Inorganic lightweight aggregate insulation board maintenance equipment

A technology of inorganic lightweight aggregates and thermal insulation boards, which is applied in ceramic molding machines, clay preparation devices, cement mixing devices, etc., can solve problems such as inability to achieve better curing effects, and achieve accurate control of heating rate, good curing effects, and moisture content. low rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The inorganic lightweight aggregate insulation board prepared by the present invention includes the following raw materials: 140 parts of expanded perlite, 60 parts of Portland cement powder, 6 parts of cellulose, 5 parts of inorganic reinforcing fiber, and 1 part of early strength agent , 1 part of antifreeze, 1 part of water reducing agent, 4 parts of water repellent, 90 parts of water.

[0028] Wherein, the Portland cement powder has a mineral composition mass fraction of 65% to 75% C 3 S, 10% ~ 20% C 2 S, 6% ~ 12% C 4 AF, 4%~7%C 4 A 3 S; The mass fraction of f-CaO mass fraction is controlled to be 0.5%-1.5%, the mass fraction of liter weight is controlled to be 1280g / L-1400g / L, and the total amount of silicate minerals is greater than 70%.

[0029] The chemical composition mass fraction of the Portland cement powder is 65%-75% CaO, 18%-24% SiO 2 ,5%~7%Al 2 o 3 , 2% ~ 3% Fe 2 o 3 , 1.2%~3%SO 3 and small amounts of other oxides.

[0030] The Portland silica...

Embodiment 2

[0056] An embodiment of the preparation method of the Portland cement powder is:

[0057] S11, crushing the limestone to a sieve residue of 70mm square hole <10%, pre-homogenized and storing in the limestone shed, and mixing the raw materials such as the shale, the kaolin, the sulfuric acid slag, and the phosphogypsum Stored in the joint storage after melting;

[0058] S12, uniformly mix 75% of the limestone, 8% of the shale, 10% of the kaolin, 2% of the iron powder and 5% of the desulfurized gypsum according to the mass fraction ratio, wherein the control The mass fraction of CaO in the limestone is 51% to 52%, and the SiO in the shale 2 The mass fraction of the kaolin is 68% to 70%, and the Al in the kaolin 2 o 3 The mass fraction of the iron powder is 16% to 20%, and the Fe in the iron powder 2 o 3 The mass fraction of SO in the desulfurized gypsum is 65% to 70%. 3 The mass fraction is 40% to 45%;

[0059] S13, sending the mixed material into a vertical mill for dryi...

