Patents

Literature

32 results about "Drop casting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

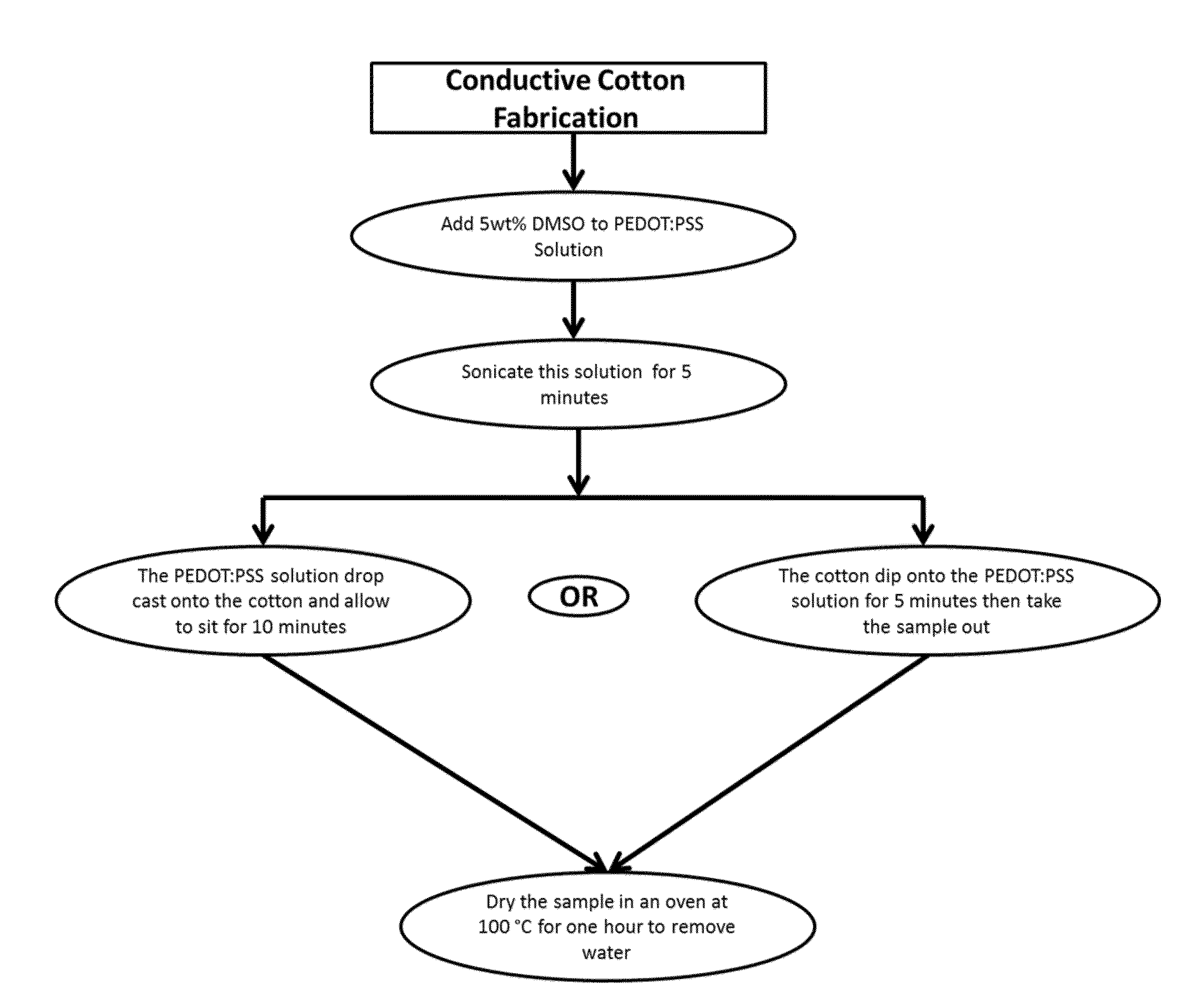

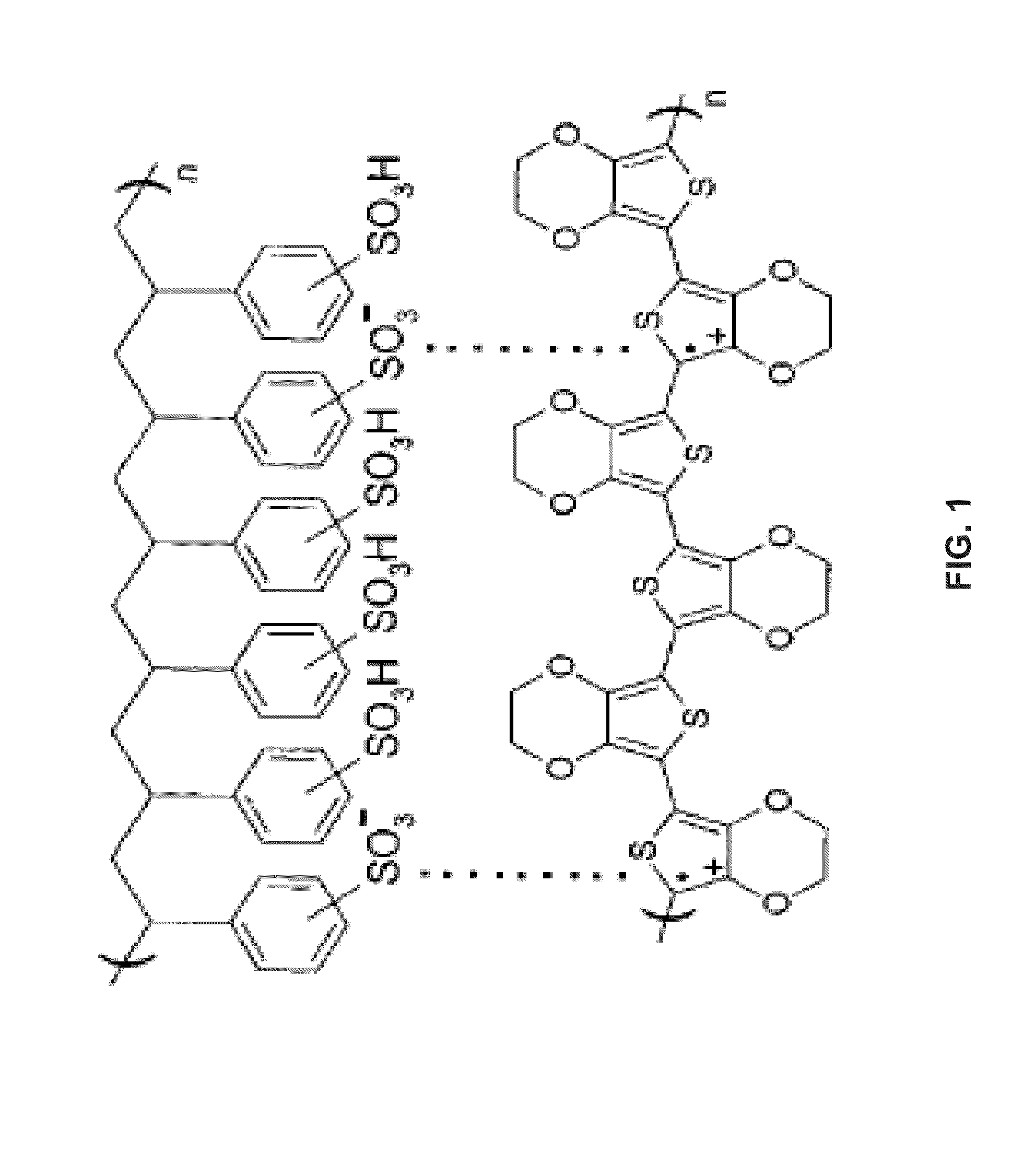

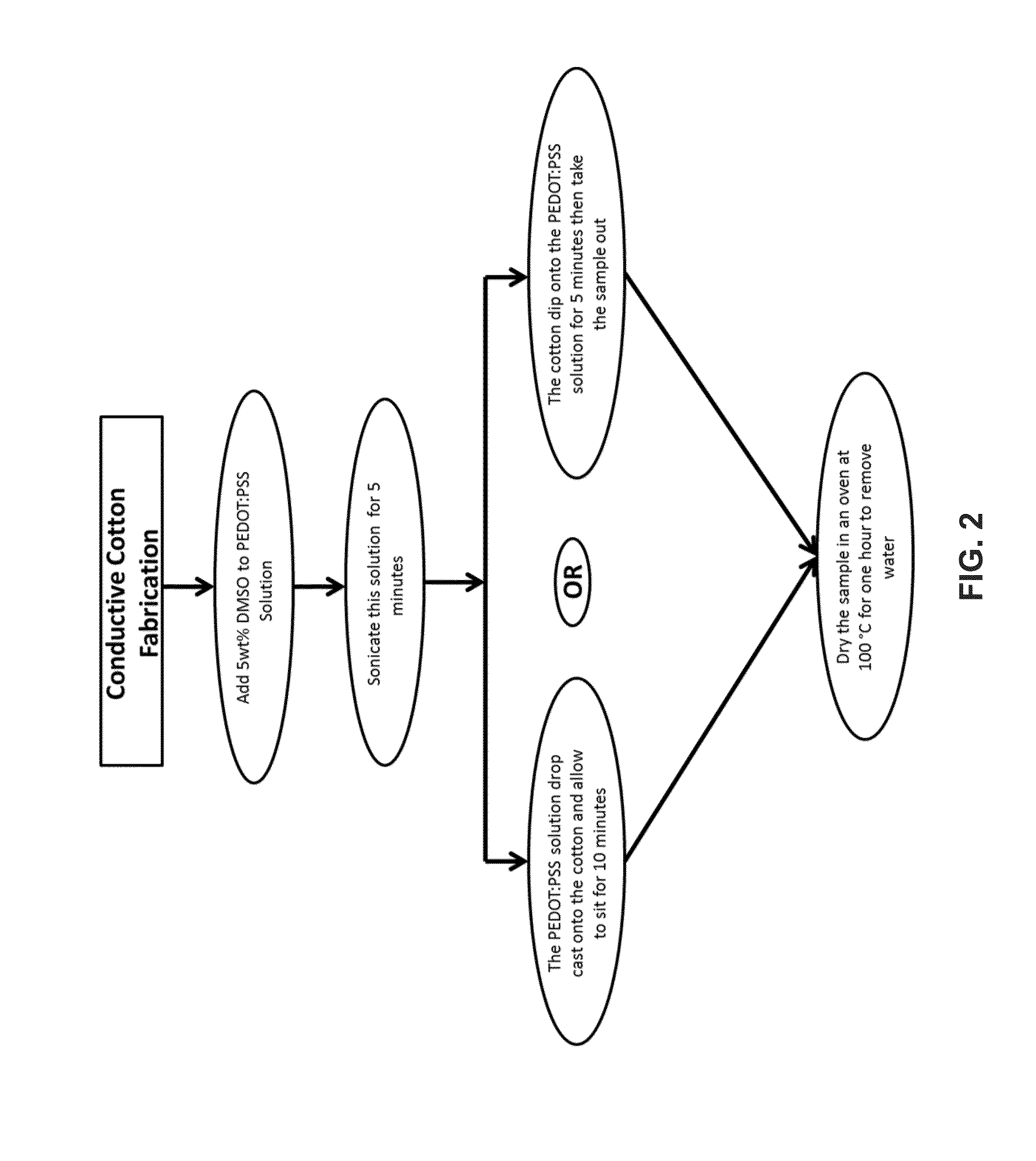

Method of making conductive cotton using organic conductive polymer

InactiveUS20160258110A1Improve concentrationNon-conductive material with dispersed conductive materialDyeing processSilica nanoparticlesConductive polymer

A method of making an electrically conductive cotton material by incorporating conductive poly(3,4-ethylenedioxythiophene) polystyrene sulfonate (PEDOT:PSS) films into a base cotton substrate by drop casting or dip coating. Unlike most conventional methods that have typically included the use of templates such as metal oxide, carbon and / or silica nanoparticles, the polymerization of PEDOT:PSS in this method is not template-assisted. The amount of PEDOT:PSS used in the fabrication process controls the conductivity and sheet resistance of the conductive cotton material, and can be varied by the number of repeated drop casting or dip coating cycles.

