Device and method for synchronous measurement and control of three-dimensional deformation and temperature of materials under high temperature environment

A high-temperature environment, three-dimensional deformation technology, applied to measuring devices, instruments, etc., can solve problems such as limitations, inability to measure high-temperature distribution in the whole field, and inability to respond to three-dimensional deformation of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

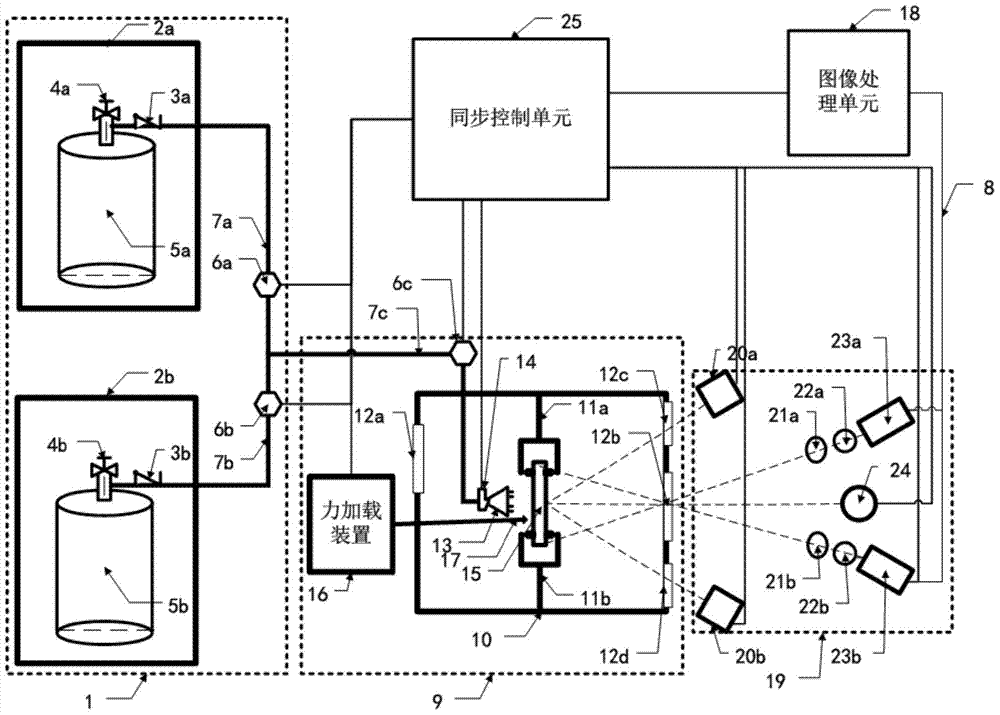

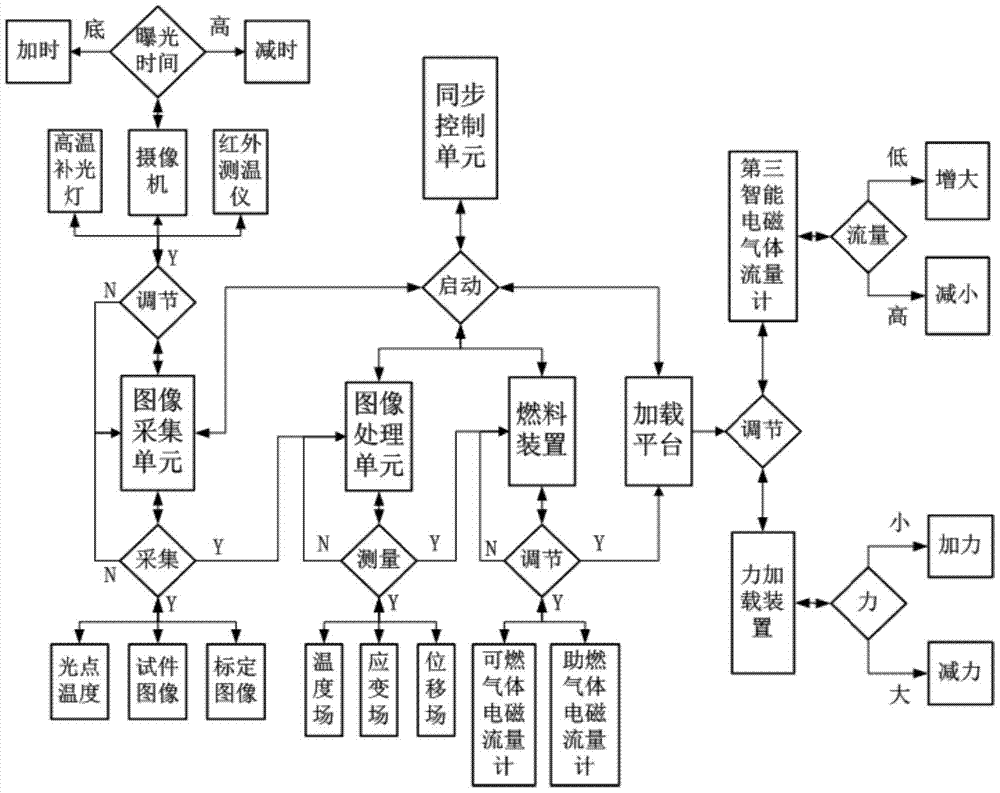

[0022] Attached below figure 1 , attached figure 2 Further illustrate the specific structure, working process and implementation of the present invention.

[0023] figure 1 It is a schematic diagram of the structural principle of a three-dimensional deformation and temperature synchronous measurement and control device for materials in a high-temperature environment. The device includes a fuel device 1, a loading platform 9, an image processing unit 18, a data acquisition unit 19, and a synchronous control unit 25. The signal line is connected with the synchronous control unit 25; the fuel device 1 includes a combustible gas device 5a, a gas-supporting device 5b, a combustible gas pipeline 7a, a gas-supporting pipeline 7b, a first intelligent electromagnetic gas flow meter 6a and a second intelligent electromagnetic gas flow The meter 6b, the combustible gas device 5a and the gas-supporting device 5b are connected to the mixed gas pipeline 7c through the combustible gas pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com