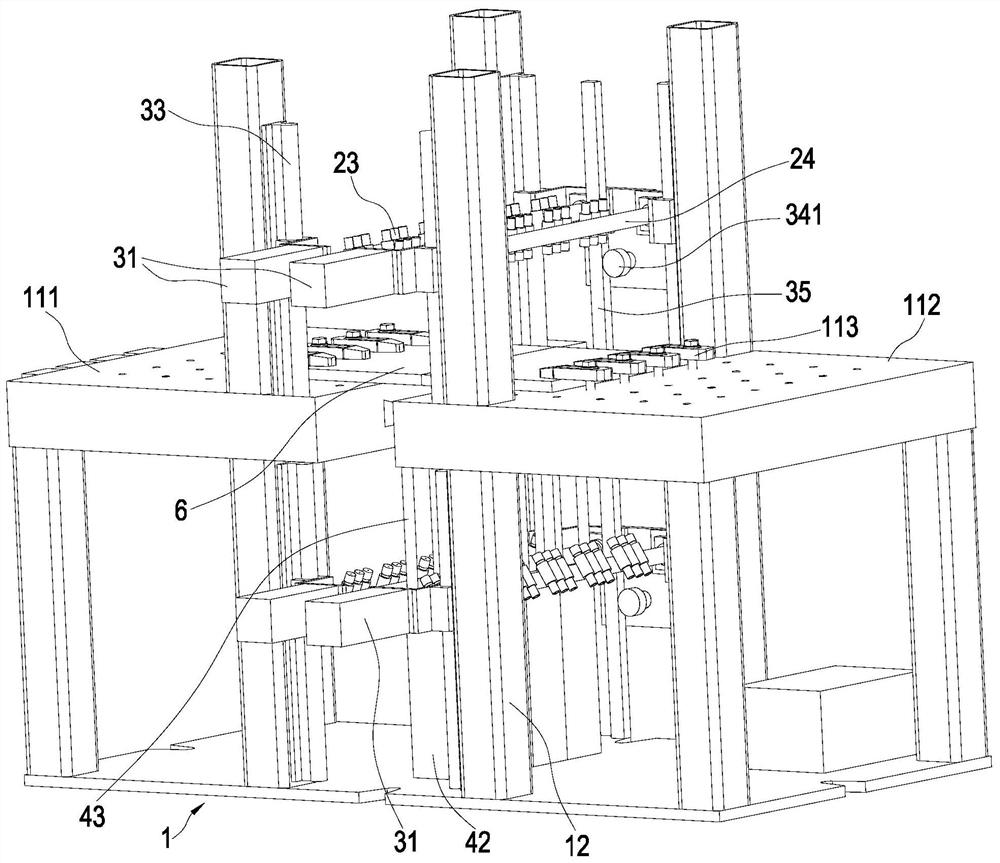

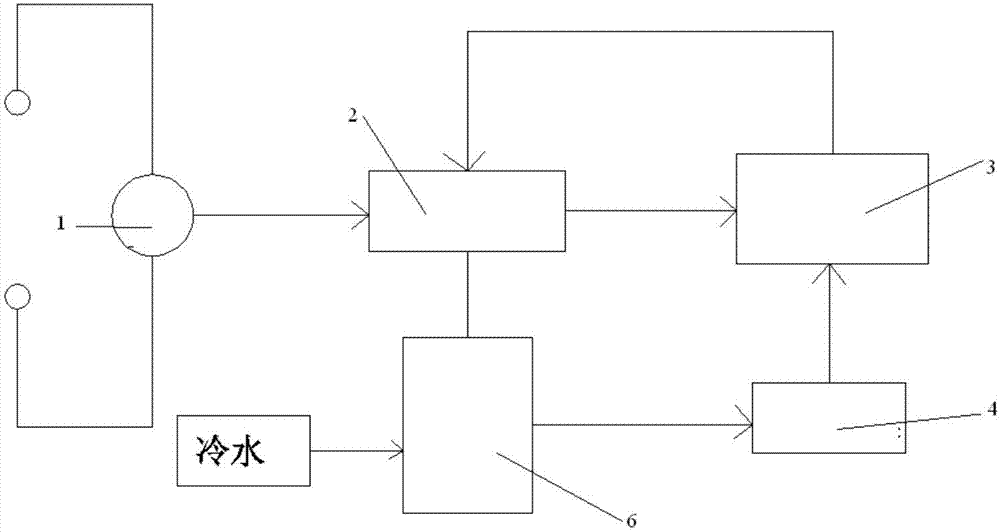

A cooling rate controllable heat treatment device and method

ActiveCN109737739BIncrease profitPrecise control of cooling rateFurnace typesHandling discharged materialAir pumpEngineering

A cooling speed controllable heat treatment device and method. The device includes a heating furnace, a transfer channel and a cooling tank. There are guide rails and sample carrying vehicles in the furnace and the tank. There are transport rollers in the channel. Both ends of the transfer channel It is sealed and connected with the heating furnace and the cooling tank respectively, and both communication ports are equipped with lift doors; there is an air pump and flow meter between the bottom of the cooling tank and the cooling air source, and there is an air supply pump between the top of the bottom of the cooling tank and the atmosphere. The air outlet pipeline is equipped with a water-cooling jacket. The method is: complete the sample heating and insulation in the furnace; open the first lift door, transfer the sample to the transport roller and then close the lift door; open the second lift door, transfer the sample to the cooling via the transport roller Close the lift door again in the tank; measure the real-time temperature of the sample, enter the target cooling rate into the computer, and determine the cooling gas type and flow rate; input cooling gas into the tank to cool the sample, and start pumping to keep the temperature and pressure in the tank stable. ; until the sample is completely cooled.