Owner:UMM AL QURA UNIVERISTY

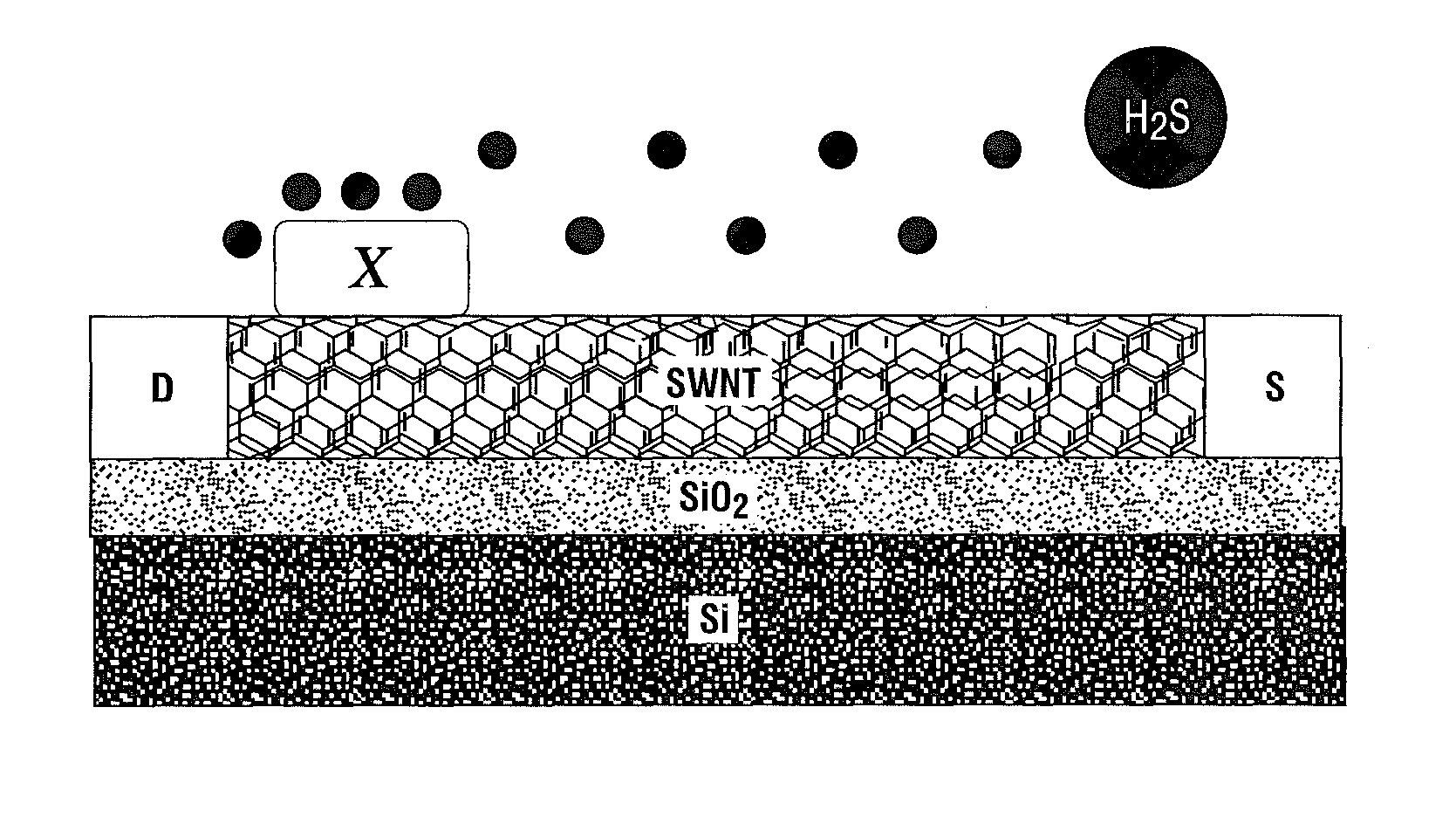

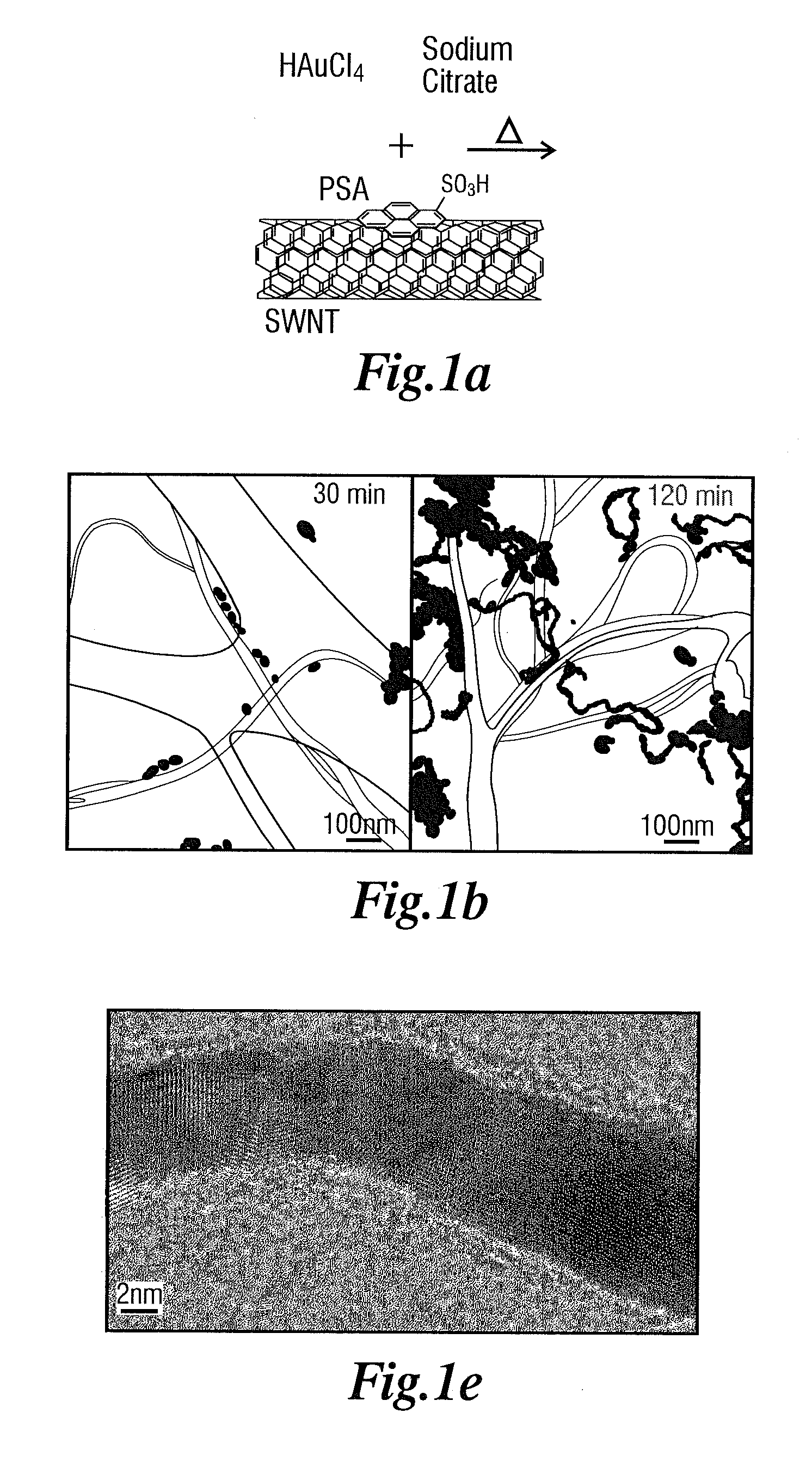

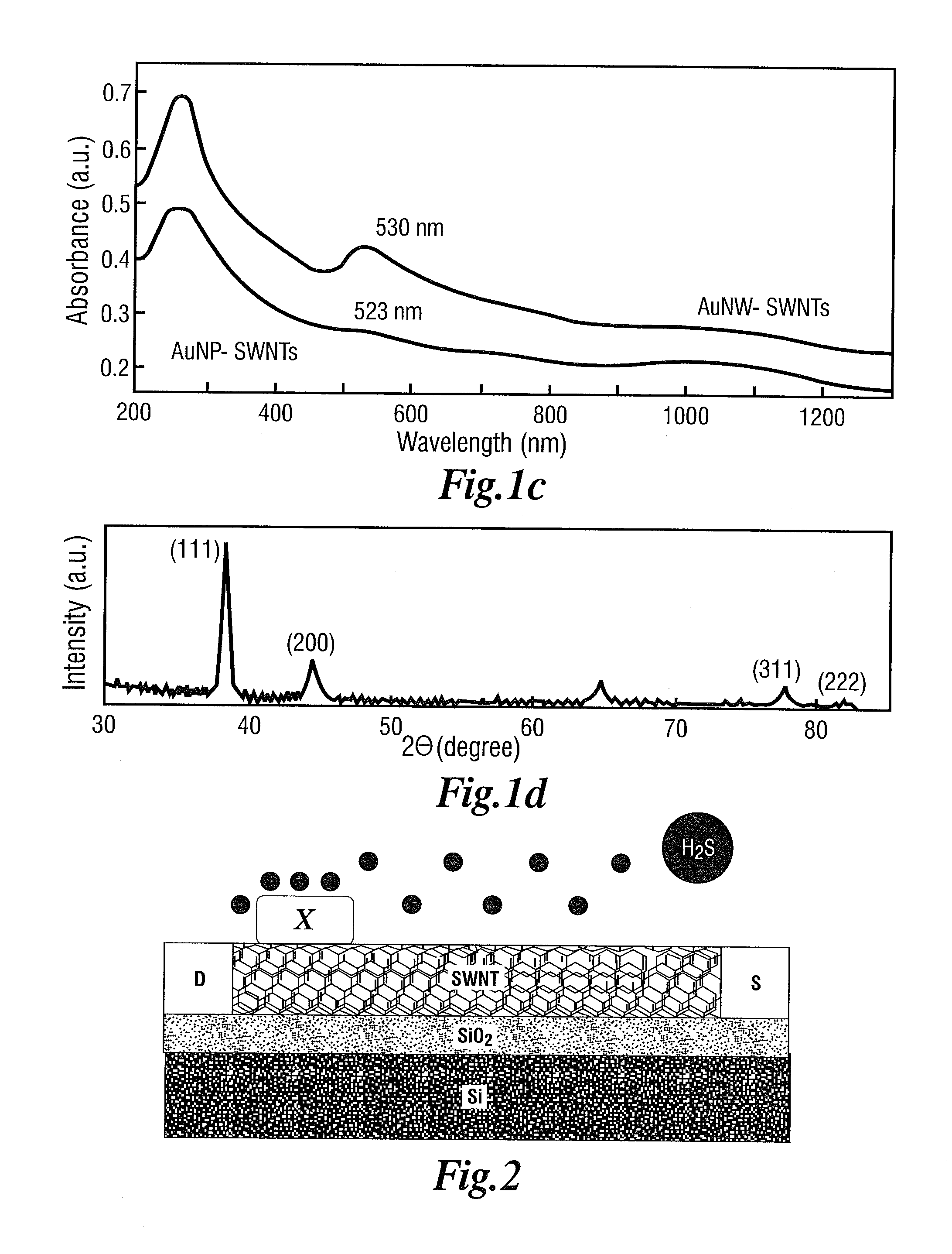

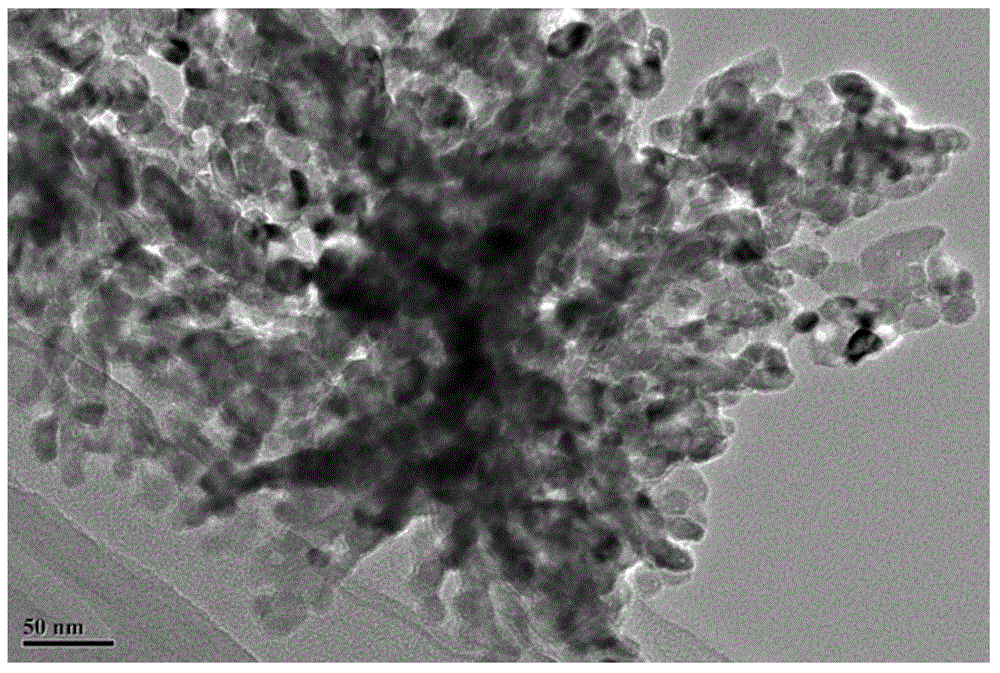

Detection of hydrogen sulfide gas using carbon nanotube-based chemical sensors

InactiveUS20130040397A1Improve portabilityHigh sensitivityMaterial thermal conductivityLayered products1-pyrenesulfonic acidNanowire

A method for preparing carbon allotrope based sulfide detectors comprising first functionalizing a carbon allotrope, such as a single-walled carbon nanotubes or graphene, with a solution of a polynuclear aromatic hydrocarbon-sulfonic acid, such as 1-pyrenesulfonic acid, followed by treatment with a metal, such as gold nanowires or cupric salt doped polyaniline, to give a metal-functionalized carbon allotrope, then drop casting the metal-functionalized carbon allotrope onto an inert surface, such as a silicon dioxide film on a silicon wafer having electrodes. Detection of sulfides may be by means such as photochemical or conductance methods. The hydrogen sulfide detectors may be used to detect and / or quantitate ppb and ppm levels of hydrogen sulfide in industrial settings or in detecting halitosis.