Embodiment 3

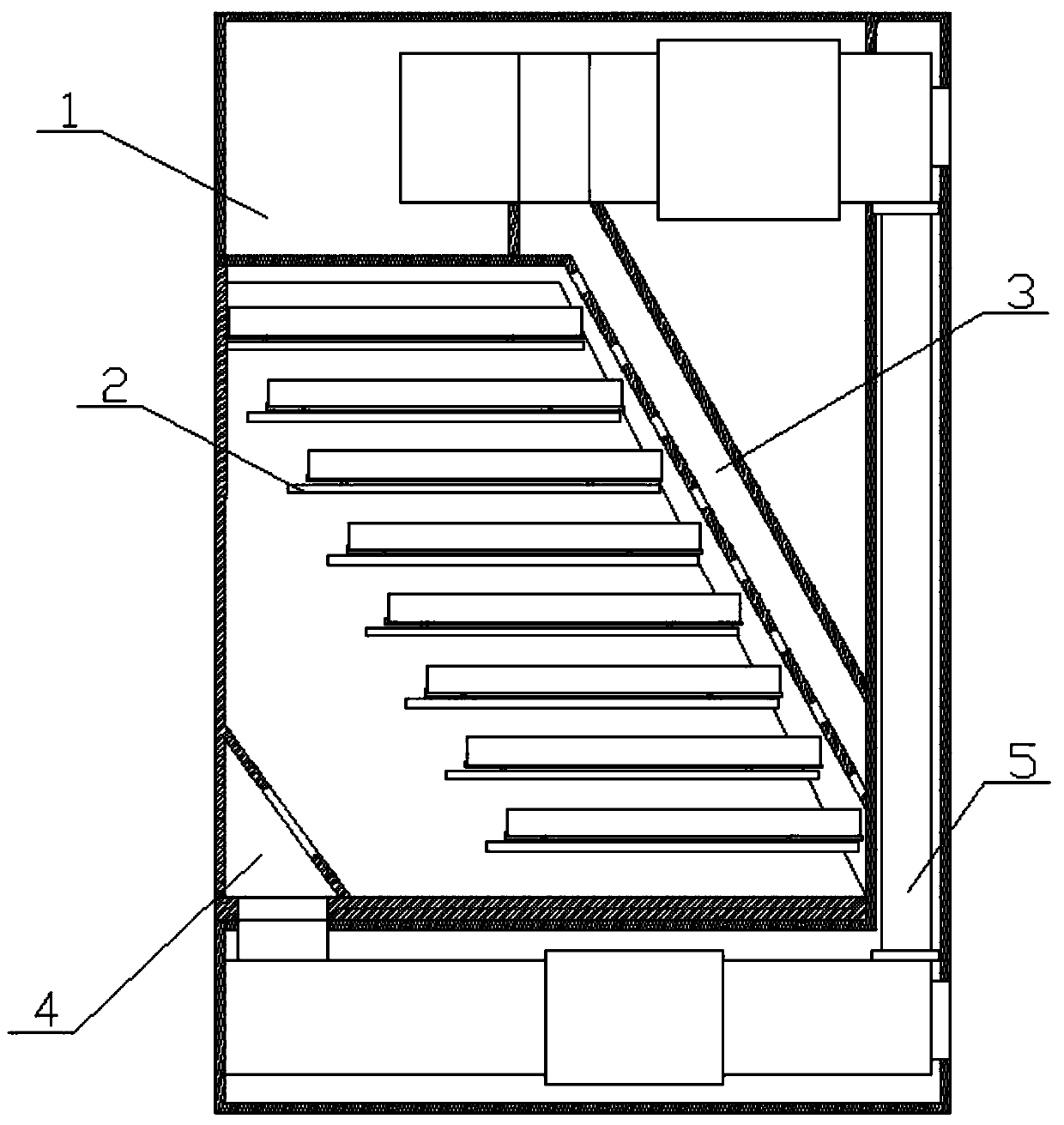

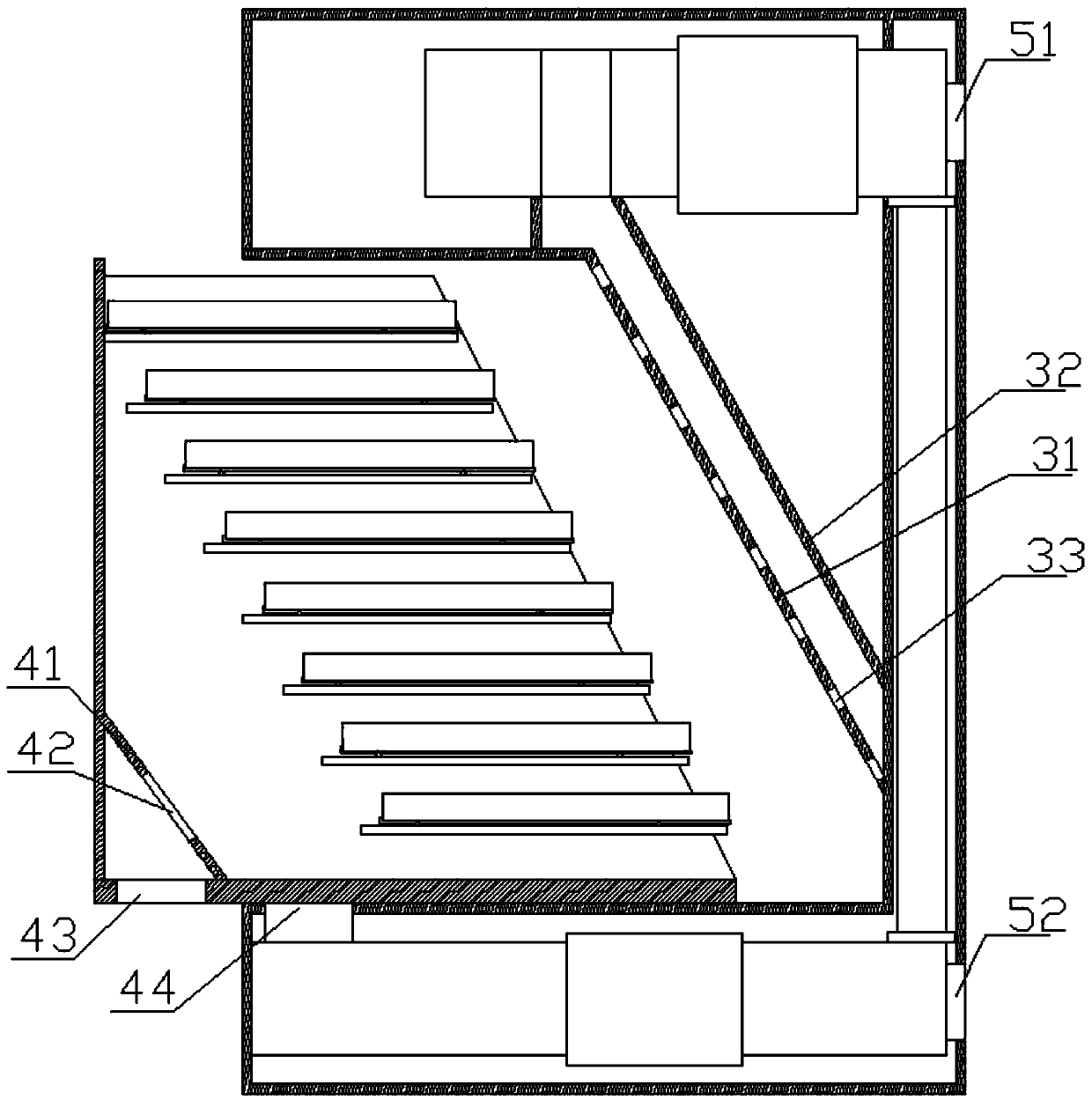

[0064] Such as figure 2 , image 3 as shown, figure 2 is a structural view of the closed state of the maintenance equipment; image 3 It is a structural view of the maintenance equipment in an opened state; the maintenance equipment used in the preparation method of the inorganic light aggregate insulation board includes a box body 1, and an inner cavity is arranged in the box body 1, and the A storage rack 2 is provided in the inner cavity, and the storage rack 2 is movably connected with the inner wall of the inner cavity. The box body 1 is also provided with a wind circulation system, and the wind circulation system is used to control the inner cavity Humidity and temperature of the air inside.

[0065] Preferably, the air circulation system includes an air outlet assembly 3 arranged on the upper part of the storage shelf 2, an air suction assembly 4 arranged on the storage shelf 2, and a ventilation duct arranged on the box body 1 5. The air outlet assembly 3 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com