Numerical control machine tool and machining method thereof

A CNC machine tool and bed technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problem of unsatisfied cooling and cooling speed requirements and temperature accuracy control, automatic adjustment of transmission belt tension, The temperature control effect of the temperature control device is poor, so as to achieve the effect of less water resource utilization, good cooling effect and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

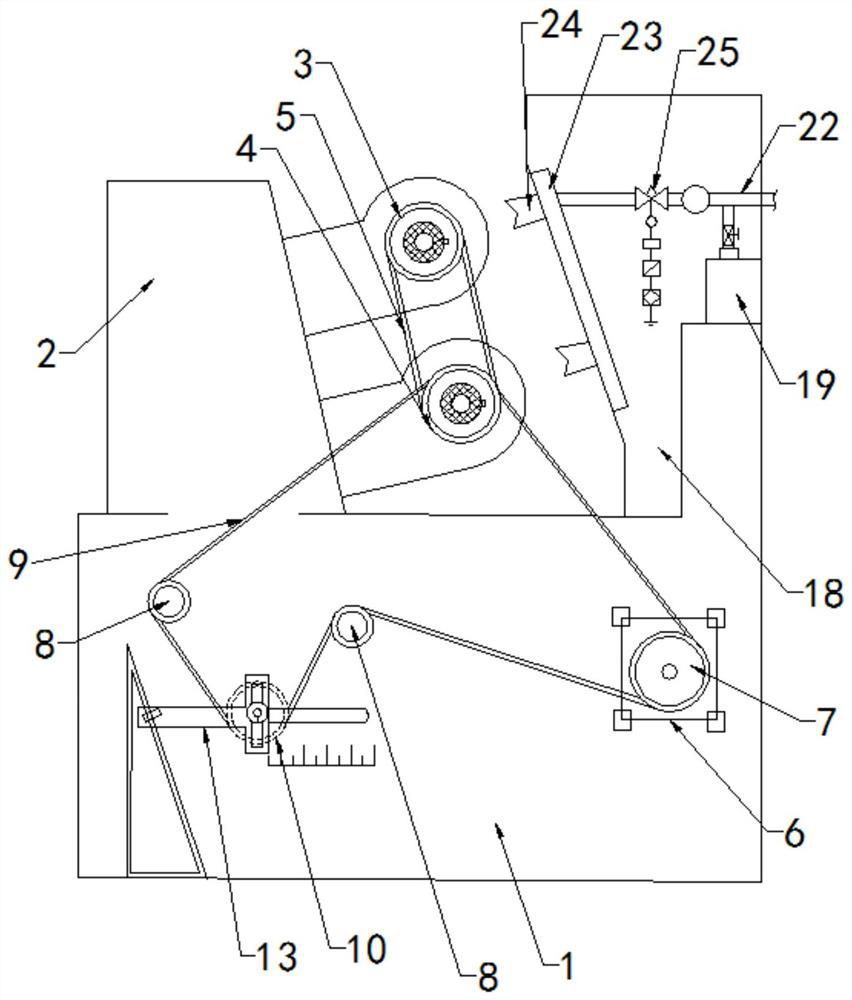

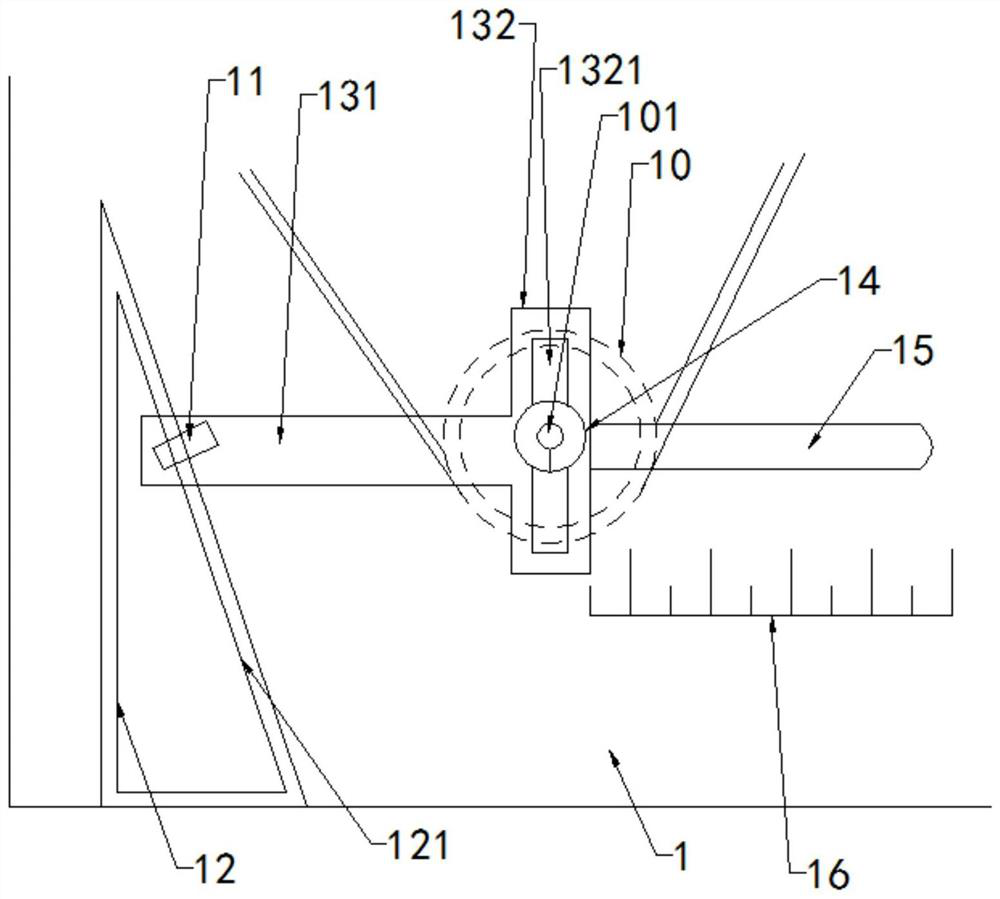

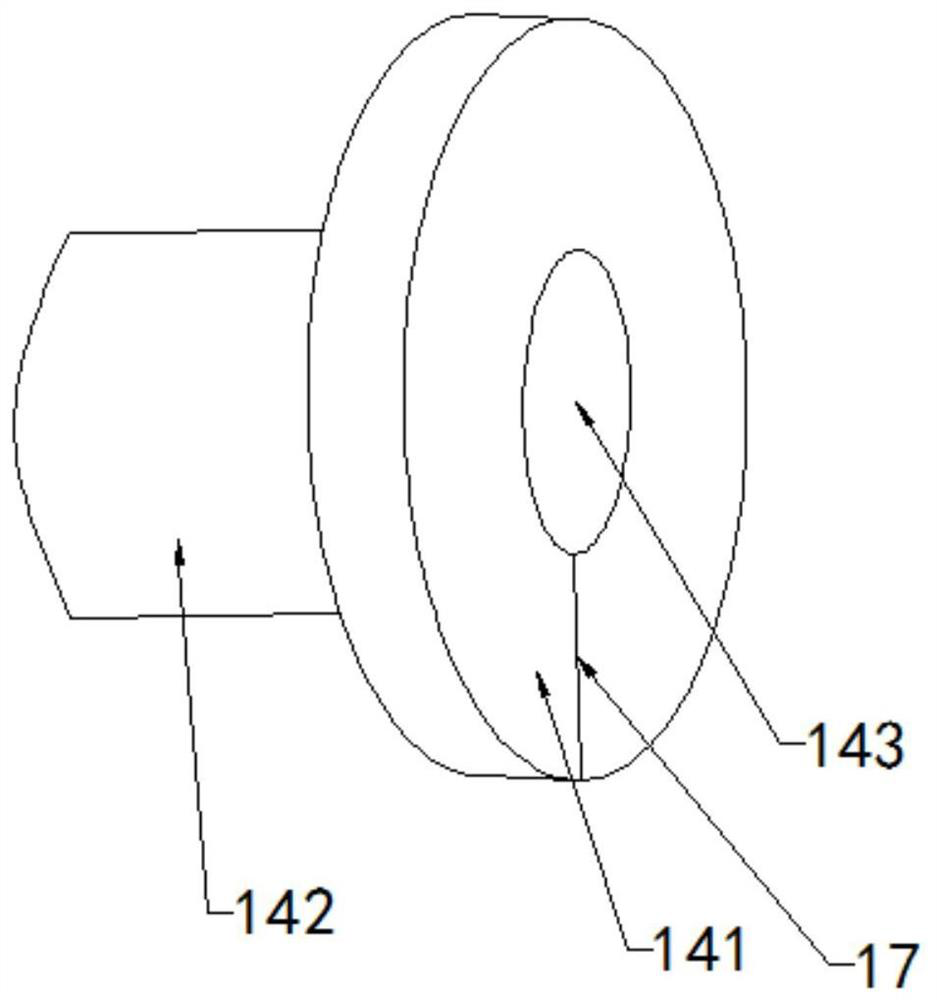

[0029] like Figure 1 to Figure 3 As shown, the present invention discloses a numerically controlled machine tool. In a specific embodiment of the present invention, it includes a machine bed 1, a headstock 2, an upper spindle 3 and a lower spindle 4 arranged on the machine bed 1. The upper spindle 3 The structure is the same and symmetrical as the lower main shaft 4. The upper main shaft 3 and the lower main shaft 4 are connected by a first belt 5. The first belt is a toothed belt to ensure the stability of the connection between the upper main shaft and the lower main shaft. , a drive mechanism is installed on the bed 1, and the drive mechanism includes a drive motor 6, a driving wheel 7 connected to the output end of the drive motor 6 and controlled by the drive motor 6 to rotate, and rotated and installed on the bed 1 through a rotating shaft 101. The upper driven wheel 8 and the second belt 9 arranged on the driving wheel 7, the driven wheel 8 and the lower main shaft 4, ...

Embodiment 2

[0035] like Figure 4 to Figure 6 As shown in the figure, the difference between this embodiment and the above-mentioned embodiment is that: in this embodiment, the bed 1 is provided with a mounting frame 18, and an automatic cooling device is provided on the mounting frame 18, and the automatic cooling The device includes a water tank 19, a water delivery pipe 20, an atomizer 21, an air inlet pipe 22 and a spray pipe 23. The water tank 19 and the spray pipe 23 are both fixed on the mounting frame 18. The cooling liquid is stored in the water tank. The water tank 19 is communicated with the air inlet pipe 22 through the water delivery pipe 20. One end of the air inlet pipe 22 is connected to the cold air and the other end is communicated with the jet pipe 23. The spray head 24, the atomizer 21 is installed in the water delivery pipe 20, the atomizer atomizes and transports the cooling liquid, and in this embodiment, the air inlet pipe is also provided with a pump body that dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com