Flow guide type freezing crystallizer

A frozen crystallizer and crystallization tank technology, which is applied in heat exchange cooling crystallization, solution crystallization, crystallization adjustment/control, etc., can solve the problems of stopping production and cleaning heat exchangers, and having no technical advantages, so as to improve equipment production capacity and reduce scarring Risk, the effect of optimizing flow patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

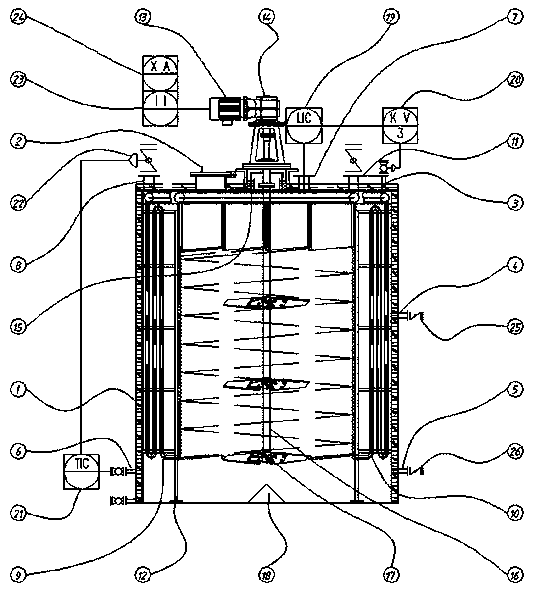

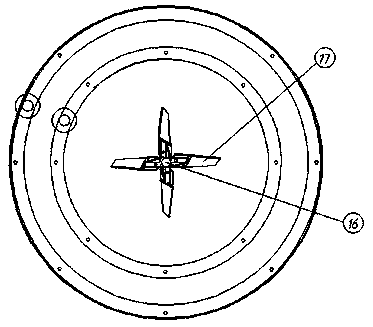

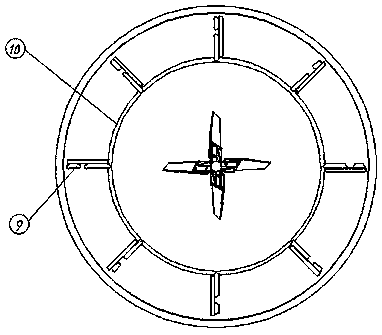

[0032] Specific implementation method: see Figure 1-3 As shown, it includes crystallization tank, cooling system, stirring system and control system;

[0033] The crystallization tank includes a tank body 1, a bottom bracket, and a top bracket; the tank body 1 adopts the simplest cylindrical structure, which is beneficial to layout and installation, and is also beneficial to the layout of coils, baffles and other internal parts, and its length-to-diameter ratio is between Between 2:1 and 1:1, the manufacturing cost per unit volume is lower. The inner wall of the tank body 1 is provided with a cold insulation layer, and the cold insulation layer adopts the overall foaming spraying process, which has strong adhesion, no gaps, and good cold insulation effect; the tank body 1 is fixed on the bottom bracket; the top bracket is fixed on the upper part of the tank body 1, and the top bracket The bracket is used to support components such as the frequency conversion motor 13 and the...

Embodiment 1

[0061] Embodiment 1: the feed liquid of sodium sulfate solution consists of: LiOH 4.2%, NaOH 1.1%, Na 2 SO 4 31.0%, the feed temperature is 39°C;

[0062] During the crystallization process, it took 90 minutes at 40-25°C, 242 minutes at 25-5°C, 146 minutes at 10-0°C, and 110 minutes at 0-5°C, totaling 588 minutes, or 9.8 hours;

[0063] The crystal growth process takes 1h;

[0064] During the settling process, after 30 minutes, take a sample from the clear liquid port 4, and there is still a small amount of solids. After another 30 minutes of settling, there is no obvious solid in the sample taken from the clear liquid port 4, and the settling process takes 1 hour;

[0065] During the discharge process, it takes 58 minutes to discharge the clear liquid, and 74 minutes to discharge the crystal slurry, a total of 132 minutes, or 2.2 hours;

[0066] The whole process takes a total of 14.0 hours, and the composition of the clear liquid is: LiOH 9.5%, NaOH 2.5%, NaOH 2 SO 4 ...

Embodiment 2

[0067] Embodiment 2: the feed liquid of sodium sulfate solution consists of: LiOH 4.4%, NaOH 1.2%, NaOH 2 SO 4 30.5%. The feed temperature was 37°C.

[0068] During the crystallization process, it took 86 minutes at 40-25°C, 236 minutes at 25-5°C, 148 minutes at 10-0°C, and 115 minutes at 0-5°C, totaling 585 minutes, or 9.8 hours;

[0069] The crystal growth process takes 1h;

[0070] During the settling process, take a sample from the clear liquid port 4 after 30 minutes, there is no obvious solid, and the settling process takes 0.5h;

[0071] During the discharge process, it takes 55 minutes to discharge the clear liquid and 75 minutes to discharge the crystal slurry, a total of 130 minutes, that is, 2.2 hours;

[0072] The whole process takes a total of 13.4 hours, and the composition of the clear liquid is: LiOH 9.8%, NaOH 2.7%, NaOH 2 SO 4 4.2%. Na 2 SO 4 ﹒ 10H 2 O crystallization rate 93.8%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com