Intelligent automobile accessory mold system and using method

A smart car and mold technology, applied in the field of injection molds, can solve problems such as long cooling time, large waste of raw materials, and inability to apply different parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

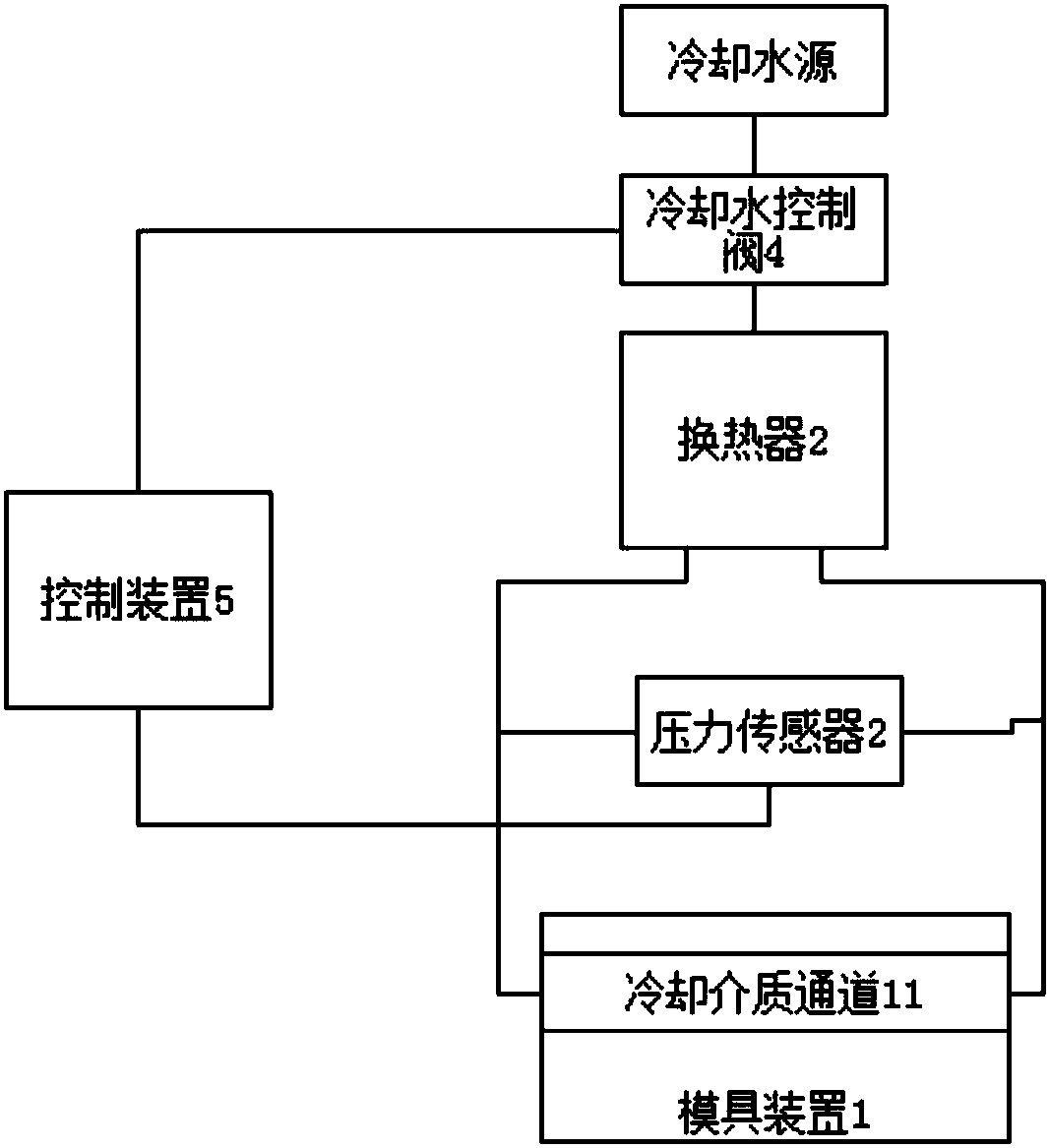

[0006] The intelligent auto parts mold system provided by the present invention is composed of a mold device 1, a heat exchanger 2, a pressure sensor 3, a cooling water control valve 4 and a control device 5. The mold device has a closed cooling medium passage 11, and the Pressure sensors are respectively installed at the cooling medium channel ends and connected to the hot fluid inlet and outlet of the heat exchanger through hot fluid pipes, the cold fluid inlet of the heat exchanger is connected to the cooling water source through pipes, and the cooling water control valve is installed on the On the pipeline between the cold fluid inlet of the heater and the cooling water source; the control device is respectively connected with the pressure sensor and the cooling water control valve. The structure of the intelligent auto parts mold system is as follows figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com