Patents

Literature

46results about How to "Precise frequency control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Current-adjustable and PWM flicker controlled constant-current driving circuit and control method

ActiveCN111629490AAccurate outputConstant controlElectrical apparatusSemiconductor lamp usageHemt circuitsControl theory

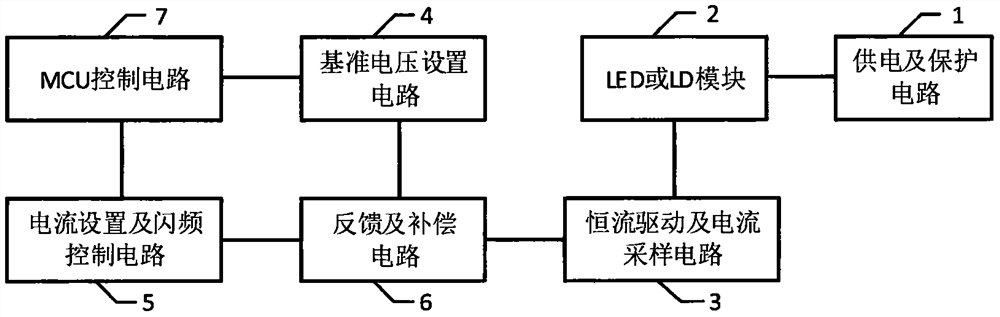

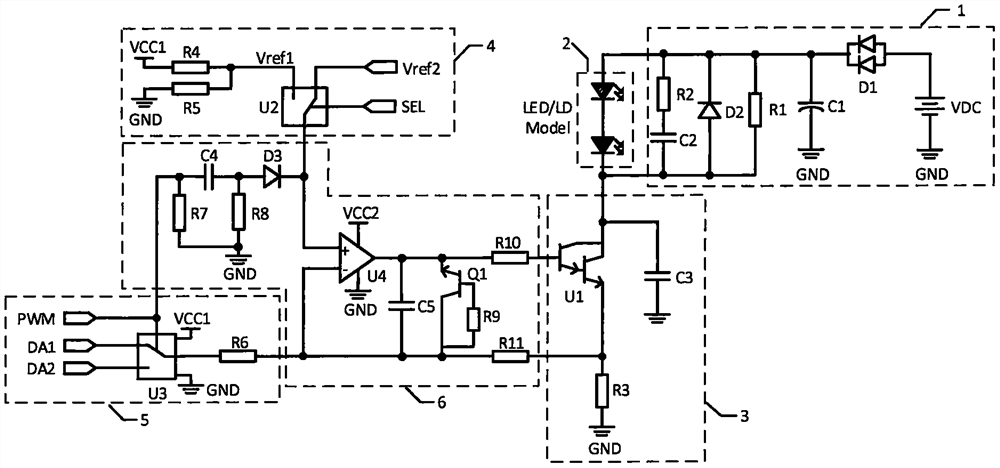

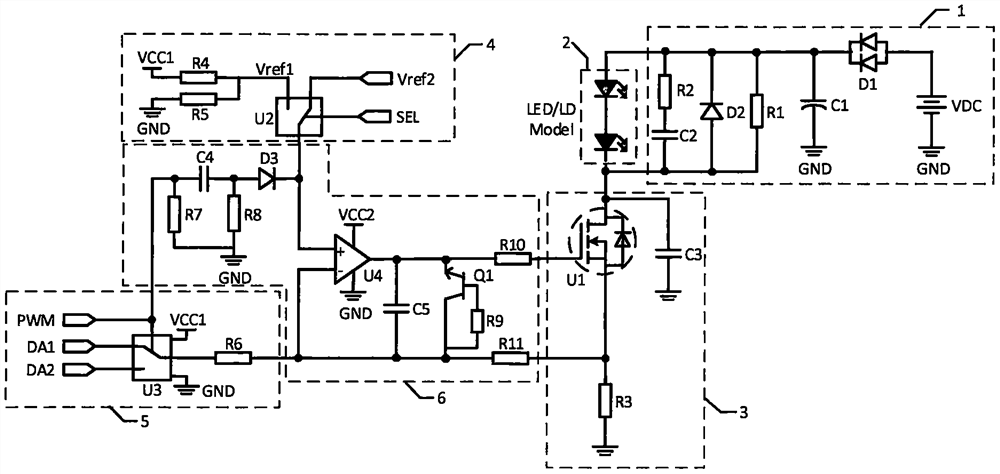

The invention relates to a current-adjustable and PWM flicker control constant-current driving circuit, which comprises a power supply and protection circuit (1), an LED or LD module (2), an MCU control circuit (7), a constant-current driving and current sampling circuit (3), a reference voltage setting circuit (4), a current setting and flicker control circuit (5) and a feedback and compensationcircuit (6). The constant-current driving and current sampling circuit is used for realizing adjustment of current output. The reference voltage setting circuit is used for setting reference voltageof the output current. The current setting and flicker control circuit is used for setting a pulse or a constant current value and setting frequency and pulse width. The feedback and compensation circuit realizes current feedback and dynamic compensation of the system, achieves the purpose of stabilizing current output, and has the effects of improving the rising speed of output current and widening the width of the output current. According to the invention, the constant current or pulse current of the LED or LD module can be adjusted, PWM adjustment and flicker control of the pulse current can be carried out, and the requirement of constant current driving in an LED light source and an LD laser system in a machine vision system can be met.

Owner:CASI VISION TECH (LUOYANG) CO LTD

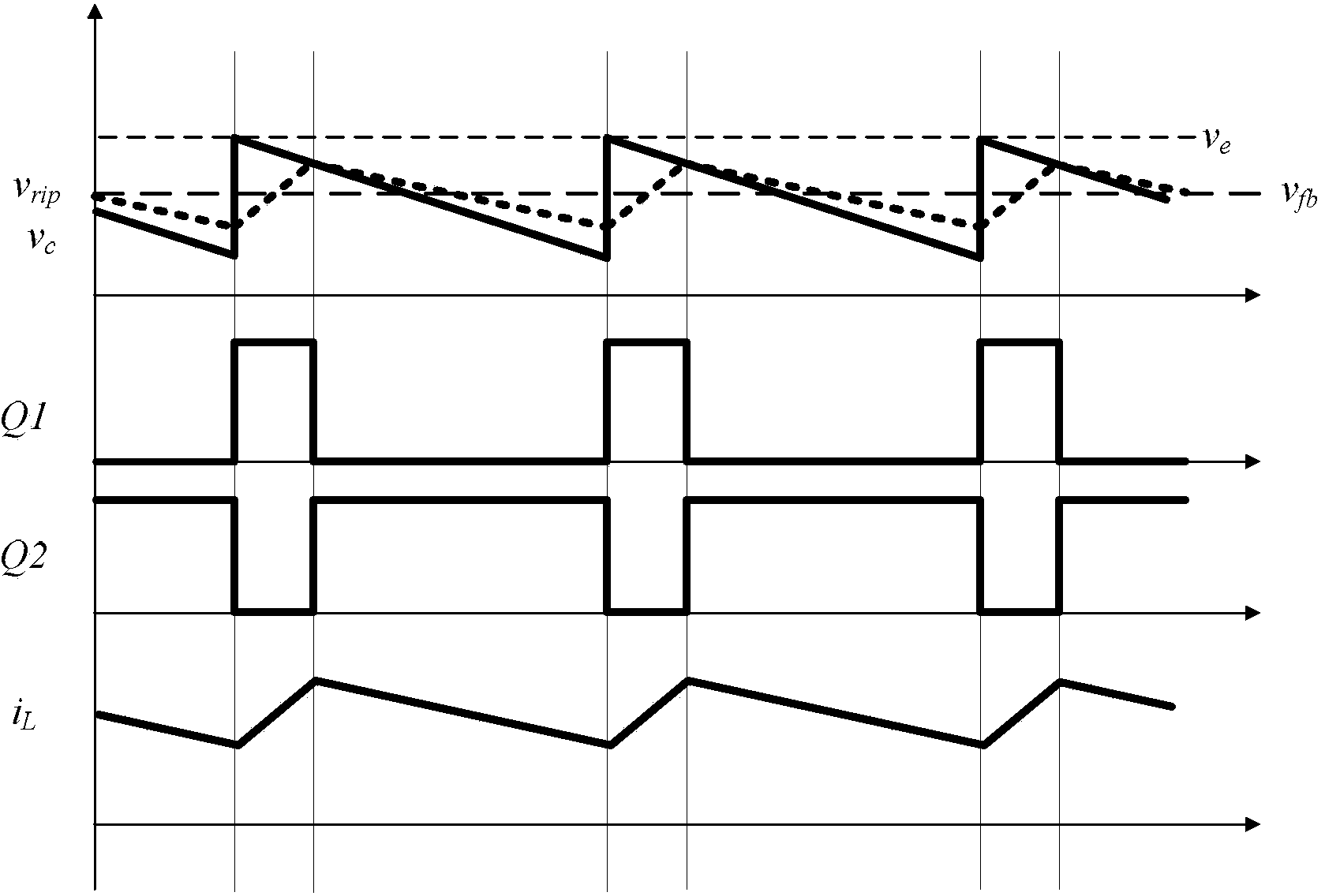

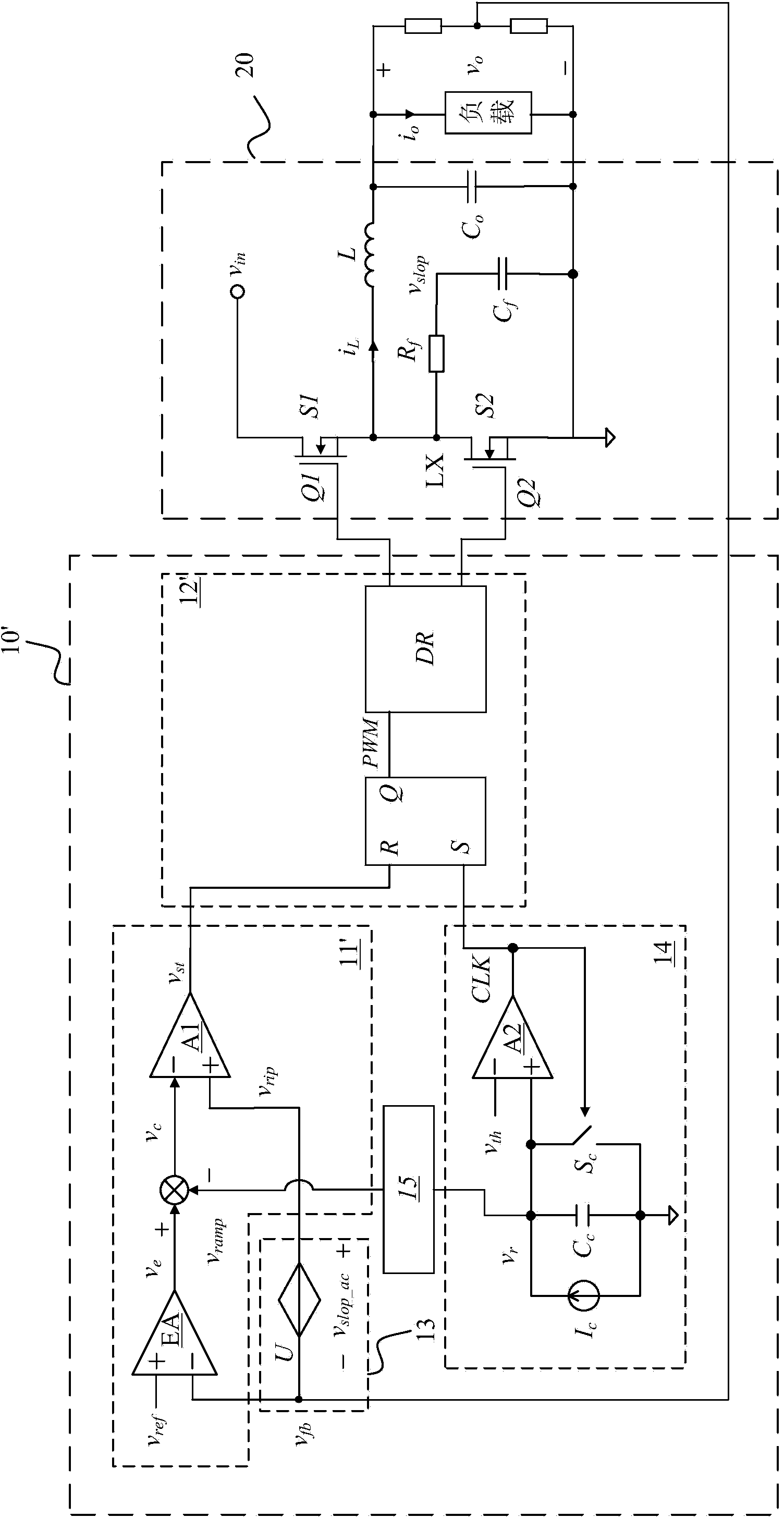

Control circuit, switching power supply and control method

InactiveCN104079167AHigh control precisionPrecise Frequency ControlDc-dc conversionElectric variable regulationVoltage referenceFixed frequency

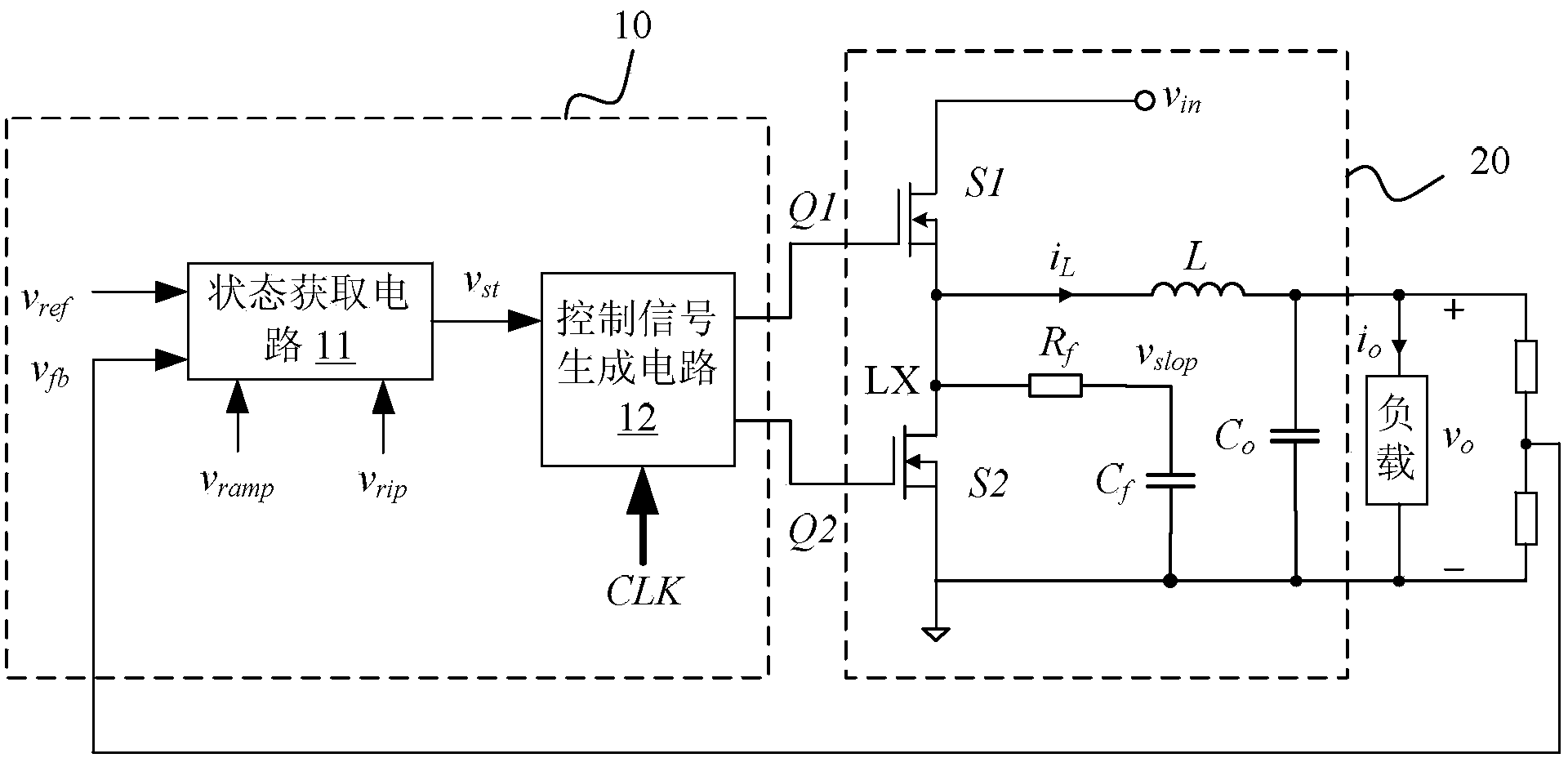

The invention discloses a control circuit, a switching power supply and a control method. The control circuit is used for controlling a switching converter and comprises a status acquisition circuit and a control signal generation circuit. The status acquisition circuit is used for generating an error amplifying signal according to a feedback voltage and a reference voltage, carrying out slope compensation on the error amplifying signal through a slope compensation signal with a preset frequency, and comparing the error amplifying signal which has undergone slope compensation with a voltage ripple to output a status signal, wherein the voltage ripple changes synchronously with the current of an energy storage element of the switching converter. The control signal generation circuit is used for outputting a switching control signal according to the status signal to control the switching converter, wherein the switching control signal has the preset frequency. By carrying out fixed-frequency control with the voltage ripple changing synchronously with the current of the energy storage element of the switching converter as the parameter, the control accuracy of the switching converter is improved, and frequency control is more accurate.

