Quantitative glue spraying device for precise gluing of new energy vehicle drive motor iron core

A technology for new energy vehicles and driving motors, which is applied to the device and coating of the surface coating liquid, which can solve the problems of unstable spray glue dosage, reduce the automation effect, and unfavorable glue stability, etc., so as to reduce artificial The frequency of maintenance, the effect of improving automation, and the effect of ensuring accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

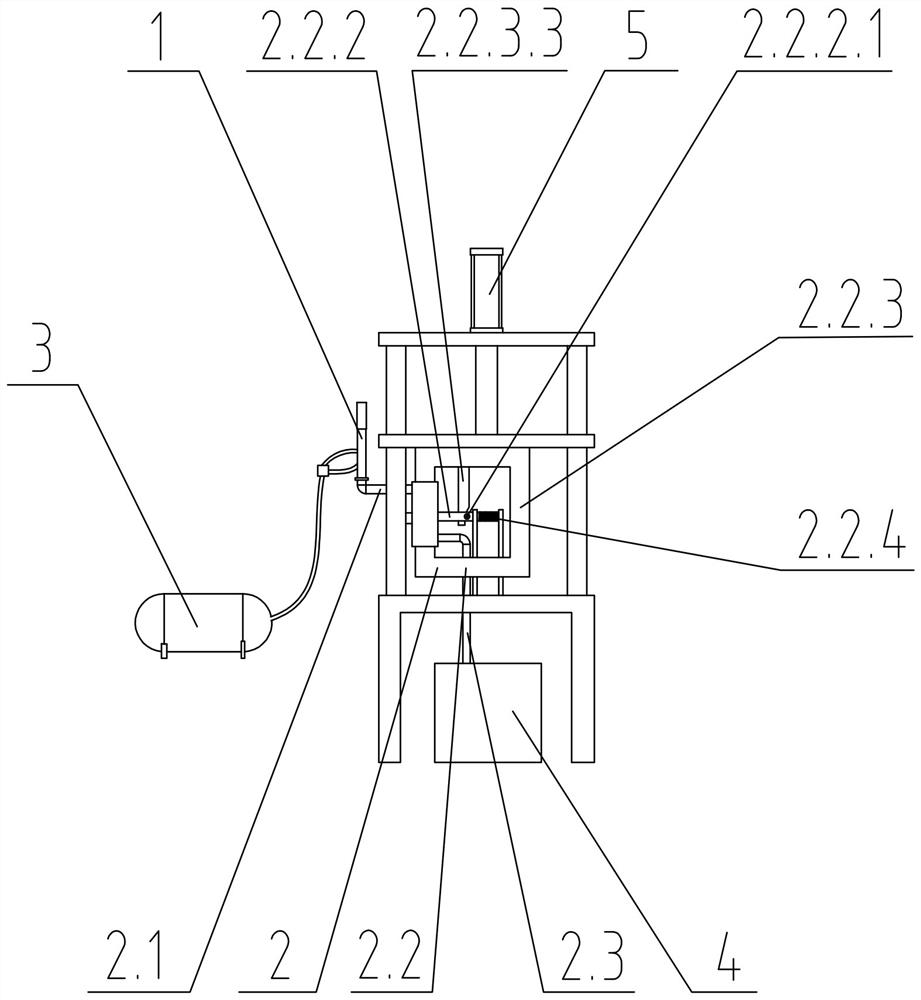

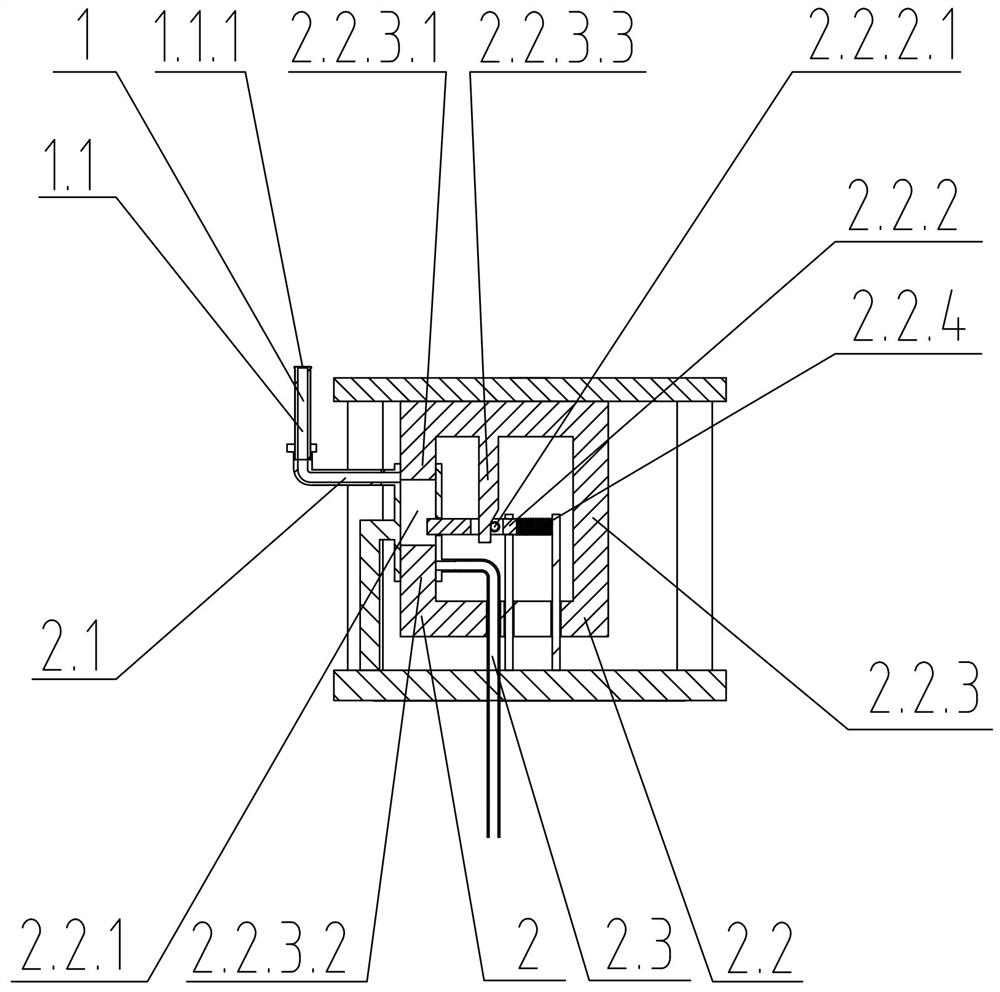

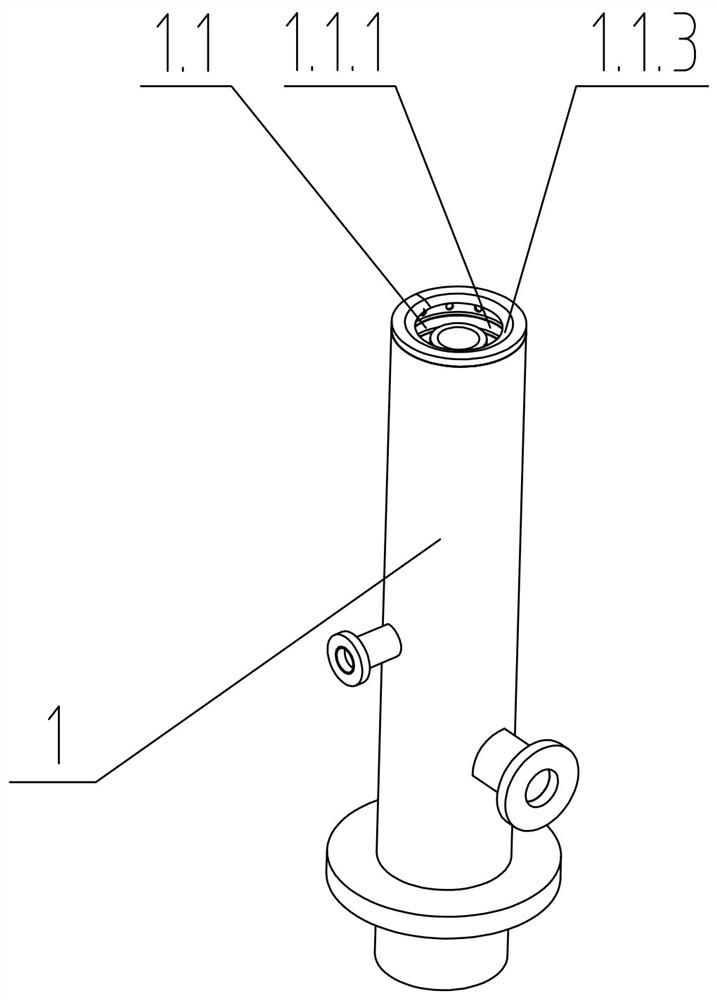

[0028] Such as Figure 1-2 As shown, a quantitative glue spraying device for accurately gluing the iron core of a drive motor of a new energy vehicle includes a glue spray head 1 for spraying glue and a glue supply machine 2 for supplying glue to the glue spray head 1. Glue feeder 2 is provided with glue outlet pipe 2.1, and described glue spray head 1 is connected on the glue outlet pipe 2.1, and described glue spray head 1 comprises the glue spray channel 1.1 for spraying glue and is used for glue drop from the glue spray channel. The cutting air duct 1.2 for separation in 1.1, the glue spraying channel 1.1 includes a glue outlet 1.1.1, the glue outlet 1.1.1 is set vertically