Owner:UNIVERSITY OF PITTSBURGH

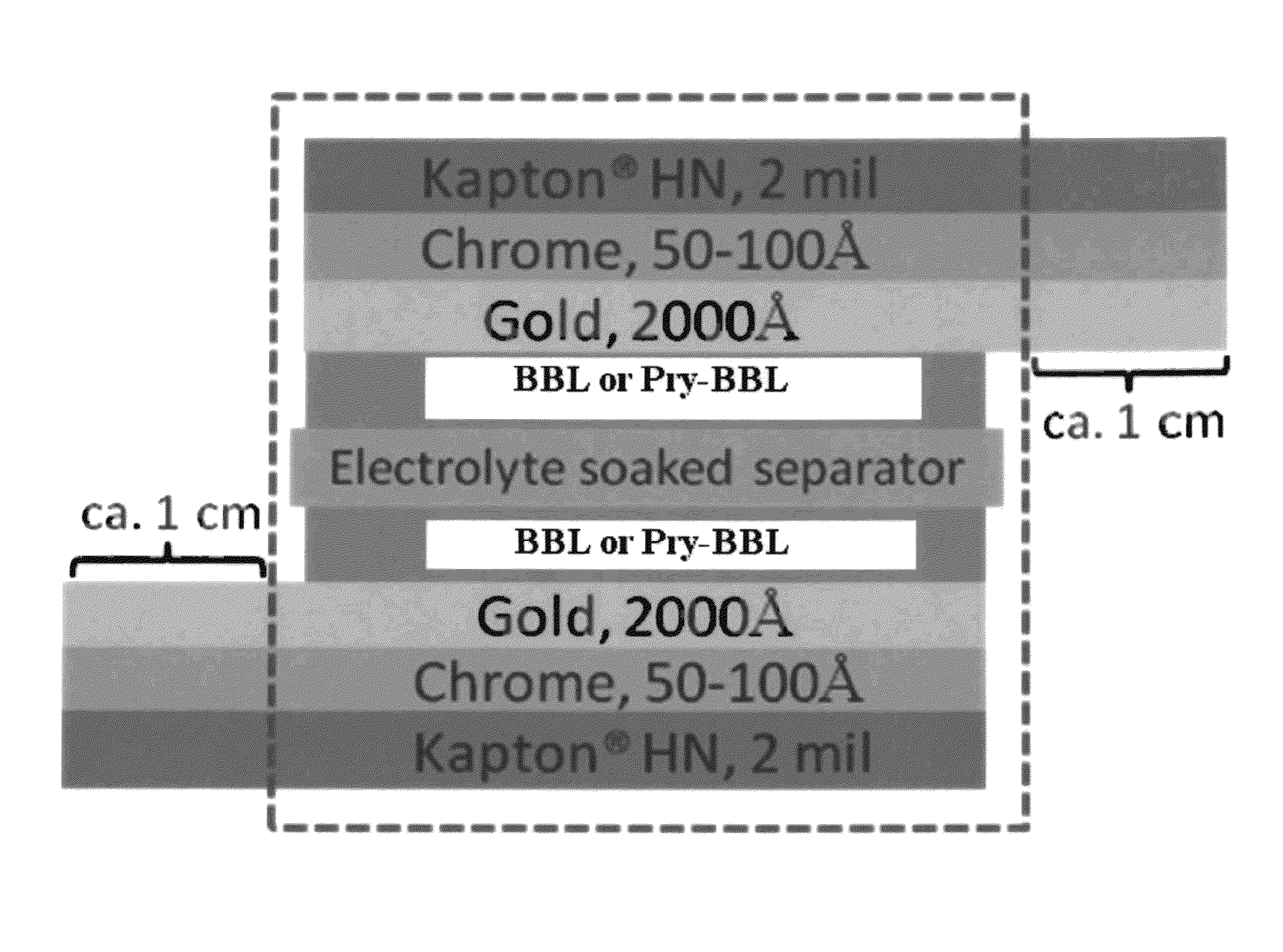

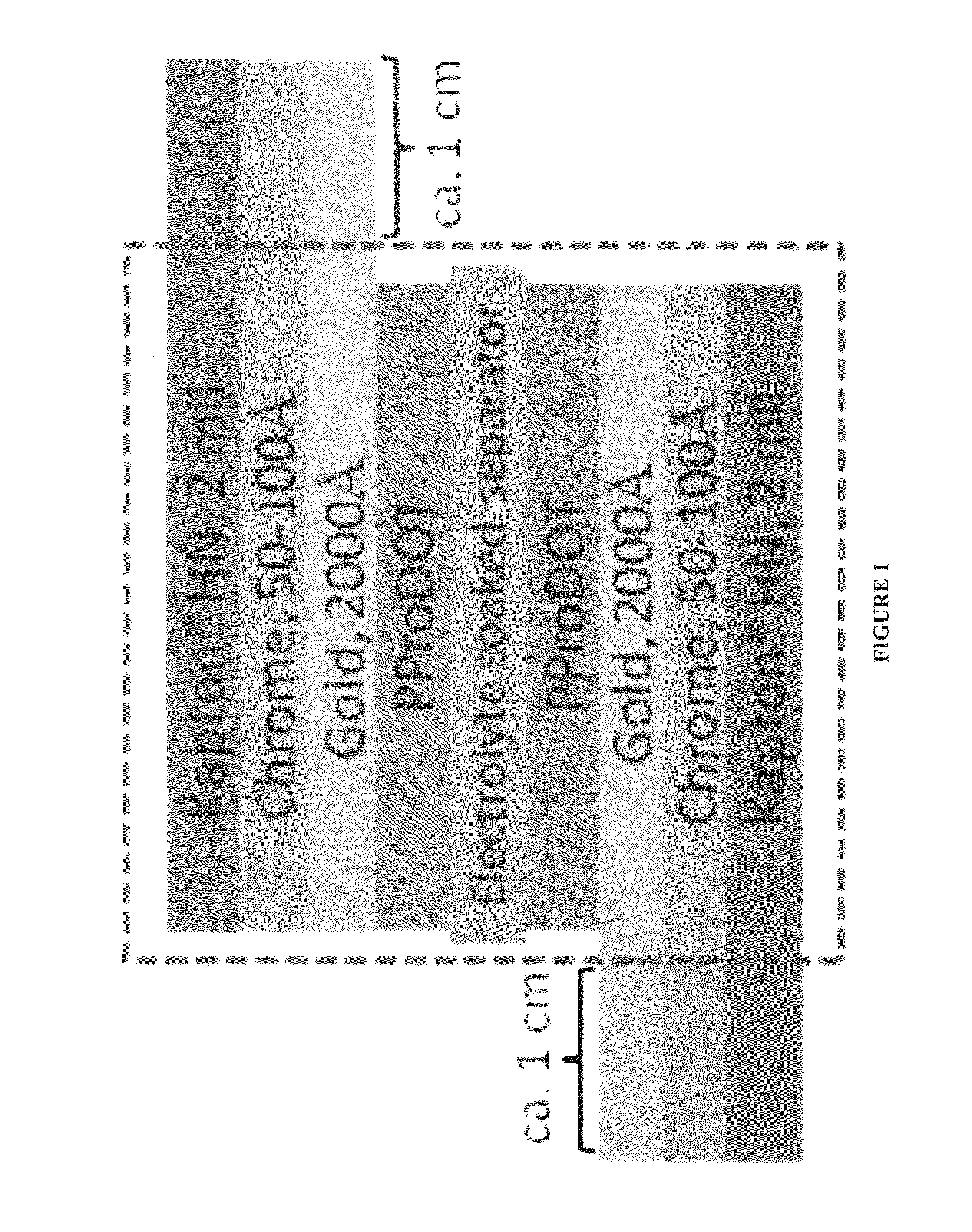

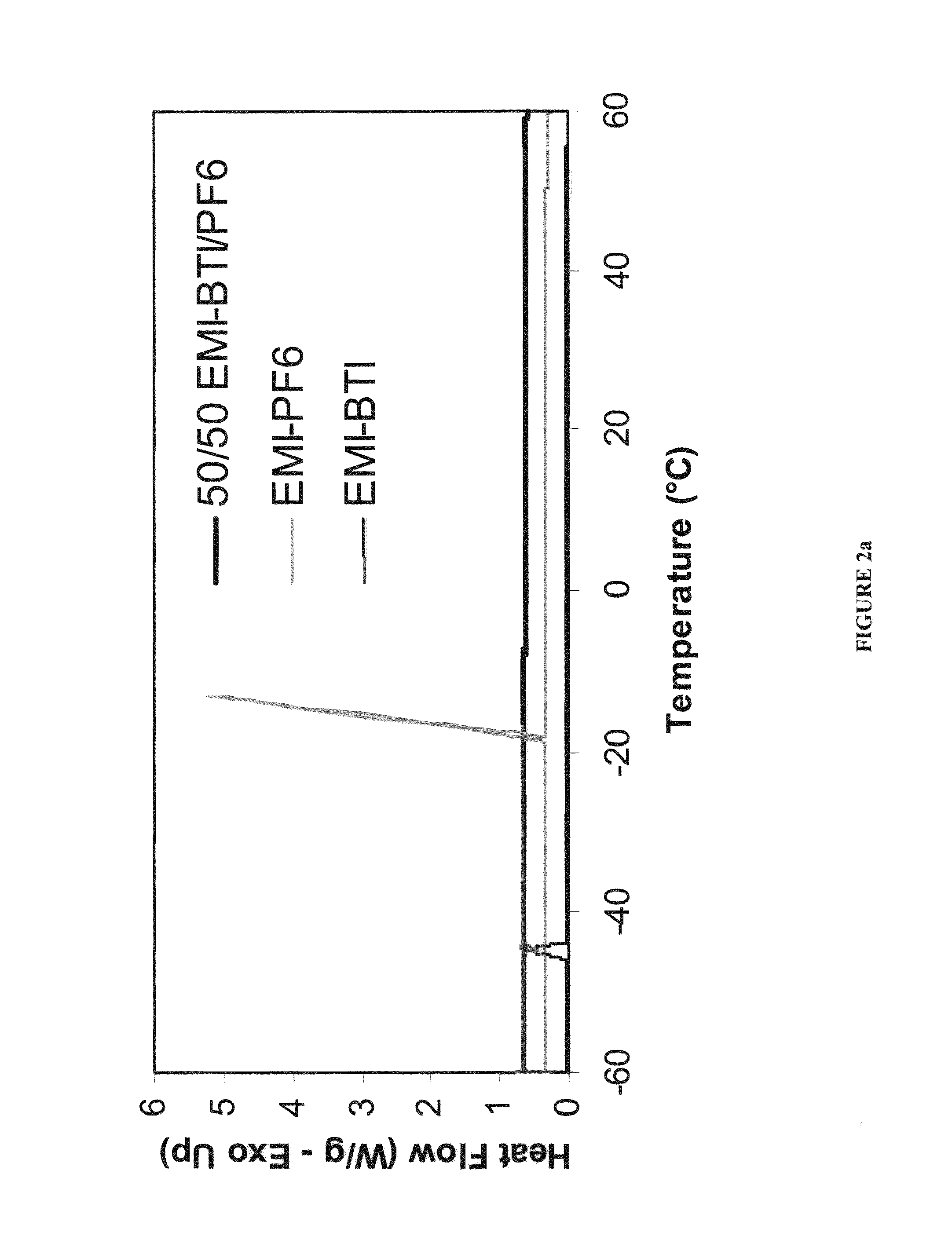

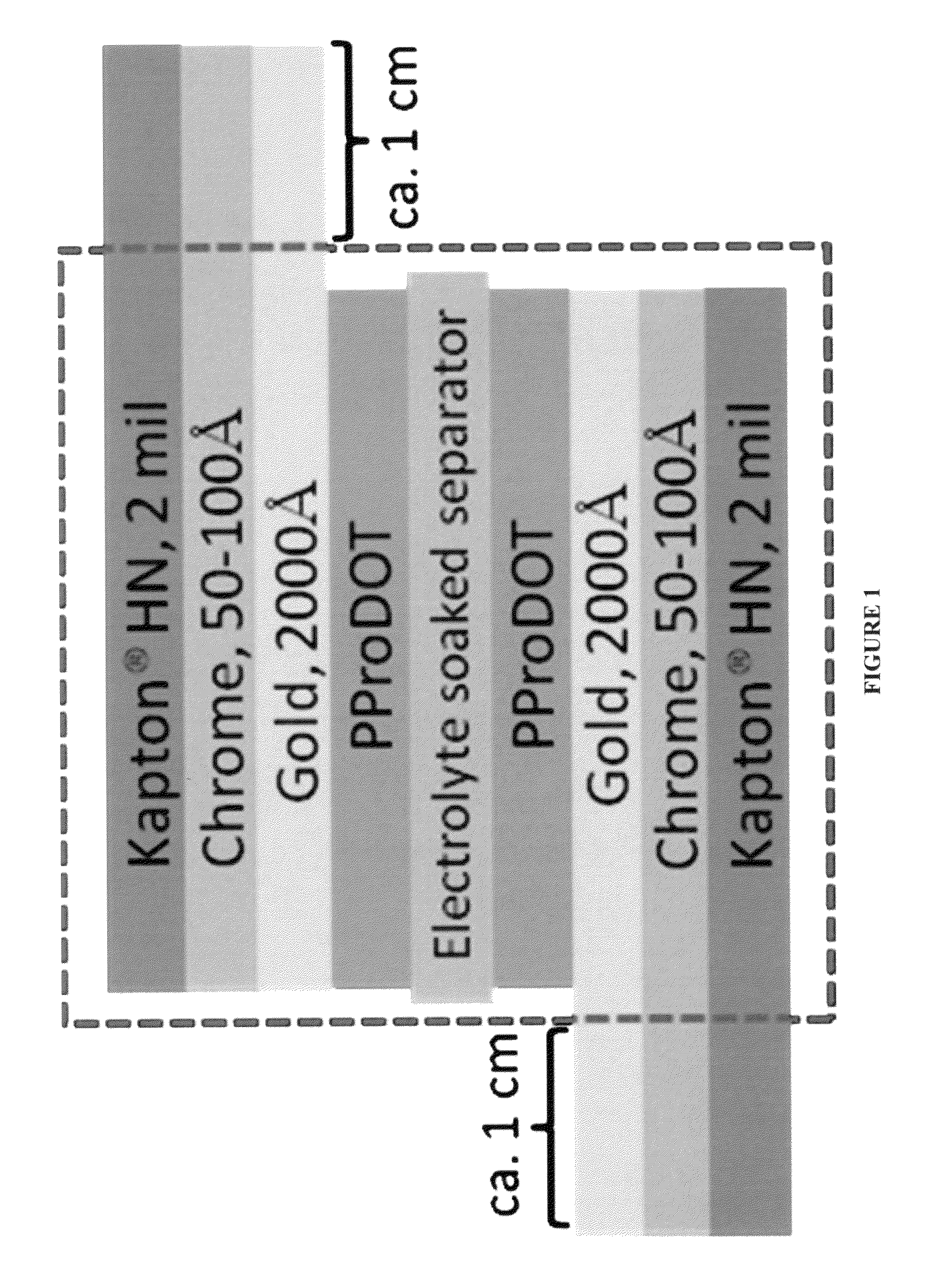

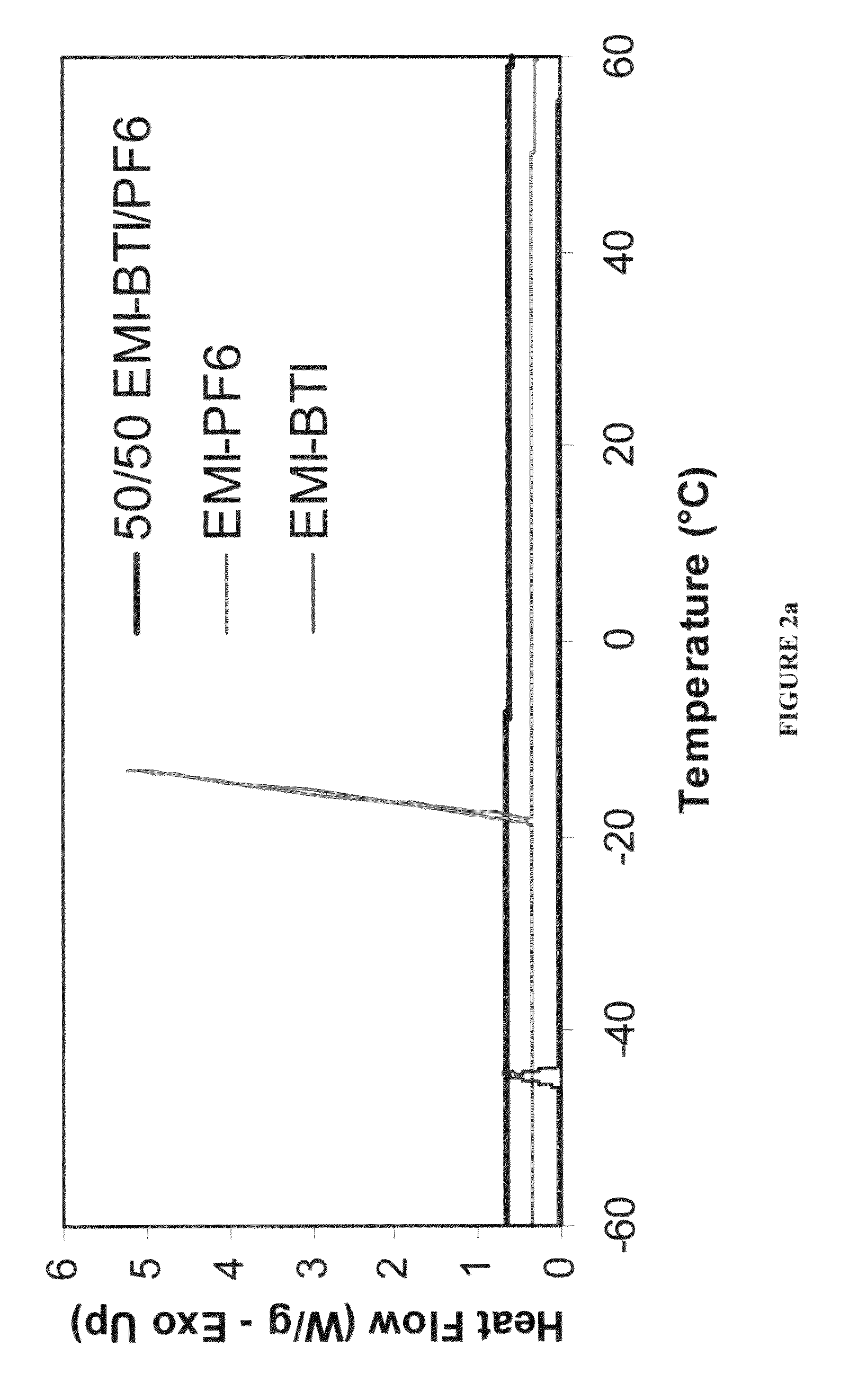

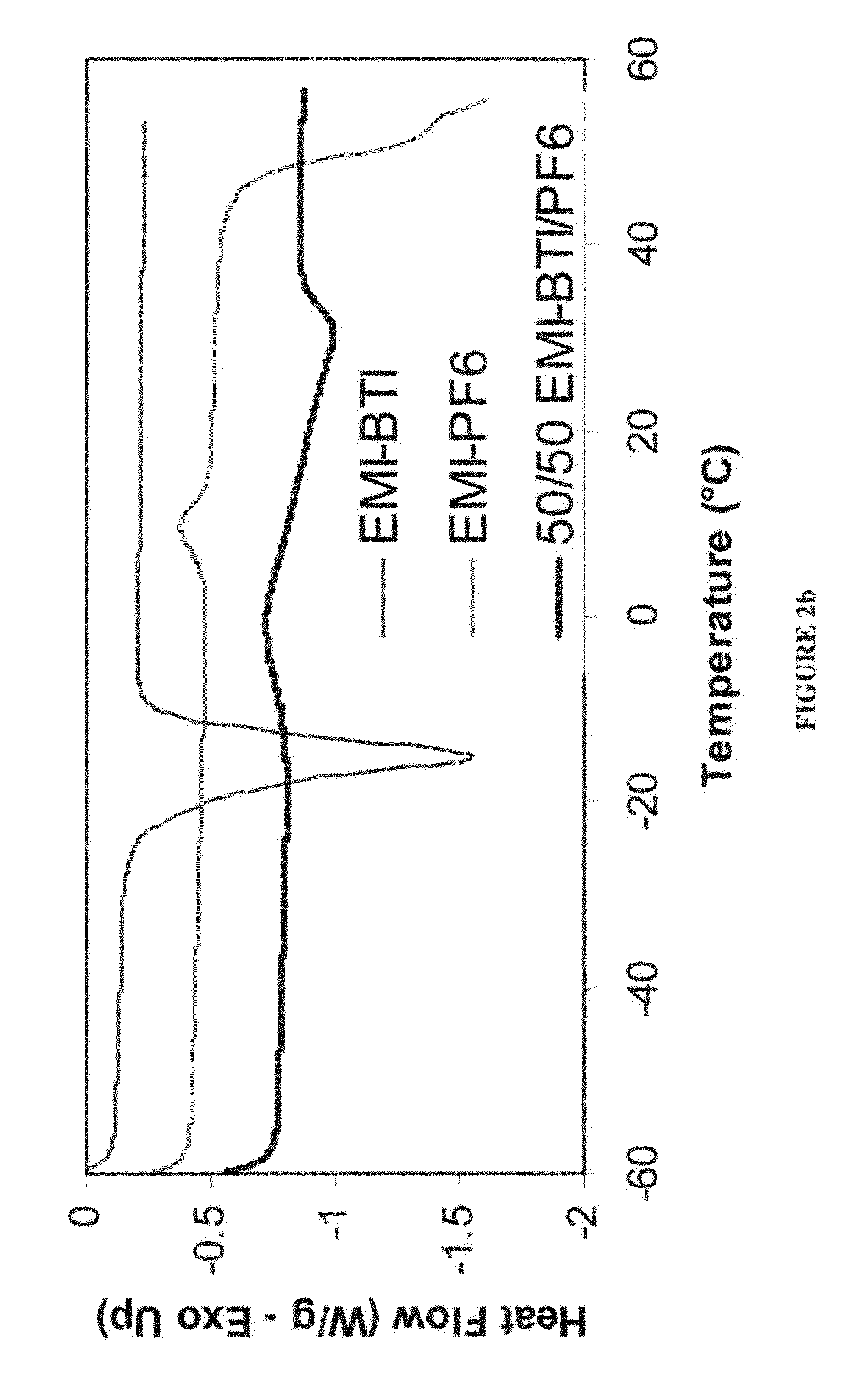

Electroactive polymer based supercapacitors including a cathode having BBL or Pry-BBL

