Temperature cooling regulator for self-consumable electrode arc furnace

A technology of temperature control device and consumable electrode, applied in furnace cooling, furnace, furnace components, etc., can solve the problem of installing temperature control cooling device and other problems that have not been found, and achieve the effect of preventing oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

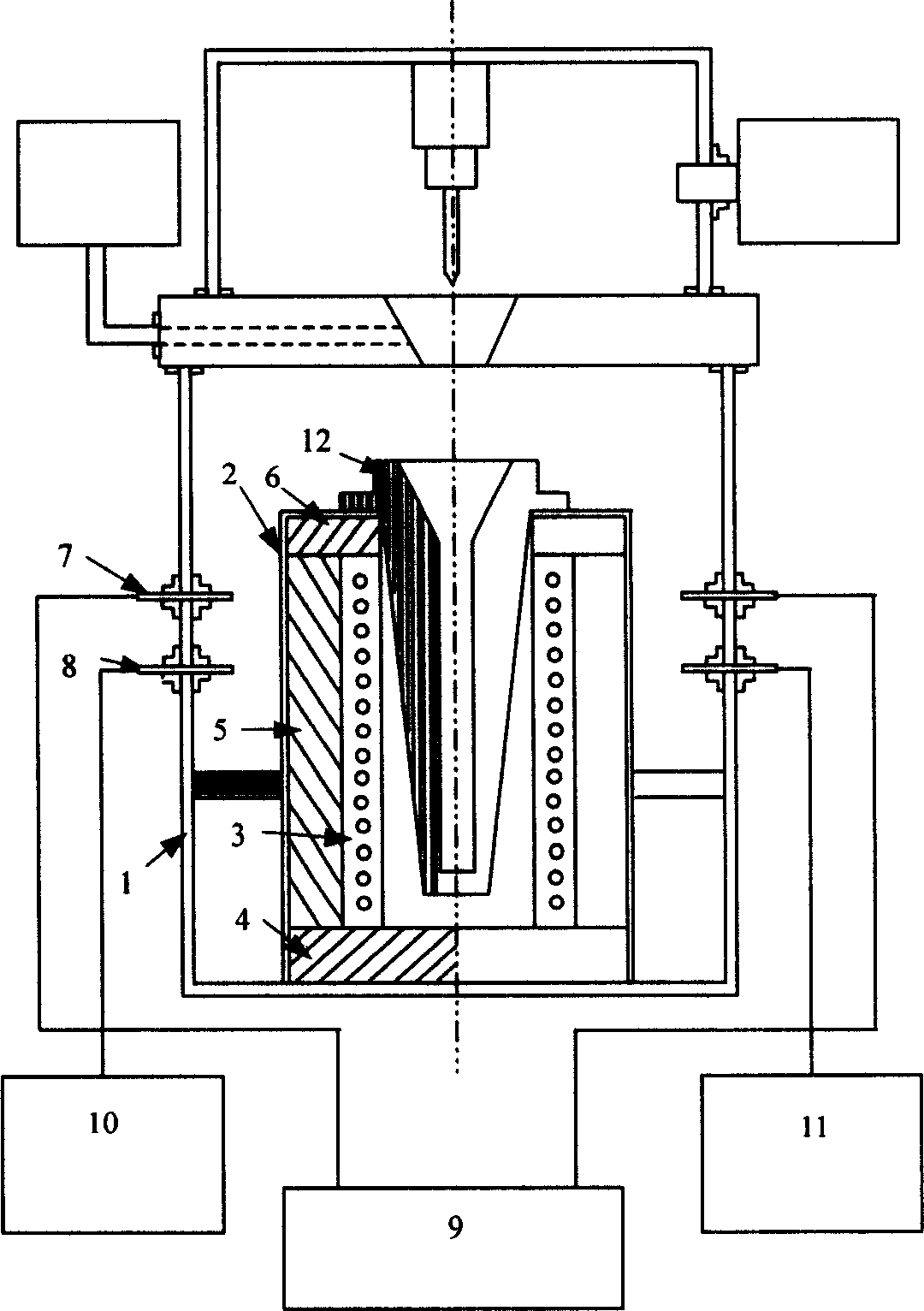

[0010] Such as figure 1 As shown, the present invention comprises: stainless steel sheath 1, stainless steel housing 2, resistance wire furnace 3, refractory insulation material 4,5,6, and its connection relation is: be provided with a stainless steel housing (2 in stainless steel sheath 1 ), the resistance wire furnace 3 is fixed in this stainless steel shell 2, and the refractory heat preservation materials 4, 5, 6 are lined between the resistance wire furnace 3 and the stainless steel shell 2, and the stainless steel sheath 1 is provided with terminal posts 7, 8.

[0011] The stainless steel sheath 1 is an airtight stainless steel sheath. A circular opening is arranged above the stainless steel shell 2, and the copper mold 12 is inserted into the resistance wire furnace 3 through the circular opening.

[0012] The present invention is matched with non-consumable electrode electric arc furnace (drop casting type), and the heating device 7, temperature control device 8 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com