Workblank forging air cooling process for automobile engine connecting rod and air cooling equipment of workblank forging air cooling process

An automotive engine and air-cooling technology, which is applied to air-cooled equipment and air-cooled forging of non-quenched and tempered automotive engine connecting rod blanks, can solve problems such as affecting the quality of forgings and inability to control the cooling speed of forgings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

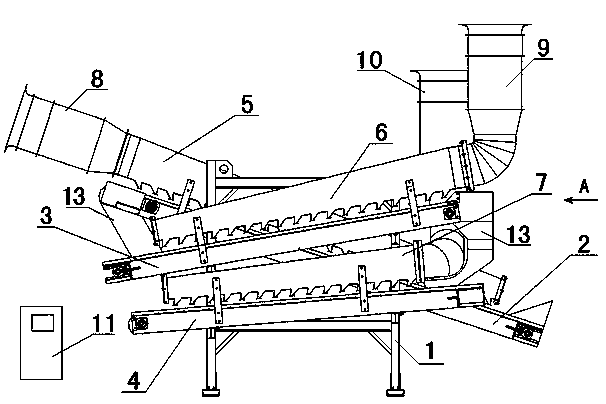

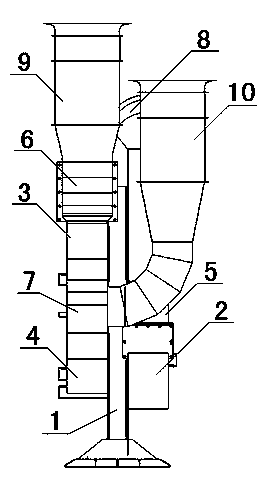

[0018] Such as figure 1 Shown: The air-cooled unit includes:

[0019] System Rack 1;

[0020] Three inclinedly arranged interconnected conveyor chains 2, 3, 4 arranged on the system rack 1;

[0021] Air ducts 5, 6, 7 arranged on each conveyor chain 2, 3, 4 on the system rack 1;

[0022] Blowers 8, 9, 10 arranged at one end of each air duct 5, 6, 7;

[0023] A computer control device 11 for controlling the speed of the conveyor chain and the speed of the blower;

[0024] The three interconnected conveyor chains arranged obliquely refer to the first conveyor chain 2 arranged obliquely on one side, and the second conveyor chain 3 and the third conveyor chain 4 arranged parallel up and down on the other side.

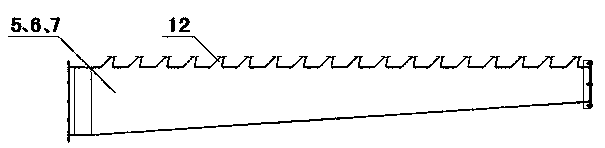

[0025] A plurality of air outlets 12 are uniformly arranged on the lower side of each air duct 5 , 6 , 7 .

[0026] The transmission chains 2, 3 and 4 are connected end-to-end through the intermediate slideway 13 to realize the continuous transmission of forgings on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com