A process used to cast films including: mixing BBL and a room temperature molten salt from a range of about 35:65 weight ratio, dissolving the mixture in about 1% methanesulfonic acid to produce a BBL solution, drop casting the solution onto glass or gold coated glass at 140° C. in air and heating for about 2 hours to produce films, drying the films in a vacuum oven at about 100° C. for at least 24 hours under dynamic vacuum, and rinsing the films to remove residual ionic liquid.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

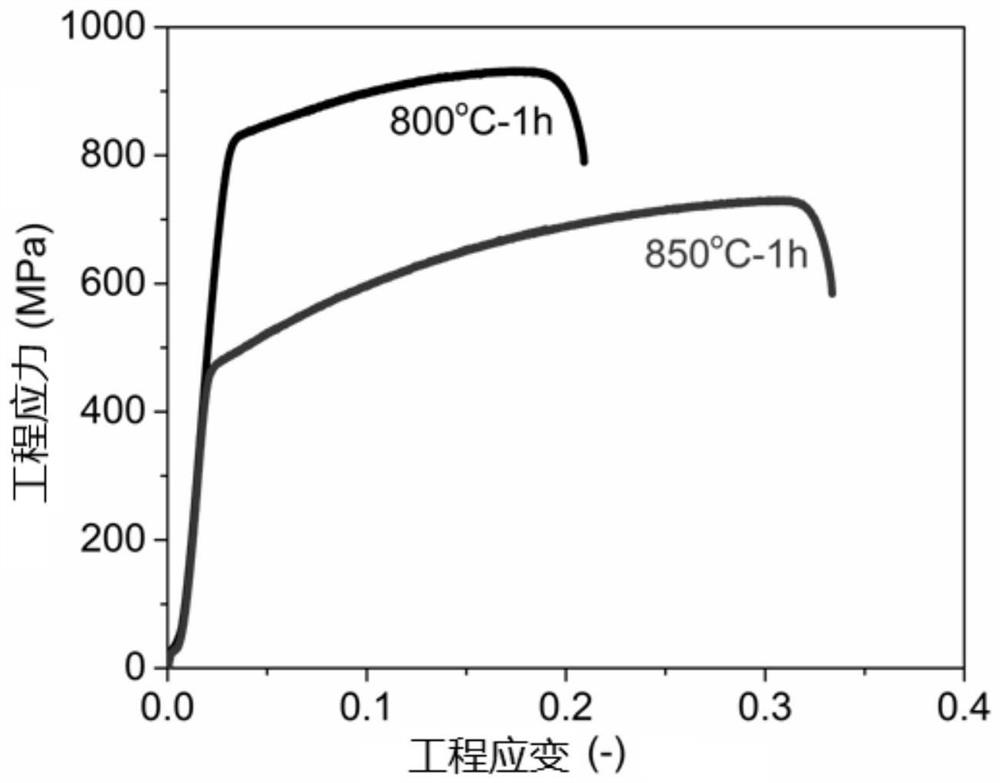

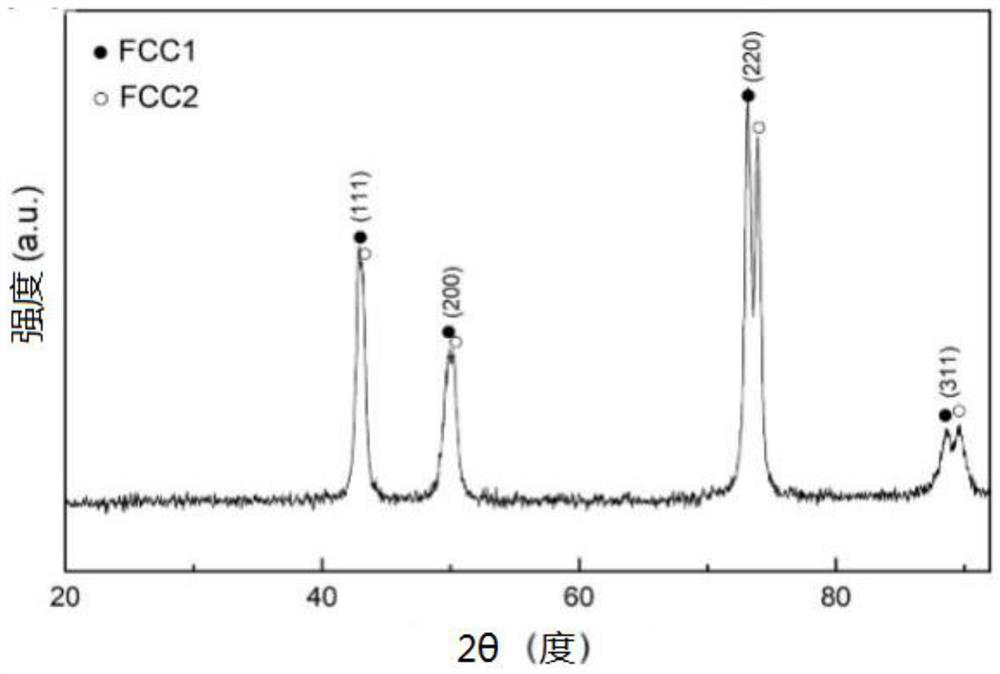

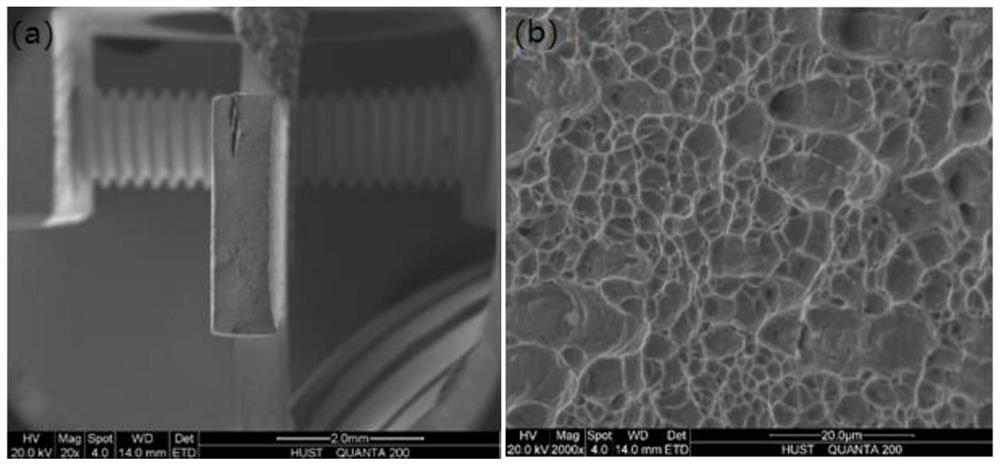

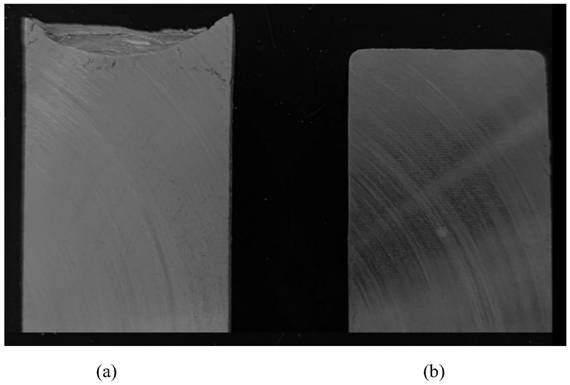

Precipitation-enhanced high-entropy alloy without sigma-phase precipitation tendency and preparation method of precipitation-enhanced high-entropy alloy

