Method for preparing carrier resin for high-temperature-resistant molding process coloring materials

A technology of carrier resin and coloring material, applied in the field of preparation of carrier resin for color paste, can solve the problems of high price, strength aging and heat resistance, poor color paste stability, etc., to reduce the amount of small molecules and improve the resistance The effect of high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a method for preparing a carrier resin used in a high temperature resistant molding process coloring material, comprising the following steps:

[0032] Step 1: Mix and stir 70-100 parts of dihydric alcohol, 60-100 parts of polybasic acid and 15-25 parts of dianhydride in a nitrogen atmosphere according to the parts by weight, and gradually heat up to 195-235°C for condensation reaction. After the reaction system becomes uniform and transparent, keep warm and continue the reaction until the measured acidity value of the reaction product is less than or equal to 18mgKOH / g, wherein the dihydric alcohol is diethylene glycol or dipropylene glycol, and the polybasic acid is adipic acid Or sebacic acid, the dianhydride is maleic anhydride.

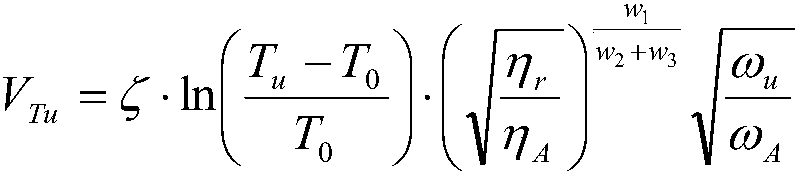

[0033] Gradually raise the temperature to 195-235°C to carry out the condensation reaction, and the heating rate satisfies:

[0034]

[0035] Among them, V Tu is the heating rate (°C / h), ζ is the temperature ris...

Embodiment 1

[0043] Step 1: According to the parts by weight, mix and stir 70 parts of diethylene glycol, 60 parts of adipic acid and 15 parts of maleic anhydride in a nitrogen atmosphere, the stirring speed is 5r / s, and gradually heat up to 195 Condensation reaction is carried out at ℃, after the reaction system becomes uniform and transparent, keep warm and continue the reaction until the measured acidity value of the reaction product is less than or equal to 18mgKOH / g.

[0044] The initial viscosity of the mixed solution is 4.0mPa·s, the mass fraction of diethylene glycol in the mixed solution is 0.48, the mass fraction of adipic acid in the mixed solution is 0.41, and the mass fraction of maleic anhydride in the mixed solution The mass fraction in is 0.11.

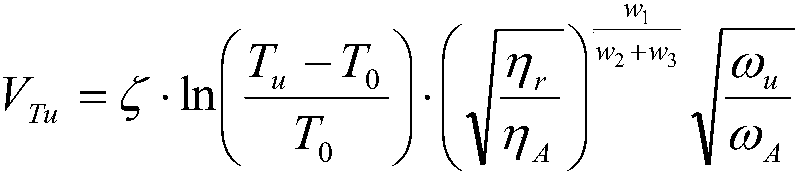

[0045] Gradually raise the temperature to 195°C to carry out the condensation reaction, and the heating rate satisfies:

[0046]

[0047] When diethylene glycol, adipic acid and maleic anhydride are mixed and stirred under a ni...

Embodiment 2

[0054] Step 1: According to the parts by weight, mix and stir 100 parts of dipropylene glycol, 100 parts of sebacic acid and 25 parts of maleic anhydride in a nitrogen atmosphere, the stirring speed is 7r / s, and the temperature is gradually raised to 235°C Carry out the condensation reaction, after the reaction system becomes uniform and transparent, keep warm and continue the reaction until the acidity value of the reaction product is less than or equal to 18mgKOH / g.

[0055] The initial viscosity of the mixed solution is 4.5mPa·s, the mass fraction of dipropylene glycol in the mixed solution is 0.44, the mass fraction of adipic acid in the mixed solution is 0.44, and the mass fraction of maleic anhydride in the mixed solution The mass fraction is 0.12.

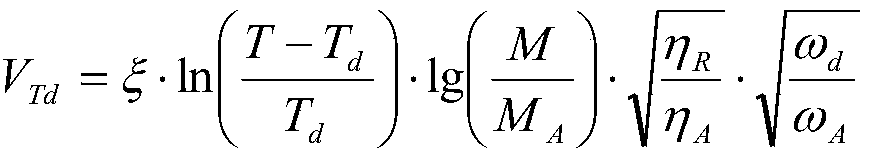

[0056] Gradually raise the temperature to 195°C to carry out the condensation reaction, and the heating rate satisfies:

[0057]

[0058] When dipropylene glycol, sebacic acid and maleic anhydride are mixed and stirred u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com