Owner:SILERGY SEMICON TECH (HANGZHOU) CO LTD

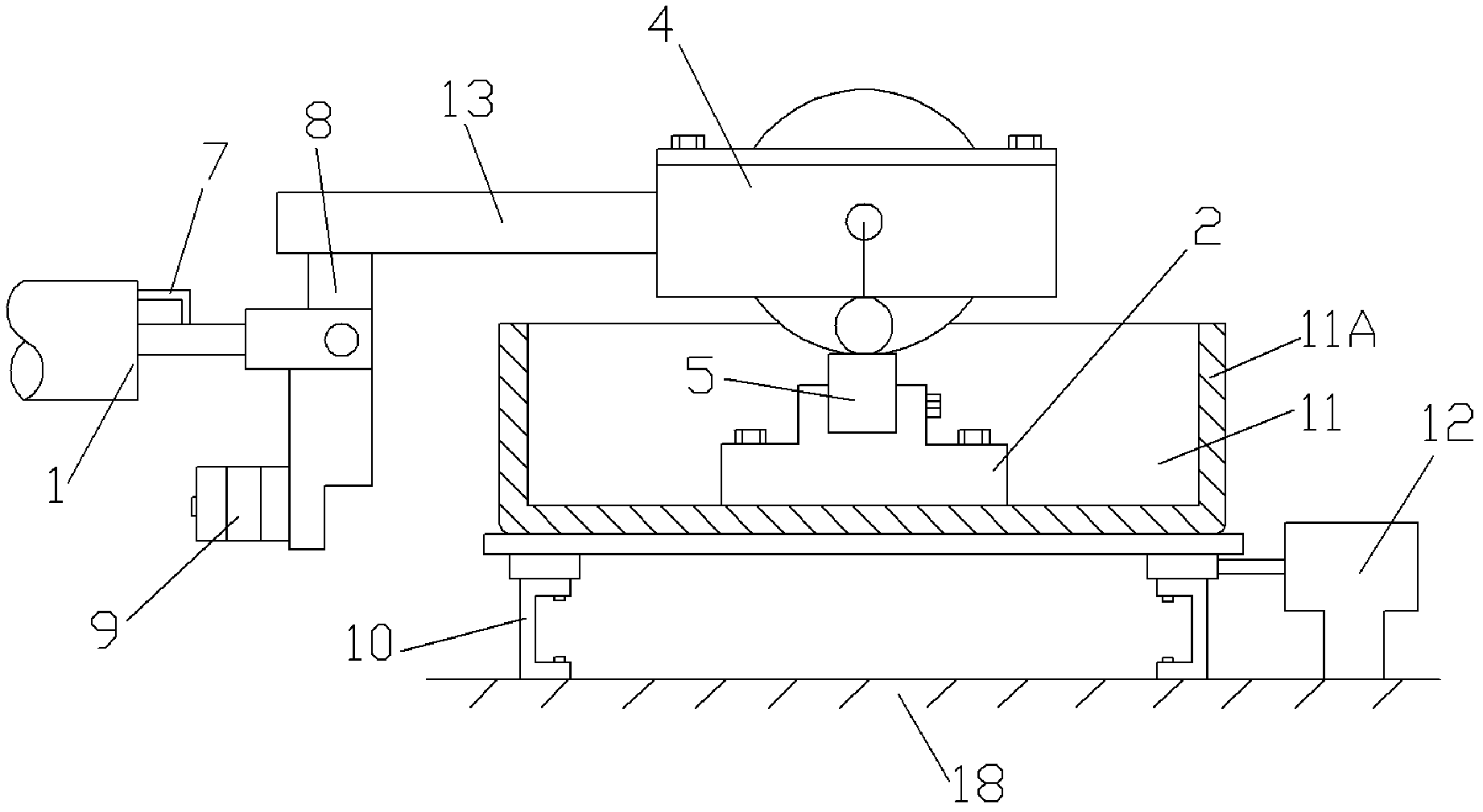

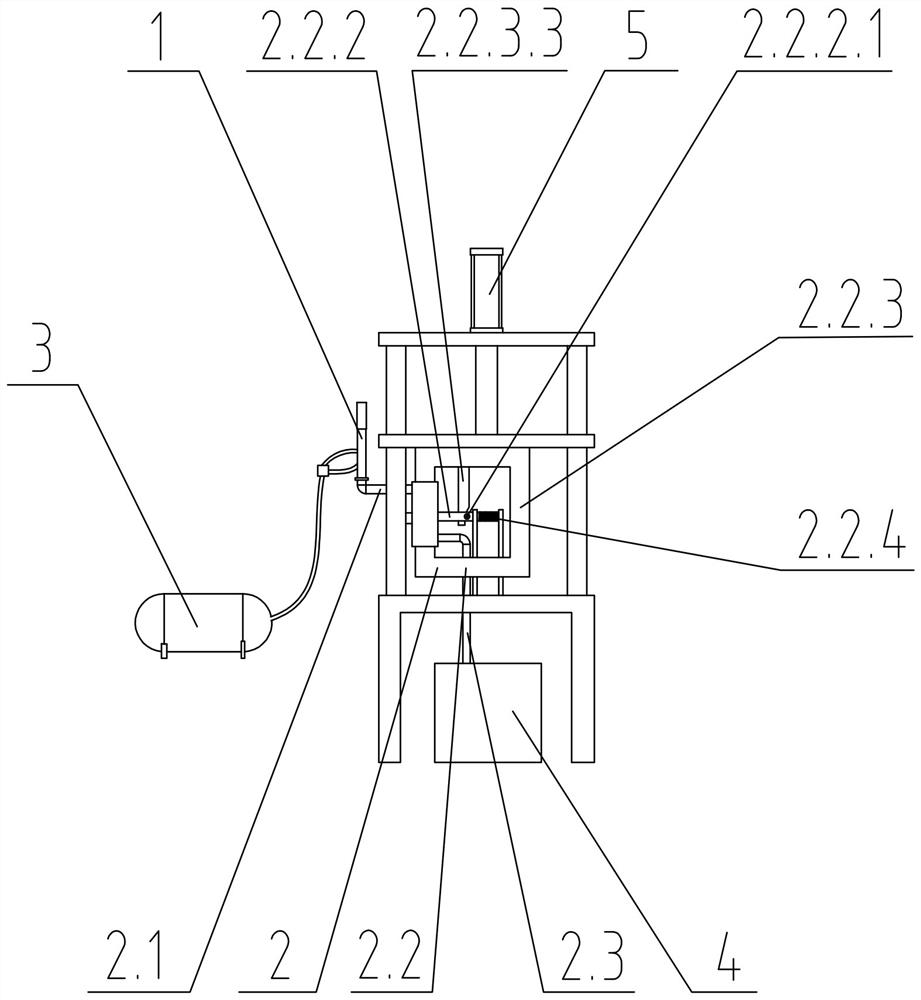

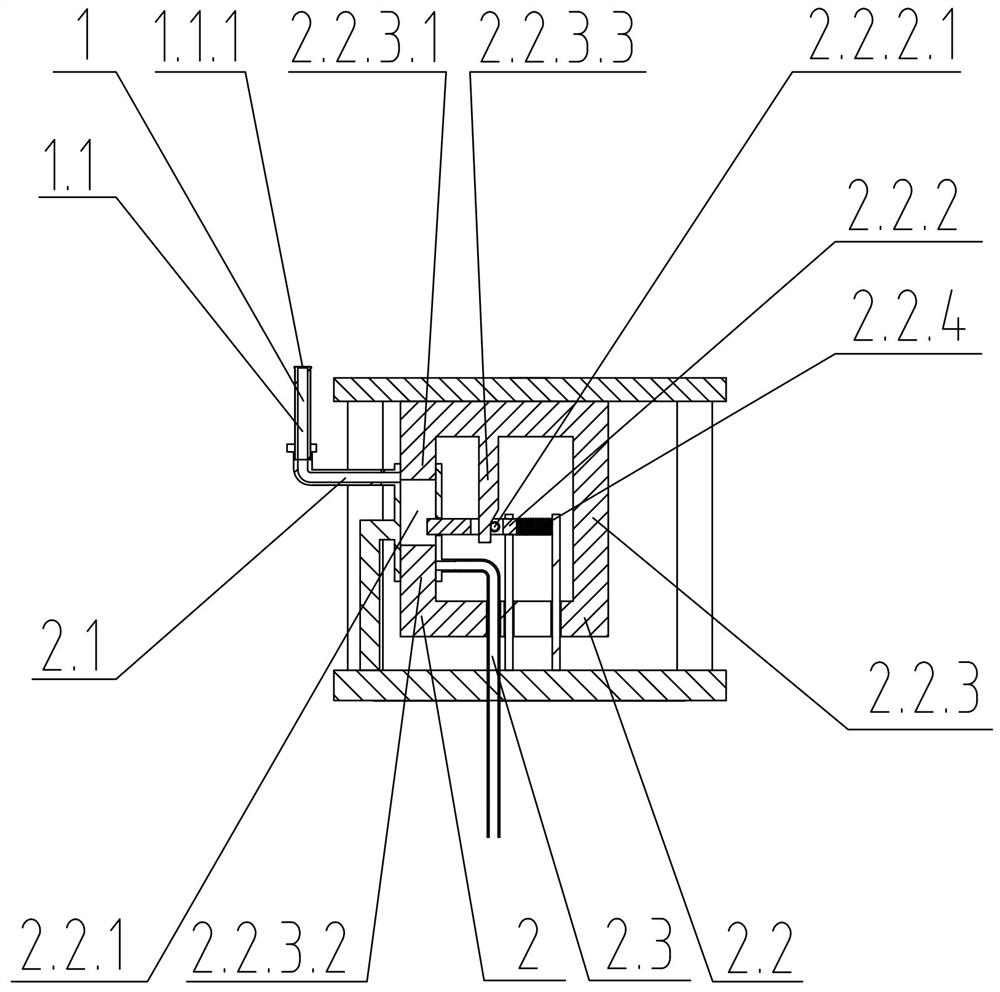

Tangential final-motion frictional wear test equipment

InactiveCN102590002AAchieve decouplingRealize the application of vertical loadInvestigating abrasion/wear resistanceControl systemData acquisition

The invention discloses tangential final-motion frictional wear test equipment. The equipment is characterized in that a lateral hydraulic piston connected with a data acquisition and control system is connected with a hinged shaft at the middle upper part of a vertical connecting rod; the upper end of the connecting rod is connected with one side of an upper test piece chuck through a cross bar; the other side of the upper test piece chuck is connected with a tangential displacement sensor fixed on the side wall of an experiment medium cavity; the upper test piece chuck is used for clamping a spherical test piece; a lower test piece chuck for clamping a plane test piece is arranged right below the upper test piece chuck; the lower test piece chuck is fixed at the bottom of the experiment medium cavity; the bottom of the experiment medium cavity is arrange on two longitudinal supporting rods; and a deformation sensor is arranged between the top of the longitudinal supporting rods and the bottom of the experiment medium cavity. The tangential final-motion frictional wear test equipment can effectively simulate the tangential final-motion friction and has the advantages of simple structure and high test precision, is convenient to maintain, can carry out a final-motion frictional test under the medium conditions, such as controllable high temperature, lubrication and liquid, and can provide more accurate and reliable test bases for designing, manufacturing and maintaining relevant parts.

Owner:SOUTHWEST JIAOTONG UNIV

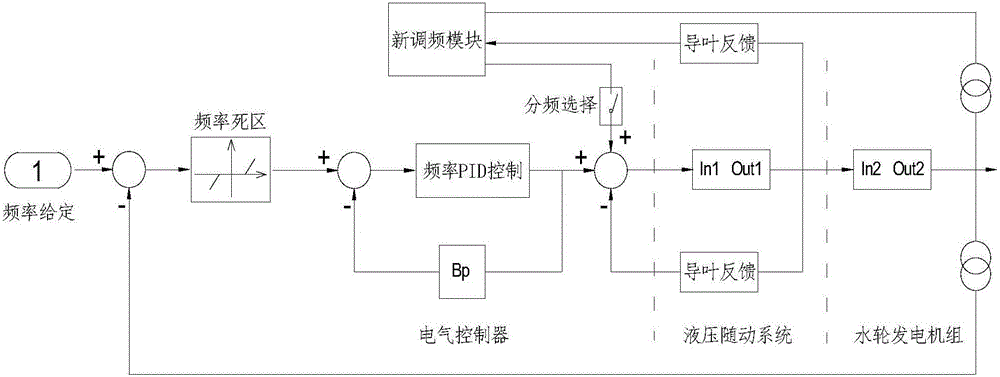

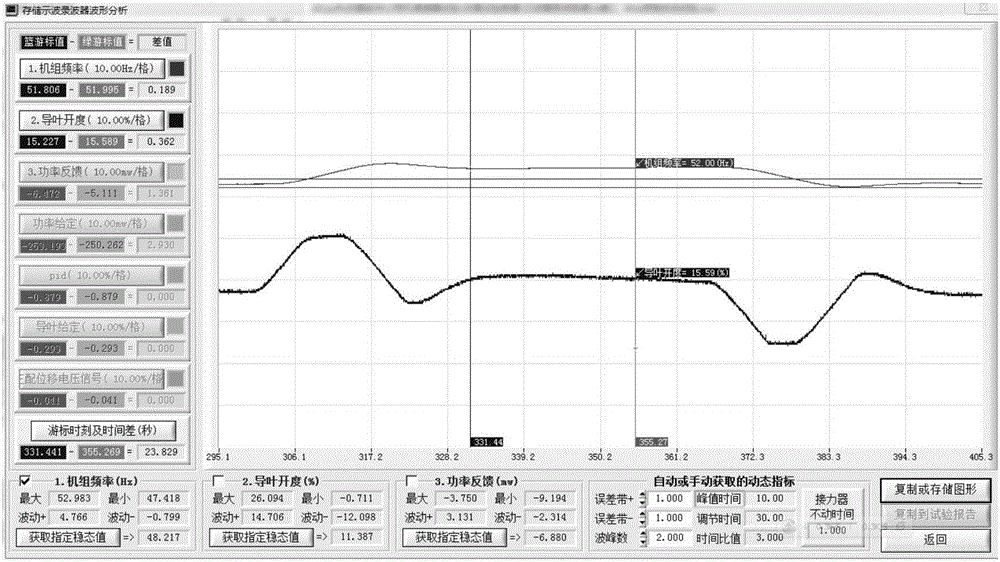

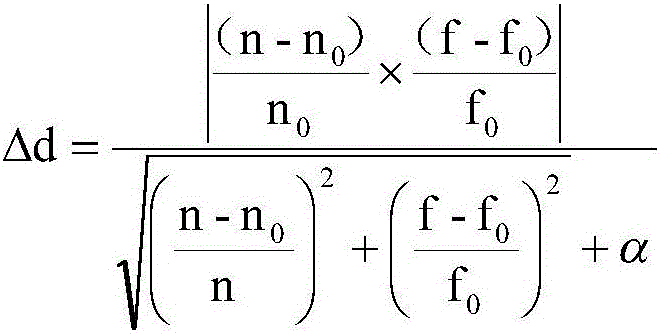

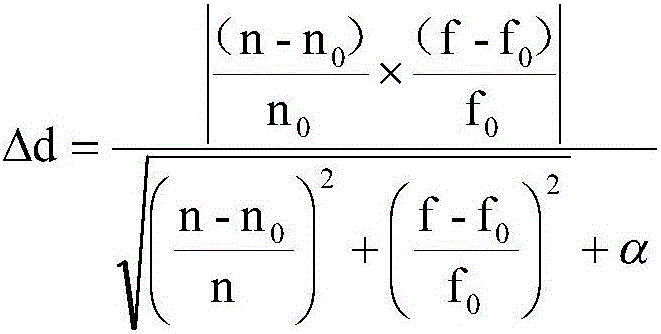

Control method for frequency regulation of electric power isolated network system

ActiveCN105743107ASimple formulaClear formulaPower oscillations reduction/preventionPower qualityInstability

The invention discloses a control method for frequency regulation of an electric power isolated network system. The control method is characterized by comprising the following steps of step 1, setting the permanent rotating-speed difference coefficient bp, PID parameters, frequency modulation dead zone 0.05Hz, and a frequency range from minus and plus 0.05Hz to minus and plus <theta>Hz for retrieving a frequency modulation module according to power grid requirements, wherein <theta> is a positive number greater than 0.05; step 2, detecting the current unit frequency by a speed regulator; step 3, obtaining a difference value <delta>f between the current unit frequency and a rated frequency 50Hz; and step 4, performing regulation according to the numerical value range of the frequency difference <delta>f. By adoption of the method, the problems of high frequency control error, low precision and instability of the electric power system, particularly the isolated network system can be solved; therefore, accurate and stable control of the power grid frequency is realized; the electric energy quality of the power system is ensured; power grid accident extension is prevented; and rapid recovery of the power grid in faults can be realized.