ActiveCN111826573AImprove mechanical propertiesEliminate precipitation tendencyElectric arc furnaceHigh entropy alloys

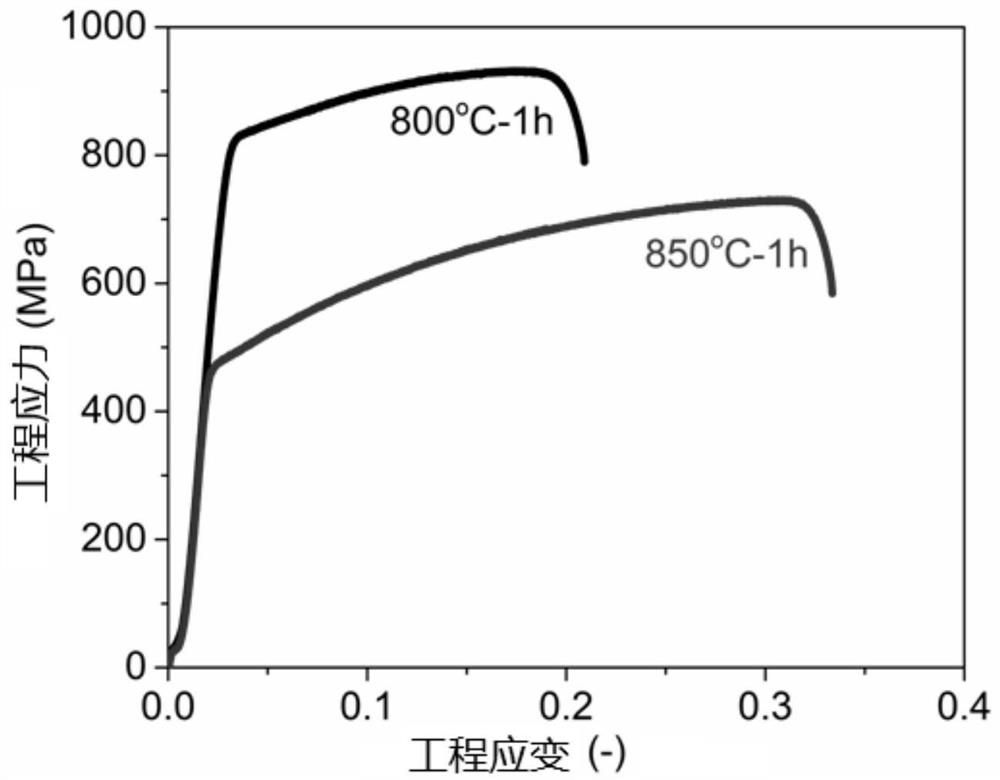

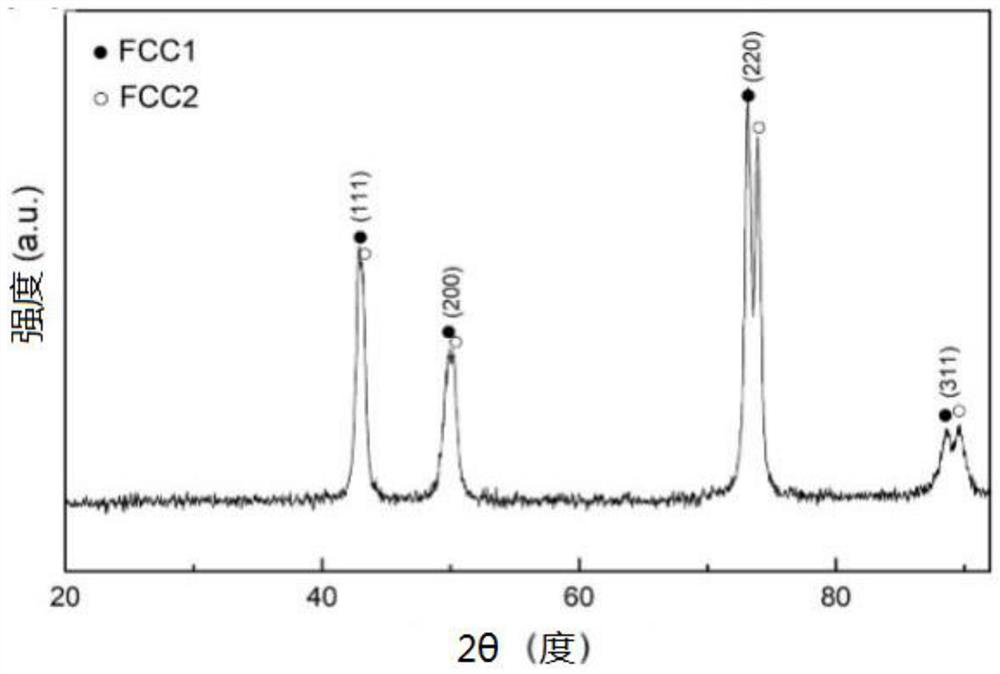

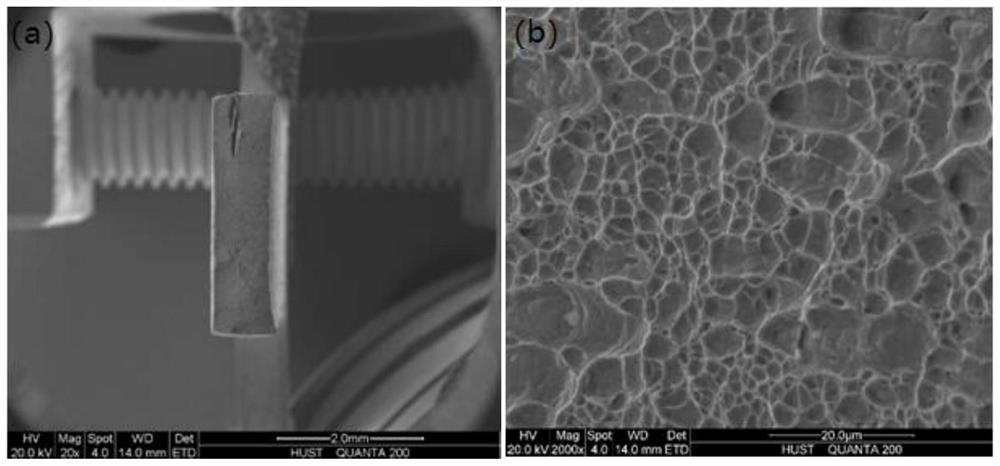

The invention discloses a precipitation-enhanced high-entropy alloy without a sigma-phase precipitation tendency and a preparation method of the precipitation-enhanced high-entropy alloy, and belongsto the field of high-entropy alloys. The precipitation-enhanced high-entropy alloy is composed of such four elements as Fe, Ni, Mn and Cu at a molar ratio. According to the preferred preparation method of the precipitation-enhanced high-entropy alloy, the prepared raw materials are smelted in an electric-arc furnace under the protection of vacuum argon gas at first, and then the precipitation-enhanced high-entropy alloy without the sigma-phase precipitation tendency is obtained through the steps of drop casting, homogenization annealing, cold rolling and aging. The precipitation-enhanced high-entropy alloy without the sigma-phase precipitation tendency has the beneficial effects that the optimal values of the room temperature yield strength and the tensile strength can reach 825 MPa and 933 MPa correspondingly; the elongation can be higher than 15%; and the mechanical performance indexes can be adjusted by utilizing aging parameters. Furthermore, the precipitation-enhanced high-entropyalloy without the sigma-phase precipitation tendency has the excellent comprehensive mechanical performance at room temperature.