Owner:NORTHEASTERN UNIV LIAONING

Non-Newtonian crude oil shear history simulation experiment device and method

InactiveCN103728439BAvoid two-phase flowReduce the amount of adhesionMaterial testing goodsWater bathsDrive shaft

The invention discloses shear history simulation experiment device and method for non-Newtonian crude oil. The device comprises a motor, an infinitely variable transmission, a computer, a temperature measurement collection device and a stirring device, wherein the stirring device comprises a stirring tank, a stirrer, a hot bath heating coil and an arc double-hole floating cover; the stirring tank comprises a water bath jacket; the stirrer is inserted into the stirring tank; the hot bath heating coil encircles around the inner wall of the stirring tank; the arc double-hole floating cover is arranged at the top of the stirring tank; a hole I and a hole II are formed in the floating cover; the motor is connected with a driving shaft of the infinitely variable transmission; a driven shaft of the infinitely variable transmission is connected with the stirrer through the hole I; the computer is respectively connected with the infinitely variable transmission and a temperature collection device; the temperature collection device is connected with the stirring device. The shear history simulation experiment device and method have the beneficial effects that the shearing action of in-line flow shear and pump high-speed shear under a turbulence state on the rheological property of the non-Newtonian crude oil can be measured by using the device, and a whole transportation process of a crude oil pipeline is simulated.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

