Double-fluid injector

A dual-fluid, ejector technology, applied in liquid ejection devices, ejection devices, ejection devices, etc., can solve the problems of not considering the fluid, inconsistent size of glue points, different responses, etc., and achieve long service life, convenient operation and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

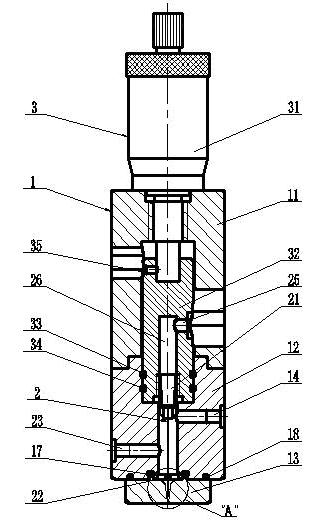

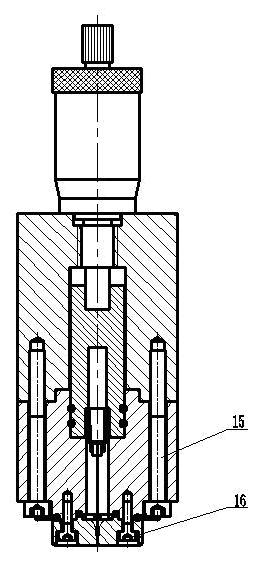

[0037] refer to figure 1 and figure 2 , the dual-fluid injector includes a valve body (1), an injection mechanism (2), and a stroke adjustment mechanism, and is characterized in that: the valve body (1) is fixedly connected to the upper valve body by the upper and lower ends of the middle valve body (12) (11) and the lower valve body (13); the stroke adjustment mechanism is placed in the inner cavity formed between the middle valve body (12) and the upper valve body (11), and the stroke adjustment mechanism is a differential head stroke adjustment Mechanism (3); the dual-fluid injection mechanism (2) is arranged in the inner cavity formed between the middle valve body (12), the lower valve body (13) and the differential head stroke adjustment mechanism (3).

Embodiment 2

[0039] This embodiment is basically the same as Embodiment 1, and the special features are as follows:

[0040]The differential head stroke adjustment mechanism (3) includes a differential head (31), a needle valve (32), O-rings (33, 34) and set screws (35); it is characterized in that: the differential head (31 ) at the installation position, the external thread is screwed with the internal thread on the upper end of the upper valve body (11) to realize the fixed connection between the differential head (31) and the valve body (1), the end of the differential head (31) and the top of the needle valve (32) The countersunk head fits and is fixedly connected by the side wall set screw (35); O-rings (33, 34) are arranged between the side wall of the needle valve (32) and the middle valve body (12) to realize the needle valve (32) and the seal between the middle valve body (12).

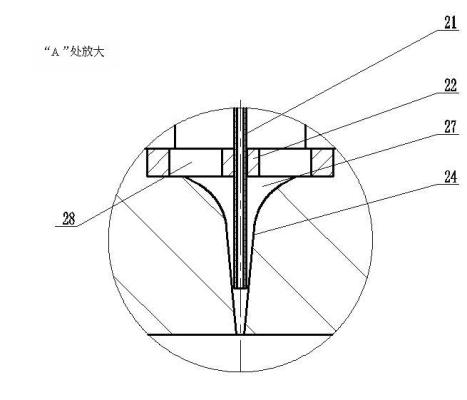

[0041] refer to image 3 , the dual-fluid injection mechanism (2) includes a gas needle (21), a gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com