Owner:NANJING NARI GROUP CORP +1

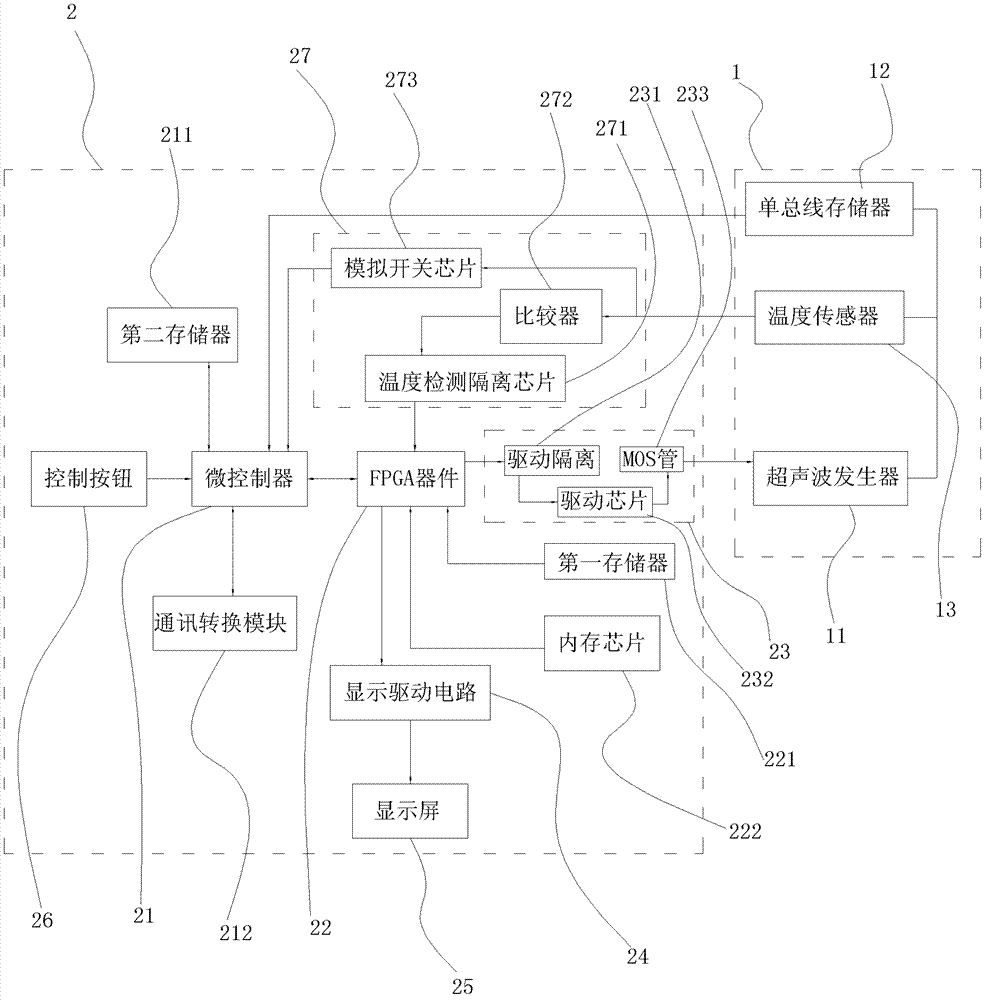

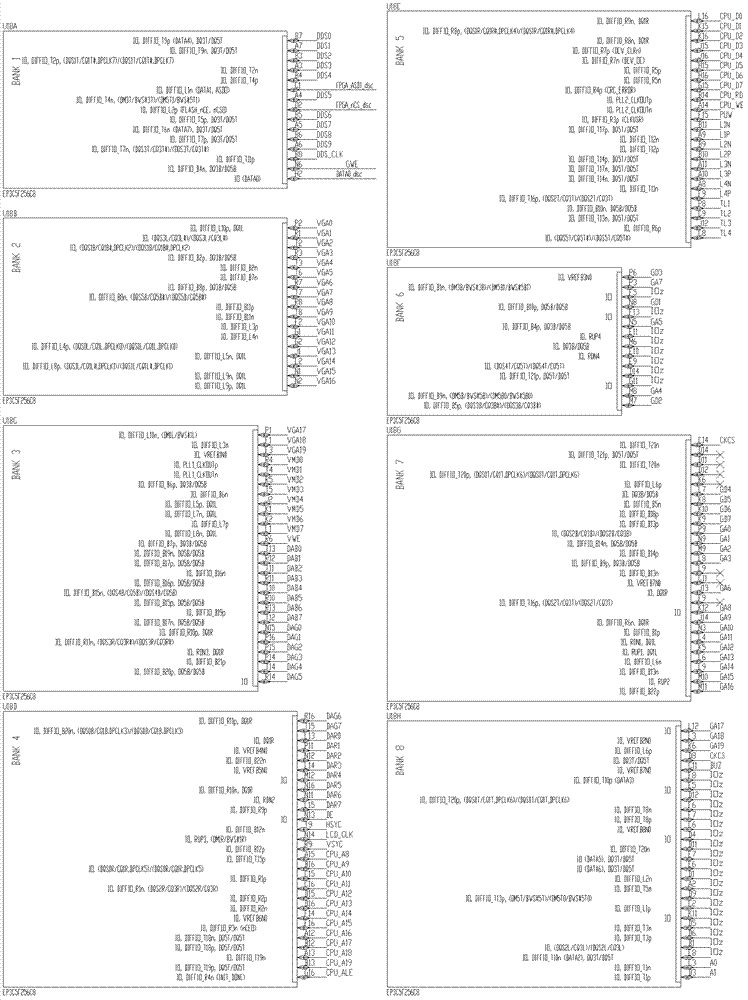

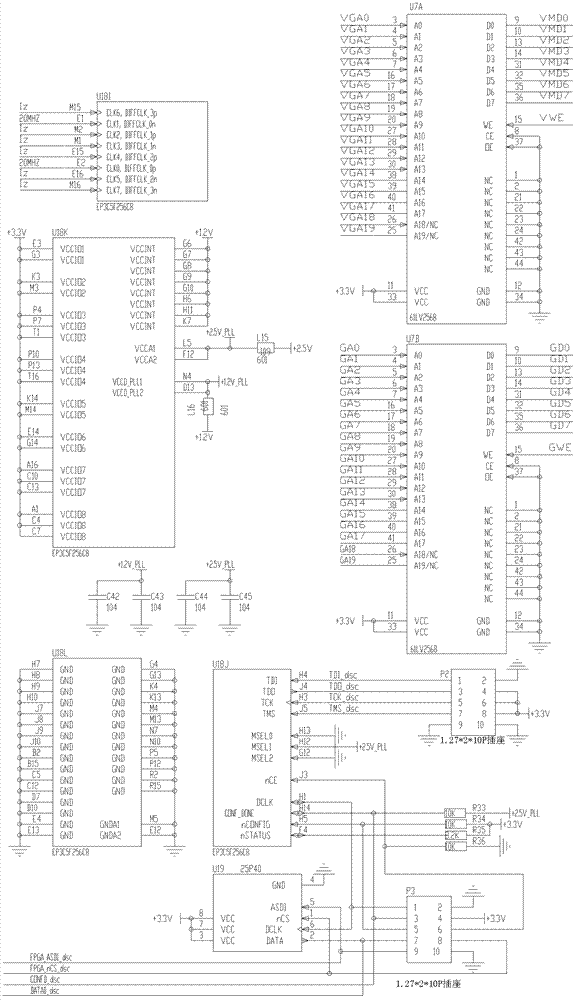

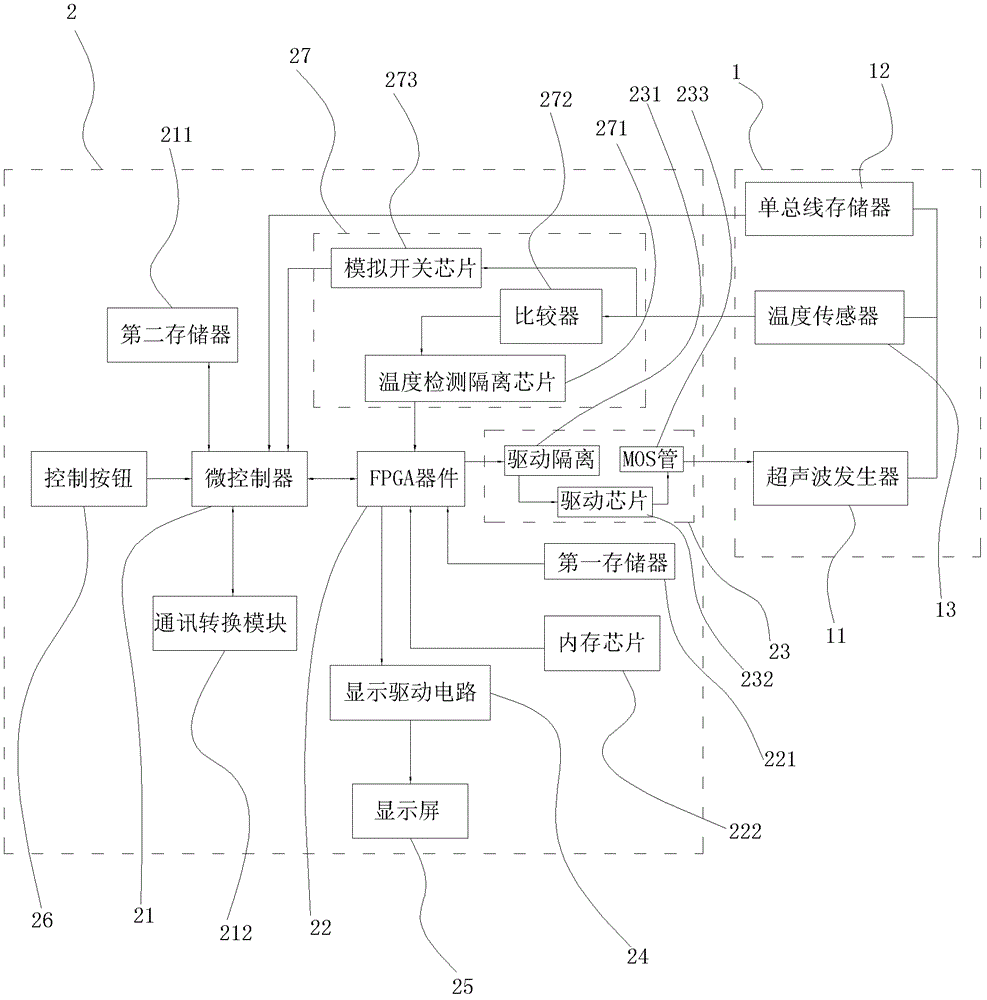

Ultrasonic probe with recognition function and ultrasonic therapy device

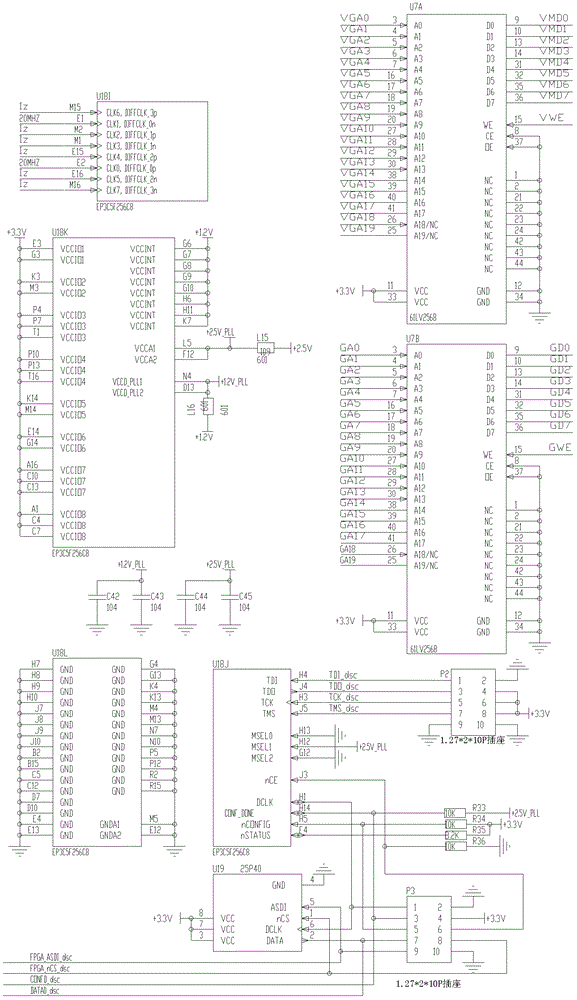

ActiveCN103083829APrecise frequency controlPrecise Control of Duty CycleUltrasound therapyMicrocontrollerSonification

The invention discloses an ultrasonic probe with a recognition function and an ultrasonic therapy device. The ultrasonic probe with the recognition function comprises a probe body and an ultrasonic generator which is arranged in the probe body. A unibus memory in series connection with the ultrasonic generator is further arranged in the probe body, and probe identification codes are arranged in the unibus memory. According to the ultrasonic probe with the recognition function and the ultrasonic therapy device, a microcontroller and a field programmable gate array (FPGA) device can be utilized for generating drive signals to accurately control the frequency, the duty ratio, the number of pulses and other parameters of the ultrasonic probe; the microcontroller enables the ultrasonic probe to have an automatic probe identification function through the probe identification codes stored in the unibus memory in the probe body so that the ultrasonic probe can automatically match the probe emission parameters, and therefore the emission efficiency of probe operation is enabled to be improved at an optimum resonant frequency point; the microcontroller can detect the temperature of the probe body and realize on-line fault automatic detection; and due to the fact that a category D amplifier is adopted in a driving circuit, compared with an existing ultrasonic treatment instrument in the same type, the power consumption of the ultrasonic therapy device is lowered by 40%.

Owner:SHENZHEN WELL D MEDICAL ELECTRONICS

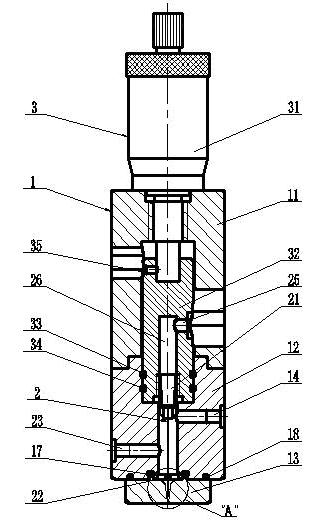

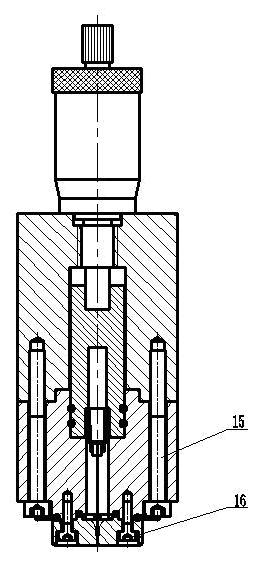

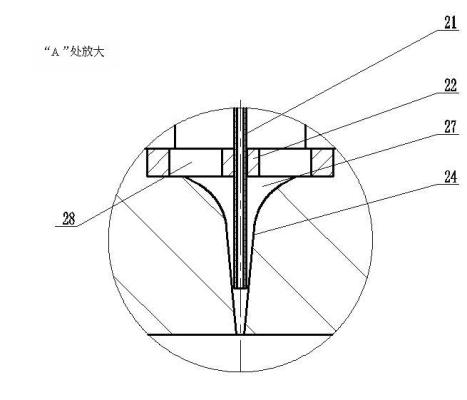

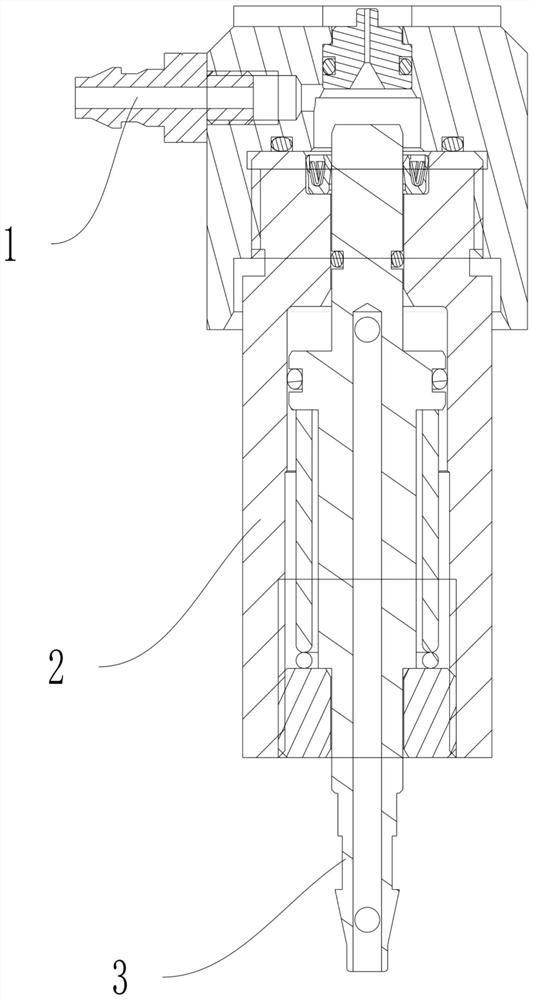

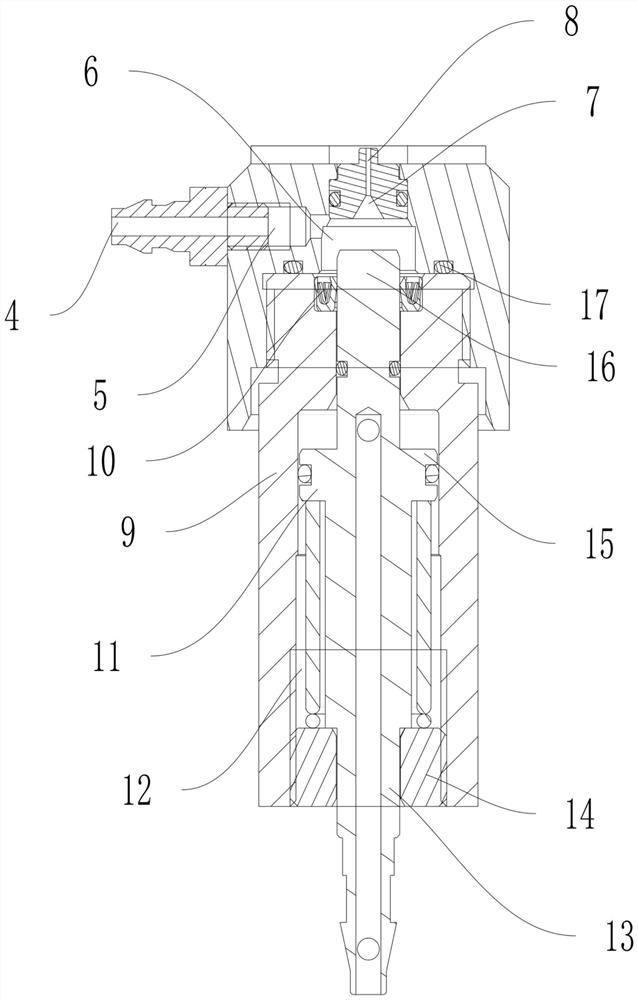

Double-fluid injector

ActiveCN102069050ASimple structureEasy to operateSpray nozzlesLiquid spraying apparatusChemical industryEngineering

The invention relates to a double-fluid injector, which comprises a valve body, an injection mechanism and a travel adjusting mechanism, wherein the valve body consists of an upper valve body and a lower valve body which are fixedly connected to the upper end and the lower end of a middle valve body respectively; the travel adjusting mechanism is arranged in a cavity formed between the middle valve body and the upper valve body and is a micrometer head travel adjusting mechanism; and the injection mechanism is arranged in a cavity formed among the middle valve body, the lower valve body and the travel adjusting mechanism and is a double-fluid injection mechanism. The flow forms of double fluids in a mixing cavity are controlled by adjusting the flows and pressures of input gas and liquid,so that liquid is sprayed from a nozzle on the lower valve body in dot, line and mist forms. The double-fluid injector has a simple structure, long service life, high gas and liquid controllability, high injection accuracy and high working frequency, and can be applied to multi-fluid injection processes in preparation of semiconductor membranes, preparation of composite materials, electronic encapsulating, (MENS) systems, ink jet, spraying, lubrication, powder metallurgy, food processing, biomedicine, welding, rapid prototyping manufacturing, combustion, engines, chemical industry and the like.

Owner:SHANGHAI UNIV

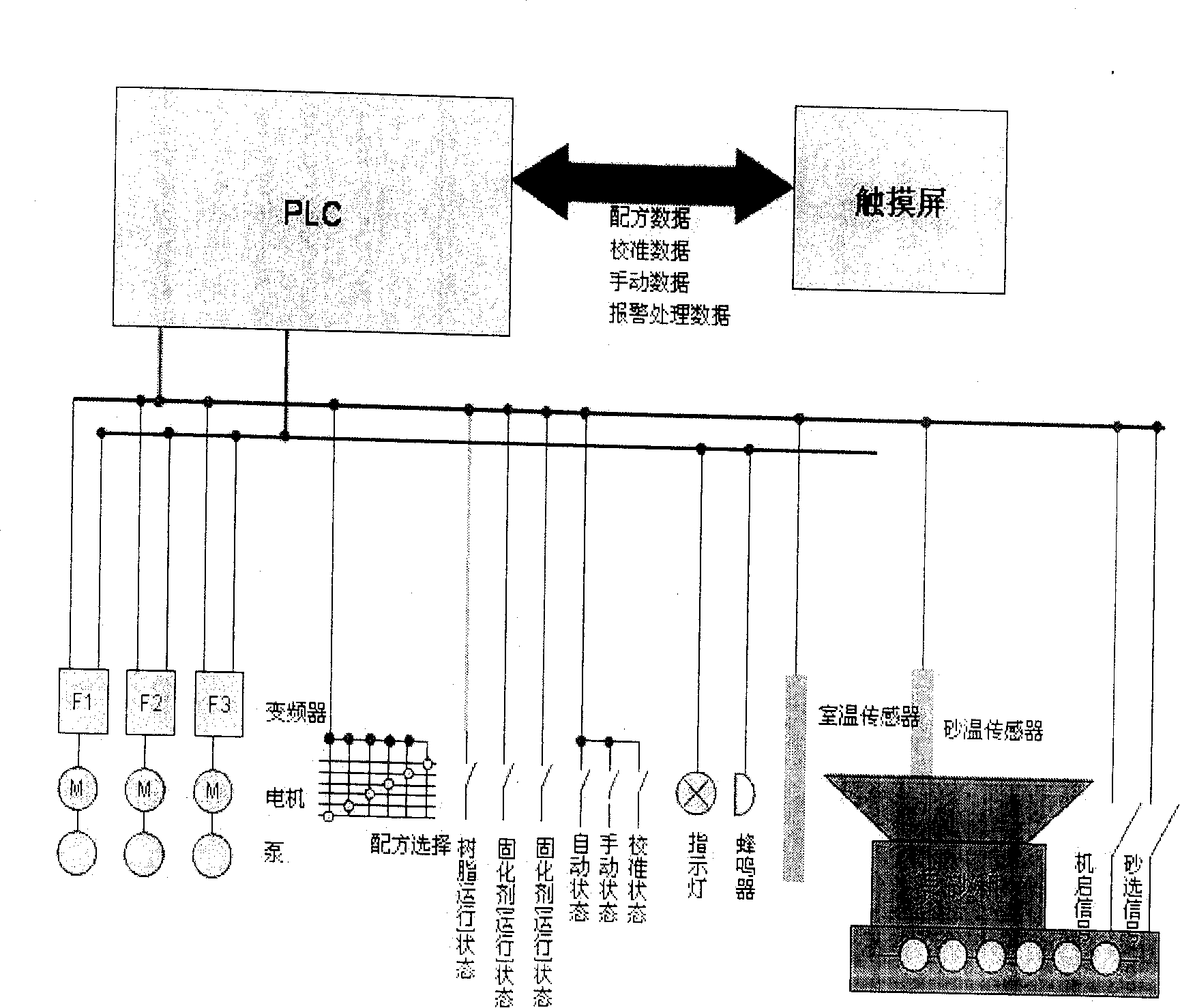

Intelligent type sand mulling control method

InactiveCN101081427AControl the number of additionsAutomatic calculation of added quantityMould controlling devicesSpecial data processing applicationsLow speedMathematical model

The present invention provides one kind of intelligent sand mixing controlling method. The key point of the present invention includes establishing the mathematic model of the relation among sand temperature, facing sand / back sand amount, demolding time, and the amount of fast curing agent and slow curing agent; calculating the amount of curing agent and calculating the rotation speed of conveying pump. The present invention adopts mathematic model and curve fitting technology in fitting the nonlinear relation of pump flow rate, has the active effects of accurate material compounding, saving material and raised product quality.

Owner:SHENYANG XUNTIAN TECH

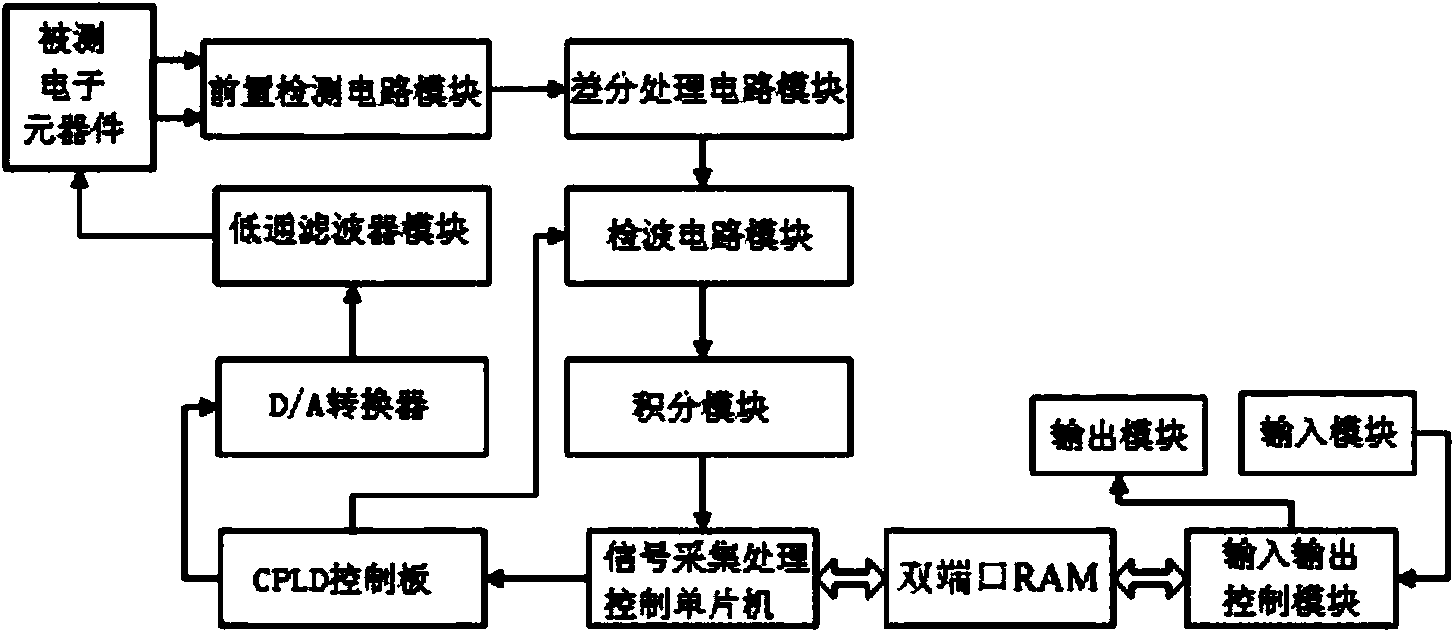

RLC measuring instrument and measuring method

InactiveCN104142430AImprove waveform qualityLarge measuring rangeResistance/reactance/impedencePhase noiseMeasuring instrument

The invention relates to an RLC measuring instrument. The CPLD technology is adopted for replacing a digital circuit to generate sine detection signals, chip resources on a CPLD development board are rich, PLLs are contained in the CPLD development board, and the frequency can be multiplied and divided conveniently. The RLC measuring instrument comprises a storage unit, a ROM table macroblock can be directly called, an SOPC can be used as a kernel, high-frequency test signals can be obtained conveniently, and the waveform quality of the sine detection signals can be improved. The invention further relates to a measuring method based on the RLC measuring instrument. The direct digital frequency synthesis technique is adopted, the frequency and the phase of the output sine detection signals can be accurately controlled, and meanwhile, the measuring instrument has the advantages that frequency switching time is short, the frequency resolution is high, the phase is changed continuously, phase noise and drifting are low, and integration and adjustment are easy.