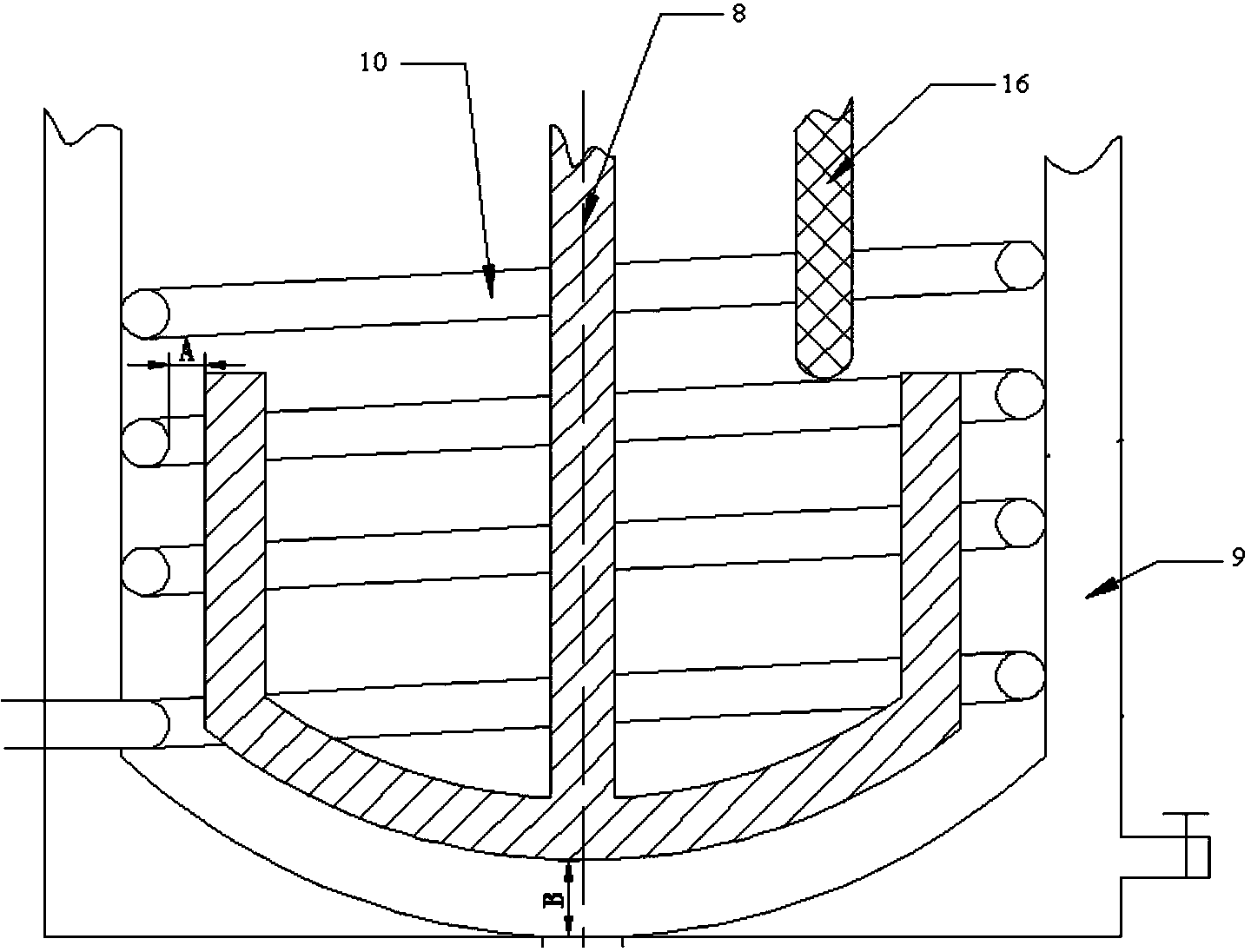

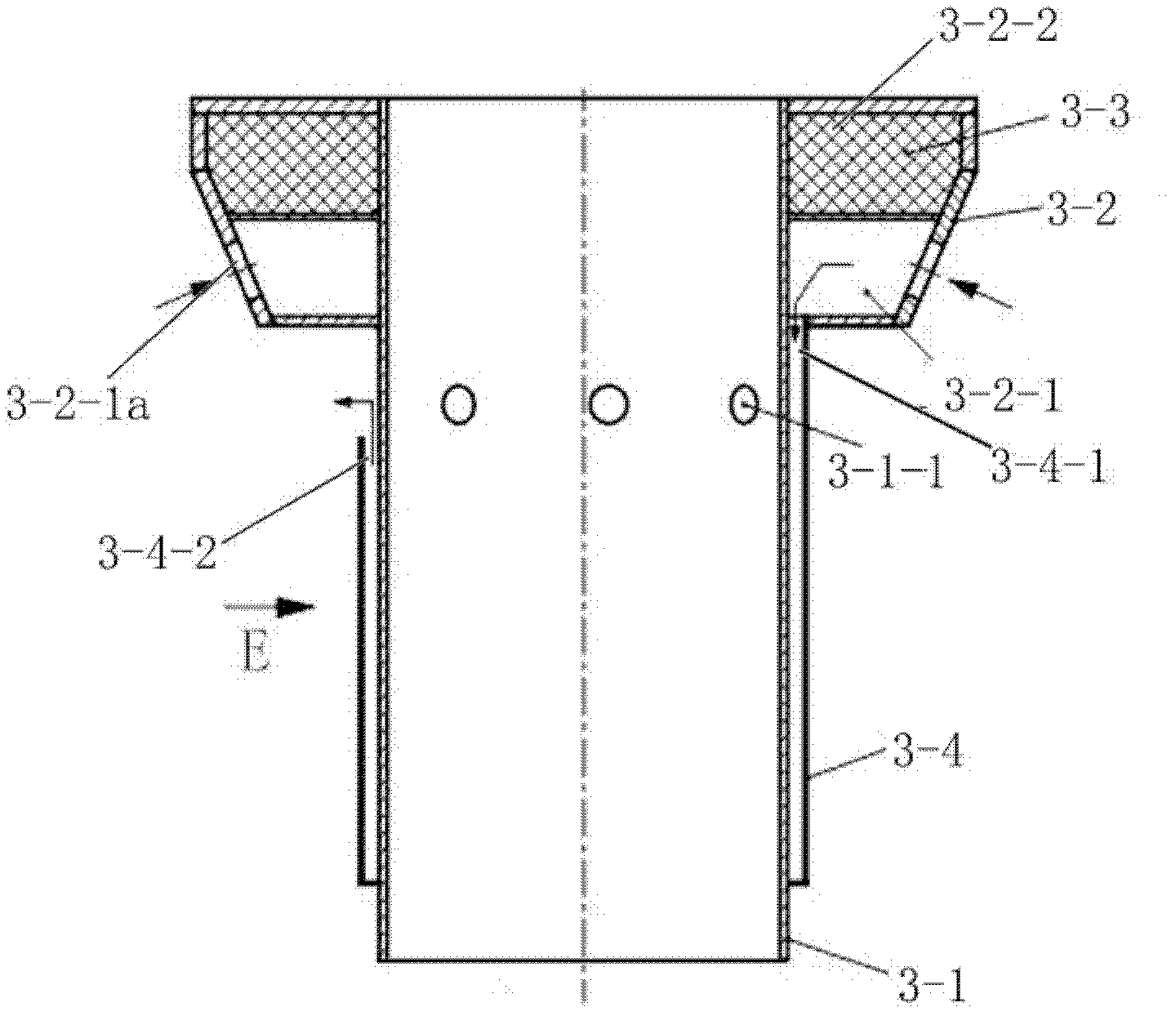

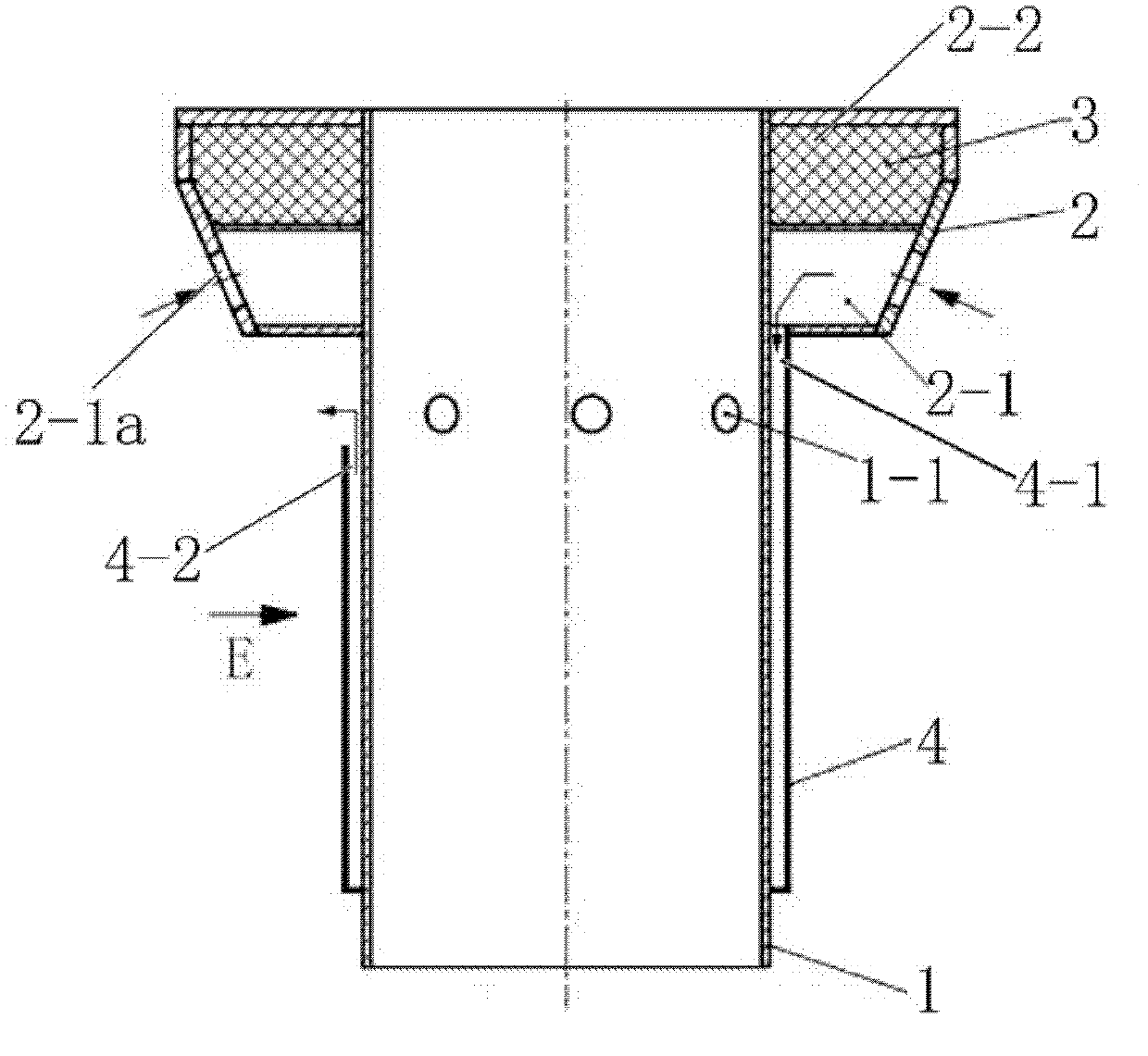

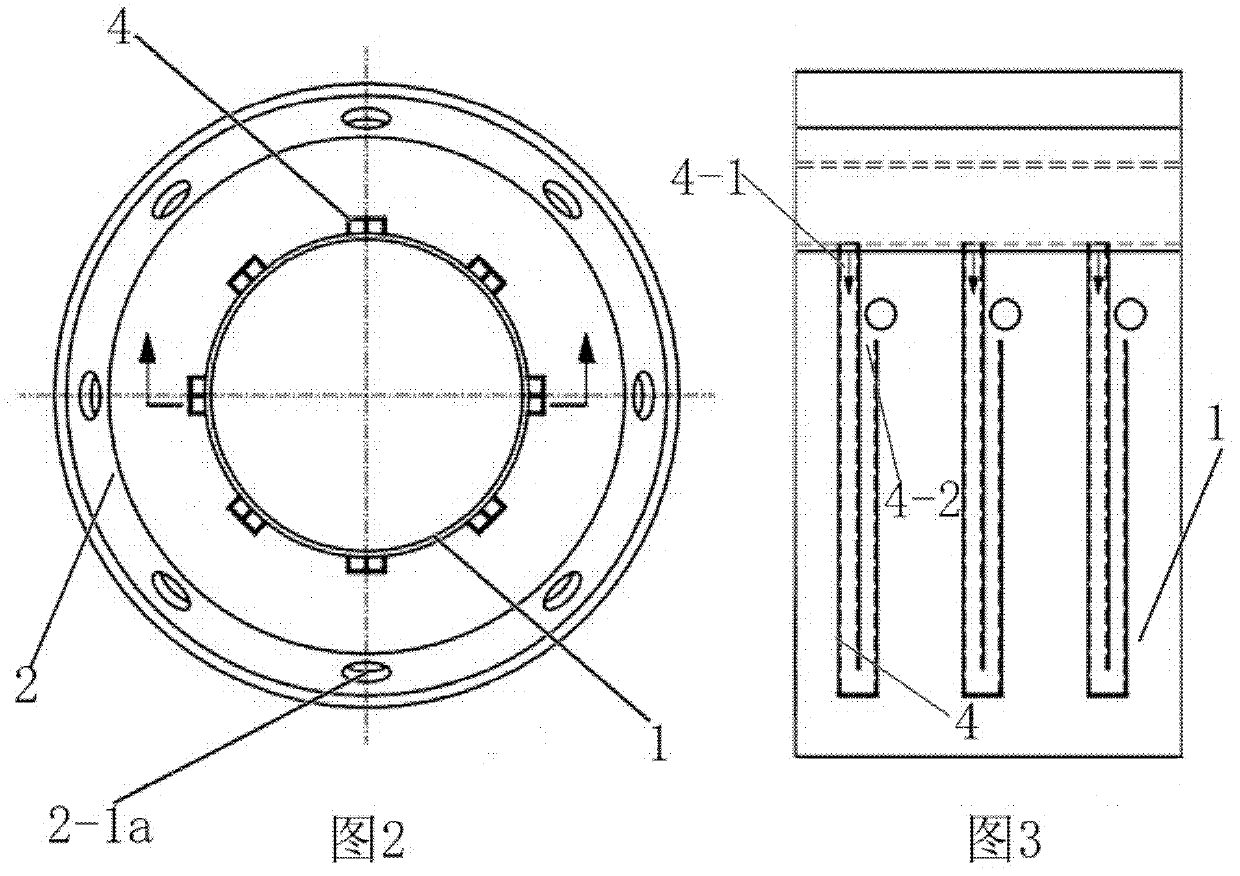

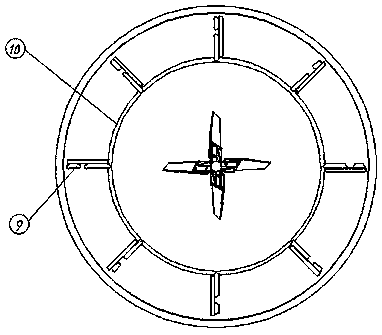

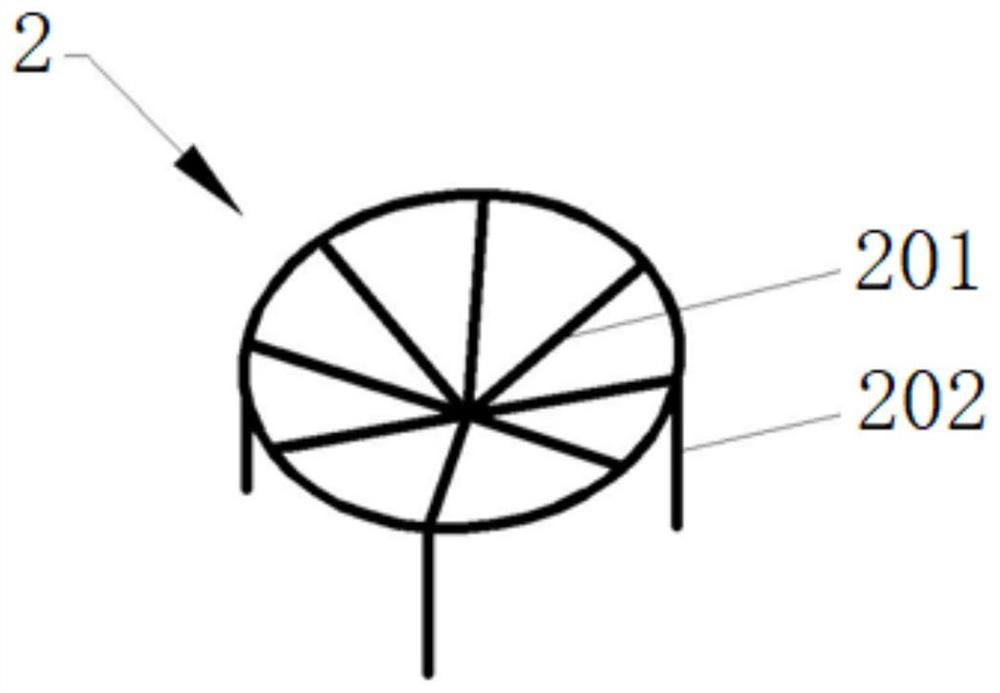

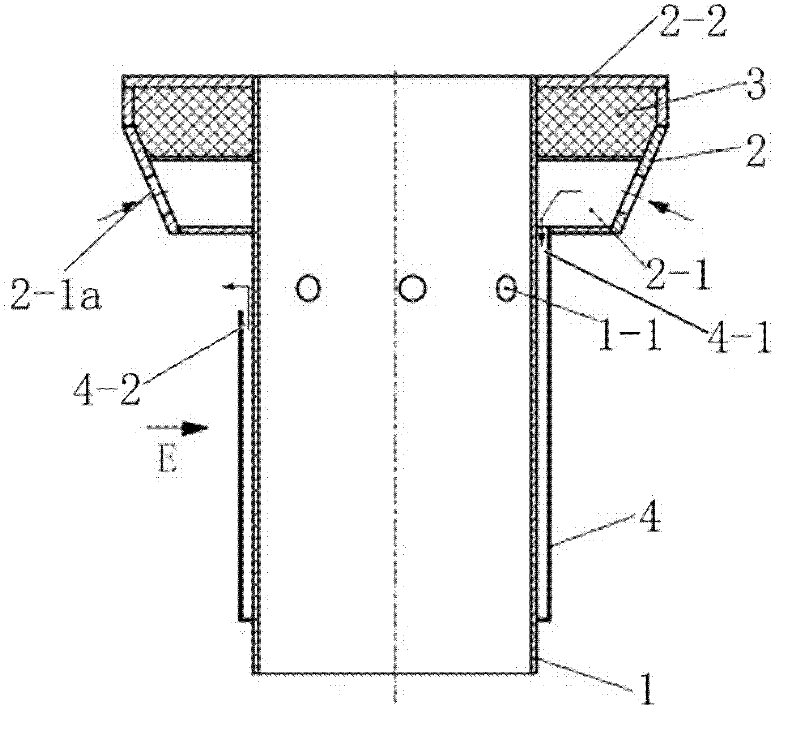

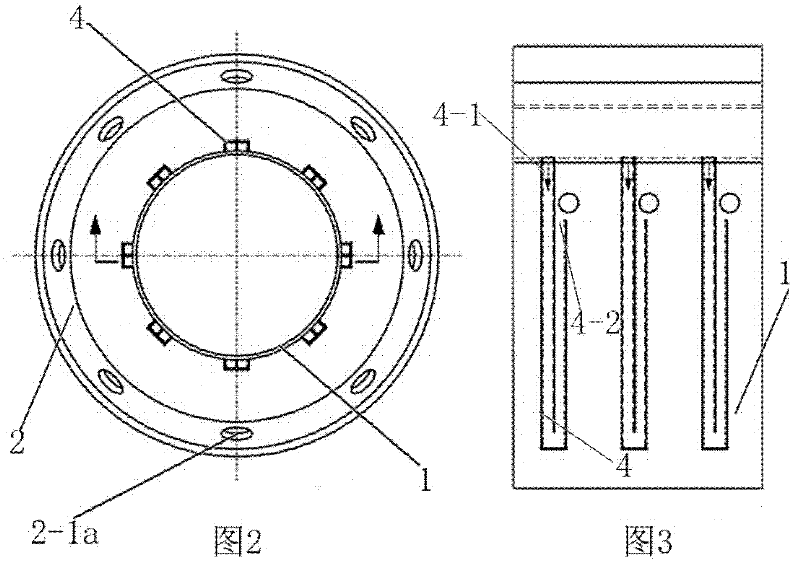

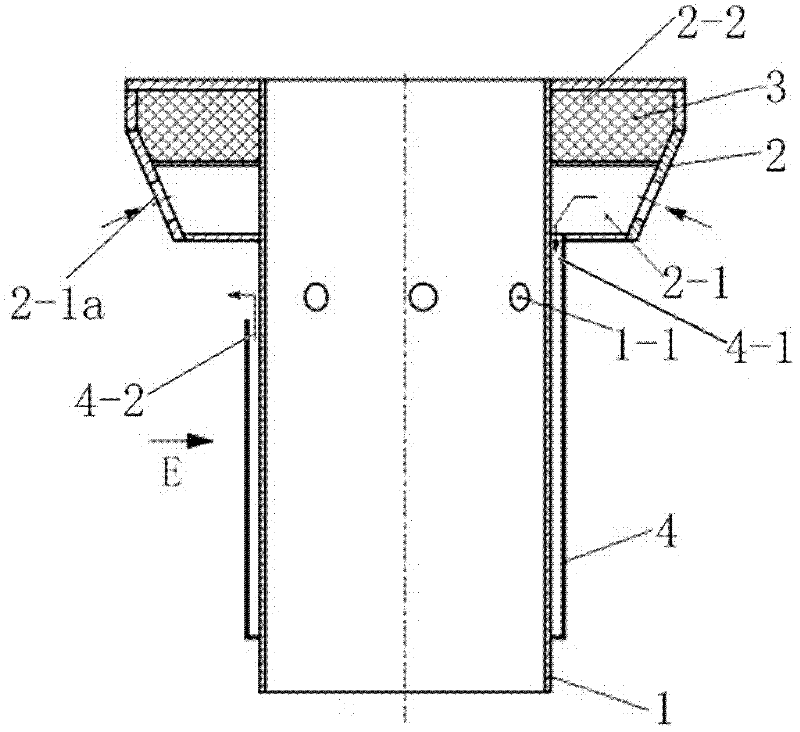

Uniform-heating screen with cooling structure for thermally-stimulated furnace

ActiveCN102288030BPrecise control of cooling rateReduce weightFurnace typesFurnace coolingFlangeCooling speed

The invention relates to a uniform-heating screen with a cooling structure for a thermally-stimulated furnace, which is characterized by comprising a shell (1) and a hollow flange (2), wherein the hollow flange (2) is connected to the top of the shell (1); an inner cavity of the hollow flange (2) is divided into an air-inlet cavity (2-1) and a heat-insulating cavity (2-2); a plurality of uniformly-distributed air-inlet holes (2-1a) are arranged on the lateral wall of the air-inlet cavity (2-1), and heat-preserving cotton (3) is arranged in the heat-insulating cavity (2-2); and a plurality of uniformly-distributed cooling-air channels (4) are arranged on the outer wall of the shell (1), an air inlet (4-1) of each cooling-air channel (4) is communicated with the air-inlet cavity (2-1), and an air outlet (4-2) of each cooling-air channel (4) is open. The uniform-heating screen has the characteristics that a workpiece can be more uniformly heated, and meanwhile, the cooling speed can be accurately controlled.

