Power generation system based on waste heat of rotary kiln byproduct

A technology of power generation system and rotary kiln, applied in furnaces, waste heat treatment, furnace components, etc., can solve the problems of large environmental pressure, waste of heat source, air pollution, etc., to ensure frequency accuracy, improve the utilization of waste heat, and improve the economy. effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below with reference to the accompanying drawings and preferred embodiments. However, it should be noted that many of the details listed in the specification are only for readers to have a thorough understanding of one or more aspects of the present invention, and the present invention can be practiced without these specific details.

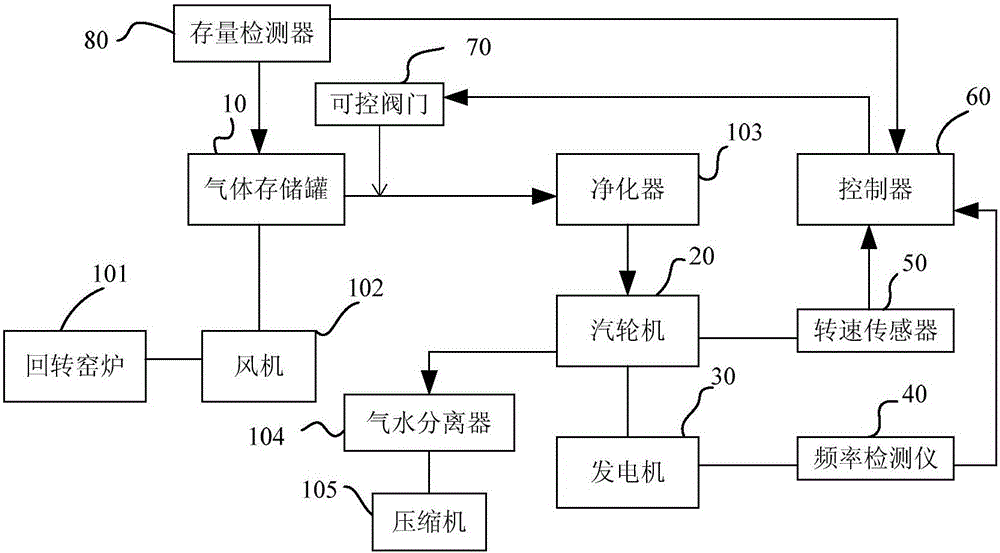

[0030] In the process of calcining magnesium ore in the rotary kiln, the main product is magnesium powder, and a large amount of high-temperature and high-heat carbon dioxide gas is produced at the same time. In the present invention, the high-temperature and high-heat carbon dioxide gas is first input into the steam turbine to drive the steam turbine to rotate, and the steam turbine drives the generator to generate electricity. In this way, the thermal energy in the carbon dioxide gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com