A three-stage aluminum profile quenching cooling device and cooling method

A cooling method and technology of cooling device, which are applied in the direction of quenching device, furnace type, furnace, etc., can solve the problems of inability to accurately control the cooling rate of aluminum profiles of different materials and wall thicknesses, and the quenching deformation of aluminum alloy profiles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A three-stage quenching and cooling method for aluminum profiles, comprising the following steps:

[0027] Step 1, the first section A is cooled by strong water mist;

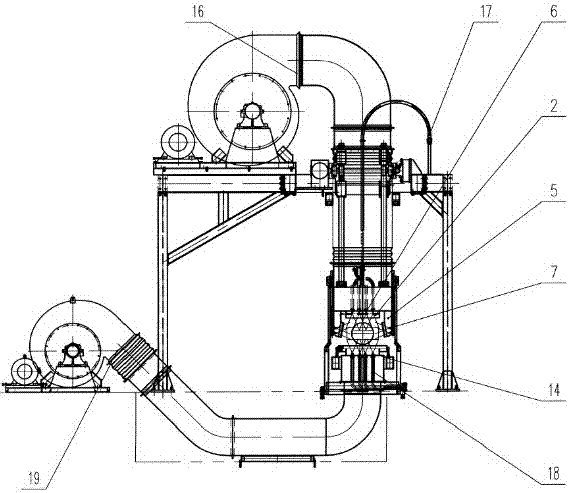

[0028] When the aluminum profile passes through the first section A, the upper air nozzle 2 and the side air nozzle 5 of the upper front spraying device 1 pass through the upper air cooling system 16, the lower air nozzle 11 of the lower front spraying device 15 passes through the lower air cooling system 19, and the upper air nozzle 11 passes through the lower air cooling system 19. The upper nozzle 6, the side nozzle 7, and the atomizing nozzle 3 of the front spraying device 1 pass through the upper water system 17, and the lower nozzle 14 and the atomizing nozzle 3 of the lower front spraying device 15 pass through the lower water system 18 to strengthen the aluminum profile. Water mist quenching and cooling;

[0029] Step 2, the second section B is cooled by strong water mist;

[0030] When the alu...

Embodiment 2

[0036] A three-stage quenching and cooling device for aluminum profiles, including three-stage cooling methods, the first stage A is cooled by strong wind + water mist, the second stage B is cooled by strong water mist, and the third stage C is cooled by strong wind.

[0037] This three-stage quenching and cooling device for aluminum profiles is divided into three stages to achieve gradual cooling; the first stage A has functions including strong wind cooling, gas mist quenching and water mist quenching, and the second stage B has functions including strong wind cooling and water mist quenching. Fog quenching, the third section C has the function of strong wind cooling, the flow of wind and water can be adjusted proportionally, the strong wind cooling is to cool the aluminum profile through the fan, air duct and air nozzle, and the air volume can be adjusted by the air valve and the fan Adjustment; the gas mist quenching is to cool the aluminum profile through the gas valve and...

Embodiment 3

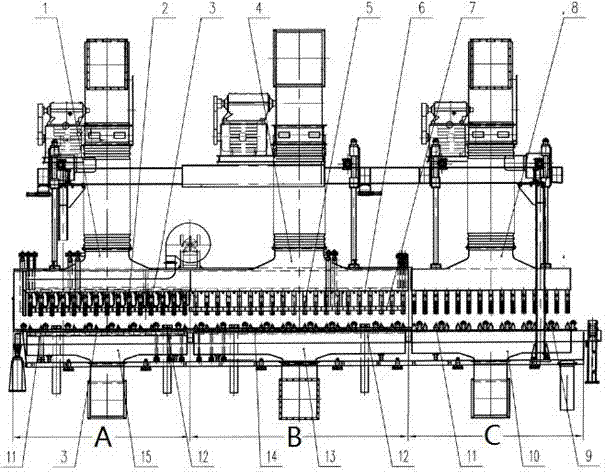

[0039] Such as figure 1 and figure 2 As shown, the first section A includes the upper front sprinkler 1 and the lower front sprinkler 15, the second section B includes the upper middle sprinkler 4 and the lower middle sprinkler 13, and the third section C includes the upper rear air-cooled Device 8 and lower rear air cooling device 10;

[0040] The upper front spray device 1, the upper middle spray device 4, and the upper rear air cooling device 8 are respectively arranged with an upper air nozzle 2 and a side air nozzle 5, and the upper air nozzle 2 and the side air nozzle 5 realize strong wind cooling and cooling through the upper air cooling system 16. proportional adjustment;

[0041] The upper front spray device 1 and the upper middle spray device 4 are also equipped with an upper nozzle 6 and a side nozzle 7. The upper nozzle 6 and the side nozzle 7 adjust the water pressure and flow rate through the upper water system 17 to realize water mist quenching. Features;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com