Owner:GUANGDONG STRONG METAL TECH

Flow guide type freezing crystallizer

InactiveCN111514607AKeep Automatic Scar RemovalIncrease the heat exchange areaSolution crystallizationHeat exchange cooling cystallizationInsulation layerControl system

The invention discloses a flow guide type freezing crystallizer which comprises a crystallizing tank, a cooling system, a stirring system and a control system; the crystallizing tank comprises a tankbody; a cold insulation layer is arranged on the inner wall of the tank body; a manhole, a feeding hole, a liquid level meter hole, a clear liquid hole, a crystal mush hole and a thermometer hole areformed in the tank body; the cooling system comprises an inlet header pipe, a racemization coil pipe, a flow guide coil pipe, an outlet header pipe and a bracket; the stirring system comprises a variable frequency motor, a speed reducer, a water seal, a rigid shaft, a push type paddle and a bottom cone; the control system comprises a liquid level sensor, a feeding switch valve, a temperature sensor, a refrigerant regulating valve, an ampere meter, a variable frequency controller, a clear liquid switch valve, a crystal mush switch valve and a logic controller; compared with a conventional intermittent groove type freezing crystallizer, the flow guide type freezing crystallizer has the advantages of being large in heat exchange area, large in capacity, few in scabs and the like, has a certain crystal selection function and a crystal slurry thickening function, and facilitates subsequent crystal slurry solid-liquid separation operation.

Owner:GANFENG LITHIUM CO LTD

Chalcogenide glass air cooling device and air cooling control method

ActiveCN112710122BEasy to fixAvoid breakingLighting and heating apparatusCooling fluid circulationChalcogenide glassCooling chamber

The invention provides an air-cooling device for chalcogenide glass and an air-cooling control method thereof. The air-cooling device for chalcogenide glass comprises a device body, a center positioning device, a synthesis container, a guiding mechanism and an air-cooling system. The device body includes an inner barrel and The outer barrel is sleeved on its outer side, and a closed and connected air-cooling cavity is formed between the outer side wall of the inner barrel and the inner side wall of the outer barrel; an air-cooling chamber is formed inside the inner barrel, and the air-cooling chamber and the air-cooling chamber are formed. The outer barrel is provided with an air inlet for connecting the air-cooling cavity; the air-cooling system communicates with the air-cooling cavity through the air-inlet; the center of the room. The chalcogenide glass air-cooling device realizes the stable and safe fixing of the synthesis container in the center of the air-cooling chamber through the center positioning device and the fixing device, and realizes the uniform flow of the air flow through the setting of the guiding mechanism to ensure the uniform temperature of each part during the cooling process of the melt. sex.

Owner:GRINM GUOJINGHUI NEW MATERIALS CO LTD

A hot stamping hydraulic press system

ActiveCN109622776BSolve the problem of suppressionSolving Heat Balance ProblemsShaping toolsServomotor componentsHot stampingProduction line

The invention discloses a hot stamping forming hydraulic press system, which belongs to the field of hot stamping forming hydraulic press systems. A hot stamping forming hydraulic press system, the system designed in the present invention can ensure the stable operation of the system when the press speed is increased to 1000mm / s; using the hot stamping forming hydraulic press system involved in the present invention can quickly and uniformly cool the workpiece , and make the mold temperature field tend to be constant all the time, in order to solve the problem that the press presses under high-speed and high-beat conditions, effectively improve the production beat and thus increase the output, the beat of the hot stamping production line of the present invention is increased to 6-7 times / minute , the output increased by more than 30% on average, and effectively solved the problem of insufficient cooling or uneven cooling when the workpiece was formed. After forming, the workpiece had high strength and good appearance, and effectively solved the problem of mold heat balance. Continuous production, effectively reducing the energy consumption of the press to achieve the purpose of energy saving and environmental protection, and the piping is beautiful and easy to maintain.

