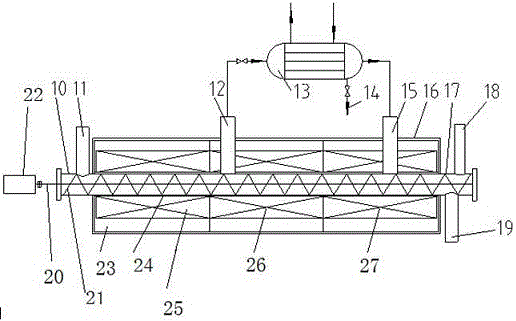

Electronic waste cracker

A technology of electronic waste and cracking device, which is applied in the direction of gasification process, petroleum industry, sustainable manufacturing/processing, etc. It can solve the problems of inability to realize continuous inflow and outflow of materials, inability to realize continuous pyrolysis of materials, etc., and achieve efficient and stable heat supply Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

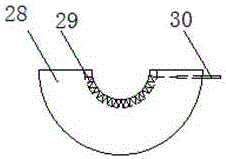

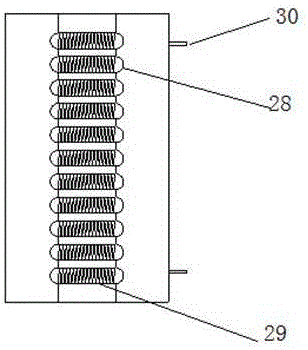

Method used

Image

Examples

Embodiment

[0036] Example: The electric heating system uses electric heating wire heating. The diameter of the heating wire is 1.4mm and the total length is 15m. The electronic waste materials (mainly circuit boards, wires and keyboards) are made into 3-6mm particles, and the imported material volume is 1kg / h, the final cracking residue is 0.5kg / h, and the cracking gas produced is 0.25 Nm 3 / h, the tar produced is 0.3kg / h, which realizes continuous feeding and exiting of materials. During the cracking process, the module temperatures of the three zones are kept at 650℃, 850℃, and 1000℃ respectively, and the heat source stability is very good.

[0037] The chemical composition of the cracked gas is as follows:

[0038] Table 1 E-waste pyrolysis gas composition

[0039] nameH2

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com