Owner:YANCHENG INST OF TECH

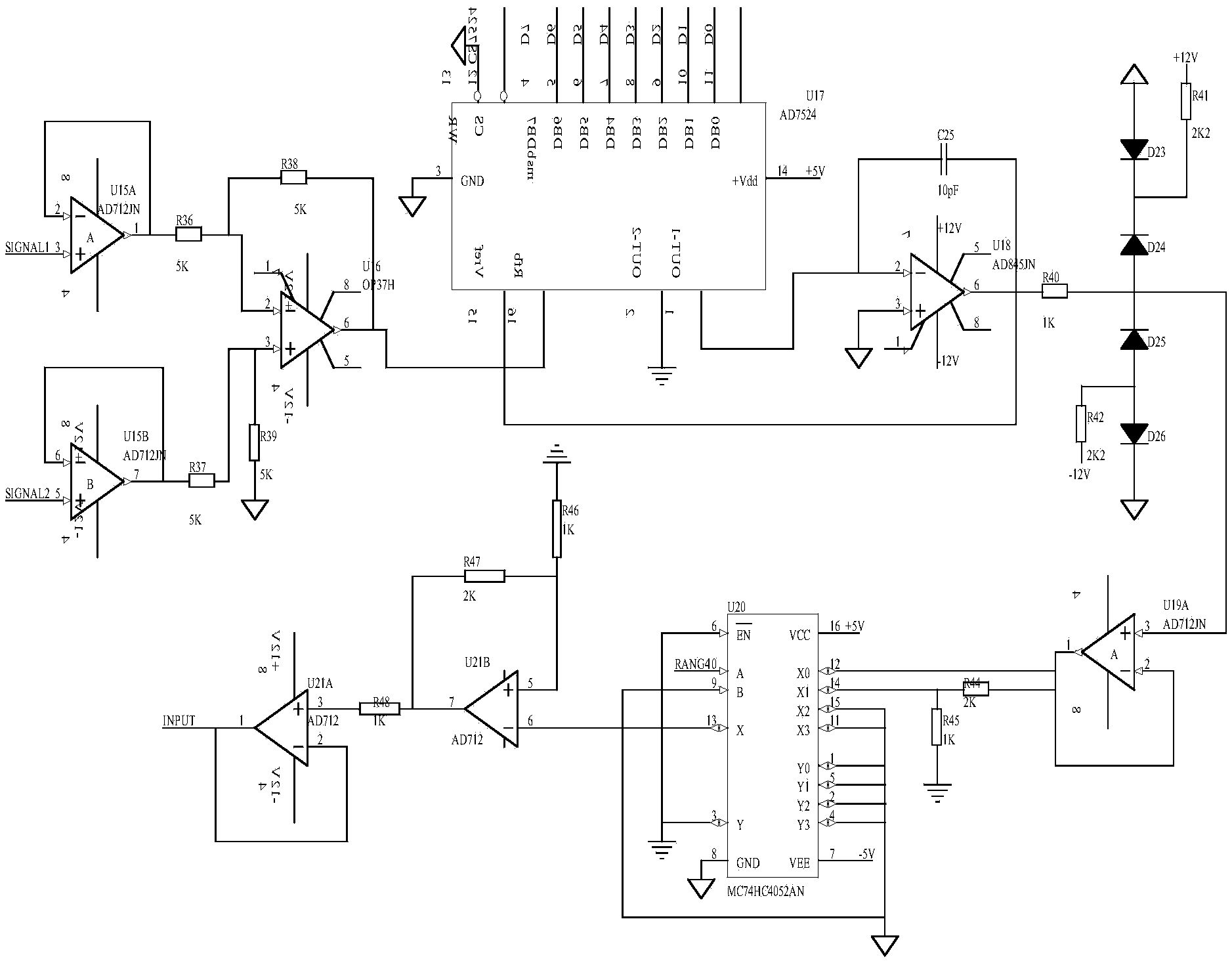

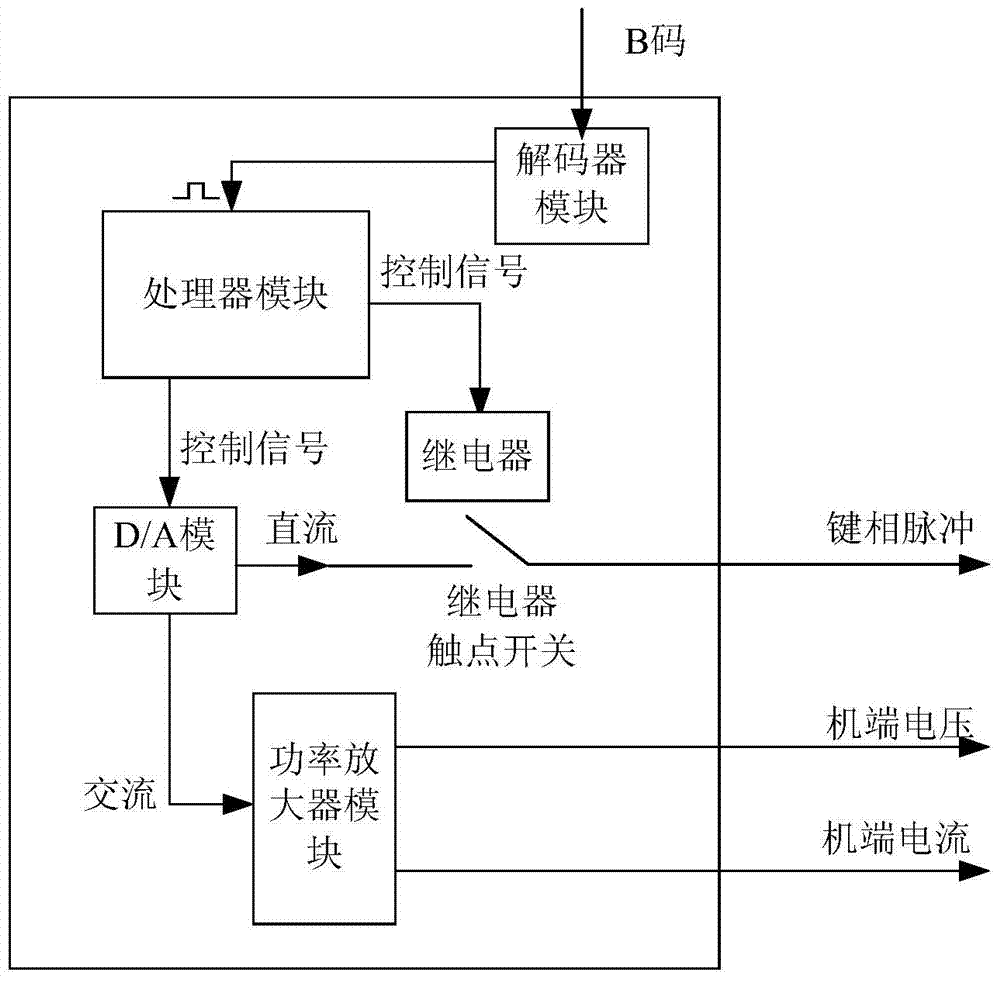

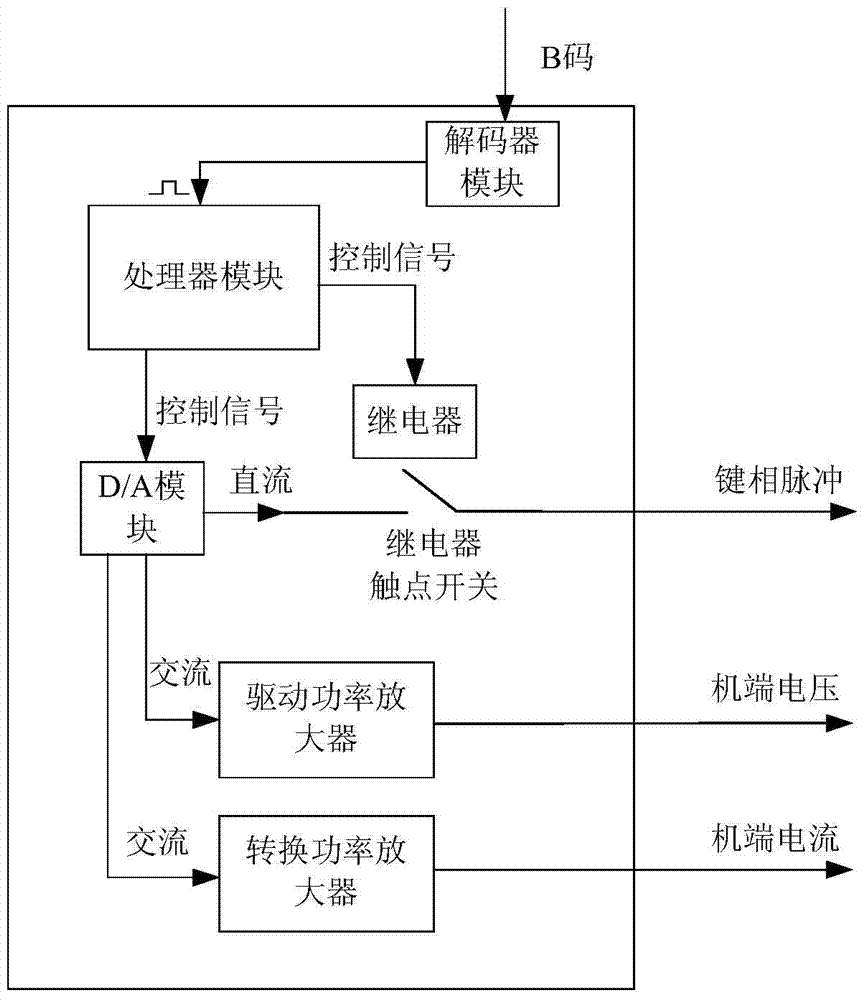

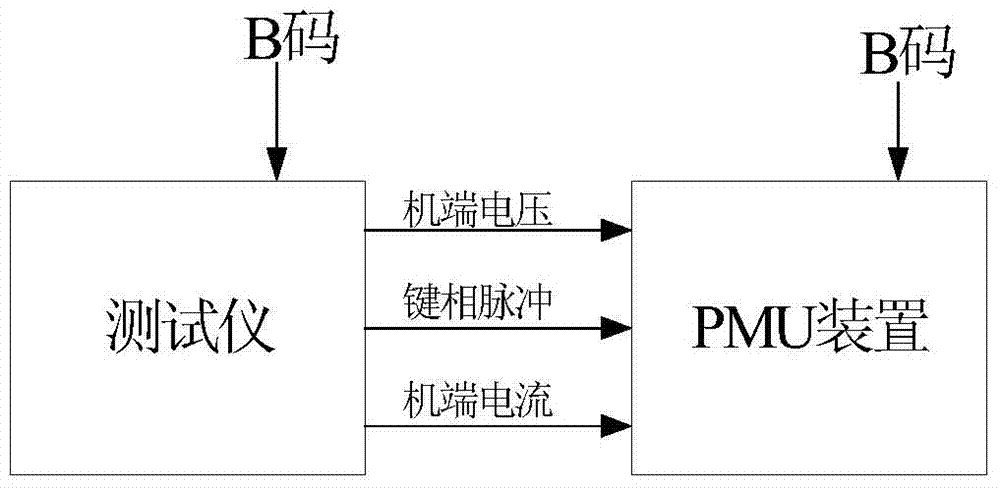

Tester for testing measurement accuracy of PMU (Pressure Measuring Unit) and testing method thereof

ActiveCN103698728APrecise control of high level valuePrecisely control the output cycleElectrical measurementsAudio power amplifierControl signal

The invention provides a tester for testing measurement accuracy of a PMU (Pressure Measuring Unit). The tester comprises a processor module, a D / A (Digital / Analog) conversion module, an electronic switch module, a power amplifier module and a decoder module. A B code time tick outputs a clock synchronization signal to the processor module through the decoder module; the processor module outputs a D / A control signal to control the D / A conversion module to output a direct voltage signal and an alternating voltage signal; the processor module outputs a switch control signal to control the electronic switch module to be switched on or off; the direct voltage signal outputs an analog key phase pulse signal through the electronic switch module; the power amplifier module comprises a driving power amplifier and a switching power amplifier; the alternating voltage signal is amplified through the driving power amplifier to output an analog machine end voltage signal; the analog machine end voltage signal is converted into an alternating current signal through the switching power amplifier; an analog machine end current signal is output. The invention also provides a method applying the tester to test the measurement accuracy of the PMU.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

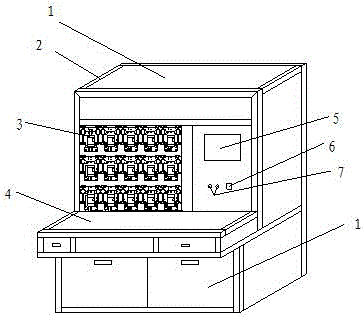

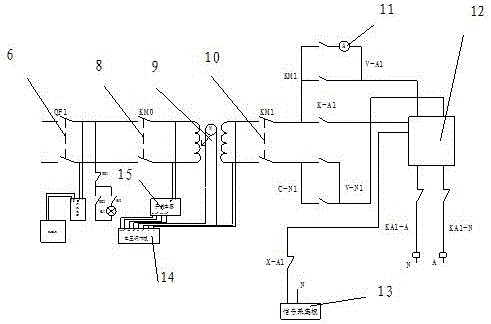

Cost control circuit breaker function test intelligent test device

PendingCN106405403APrecise frequency controlPrecise control rangeCircuit interrupters testingCost ControlsEngineering

The invention discloses a cost control circuit breaker function test intelligent test device, which belongs to the technical field of circuit breaker testing. The device provided by the invention solves the problems of scattered test function, low integration degree and uncoordinated inside test system of the existing standard characteristic test table. The test efficiency and precision are improved, which simplifies operation. The test device provided by the invention comprises a cabinet body, a control part and a wiring part. The wiring part comprises a station tooling fixture and a standard test wire. The control part comprises a test unit, a test sensor, an industrial control computer, a touch screen, a start and stop button and a variable frequency current source. The test unit comprises a first alternating current contactor, a voltage regulator, a second alternating current contactor, a collecting current plate, a signal collecting plate, a voltage regulator and a switching power supply. The test device provided by the invention is applicable to the function test of a cost control circuit breaker, and has the characteristics of rich test function, fast speed, high human-computer interaction, broad market prospect and the like.

Owner:CHINA ELECTRIC POWER RES INST +1

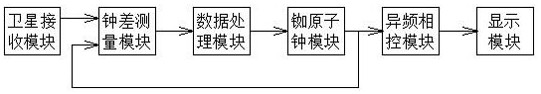

Pilot-frequency high-precision rubidium atomic frequency standard generation system based on Beidou satellite signals

InactiveCN113114240APrecise frequency controlImprove accuracyPulse automatic controlSatellite radio beaconingTelecommunicationsPhase control

The invention discloses a pilot-frequency high-precision rubidium atomic frequency standard generation system based on Beidou satellite signals. The pilot-frequency high-precision rubidium atomic frequency standard generation system comprises a satellite receiving module, a clock error measurement module, a data processing module, a rubidium atomic clock module, a pilot-frequency phase control module, a display module and a power module. The signal output end of the satellite receiving module is connected with the signal input end of the clock difference measuring module, the signal output end of the clock difference measuring module is connected with the signal input end of the data processing module, and the signal output end of the data processing module is connected with the signal input end of the rubidium atomic clock module. The signal output end of the rubidium atomic clock module is connected with the signal input end of the clock difference measuring module and the signal input end of the pilot frequency phase control module. The signal output end of the pilot frequency phase control module is connected with the signal input end of the display module. By means of the pilot frequency phase control technology, the stability and accuracy of the rubidium atomic frequency standard can be greatly improved, the stability and reliability of the system are enhanced, and the requirements of high-precision time frequency measurement users in the field of Beidou satellite positioning service are completely met.

Owner:HUNAN NORMAL UNIVERSITY

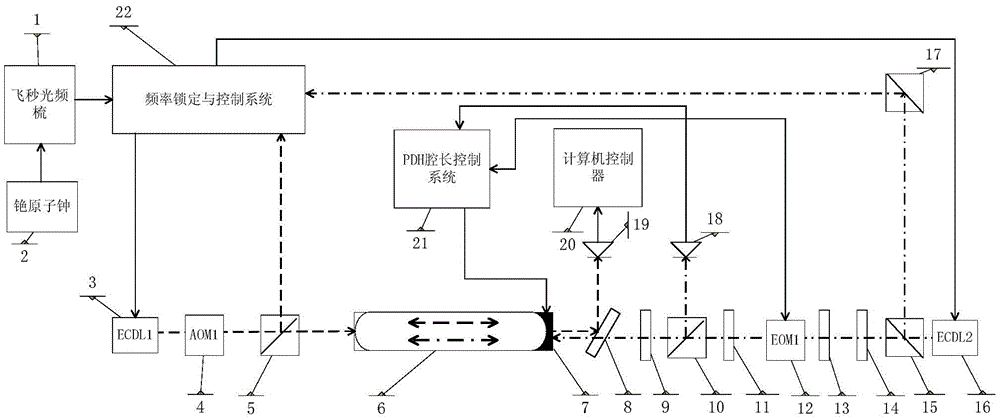

Laser cavity ring-down gas spectral measurement system based on femtosecond optical frequency combing

ActiveCN105067565APrecise frequency controlColor/spectral properties measurementsRing downFemtosecond pulsed laser

The invention relates to a laser cavity ring-down gas spectral measurement system based on femtosecond optical frequency combing and belongs to the field of cavity ring-down gas spectral measurement. The system is composed of a cavity ring-down spectral measurement system, a measuring laser frequency stabilization system and a cavity length stabilization system. A femtosecond pulse laser serves as a frequency standard, measuring laser frequency and cavity length can be traceable to the time frequency standard, and accordingly high-precision cavity ring-down spectral measurement is achieved.

Owner:TSINGHUA UNIV

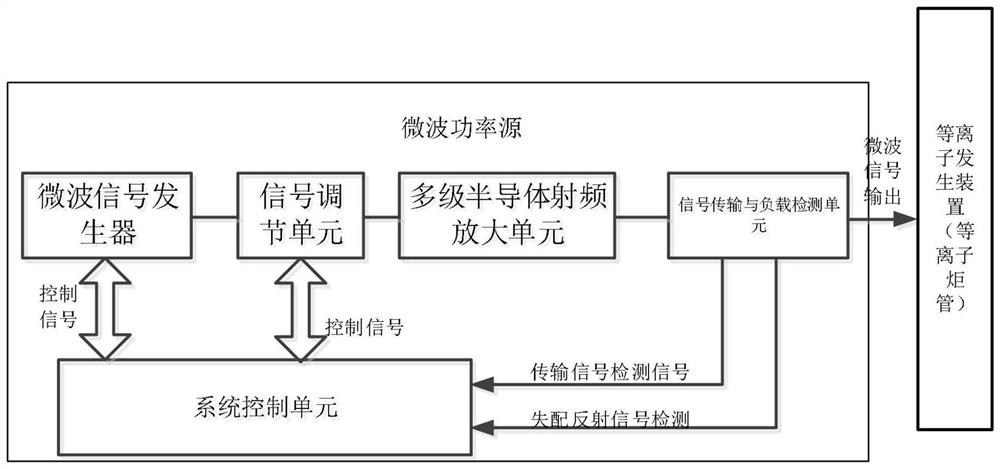

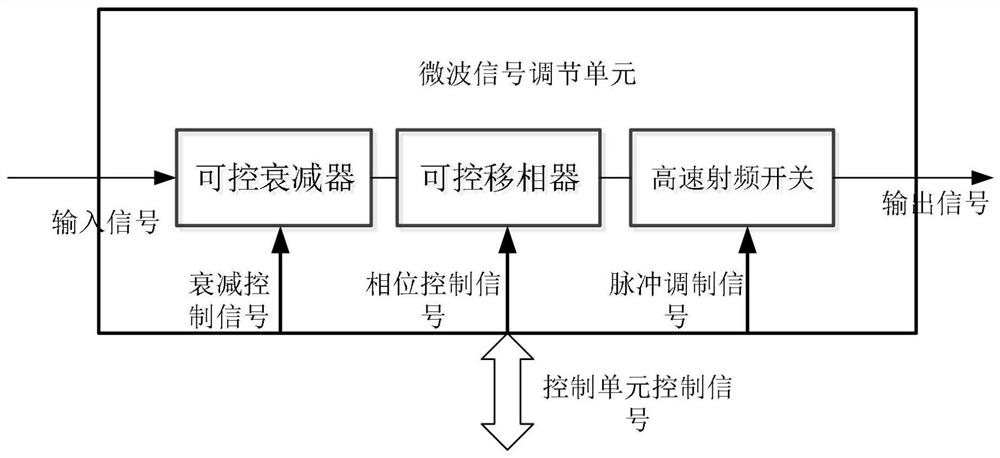

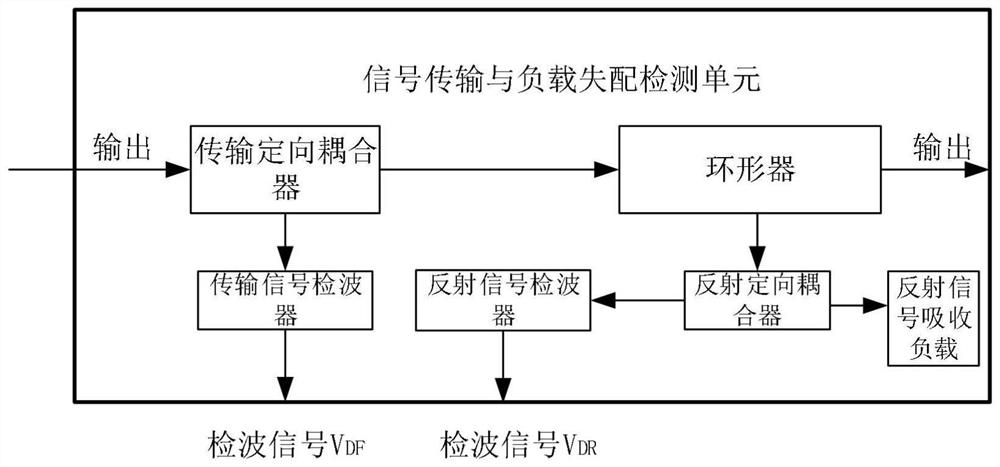

Microwave power source, microwave plasma system, ignition method and self-tuning method

PendingCN112654128AFind the best frequency for ignitionStable jobPlasma techniqueProcess engineeringMicrowave signals

The invention discloses a microwave power source, a microwave plasma system, an ignition method and a self-tuning method. The microwave power source comprises: a microwave signal generator used for generating a microwave signal; a signal adjusting unit used for adjusting the amplitude and phase of the microwave signal and loading pulse signals with different frequencies and duty ratios; a semiconductor amplification unit; a signal transmission and load detection unit used for sending the microwave signal amplified by the semiconductor amplification unit to a load and detecting the sent microwave signal and a microwave reflection signal generated by the load to obtain a detection sampling signal; and a control unit used for receiving and analyzing the detection sampling signal so as to control the signal emission frequency of the microwave signal generator and / or control the adjusting mode of the signal adjusting unit according to the analysis result. According to the invention, automatic ignition frequency searching, an automatic ignition process and a self-tuning process are achieved, and the problems that existing traditional microwave plasma equipment is difficult to ignite automatically and work stably are solved.

