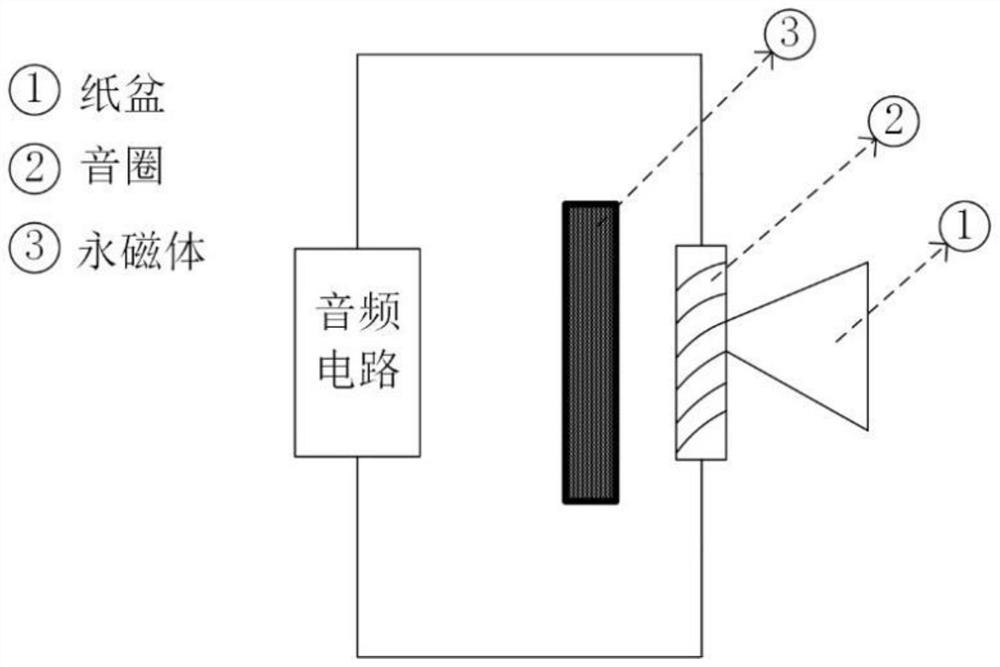

Acoustic propagation system

A sound propagation, plane technology, applied in the field of sound propagation, can solve the problems of reduced sound quality, energy loss, large structure occupied size, etc., to achieve the effect of improving sound quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