Owner:HUAZHONG UNIV OF SCI & TECH

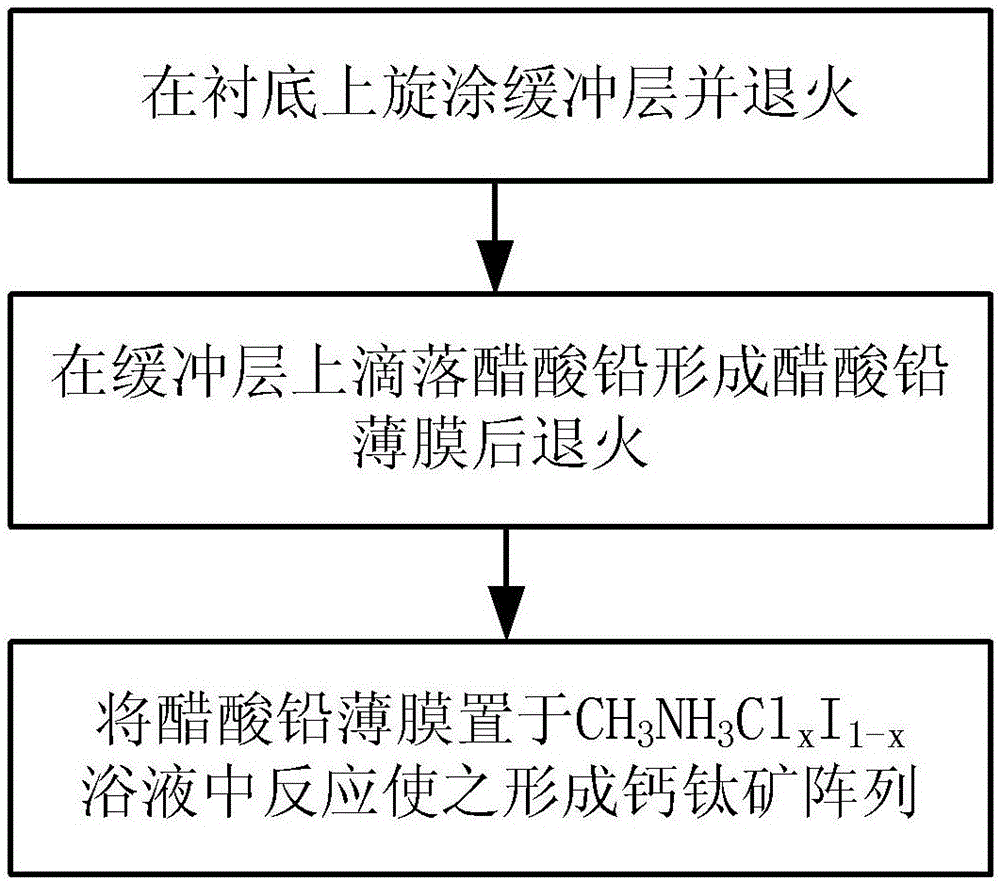

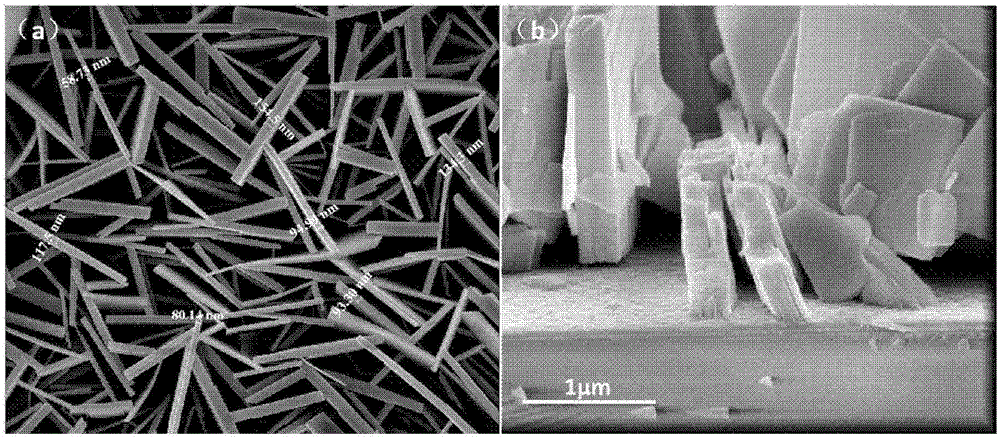

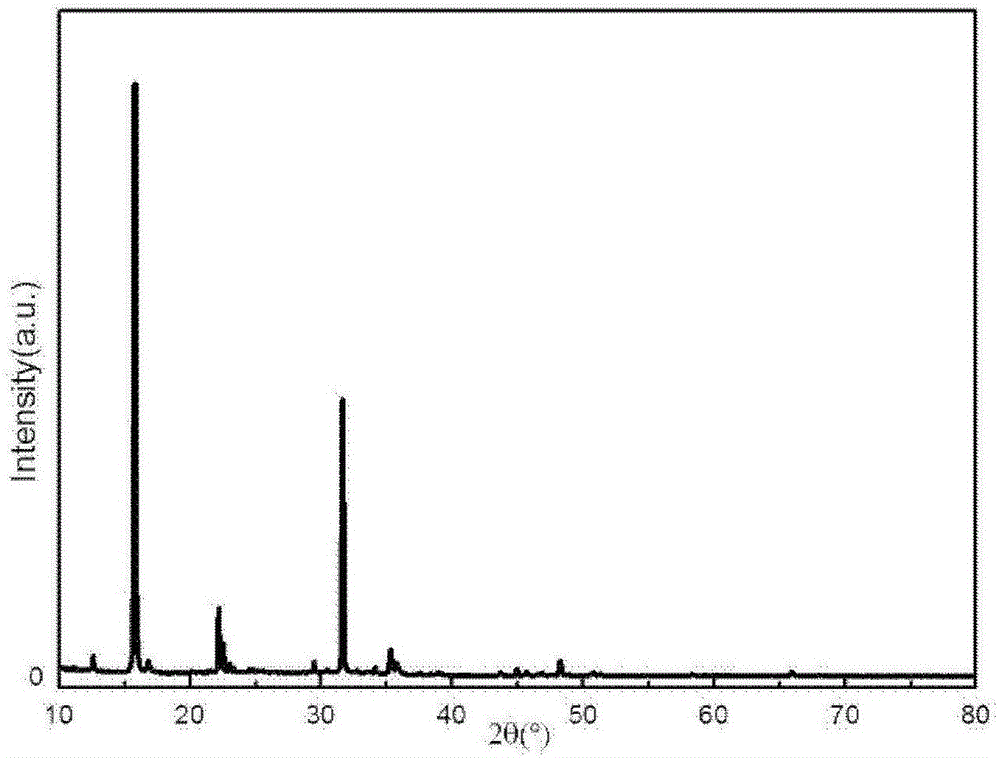

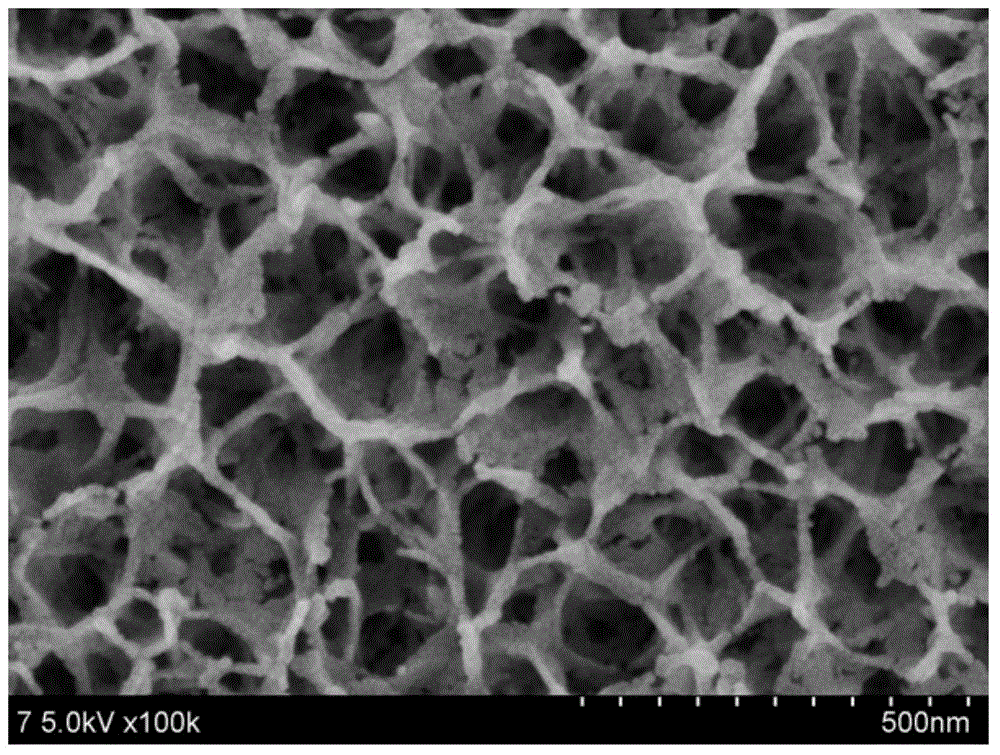

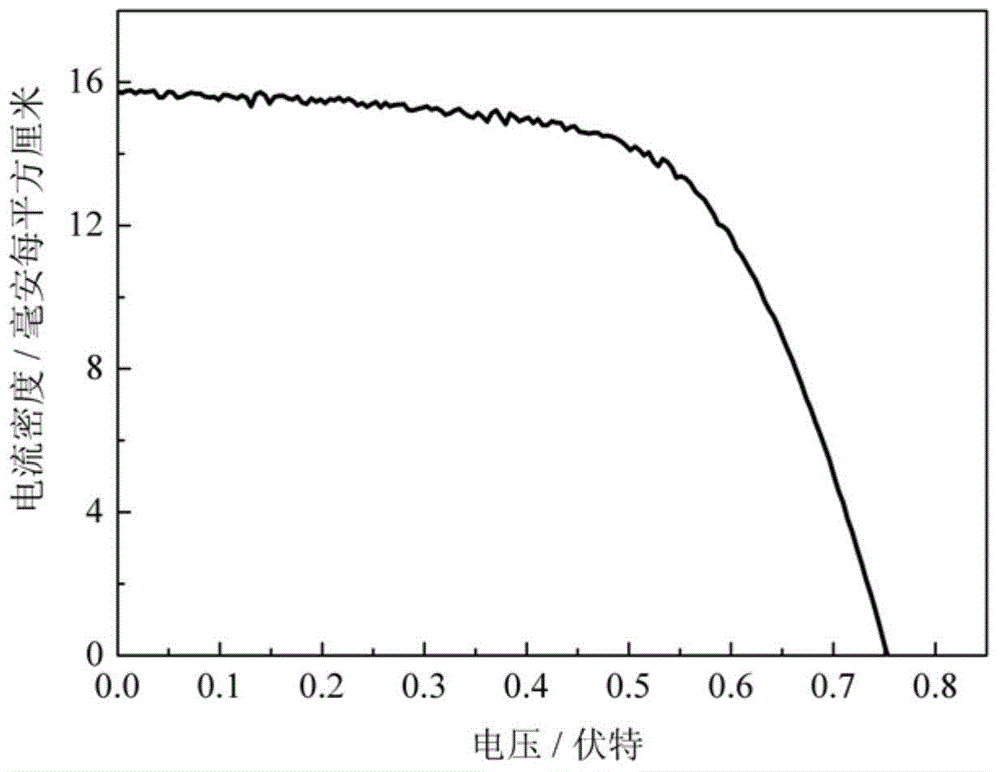

Perovskite nanosheet array-based humidity sensor and production method thereof

The invention discloses a perovskite (CH3NH3PbClxI3-x) nanosheet array-based humidity sensor and a production method thereof. The production method comprises the following steps: carrying out a chemical solution reaction technology to form a buffer layer poly(3,4-ethylenedioxythiophene)-polystyrenesulfonate (PEDOT:PSS) on a glass substrate, drop-casting a lead acetate (PbAc2) film, placing the annealed PbAc2 film in a methylammonium chloride and methylammonium iodide (CH3NH3ClxI1-x) mixed isopropanol solution, and carrying out a reaction to prepare a perovskite nanosheet structure array; and annealing the produced nanosheet array, and carrying out vapor deposition of silver electrodes on two ends of the annealed nanosheet array through a hot evaporation technology in order to produce the perovskite humidity sensor. The production method has the advantages of low cost and simple process, and the perovskite nanosheet array-based humidity sensor has the advantages of high stability and sensitive response, and can be used to detect water vapor and other polar gases.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Self-supported titanium nitride/graphene combined electrode and preparation method thereof

The invention relates to a self-supported titanium nitride / graphene combined electrode and a preparation method of the self-supported titanium nitride / graphene combined electrode. The preparation method comprises the steps that (1) titanium foil is soaked with acid liquid, ultrasonic processing is conducted on the titanium foil, the titanium foil is taken out, washed by deionized water, and soaked with a hydrogen peroxide solution, the temperature of the solution is increased to 60DEG C-95DEG C from the room temperature under the normal pressure through heating, the temperature is kept for 10-60 minutes, and the titanium foil is taken out and dried after an reaction ends; (2) the titanium foil is placed into a tubular atmosphere furnace, ammonia is fed into the tubular atmosphere furnace to conduct nitrogen treatment on the titanium foil, and titanium nitride is formed on the surface of the titanium foil; (3) a layer of graphene is formed on the surface of the titanium nitride in a deposition mode through a dipping-pull method or a drop casting method, and the graphene and the titanium nitride are placed into a drying oven at the temperature ranging from 60DEG C to 100DEG C to be dried, so that the self-supported titanium nitride / graphene combined electrode is obtained. Compared with the prior art, a graphene / titanium nitride three-dimensional network is directly formed on the surface of flexible metal foil so that the self-supported electrode can be formed. The combined electrode is low in cost, high in porosity ratio and good in catalytic activity and electrical conductivity, and has the broad application prospect.