Owner:苏州迈微能等离子科技有限公司

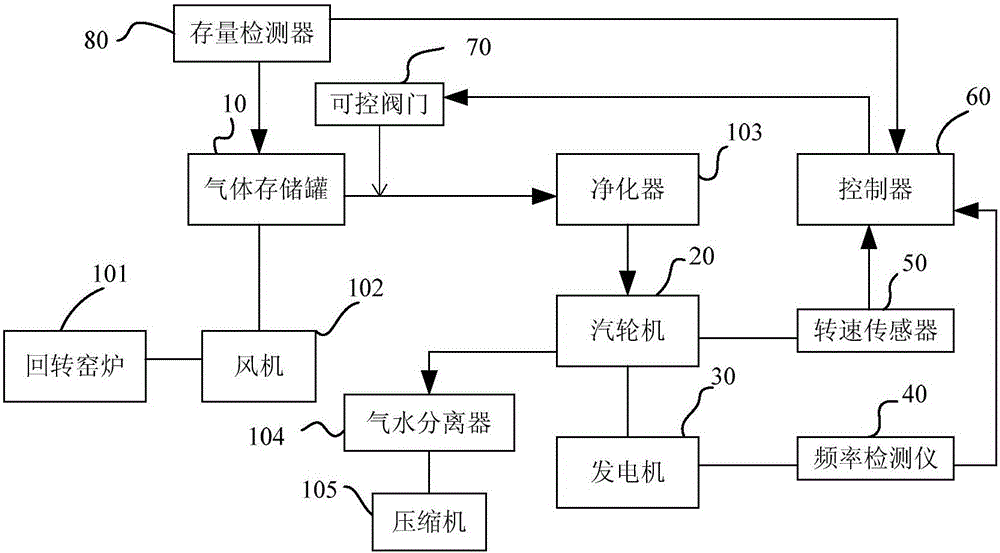

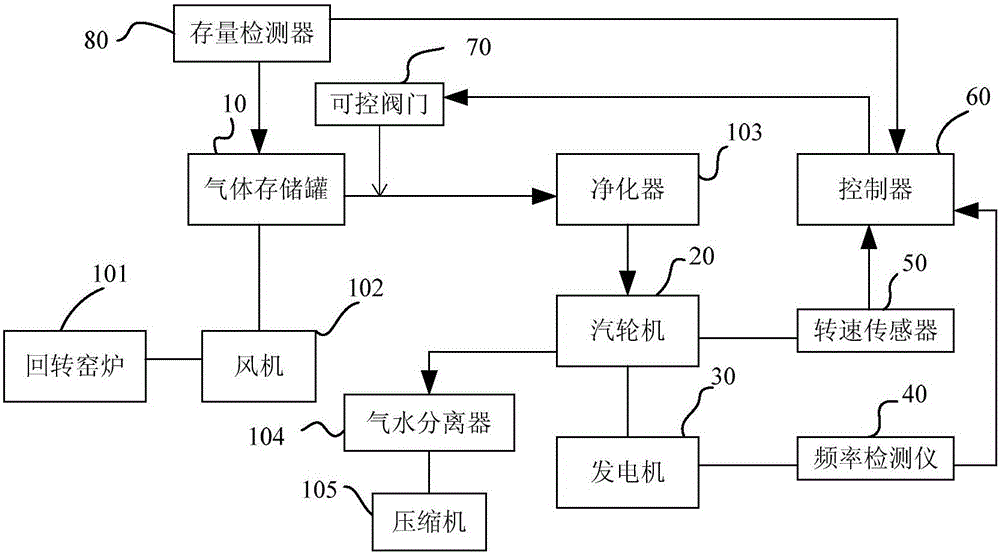

Power generation system based on waste heat of rotary kiln byproduct

ActiveCN105756734APrecise frequency controlGuaranteed Frequency AccuracySteam useIncreasing energy efficiencyEngineeringHot Temperature

The invention discloses a power generation system based on waste heat of a rotary kiln byproduct. The power generation system comprises a gas storage tank, a steam turbine, a generator, a frequency detector, a rotating speed sensor and a controller, wherein the gas storage tank is used for storing high-temperature carbon dioxide gas generated by a rotary kiln in the process of calcining magnesium ores at a high temperature; a controllable valve is arranged at an outlet of the gas storage tank so as to control a gas outflow volume of the gas storage tank; a gas inlet of the steam turbine is connected to the controllable valve so as to receive the high-temperature carbon dioxide gas; the generator is connected to an output shaft of the steam turbine and outputs a voltage along with rotation of the steam turbine; the frequency detector is used for detecting frequency of the voltage output by the generator; the rotating speed sensor is arranged on the steam turbine and is used for detecting a rotating speed of the output shaft of the steam turbine; the controller is used for determining the opening of the controllable valve according to the frequency from the frequency detector and the rotating speed from the rotating speed sensor.

Owner:刘昕

A file equalization method for an IDFS

InactiveCN108984659AReduce workloadEquilibrium transferSpecial data processing applicationsVideo optimizationEqualization

The invention discloses a file equalization method for an IDFS. The method is realized by a file index classification module, a file transfer module, a file index search module, a file performance monitoring and task distribution module, and a configuration list of HLS live broadcast on-demand video optimization. The file index classification module is used for classifying and sorting the stored contents. The file transfer module realizes balanced file transfer without stopping the service. The file index searching module realizes the update of the file index on the premise that the file indexcan be cached, and at the same time, the file index searching module does not cause the fault that the file cannot be found. The file performance monitoring and task distribution module realizes storage equalization under the condition that the influence on the performance of the existing network system is reduced as little as possible. The configuration list of the HLS live on-demand video optimization realizes accurate control of the equalization frequency and the equalization speed. The method of the invention can realize the equalization of each storage capacity to the maximum extent andrealize the equalization transfer of files.

Owner:SHANDONG INSPUR COMML SYST CO LTD

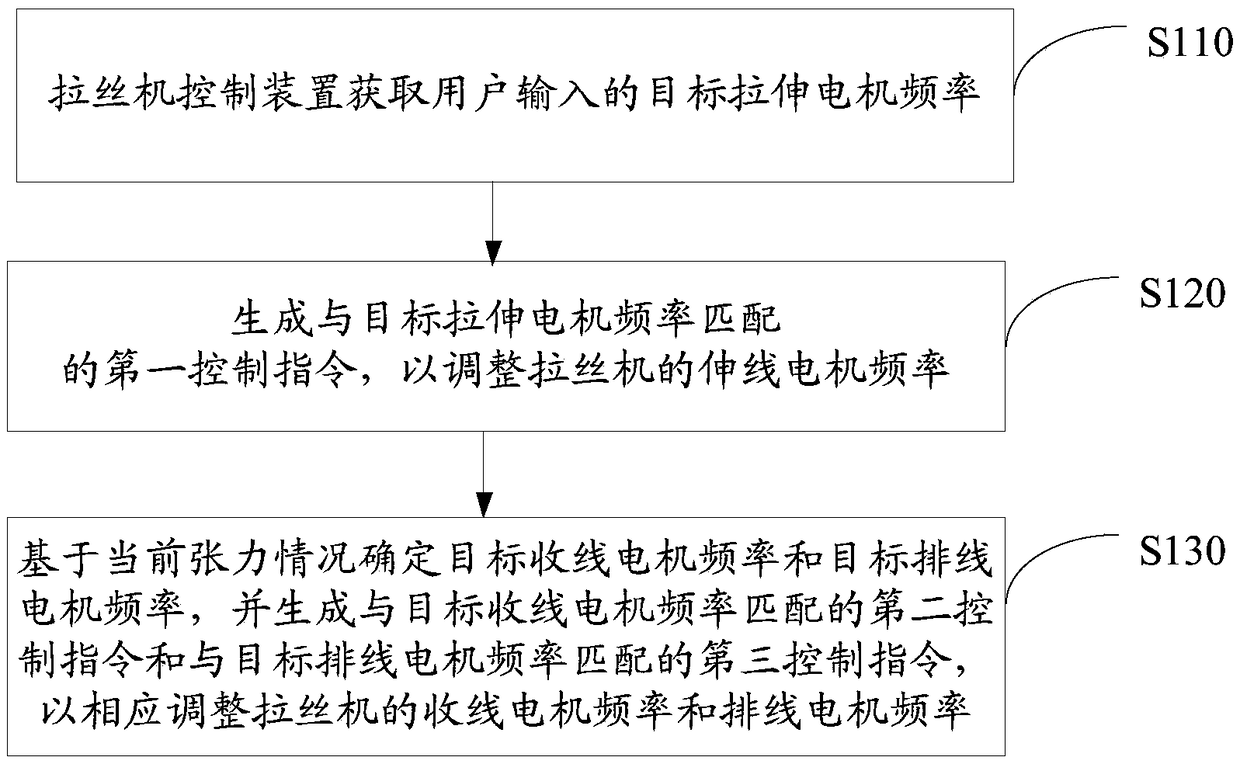

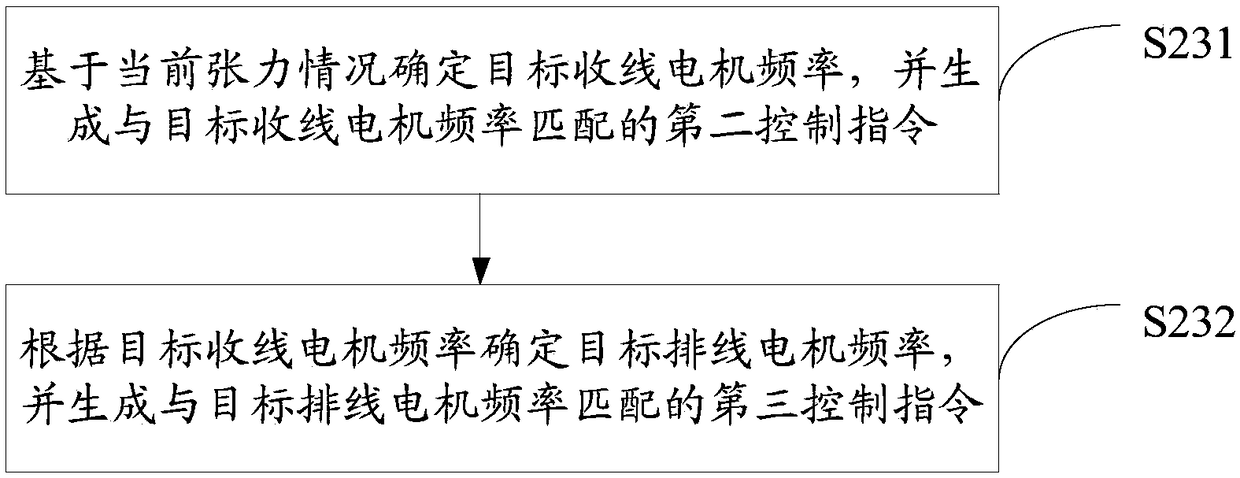

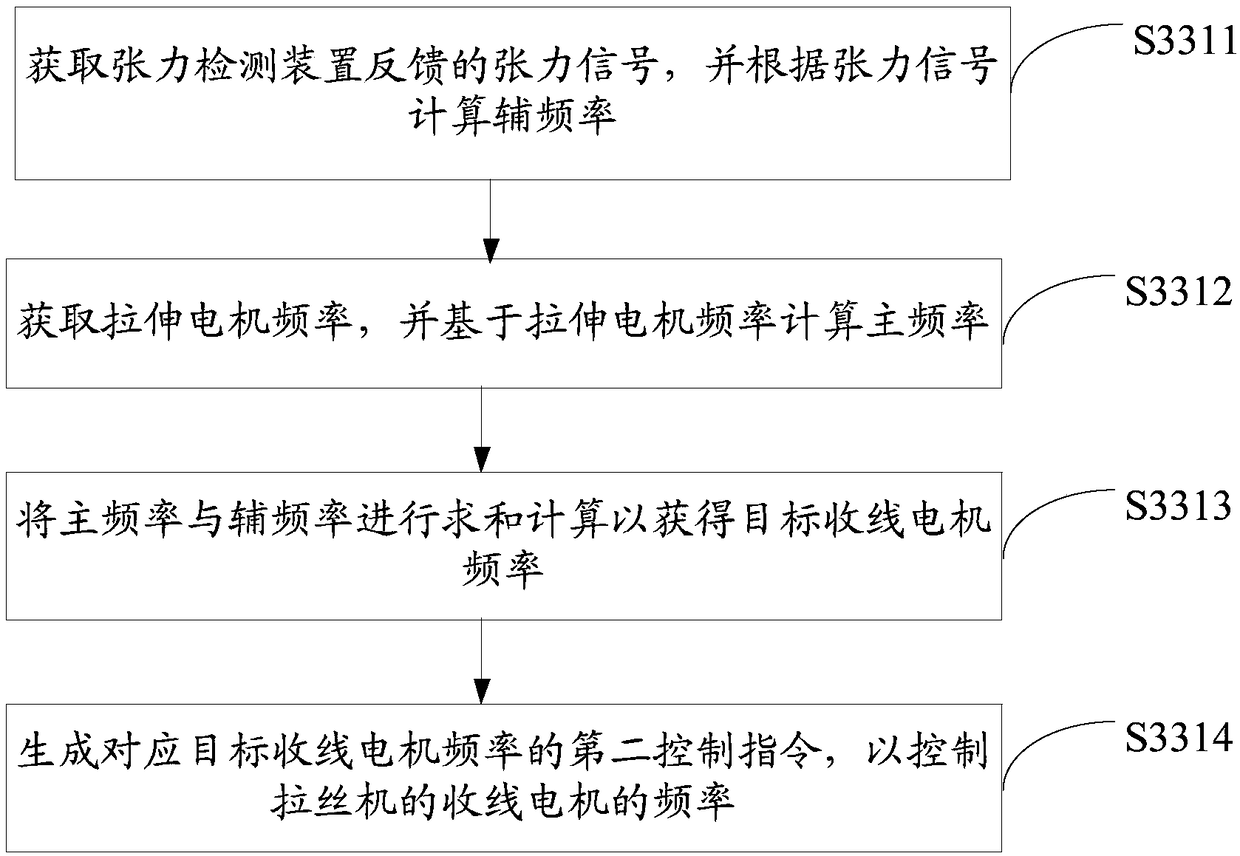

Wire take-up control method and device for drawbench and storage medium

ActiveCN109396202AFrequency controlPrecise frequency controlMetal working apparatusElectric machineryControl theory

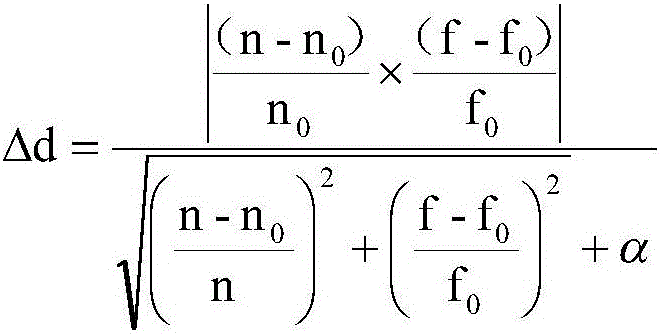

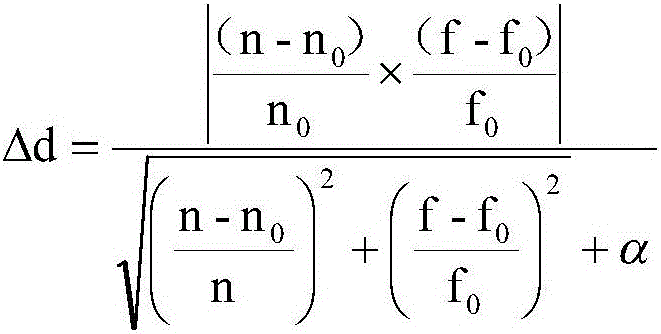

The invention discloses a wire take-up control method for a drawbench. The method is executed by a control device. The control device is used for generating a control instruction corresponding to a take-up motor and generating a control instruction for a stretching motor and / or a wire arrangement motor. The method comprises the following steps that a tension signal fed back by a tension detectiondevice is acquired, and an auxiliary frequency is calculated according to the tension signal; a frequency of the stretching motor is acquired, and a main frequency is calculated on the basis of the frequency of the stretching motor; the main frequency and the auxiliary frequency are summed to obtain a target frequency of the take-up motor; and a control instruction corresponding to the target frequency of the take-up motor is generated so as to control the frequency of the take-up motor of the drawbench. According to the wire take-up control method, through the process, the frequency can be accurately configured for the take-up motor in the drawbench according to the tension signal fed back by the tension device. The invention further provides a wire take-up control device for the drawbench and a storage medium.

