Acid making equipment and steam boiler boiling method

An equipment and steam technology, applied in the field of sulfuric acid preparation, can solve problems such as production shutdown accidents, equipment corrosion, condensation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

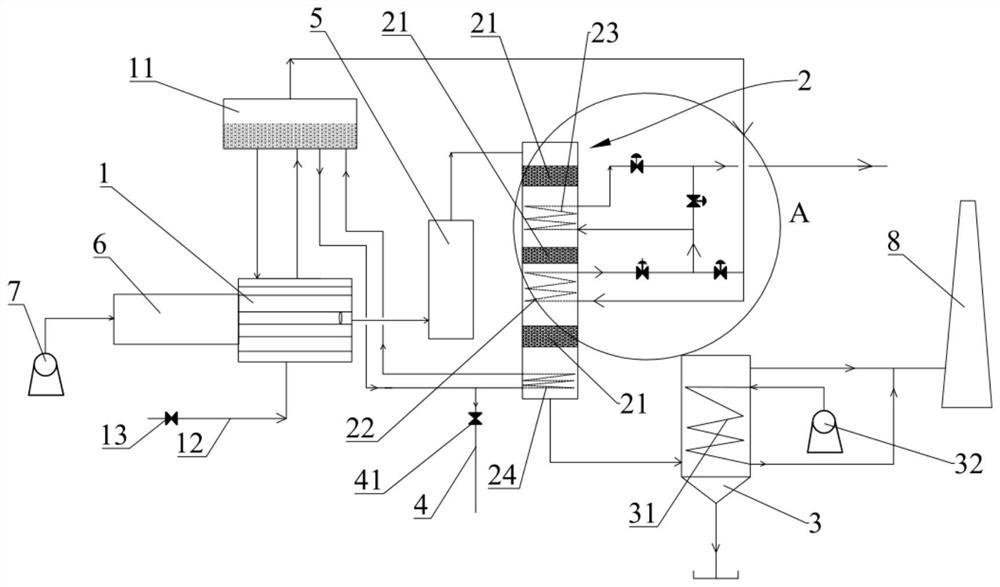

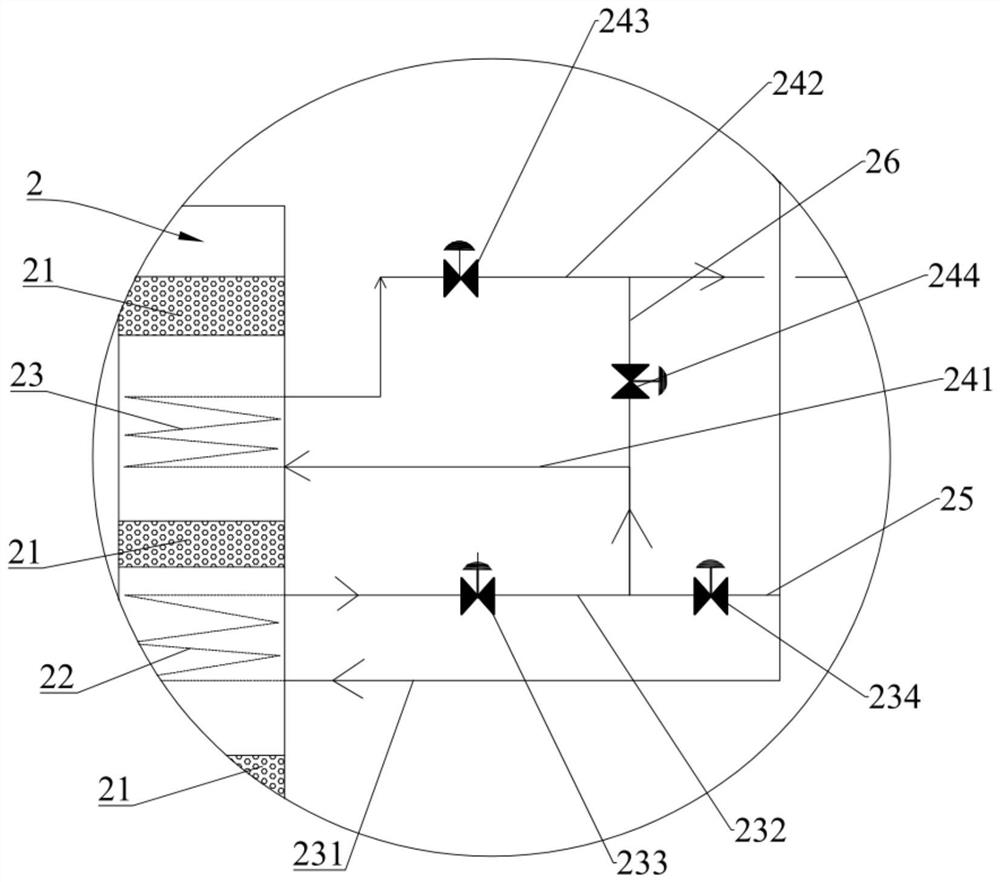

[0041] This embodiment provides an acid making equipment. like figure 1 As shown, the acid production equipment includes a waste heat boiler 1 , a converter 2 and a condenser 3 . A steam drum 11 is arranged above the waste heat boiler 1 , the waste heat boiler 1 is connected with a start-up steam pipe 12 , and the start-up steam pipe 12 is provided with a steam valve 13 . The converter 2 is provided with a catalyst 21, an inter-bed cooler and a process gas cooler 24. One end of the converter 2 is communicated with the waste heat boiler 1, the inter-bed cooler is communicated with the top of the steam drum 11, and the process gas cooler 24 is communicated with the steam boiler. The bottom of the bag 11 communicates. The condenser 3 communicates with the bottom of the converter 2 .

[0042] Specifically, the acid making equipment also includes a combustion fan 7 and an incinerator 6, and the combustion fan 7 is used to blow high-temperature air into the incinerator 6, so that...

no. 2 example

[0058] The present embodiment provides a steam boiler method, which utilizes the above-mentioned acid-making equipment, and the steps are as follows:

[0059] S1, open the steam valve 13, so that the steam enters the waste heat boiler 1 and heats the water in the waste heat boiler 1;

[0060] S2. Open the valve of the inter-bed cooler to make the steam pass through the inter-bed cooler;

[0061] S3 , open the blowdown valve 41 of the process air cooler 24 .

[0062] The operator makes the starting steam enter the waste heat boiler 1 to heat the boiler water, and exchanges heat with the combustion air blown into the waste heat boiler 1 by the combustion fan 7. After that, the steam of the boiler water enters the steam drum 11 and enters the inter-bed cooler for heating through pipes , the combustion air enters the reformer 2 and heats the reformer 2, and the whole system is heated and heated by the steam of the boiler water and the combustion air to ensure that the whole syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com