Intelligent type sand mulling control method

A control method and intelligent technology, applied in the direction of control devices, special data processing applications, instruments, etc., can solve the problems of low productivity, inaccurate control accuracy, high material consumption, etc., and achieve the effect of saving materials and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

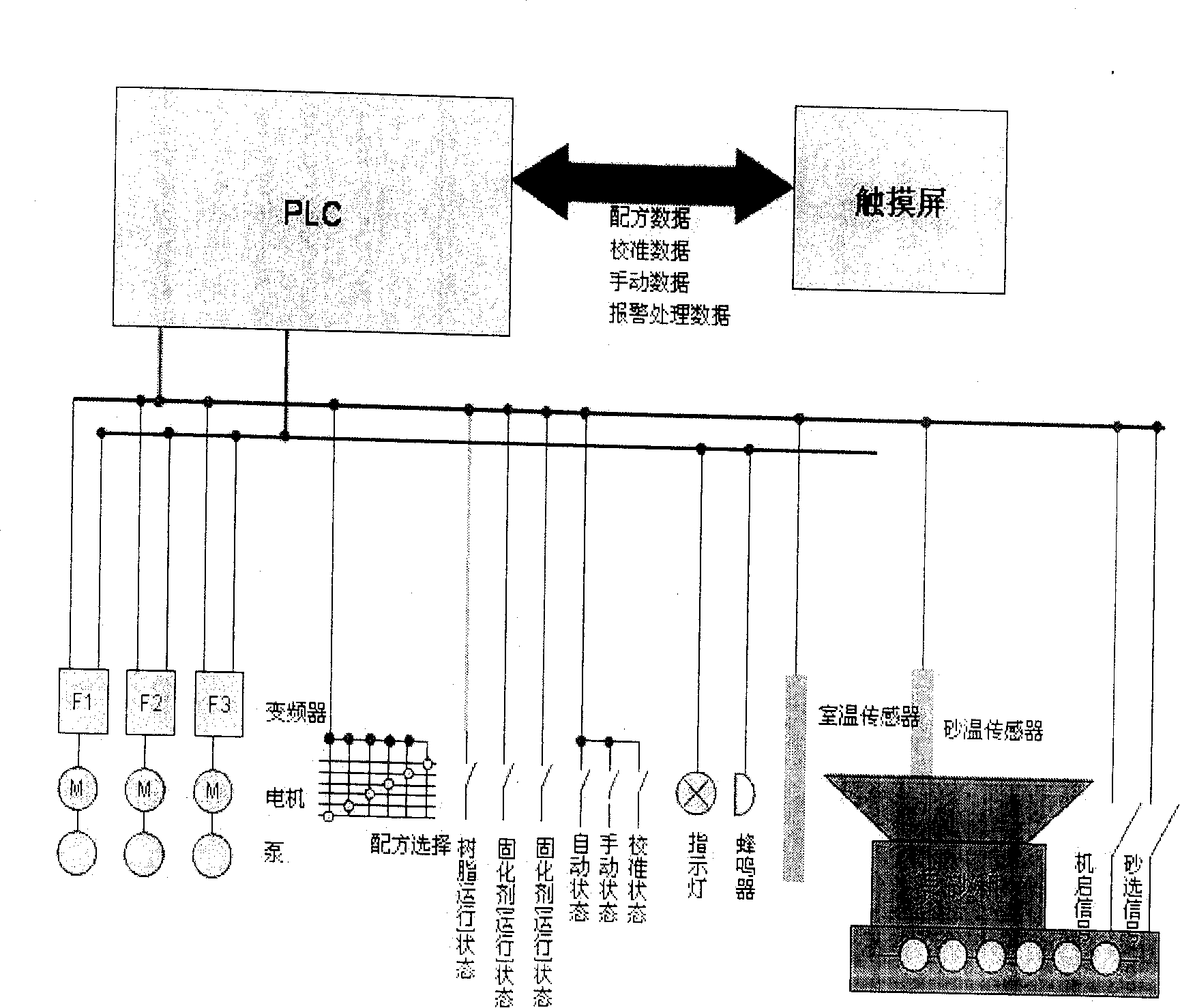

Method used

Image

Examples

Embodiment Construction

[0032] known conditions:

[0033] For a sand mixer with an output of 30 tons per hour, 30,000 kg / hour, when operating as surface sand, the amount of resin used is 1.0% of the sand amount, the sand temperature at that time is 25°C, the mold release time is 40 minutes, and the total curing agent The relative resin ratio (%) of consumption is 40%,

[0034] The mediation coefficient b is 2 when the mold drawing time is 40 minutes, which is the mediation coefficient extracted from the expert knowledge base.

[0035] Fast curing agent specific gravity = 1.05

[0036] Slow curing agent specific gravity = 1.15

[0037] Resin specific gravity = 1.15.

[0038] Solve:

[0039] Resin amount = sand flow rate * resin addition amount (surface sand) (%)

[0040] Resin amount = 30000*1.0% = 300 kg / hour = 5000 g / min

[0041] Fast curing dose = sand flow * resin addition (%) * total curing agent relative to resin ratio (%) * (k1*x+k2-b)

[0042] Wherein, x=temperature, k2=100, K1=-100 / 40=...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com