Owner:苏州安驰控制系统有限公司

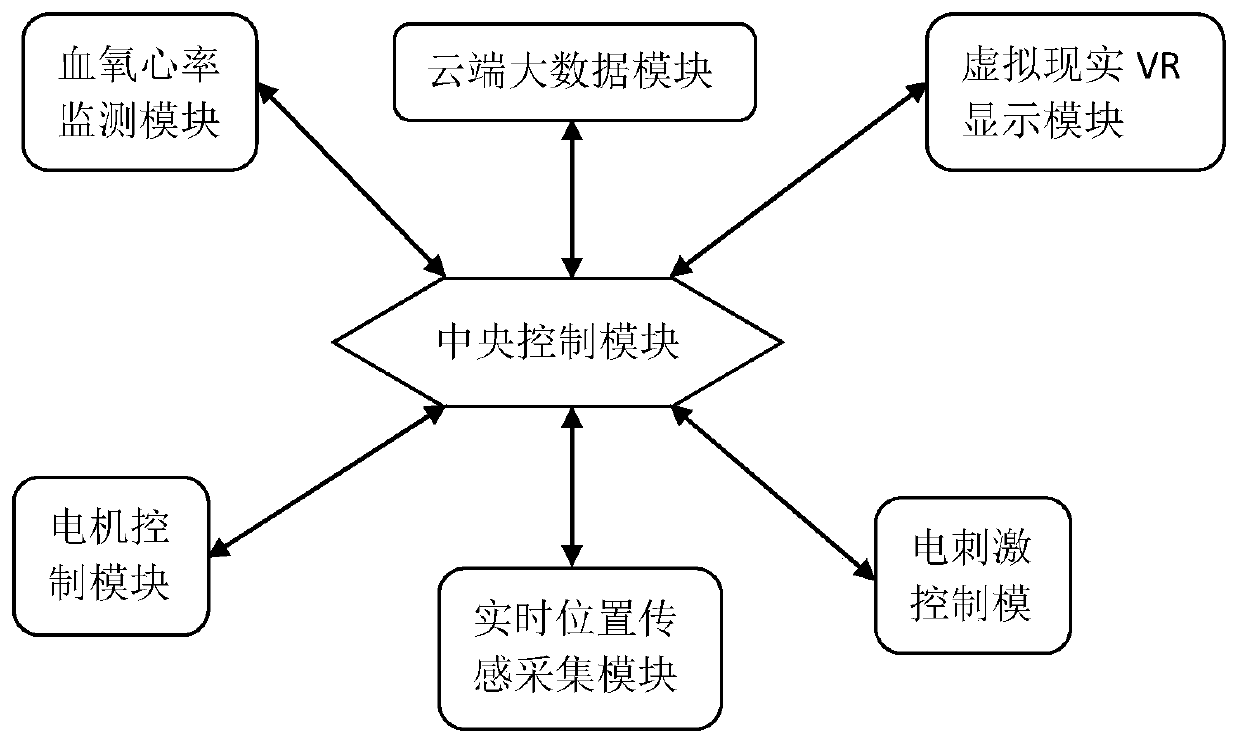

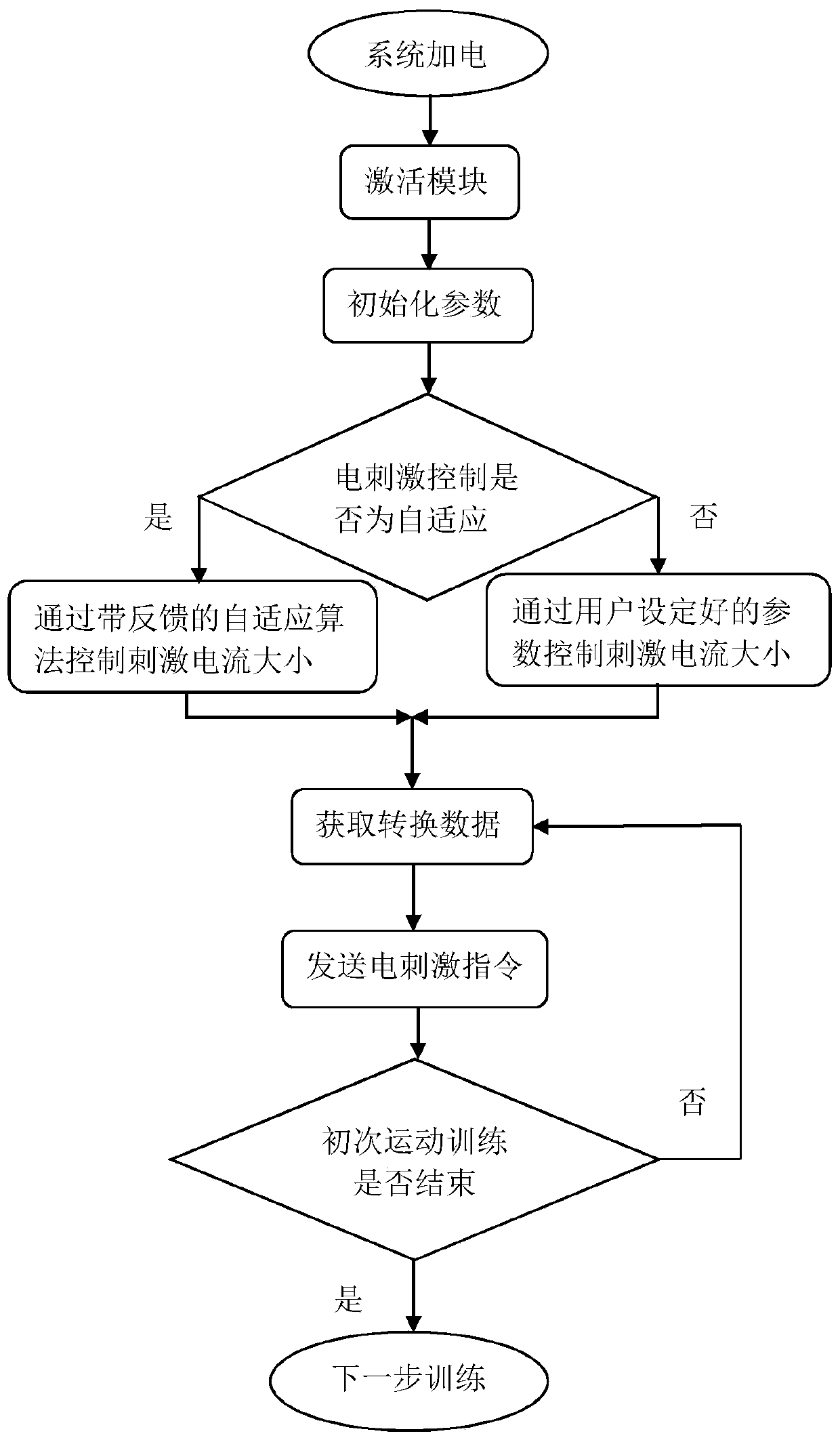

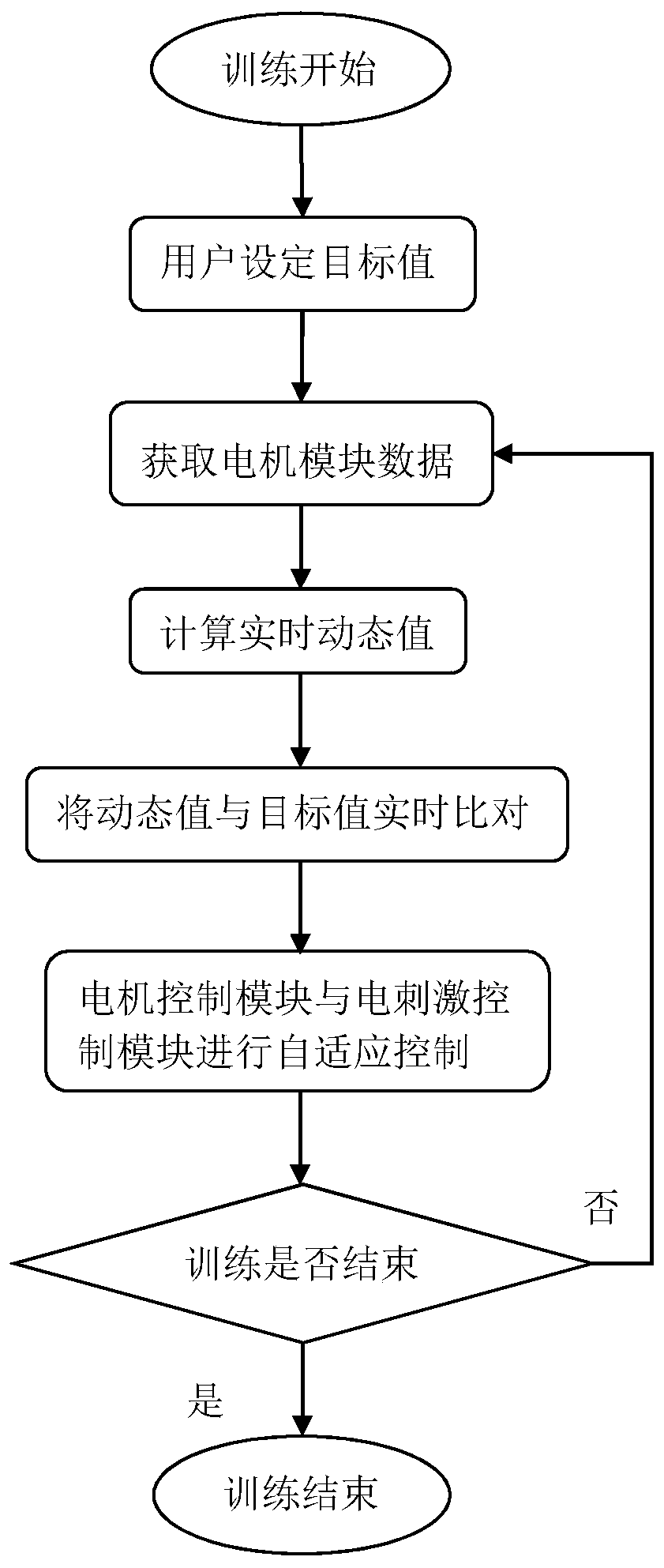

Self-adaptive treadmill system for rehabilitation training and control method of self-adaptive treadmill system

ActiveCN110251832AAccurate judgment abilityResolve resistanceElectrotherapyTherapy exerciseMuscle contractionClosed loop

The invention provides a self-adaptive treadmill system for rehabilitation. The self-adaptive treadmill system comprises a movement part, a center control module, an electrical stimulation control module, a motor control module, a real-time position sensing acquisition module, a blood oxygen heart rate monitoring module, a virtual-reality (VR) display module and a cloud big data module; the center control module is in wireless communication connection with the electrical stimulation control module, the motor control module, the real-time position sensing acquisition module, the blood oxygen heart rate monitoring module, the VR display module and the cloud big data module; the motor control module is electrically connected with the movement part; the center control module, the electrical stimulation control module and the motor control module form closed-loop adaptive control. The problems that muscles of 0-3 grade patients cannot participate actively in the process of treadmill treatment and electrical stimulation increases resistance participation in the process of muscle contraction are solved, and the balance between the healthy side and the affective side is effectively relieved.

Owner:常州锦澄医疗设备有限公司

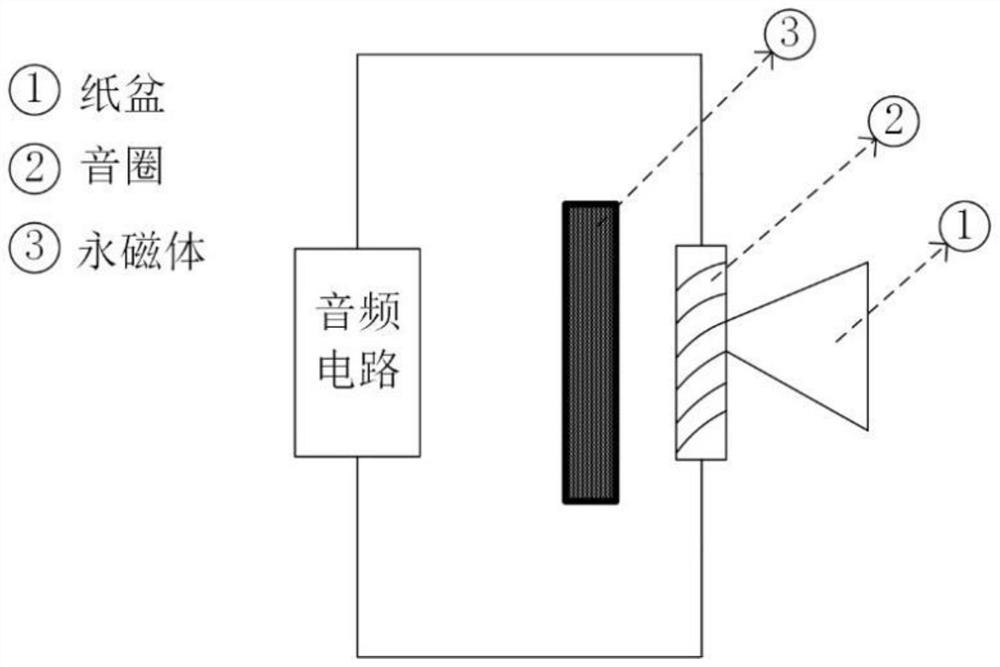

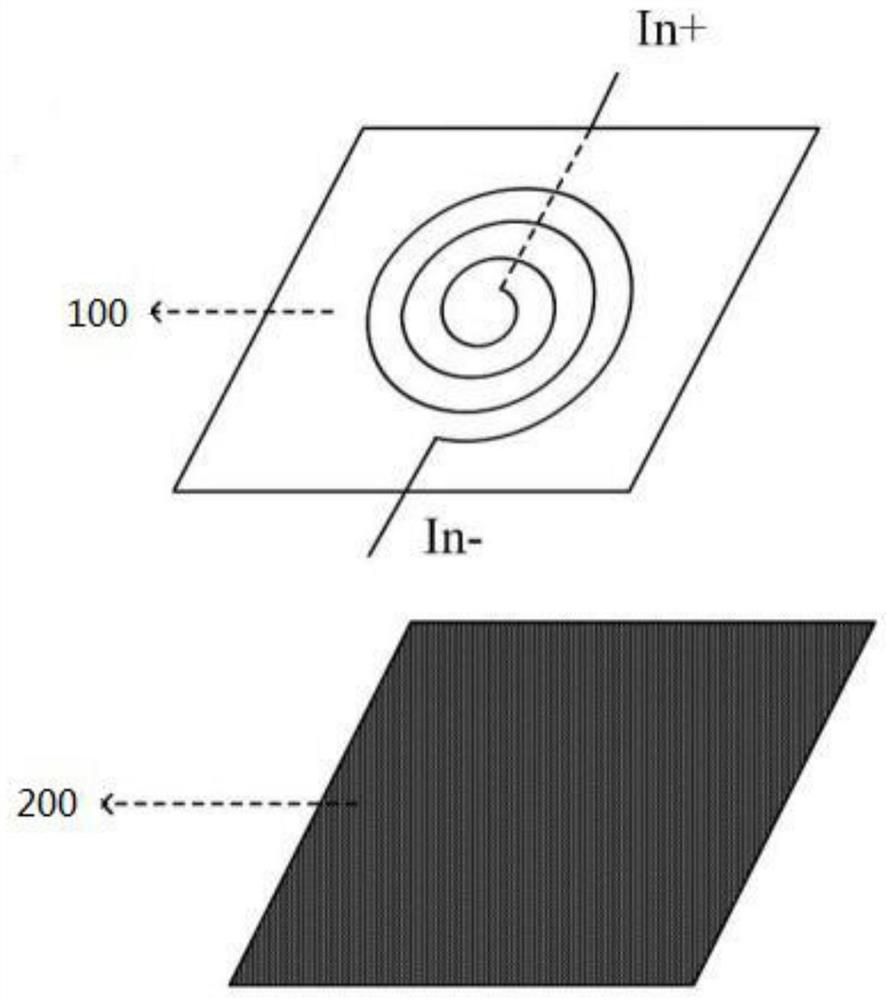

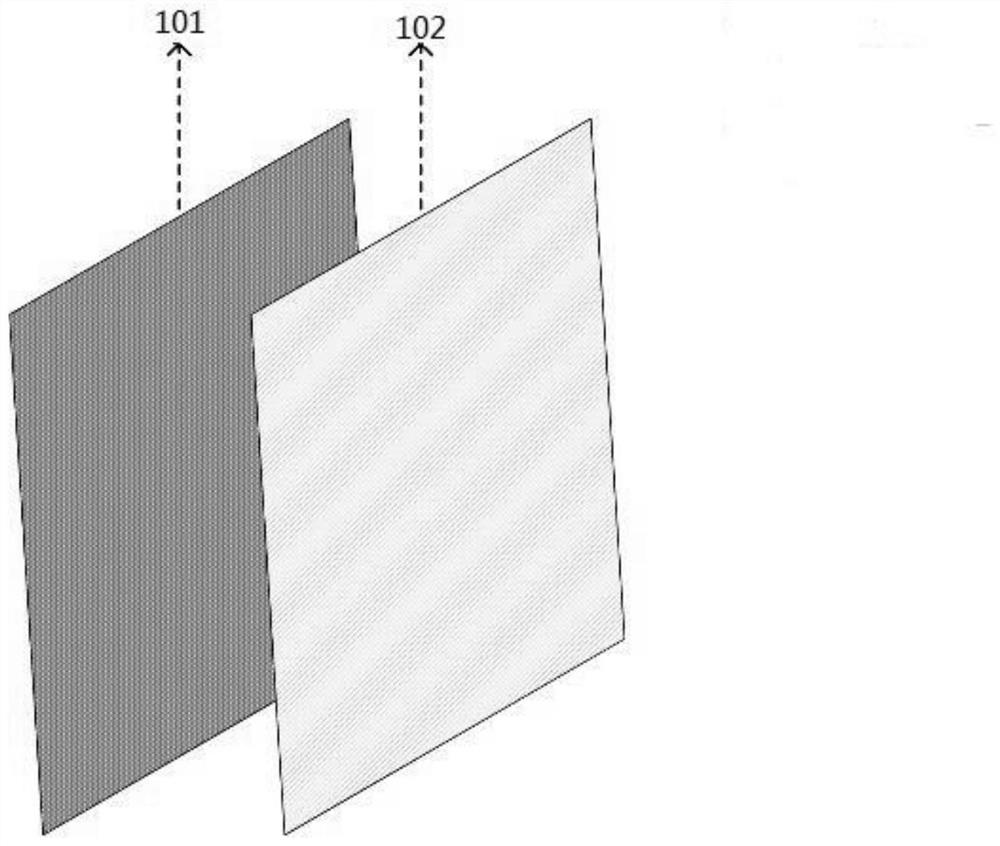

Acoustic propagation system

The invention relates to an acoustic propagation system, which comprises a planar resonance circuit that comprises a planar resonance body and a permanent magnet, the planar resonance body comprises a metal layer and a flexible film substrate layer, and the metal layer is laminated on the flexible film substrate layer; wherein the planar resonance body comprises a plurality of planar resonance units which are distributed in an array. According to the invention, the integrated planar resonant body is designed, so that the problems that the structure occupied size is large and the sound vibration frequency is limited in a fixed range due to an independent structure in the prior art are solved. The planar resonance body comprises a plurality of planar resonance units, which are distributed in an array, so that accurate frequency control can be realized, and the sound quality is obviously improved.

