Intermediate blank cooling system and cooling control technology

A cooling system and cooling control technology, applied in the field of metallurgy, can solve the problems that the water volume cannot be adjusted automatically according to the needs, the structure and properties of the intermediate billet are unfavorable, and the use effect is not ideal, so as to improve the comprehensive production capacity, facilitate the maintenance of the roller table, reduce the The effect of production organization difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with specific embodiments, but the present invention is not limited to the following specific methods.

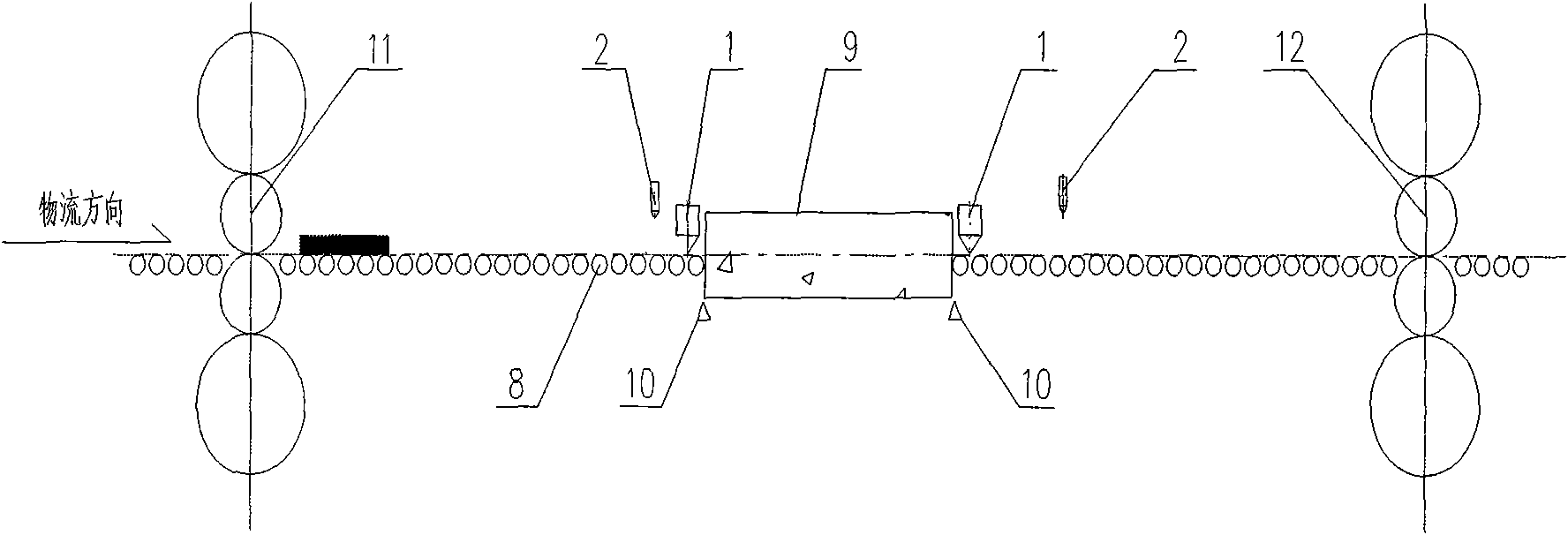

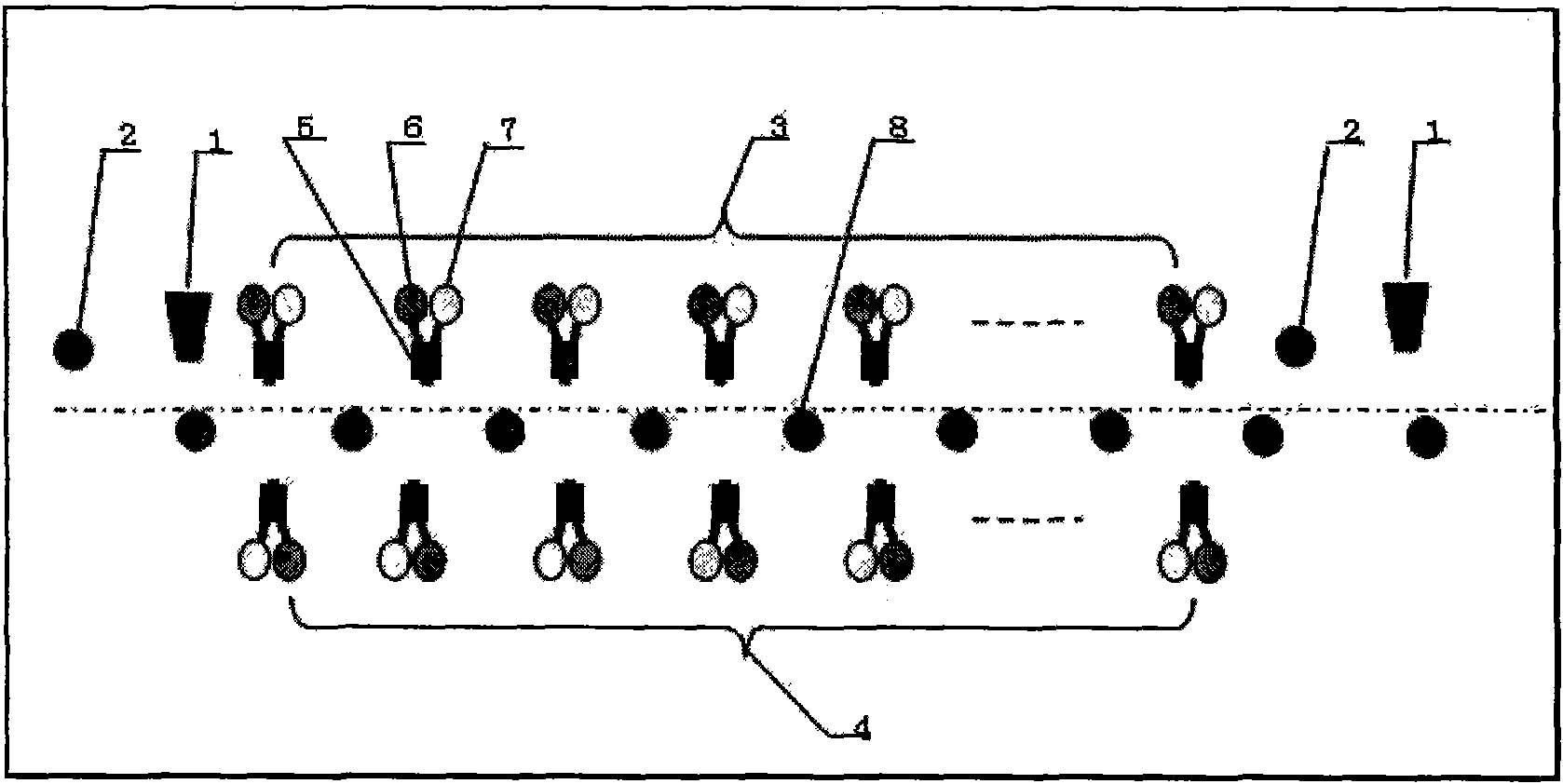

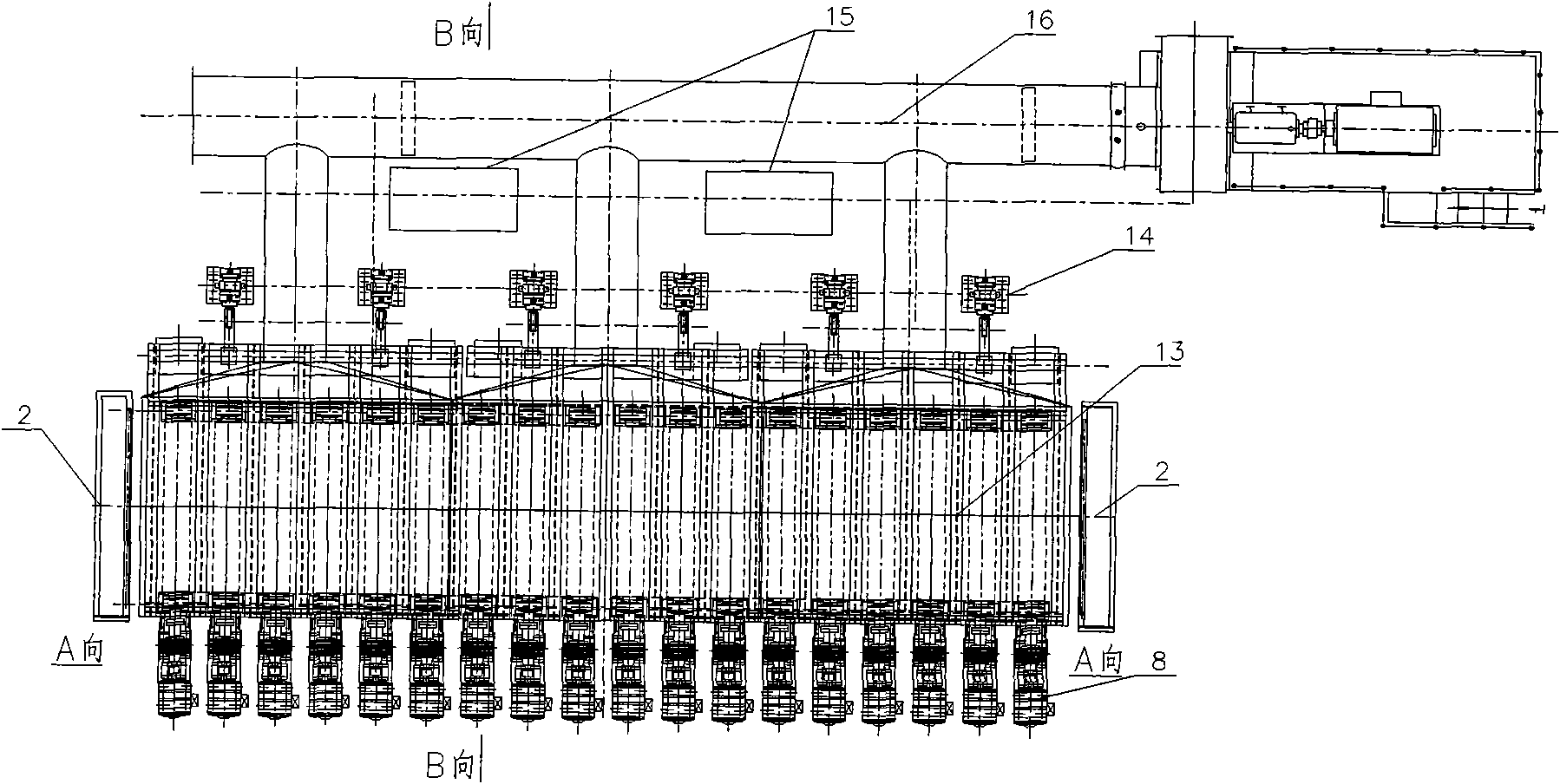

[0036] Such as Figure 1~5 As shown: between the rough rolling mill 11 and the finishing mill 12, a gas mist cooling device body 9 is arranged, and a purging device 1, a pyrometer 2 and a position detector 10 are installed at the entrance and exit thereof. The gas mist cooling device body 9 is composed of an upper cooling header 3 and a lower cooling header 4, the upper cooling header 3 is installed on the upper header frame 17, and the lower cooling header 4 is installed between the conveying rollers 8; An aerosol nozzle 6 and a compressed air pipe 7 are installed on the cooling water pipe 5 of the cooling header 3 and the lower cooling header 4;

[0037] The control valve station 15 makes the upper cooling header 3 and the lower cooling header 4 spray uniform water mist to cool the intermediate b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com