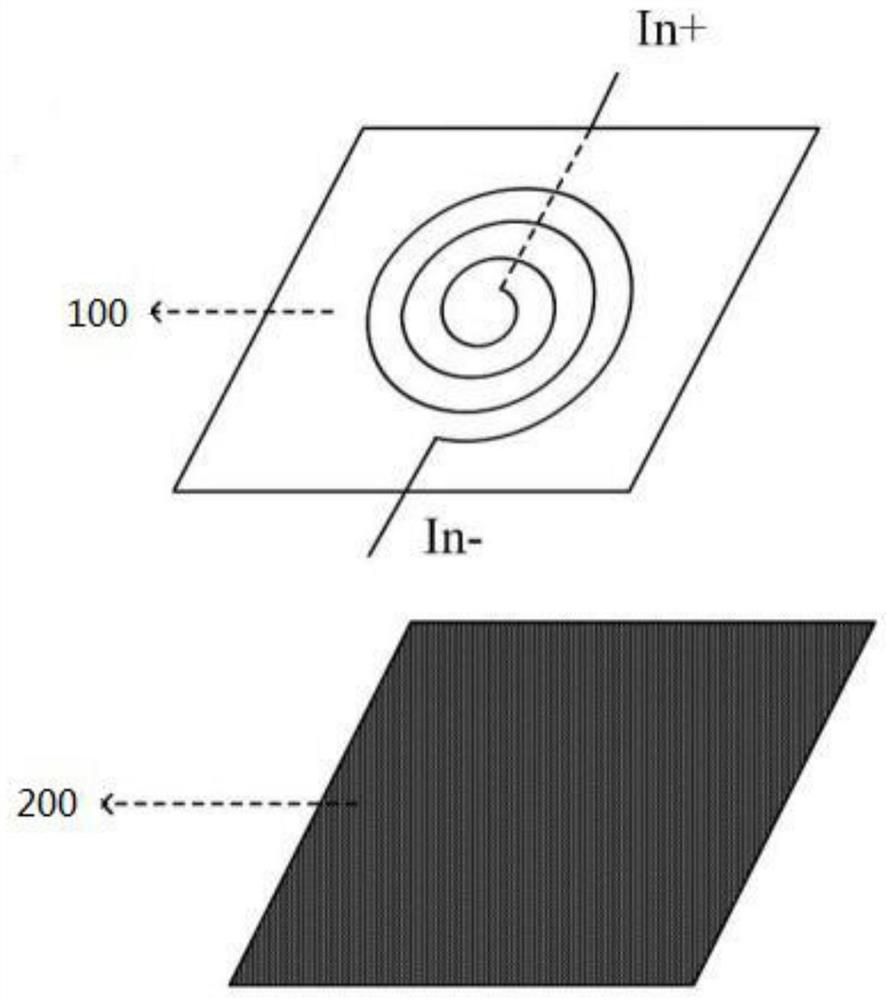

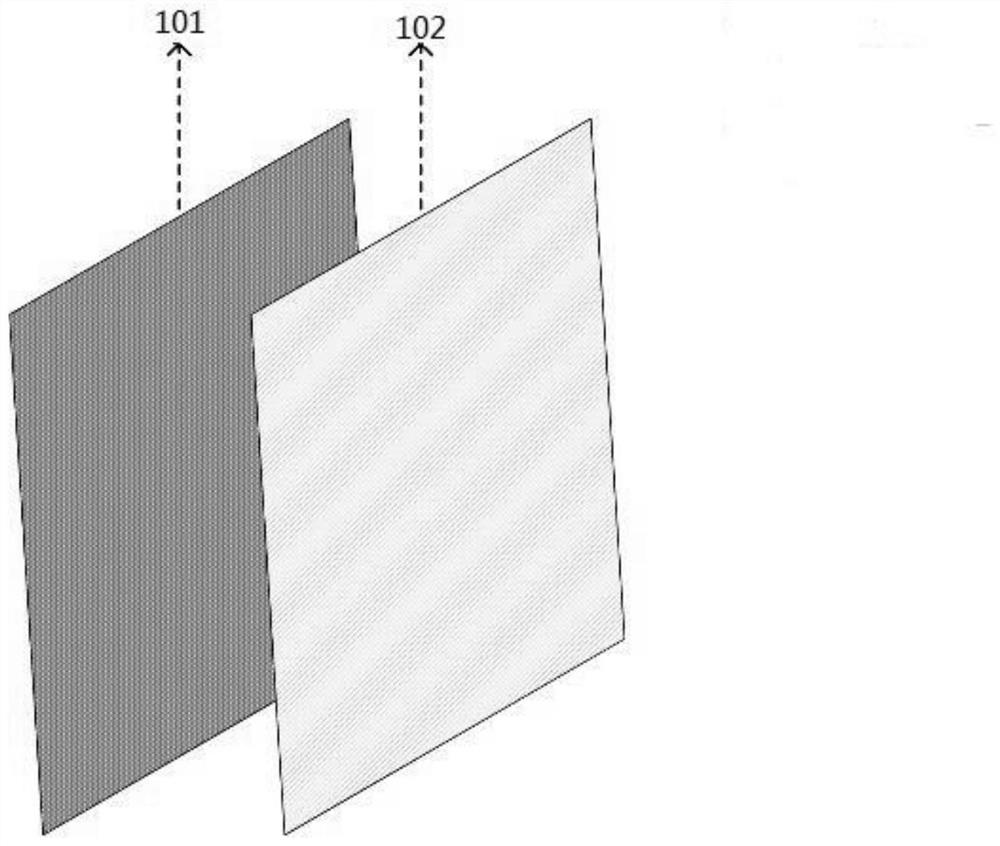

[0028] see Figure 2 to Figure 6 As shown, the present invention provides a sound propagation system, including a planar resonant circuit, the planar resonant circuit includes a planar resonator 100 and a permanent magnet 200, the planar resonator 100 includes a metal layer 110 and a flexible film substrate layer 120, and the metal layer 110 is pressed on the flexible film substrate layer 120.

[0029] The sounding principle of the above-mentioned planar resonant circuit is: when an alternating current passes through the planar resonator 100 , different magnetic fields will be generated, which will interact with the permanent magnet 200 at the bottom to generate vibration and soun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com