Owner:苏州星航综测科技有限公司 +1

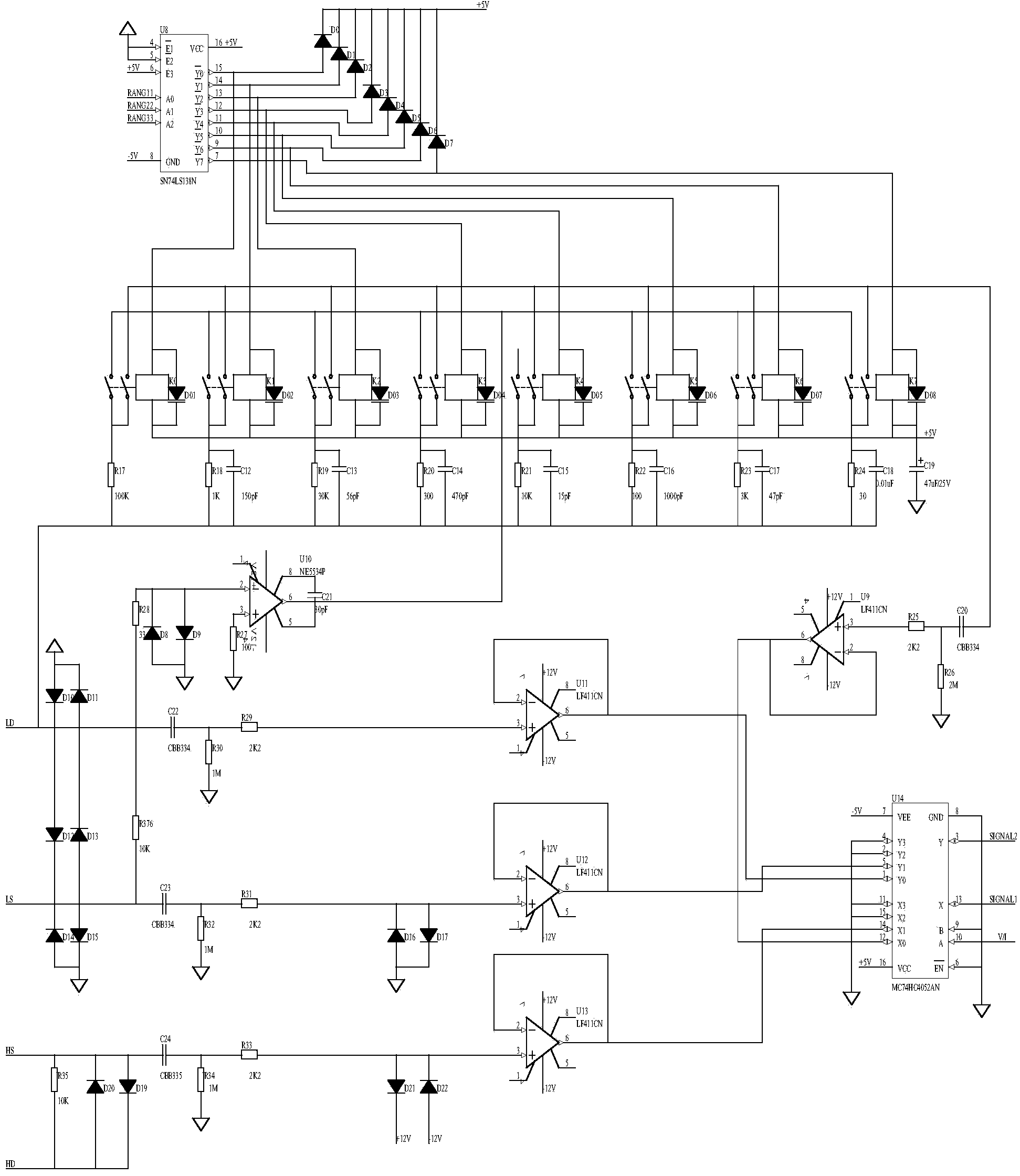

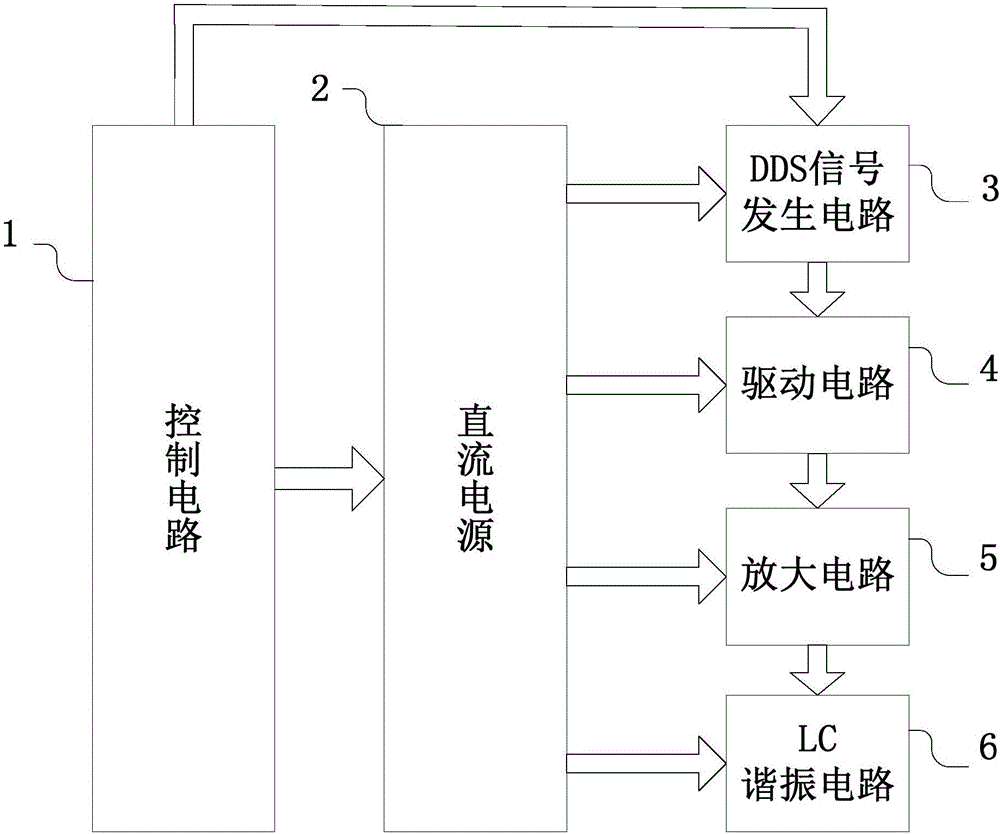

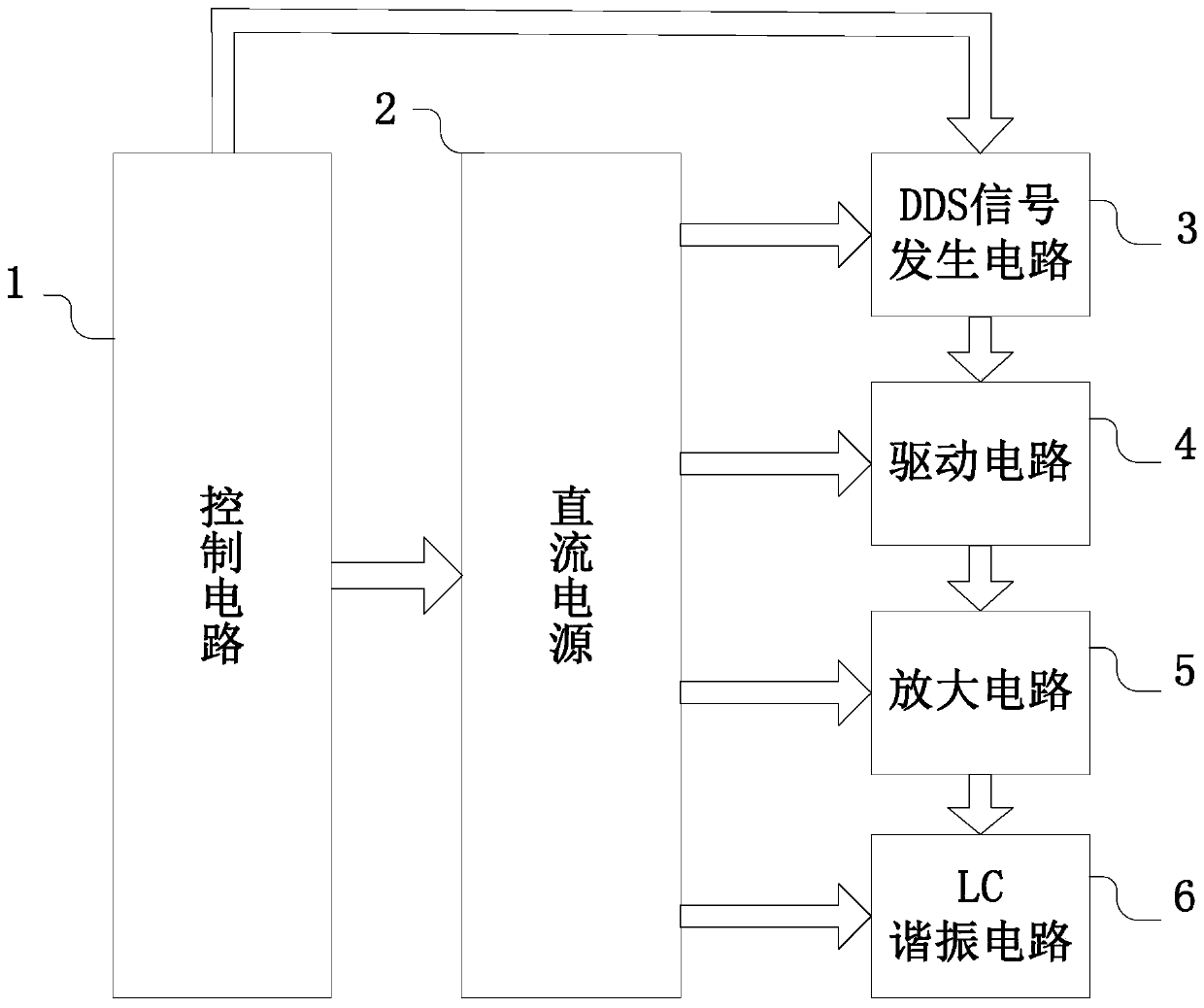

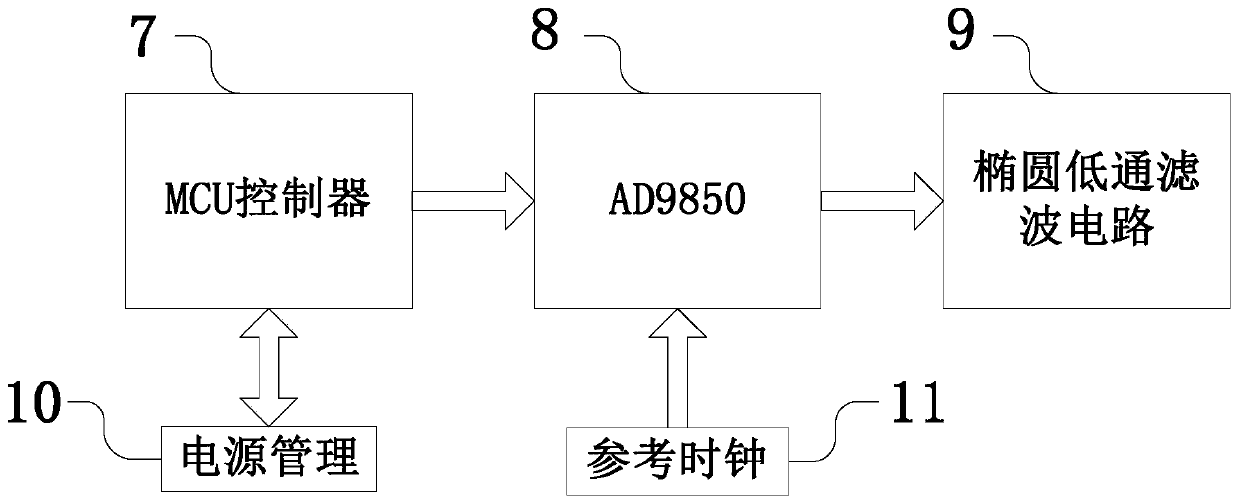

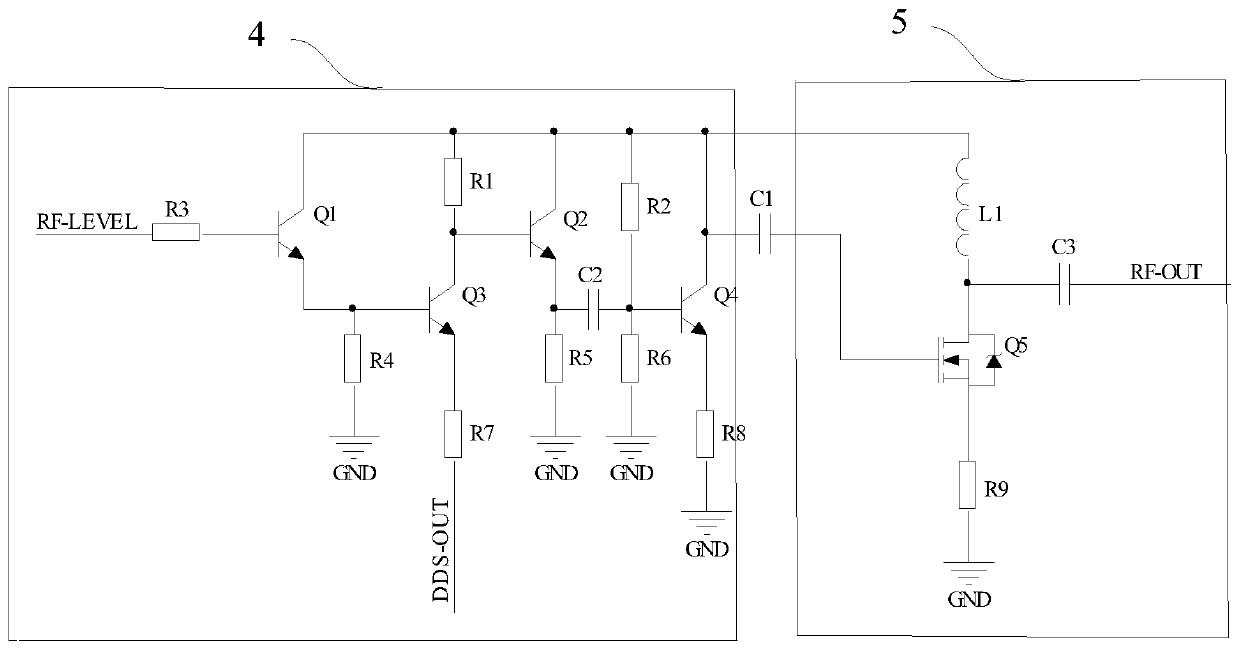

DDS-based collision reaction tank radio-frequency power supply

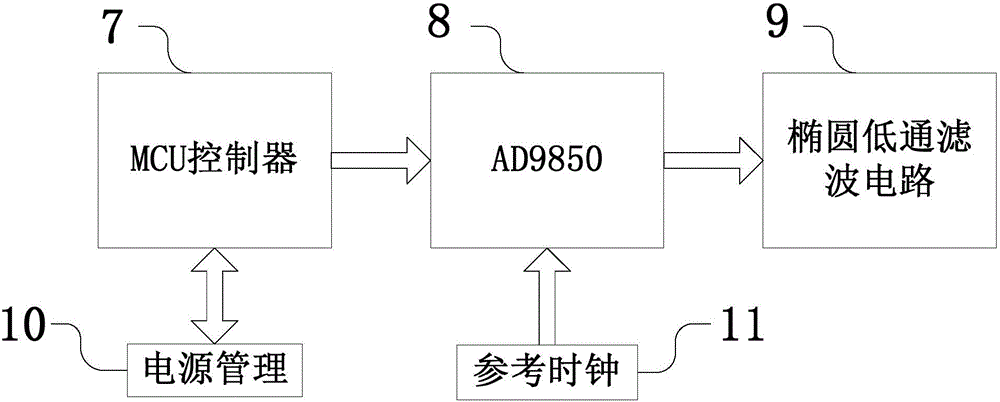

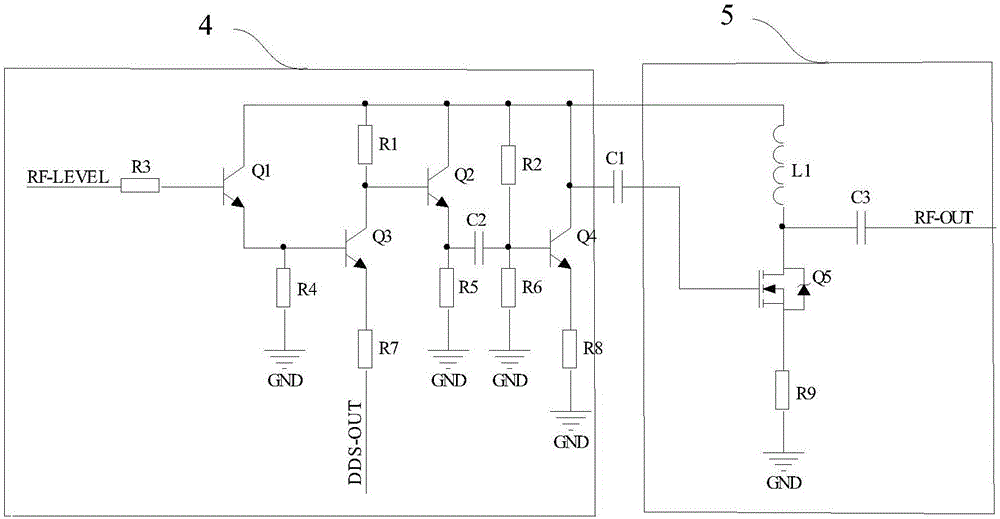

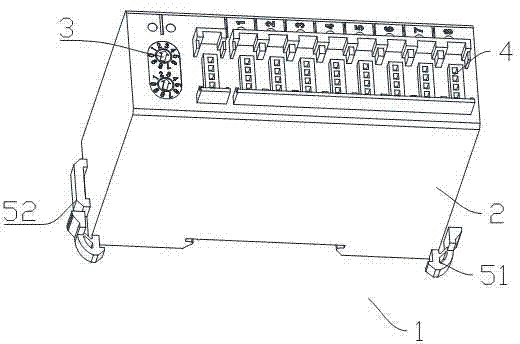

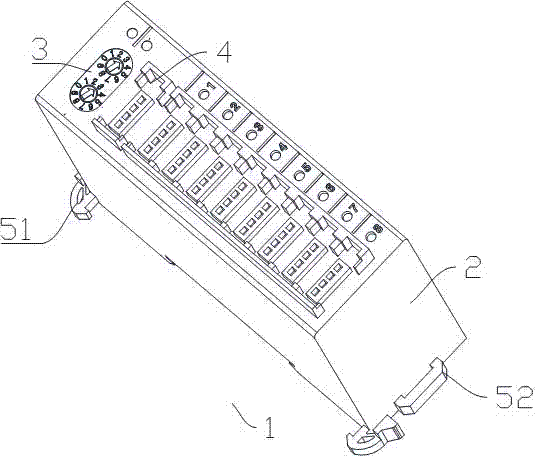

ActiveCN106169881APrecise frequency controlImprove frequency characteristicsSpectrometer circuit arrangementsEfficient power electronics conversionLc resonant circuitPhase difference

The invention discloses a DDS-based collision reaction tank radio-frequency power supply, and belongs to the field of test analysis instrument radio-frequency power supplies. The DDS-based collision reaction tank radio-frequency power supply comprises a control circuit, a direct-current power supply, a DDS signal generating circuit, a drive circuit, an amplifying circuit and an LC resonance circuit. According to the DDS-based collision reaction tank radio-frequency power supply, the control circuit is used for controlling the DDS signal generating circuit to generate a signal with specific frequency, after the signal passes through the drive circuit and the amplifying circuit, the signal is coupled to the LC resonance circuit through a coil, and the circuit parameters of the LC resonance circuit are determined by the frequency of the DDS signal and the amplitude of the final output signal. Finally, two radio-frequency signals with equal amplitude and 180-degree phase difference are output, the frequency can be hundreds of kHz to several MHz, the frequency resolution can reach 1 Hz, and the amplitude can be zero to thousands of volts. The radio-frequency power supply is applicable to multi-pole collision reaction tanks of mass spectrometers or other ion forming devices based on multiple poles.

Owner:NCS TESTING TECH

Assembled frequency modulation transformer

InactiveCN104766713AEasy to observePrecise frequency controlTransformersInductancesTransformerEngineering

The invention discloses an assembled frequency modulation transformer. The assembled frequency modulation transformer comprises a body; the upper part of the body is provided with a frequency modulation switch; the upper part of the body is provided with a plurality of transformation wiring ports; two sides of the bottom part of the body are respectively provided with a first fixing point and a second fixing point; the frequency modulation switch is provided with a fine-adjusting switch and a coarse-adjusting switch; the upper part of the frequency modulation switch is provided with an indicator lamp; and the transformation wiring ports set the voltage regulating values with various ranges. Because the frequency modulation switch of the assembled frequency modulation transformer is provided with the fine-adjusting switch and the coarse-adjusting switch and the upper part is provided with the indicator lamp, the frequency can be accurately regulated and controlled, and the frequency value is conveniently observed. Because the transformation wiring ports set the voltage regulating values with various ranges, the assembled frequency modulation transformer can be suitable for the requirements of different types of the instruments for the voltage.

Owner:李跃东

In-vivo biological reactor and its application

InactiveCN1947666BEnsure stabilityEnsure stability and continuitySurgeryMedical devicesIn vivoBiology

An intrabody bioreactor for the tissue-engineered organ transplantation is composed of an external powder pump system and an internal catheter system. It can be used to pump the cell culturing liquid containing the self blood serum of organ receptor, seed cells and growth factors into the transplanted organ and promote its vascularization.

Owner:谭强

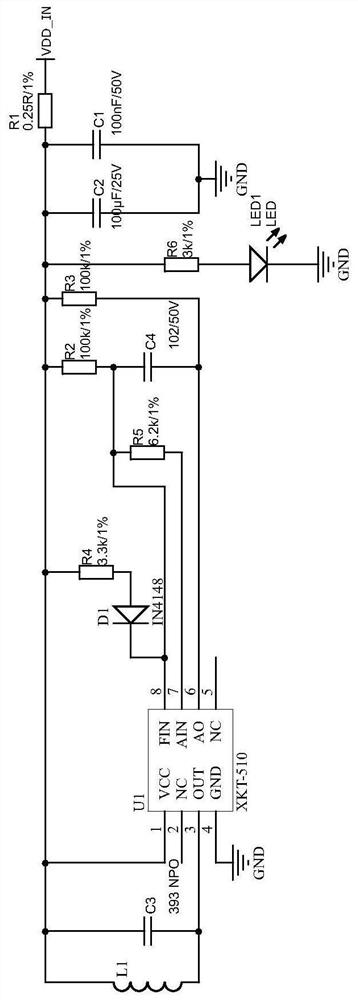

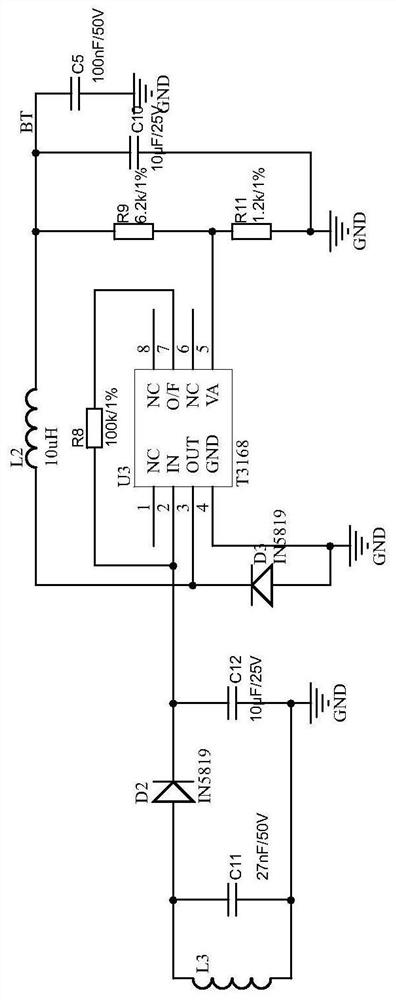

Electric toothbrush circuit supporting brush head replacement reminding

The invention discloses an electric toothbrush circuit supporting brush head replacement reminding. The electric toothbrush circuit comprises a wireless charging circuit, a power supply circuit, a main control circuit and a motor driving circuit. The circuits form an electric toothbrush control circuit, so that the characteristics of different brushing frequency control of a brush head, brush head replacement reminding, wireless charging of a battery and various excellent control are realized, and the electric toothbrush circuit has good application prospect and market effect.

Owner:深圳市成达永和电子有限公司

A radio frequency power supply for collision reaction cell based on dds

ActiveCN106169881BPrecise frequency controlImprove frequency characteristicsSpectrometer circuit arrangementsEfficient power electronics conversionDriver circuitLc resonant circuit

A DDS-based radio frequency power supply for a collision reaction cell belongs to the field of radio frequency power supplies for test and analysis instruments. Including control circuit, DC power supply, DDS signal generation circuit, drive circuit, amplifier circuit, LC resonant circuit. The radio frequency power supply of the collision reaction cell based on DDS is controlled by the control circuit to generate a signal of a specific frequency by the DDS signal generation circuit. After the signal passes through the drive circuit and the amplifier circuit, it is coupled to the LC resonant circuit through a coil. The circuit parameters of the LC resonant circuit are given by The frequency of the DDS signal and the amplitude of the final output signal determine. Finally, two radio frequency signals with equal amplitude and 180 degree phase difference are output. The frequency can range from several hundred kHz to several MHz, the frequency resolution can reach 1Hz, and the amplitude can range from zero to thousands of volts. This RF power supply is suitable for multipole collision reaction cells of mass spectrometers or other multipole-based ion shaping devices.