Owner:HEFEI METALFORMING MACHINE TOOL

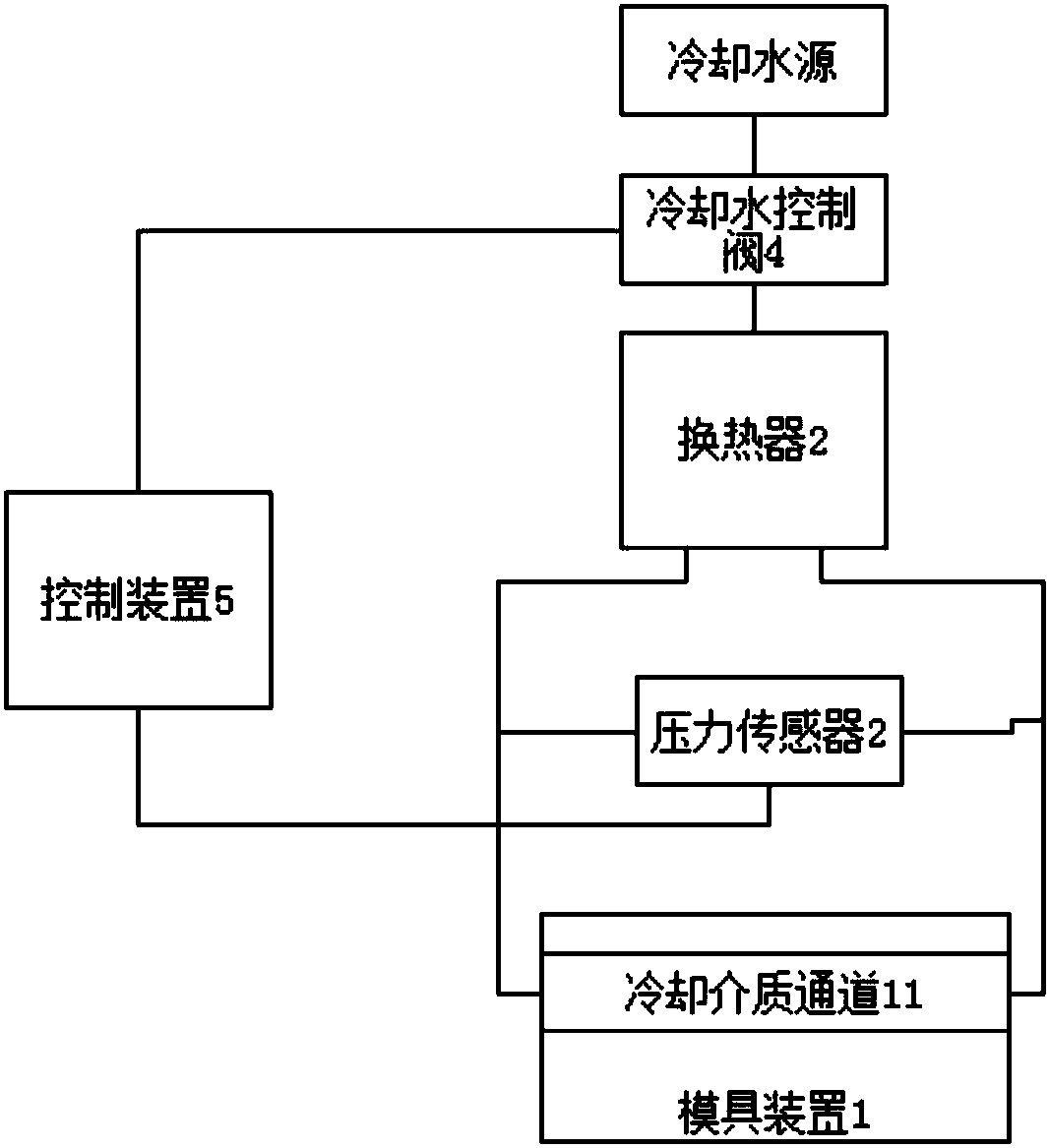

Intelligent automobile accessory mold system and using method

The invention discloses an intelligent automobile accessory mold system and a using method. The system comprises a mold device, a heat exchanger, a pressure sensor, a cooling water control valve and acontrol device, wherein a closed cooling medium channel is formed in the mold device, each of the two ends of the cooling medium channel is provided with a pressure sensor,and the two ends of the cooling medium channel are connected with a hot fluid inlet and a hot fluid outlet of the heat exchanger through a hot fluid pipeline; a cold fluid inlet of the heat exchanger is connected with a coolingwater source through the pipeline; the cooling water control valve is arranged on a pipeline between the cold fluid inlet of the heat exchanger and the cooling water source; and the pressure sensor and the cooling water control valve are connected with the control device.

Owner:天津优杰精密模具有限公司

Vapor shield with cooling structure for thermal simulation furnace

ActiveCN102288030APrecise control of cooling rateEven airflowFurnace typesFurnace coolingHeat shieldThermal simulation

The invention relates to a uniform-heating screen with a cooling structure for a thermally-stimulated furnace, which is characterized by comprising a shell (1) and a hollow flange (2), wherein the hollow flange (2) is connected to the top of the shell (1); an inner cavity of the hollow flange (2) is divided into an air-inlet cavity (2-1) and a heat-insulating cavity (2-2); a plurality of uniformly-distributed air-inlet holes (2-1a) are arranged on the lateral wall of the air-inlet cavity (2-1), and heat-preserving cotton (3) is arranged in the heat-insulating cavity (2-2); and a plurality of uniformly-distributed cooling-air channels (4) are arranged on the outer wall of the shell (1), an air inlet (4-1) of each cooling-air channel (4) is communicated with the air-inlet cavity (2-1), and an air outlet (4-2) of each cooling-air channel (4) is open. The uniform-heating screen has the characteristics that a workpiece can be more uniformly heated, and meanwhile, the cooling speed can be accurately controlled.