upward, and the inside of the side wall of the glue spraying channel 1.1 is provided with Damping pattern 1.1.2, damping pattern 1.1.2 is set at one end of the glue outlet 1.1.1, the glue spray channel 1.1 is connected with the glue outlet pipe 2.1, the cutting air duct 1.2 is connected with the air pum...

Embodiment 2

[0032] Such as figure 2 , Figure 6 As shown, a quantitative glue spraying device for accurately gluing the iron core of a drive motor of a new energy vehicle includes a glue spray head 1 for spraying glue and a glue supply machine 2 for supplying glue to the glue spray head 1. Glue feeder 2 is provided with glue outlet pipe 2.1, and described glue spray head 1 is connected on the glue outlet pipe 2.1, and described glue spray head 1 comprises the glue spray channel 1.1 for spraying glue and is used for glue drop from the glue spray channel. The cutting air duct 1.2 for separation in 1.1, the glue spraying channel 1.1 includes a glue outlet 1.1.1, the glue outlet 1.1.1 is set vertically upward, and the inside of the side wall of the glue spraying channel 1.1 is provided with Damping pattern 1.1.2, damping pattern 1.1.2 is set at one end of the glue outlet 1.1.1, the glue spray channel 1.1 is connected with the glue outlet pipe 2.1, the cutting air duct 1.2 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com