Owner:NCS TESTING TECH

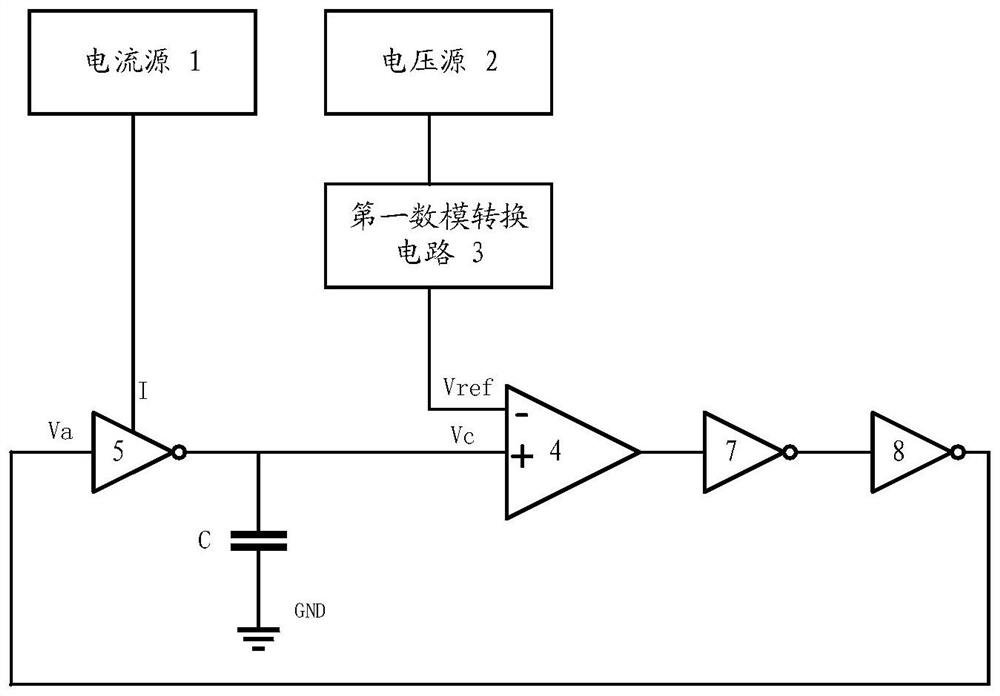

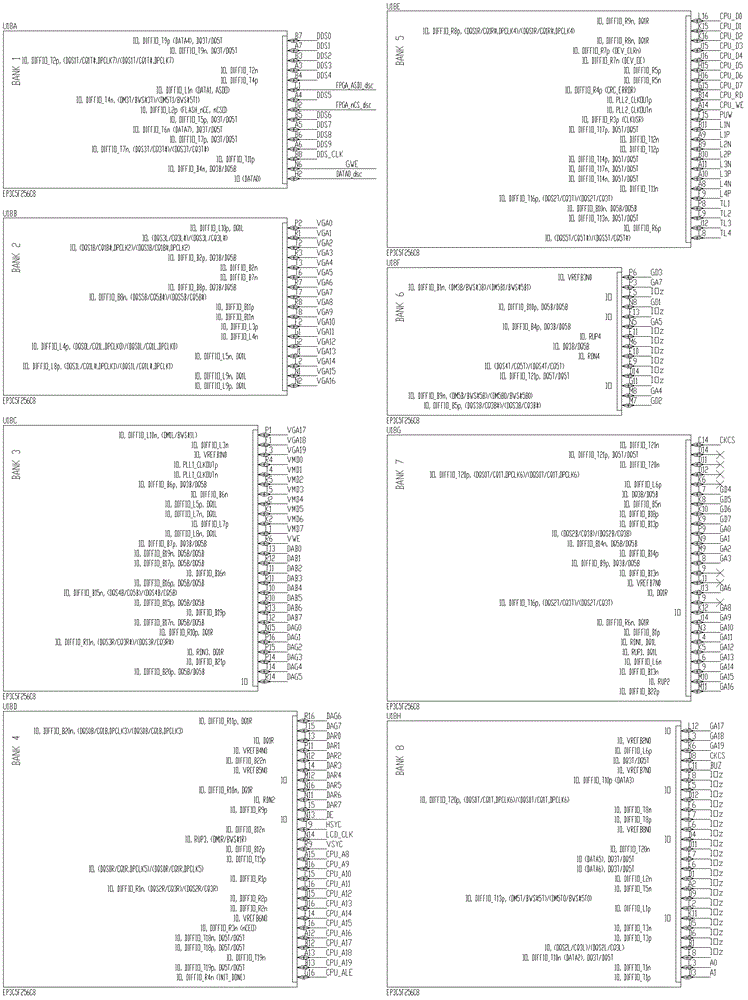

Clock signal generation device and clock signal generation method

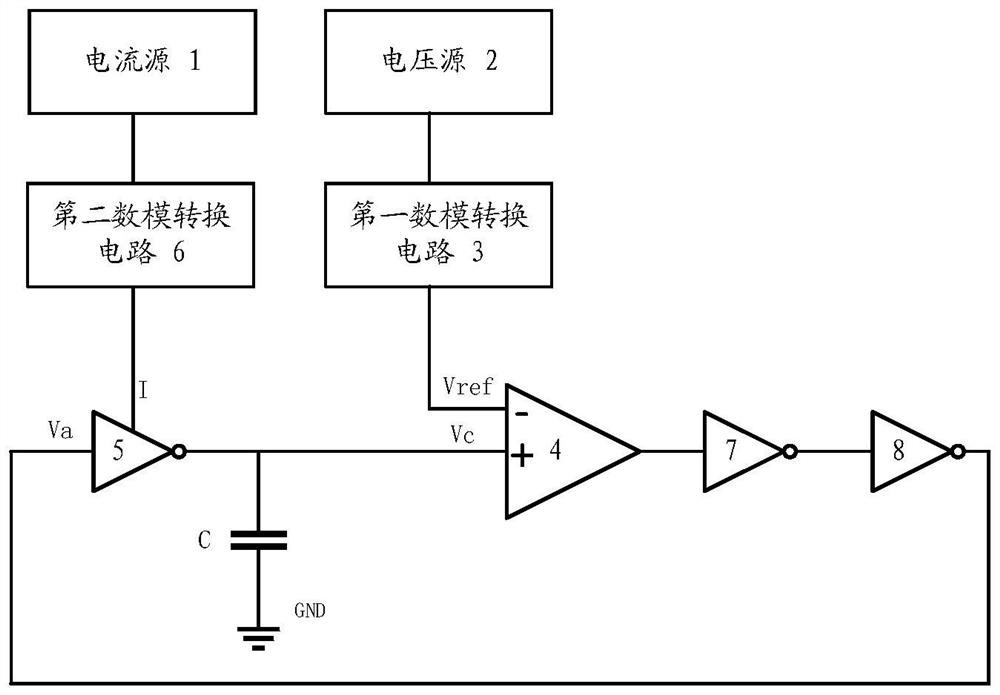

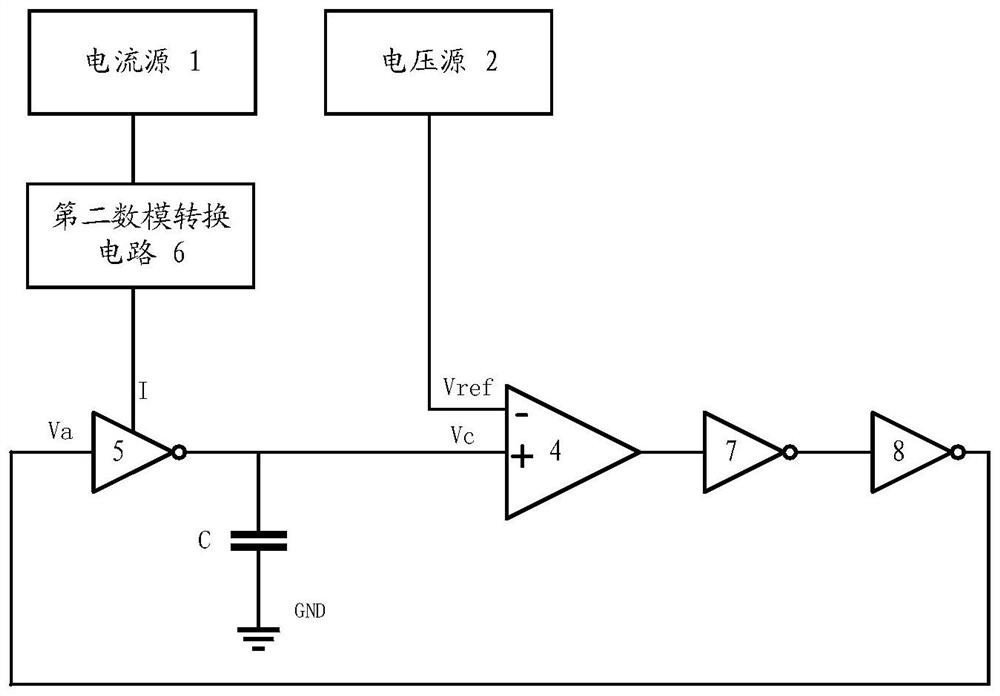

PendingCN113037281APrecise frequency controlPrecise control of charging timePulse automatic controlCapacitanceInverter

The invention provides a clock signal generation device and a clock signal generation method; the device comprises a voltage source, a current source, a first digital-to-analog conversion circuit, a comparator, a first phase inverter and a capacitor, and the input end of the first digital-to-analog conversion circuit is connected with the output end of the voltage source; the output end of the first digital-to-analog conversion circuit is connected with the first input end of the comparator, and the first digital-to-analog conversion circuit is used for adjusting the voltage output by the voltage source to obtain comparison voltage; the power supply end of the first phase inverter is connected with the output end of the current source, the input end of the first phase inverter is connected with the output end of the comparator, the output end of the first phase inverter is connected with the capacitor and the second input end of the comparator, and current generated by the current source charges the capacitor; and the comparator is used for generating a clock signal according to the comparison voltage and the output voltage of the first inverter. The charging time of the capacitor can be accurately controlled, so that the frequency of the clock signal is accurately controlled, and the frequency adjustment error of the clock signal can be reduced.

Owner:宏晶微电子科技股份有限公司

Ultrasonic probe and ultrasonic therapy device with identification function

ActiveCN103083829BPrecise frequency controlPrecise Control of Duty CycleUltrasound therapyMicrocontrollerClass-D amplifier

The invention discloses an ultrasonic probe with a recognition function and an ultrasonic therapy device. The ultrasonic probe with the recognition function comprises a probe body and an ultrasonic generator which is arranged in the probe body. A unibus memory in series connection with the ultrasonic generator is further arranged in the probe body, and probe identification codes are arranged in the unibus memory. According to the ultrasonic probe with the recognition function and the ultrasonic therapy device, a microcontroller and a field programmable gate array (FPGA) device can be utilized for generating drive signals to accurately control the frequency, the duty ratio, the number of pulses and other parameters of the ultrasonic probe; the microcontroller enables the ultrasonic probe to have an automatic probe identification function through the probe identification codes stored in the unibus memory in the probe body so that the ultrasonic probe can automatically match the probe emission parameters, and therefore the emission efficiency of probe operation is enabled to be improved at an optimum resonant frequency point; the microcontroller can detect the temperature of the probe body and realize on-line fault automatic detection; and due to the fact that a category D amplifier is adopted in a driving circuit, compared with an existing ultrasonic treatment instrument in the same type, the power consumption of the ultrasonic therapy device is lowered by 40%.

Owner:SHENZHEN WELL D MEDICAL ELECTRONICS

Power generation system based on waste heat of rotary kiln by-products

ActiveCN105756734BPrecise frequency controlGuaranteed Frequency AccuracySteam useIncreasing energy efficiencyProduct gasProcess engineering

The invention discloses a power generation system based on waste heat of a rotary kiln byproduct. The power generation system comprises a gas storage tank, a steam turbine, a generator, a frequency detector, a rotating speed sensor and a controller, wherein the gas storage tank is used for storing high-temperature carbon dioxide gas generated by a rotary kiln in the process of calcining magnesium ores at a high temperature; a controllable valve is arranged at an outlet of the gas storage tank so as to control a gas outflow volume of the gas storage tank; a gas inlet of the steam turbine is connected to the controllable valve so as to receive the high-temperature carbon dioxide gas; the generator is connected to an output shaft of the steam turbine and outputs a voltage along with rotation of the steam turbine; the frequency detector is used for detecting frequency of the voltage output by the generator; the rotating speed sensor is arranged on the steam turbine and is used for detecting a rotating speed of the output shaft of the steam turbine; the controller is used for determining the opening of the controllable valve according to the frequency from the frequency detector and the rotating speed from the rotating speed sensor.

Owner:刘昕

Automatic glue spraying and stamping device for motor silicon steel sheet

PendingCN114849975APrecise size controlPrecise flow controlShaping toolsLiquid surface applicatorsElectric machineStamping process

The automatic glue spraying and stamping device comprises a glue feeding body, a valve body and a firing pin, the valve body comprises a shell, a sealing piece and a limiting part, the limiting part comprises an upper limiting piece and a lower limiting piece, and the firing pin is controlled by electromagnetic signal induction. The invention belongs to the technical field of dispensing connection modes in high-speed stamping and application, and particularly provides a dispensing device which can accurately control the size, the flow, the position and the dispensing frequency in the dispensing process, can achieve gluing in the stamping process, can achieve high-frequency dispensing efficiency and long-time service life, can adjust the height, and is convenient to use. And the automatic glue spraying and stamping device is convenient to popularize and use.

Owner:江苏联博精密科技股份有限公司

Quantitative glue spraying device for precise gluing of new energy vehicle drive motor iron core

ActiveCN113522658BAccurately control the dosageReduce dosageLiquid surface applicatorsCoatingsNew energyAir pump

The invention discloses a quantitative glue spraying device for precisely gluing the iron core of a drive motor of a new energy vehicle, which includes a glue spray head and a glue supply machine. The glue spray head includes a glue spray channel and a cutting air duct. The glue spray channel includes a glue outlet. The glue supply assembly is provided on the glue machine. The glue supply assembly includes a glue chamber. The glue outlet pipe is set at the upper end of the glue chamber. There is also a glue discharge stick on the top, which is used to flow the glue in the glue chamber to the glue spray head through the glue outlet pipe. The invention provides a quantitative glue spraying device for precisely gluing the iron core of a drive motor of a new energy vehicle, which can prevent the glue from curing and sticking at the glue outlet of the glue spray head, and can precisely control the amount of glue sprayed.

Owner:浙大宁波理工学院

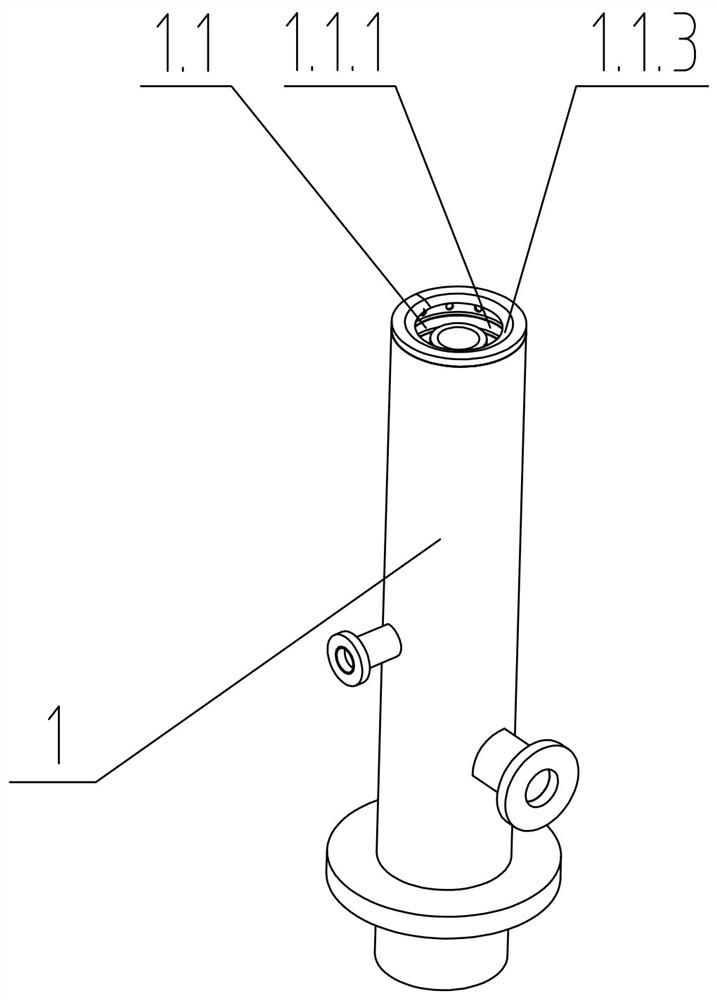

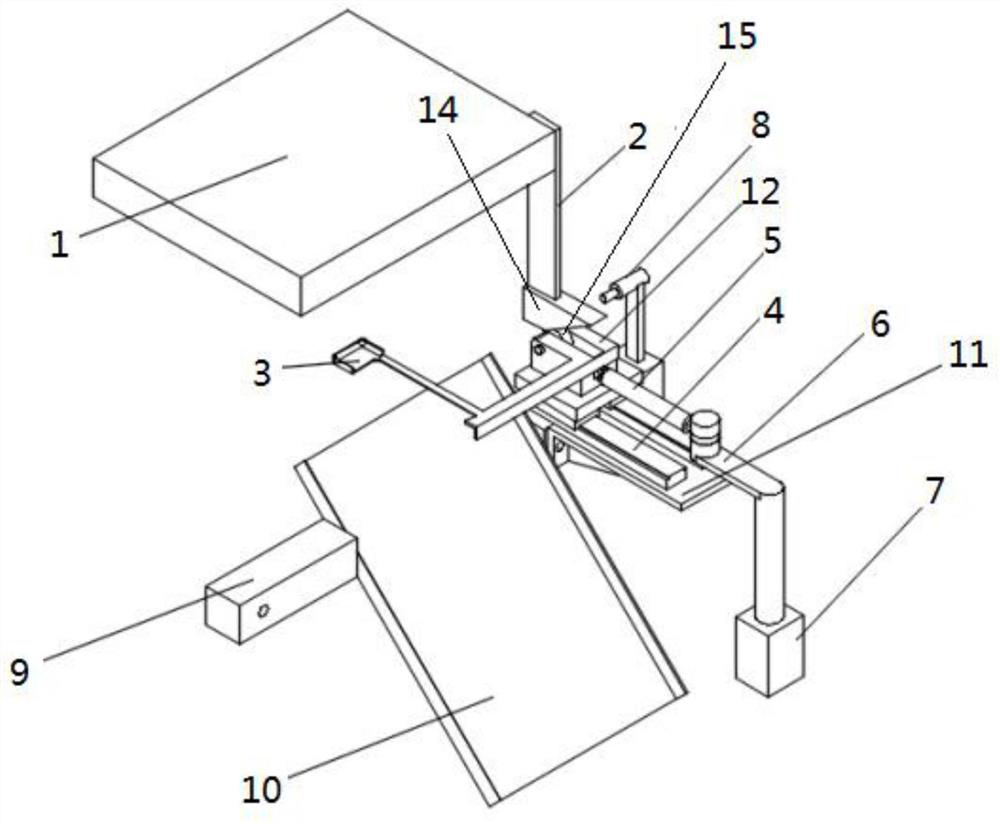

Blanking sampling device for stamping

ActiveCN113063635ARealize automatic samplingImprove quality controlWithdrawing sample devicesPreparing sample for investigationControl engineeringQuality control

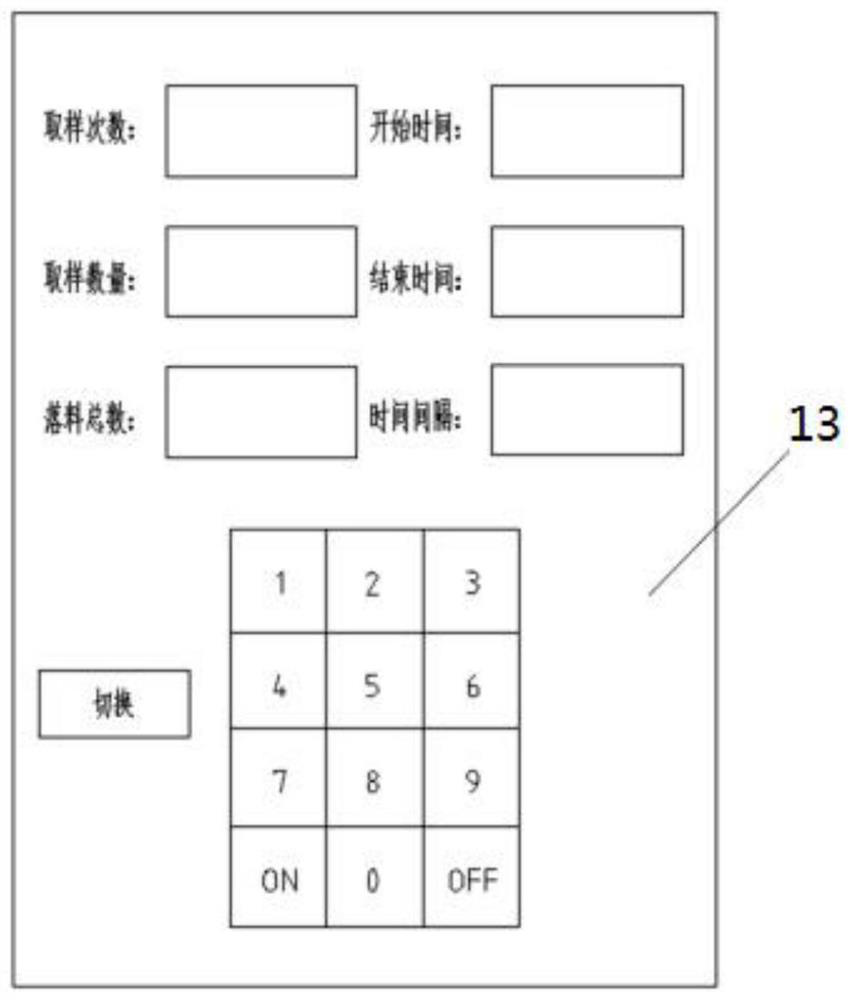

A blanking sampling device for stamping comprises a sampling mechanism and a sampling frequency control mechanism, wherein the sampling mechanism comprises an upper die, a pressing rod, a rear pressing block, a sliding block, a sliding rail and a material receiving hopper; the upper end of the pressing rod is fixedly connected with the lower end face of the upper die, the upper end of the rear pressing block is fixedly connected with the lower end of the pressing rod, the rear pressing block is used in cooperation with the sliding block, and the sliding block is in sliding connection with the sliding rail; the sliding rail is fixed through a sliding rail seat, the material receiving hopper is fixedly connected with the sliding block through a connecting rod, and the rear pressing block can extrude the sliding block in the process that the rear pressing block is pressed downwards along with the upper die and enables the sliding block to drive the material receiving hopper to move from a material receiving station to a discharging station; and the sampling frequency control mechanism is configured to control the material receiving frequency of the material receiving hopper by controlling the position of the sliding block. Automatic sampling of the stamping blanking device for the chain parts is achieved, in the sampling process, the sampling frequency and the sampling number are accurately controlled according to a preset program, errors caused by manual sampling are avoided, and quality control over the chain parts is facilitated.

Owner:QINGDAO CHOHO IND CO LTD

Molding method and application of molecular sieve adsorbent

PendingCN114433013APrecisely control the amount addedPrecise frequency controlOther chemical processesAluminium silicatesMolecular sieveSorbent

The invention relates to the field of molecular sieve preparation, and discloses a forming method and application of a molecular sieve adsorbent. The method comprises the following steps: (1) adding a mixture of a molecular sieve and clay into a ball pot filled with seed balls in batches; (2) adding water into the rolling-ball pot, so that the water content W1 of the small balls in the rolling-ball pot is maintained at 30-60wt%; (3) when the small balls grow to the particle size R of 0.15-2 mm, stopping feeding, controlling water adding, so that the water content W2 of the small balls in the rolling ball pot is maintained at 30-60 wt%, and continuously rolling for 0.5-3 hours; and (4) drying and roasting the pellets to obtain the formed molecular sieve pellets. The method for preparing the adsorbent provided by the invention is convenient to operate, improves the product percent of pass and the production efficiency, and is suitable for preparing various molecular sieve adsorbents formed by rolling balls.

Owner:CHINA PETROLEUM & CHEM CORP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com