Owner:GUANGDONG STRONG METAL TECH

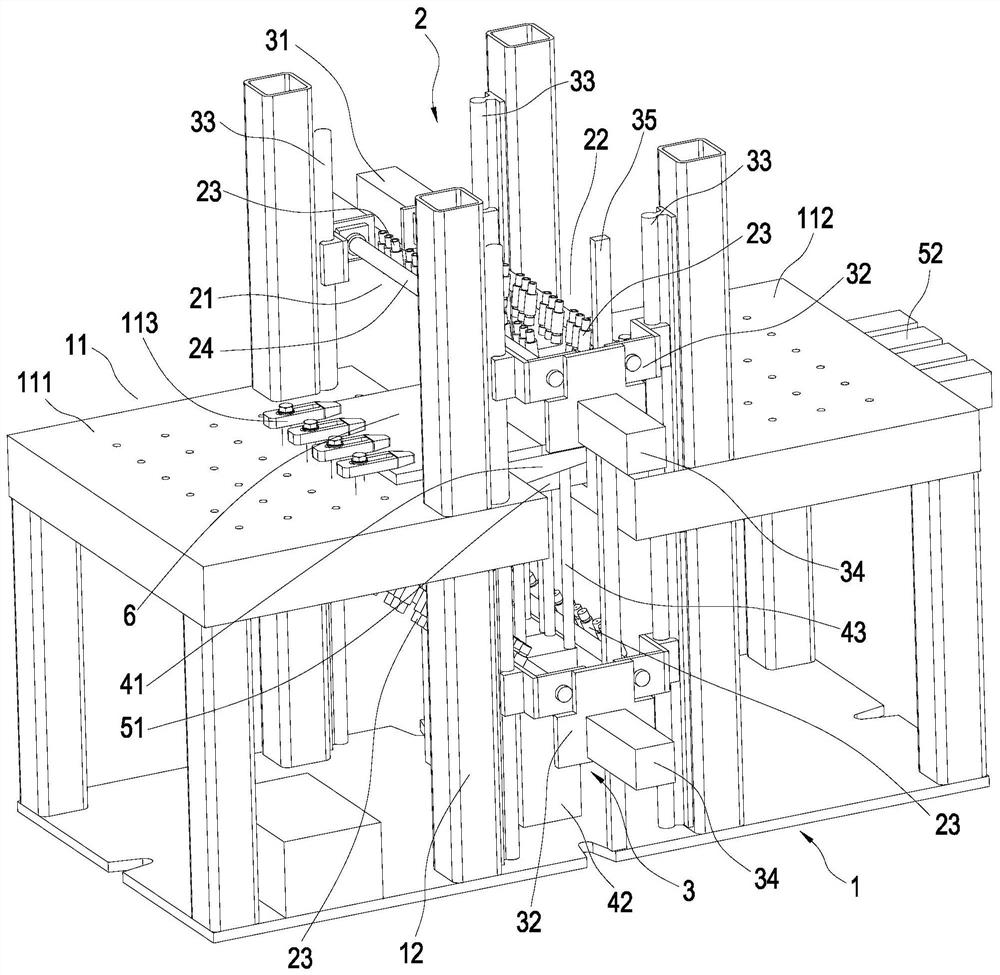

A device and method for simulating twin-roll strip continuous casting process

ActiveCN111531142BControllable surface roughnessEase of research impactMetal rolling arrangementsEngineeringThermocouple device

The invention discloses a device and method for simulating a twin-roll strip continuous casting process, comprising a smelting system for melting metal, a cooling base assembly located above the smelting system, and controlling the lifting of the cooling base assembly to be inserted into the smelting system to melt metal The lifting mechanism and the cooling system for cooling the surface of the cooling base assembly, the cooling base assembly includes a pair of cooling bases arranged parallel and side by side, and there is a gap between the pair of cooling bases for simulating the roll gap of the thin strip continuous casting crystallization roll, There is a temperature-measuring thermocouple in the gap, and it also includes a hot-rolling system that drives a pair of cooling substrates to move toward each other and an elastic reset member connected between the pair of cooling substrates. There is a cooling flow channel in the cooling substrate, and the temperature-measuring thermocouple and The cooling system is connected with the temperature acquisition system. The device can simulate the twin-roll extrusion process and the on-line hot rolling process of the strip, which has important guiding significance for improving the surface quality and mechanical properties of the steel strip.

Owner:CENT SOUTH UNIV

Numerical control machine tool and machining method thereof

InactiveCN112720018AExtended service lifeReduce utilizationDriving apparatusMaintainance and safety accessoriesNumerical controlAuto regulation

According to the technical scheme, a numerical control machine tool is characterized by comprising a machine tool body, a spindle box, an upper spindle and a lower spindle, the spindle box, the upper spindle and the lower spindle are arranged on the machine tool body, the upper spindle and the lower spindle are the same in structure and are symmetrically arranged, and the upper spindle and the lower spindle are in transmission connection through a first belt; a driving mechanism is installed on the machine tool body, and the driving mechanism comprises a driving motor, a driving wheel, a driven wheel and a second belt, the driving wheel is connected to the output end of the driving motor and is controlled by the driving motor to rotate, the driven wheel is rotationally mounted on the machine tool body through a rotating shaft, and the second belt is wound on the driving wheel, the driven wheel and the lower main shaft; and an adjusting mechanism for automatically adjusting the tension of the second belt is further arranged on the machine tool body. The numerical control machine tool and the machining method thereof have the beneficial effects that the working efficiency is high, transmission is stable, the tensioning force of the transmission belt can be automatically adjusted, meanwhile, cooling is controllable, the cooling effect is good, the working temperature is controllable, and working is stable.

Owner:浙江赫科智能装备有限公司

A New Type of Thermally Stimulated Current Measuring Device

ActiveCN108760818BAvoid harmCooling rate is fast and controllableMaterial analysis by electric/magnetic meansTemperature control using electric meansThermal stimulationEngineering

The invention discloses a novel thermal stimulation current measuring device, belongs to the field of electric medium physical measurement and study and aims to solve the technical problems that a conventional thermal stimulation current measuring device is poor in testing result repeating stability, and liquid nitrogen can be easily leaked off in a vacuum cavity when being cooled in a testing process. The device is technically characterized in that a moveable electrode module, a semiconductor refrigeration piece and a heat exchanger are arranged inside a vacuum chamber, and measurement on thermal stimulation current can be achieved. The device has the advantages of being rapid in cooling velocity, controllable in cooling process, high in measurement precision, accurate in measurement result and simple to operate; liquid nitrogen is replaced by using the semiconductor refrigeration piece and water under a certain experiment condition, experiment cost can be reduced, and security can beimproved; the device has wide application prospects in the field of medium material testing.

Owner:HARBIN UNIV OF SCI & TECH

System for precisely controlling temperature change and heat treatment device

InactiveCN109595945APrecise control of operationControl operationMaintainance of heating chambersFurnace coolingEngineeringHeat treated

The invention discloses a system for precisely controlling the temperature change. The system comprises an air inlet mechanism, an air outlet mechanism, a heat exchange mechanism, a detecting mechanism and a control mechanism; the air inlet mechanism comprises multiple air inlet pipes, the air inlet pipes are connected with air inlets located on the different positions of a furnace body, each airinlet pipe is provided with a first valve, the air inlet mechanism further comprises a fan, the air outlet mechanism comprises at least one air outlet pipe, the air outlet pipe is connected with an air outlet of the furnace body, one end of the heat exchange mechanism is communicated with the air inlet mechanism, the other end of the heat exchange mechanism is communicated with the air outlet mechanism, the detecting mechanism comprises at least one first temperature sensor, the first temperature sensors are used for detecting the temperature in the furnace body, and the control mechanism receives the information of the detecting mechanism and controls the air inlet mechanism, the air outlet mechanism and the heat exchange mechanism to run. The invention further provides a heat treatment device using the above system. The system and the device can precisely control the cooling rate.

Owner:ADVANCED FOR MATERIALS & EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com