Owner:SHANGHAI UNIV OF ENG SCI

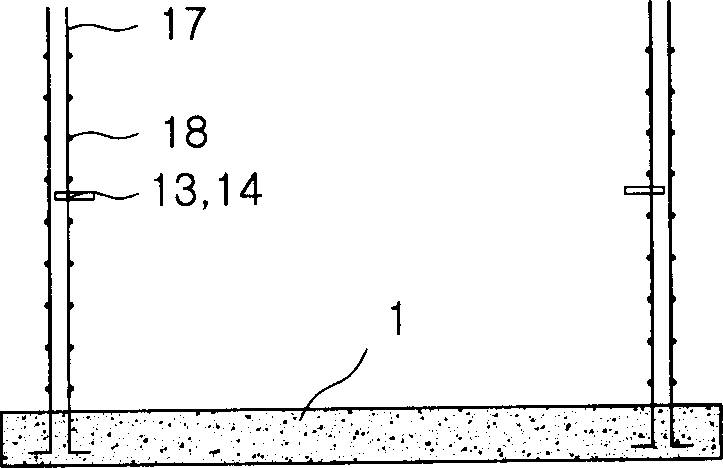

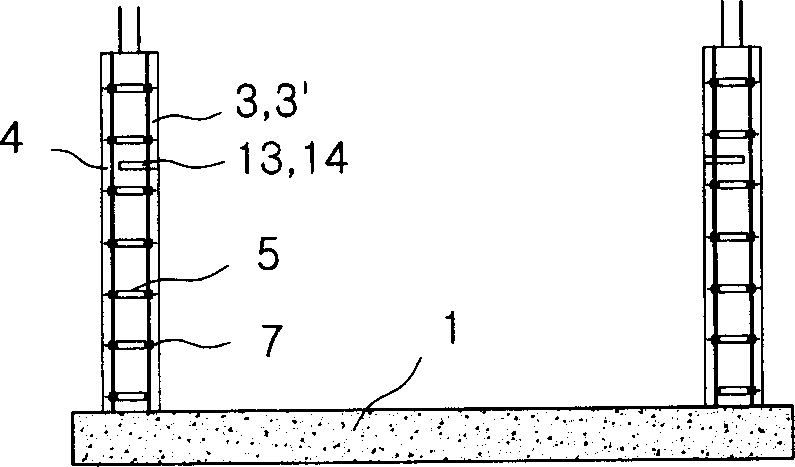

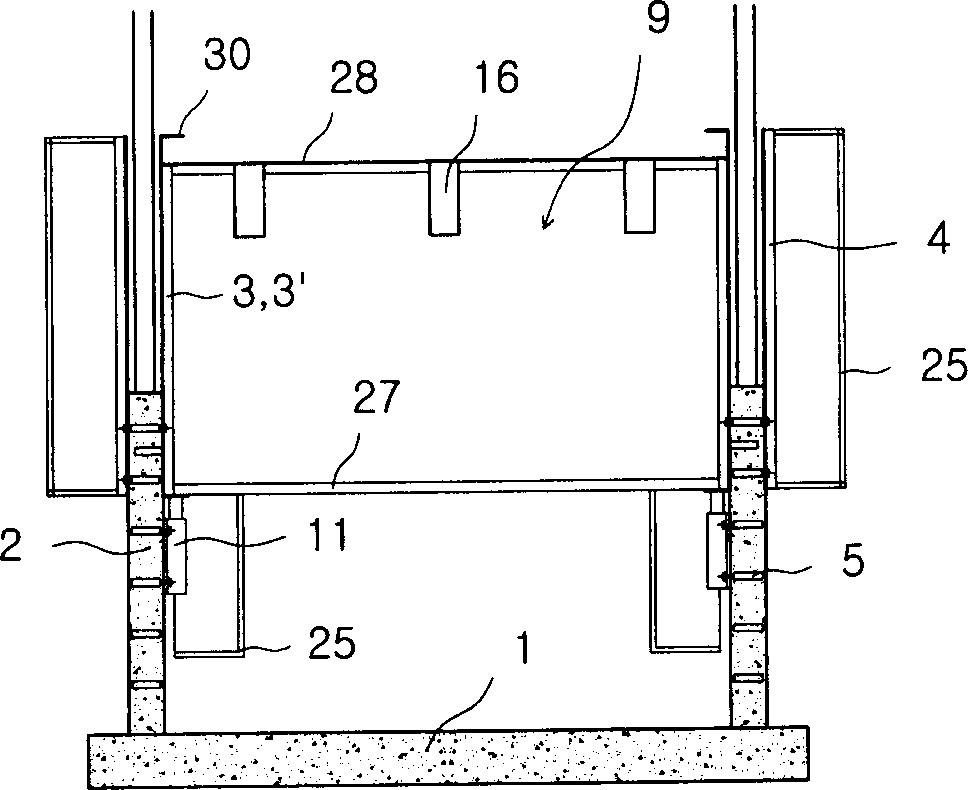

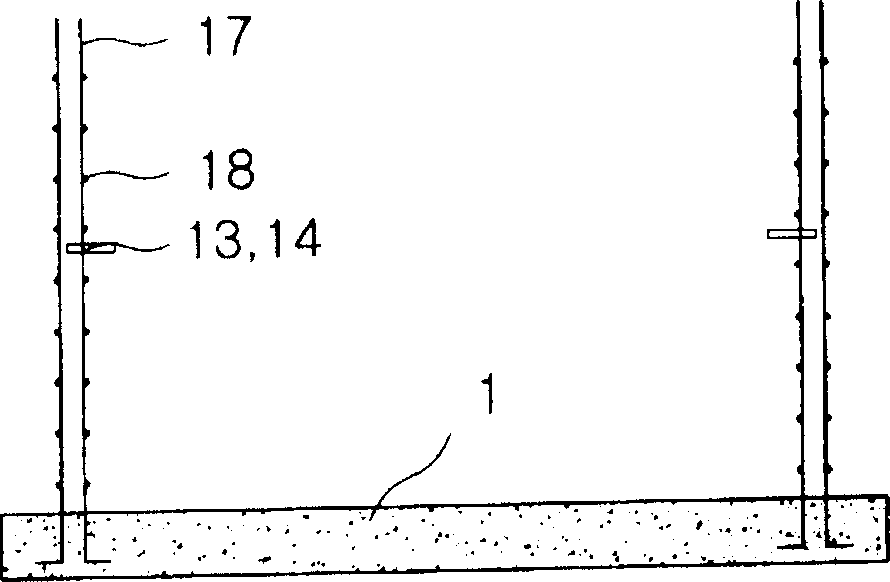

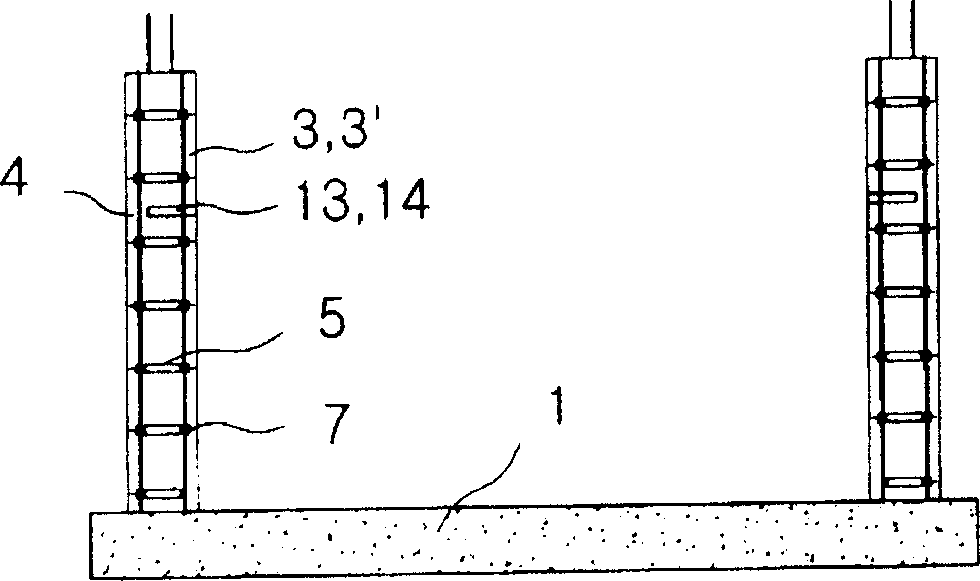

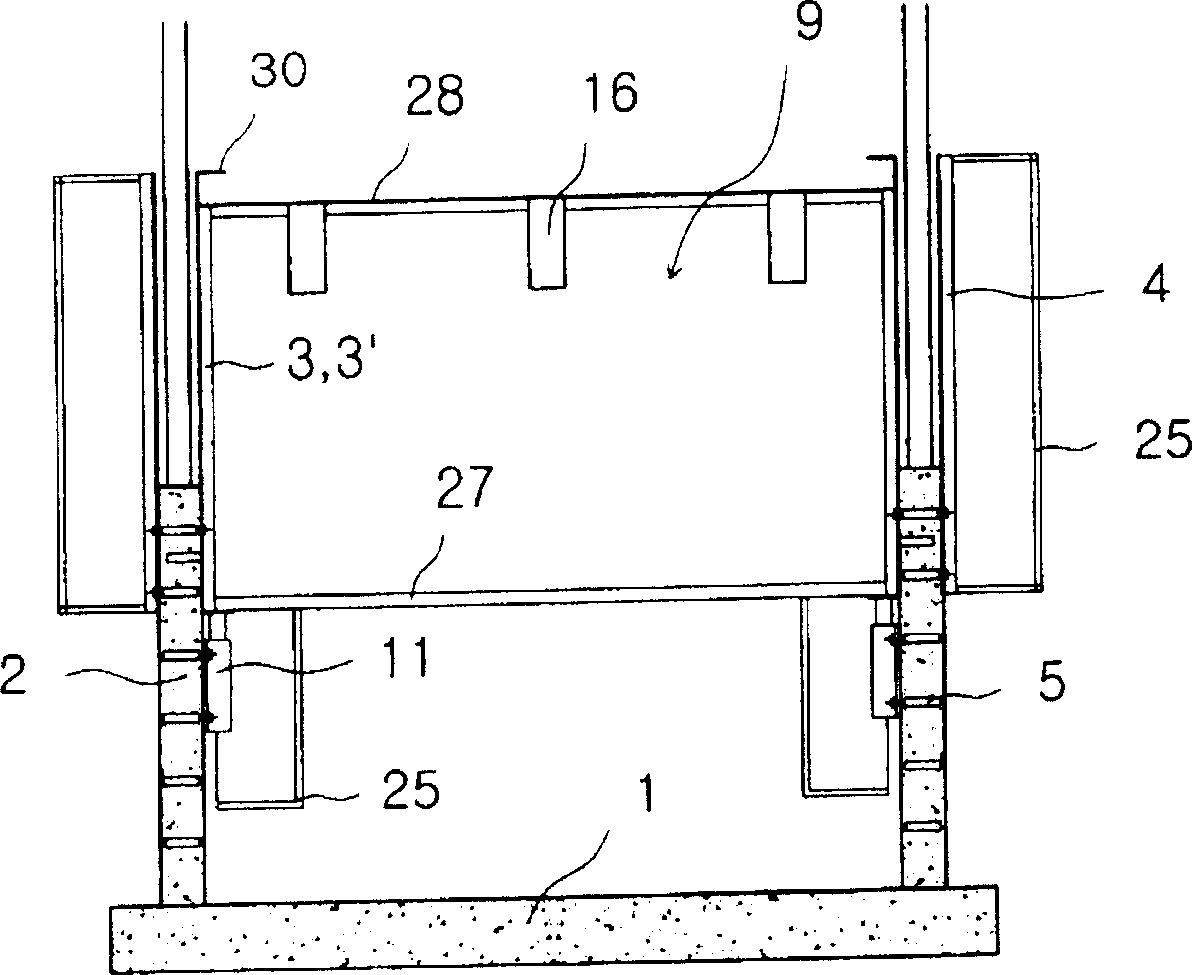

Construction method of lifting casting wall and droping casting floor

InactiveCN1355362AHigh precisionSimplify complex work proceduresForms/shuttering/falseworksFalseworkFloor slab

The invention relates to a construction method of rise concrete wall pouring and drop floor pouring when constructing concrete frame. Two flate structural inner wall templates and two 'pi' type structural inner wall templates stand face-to-face. A 'mouth' type inner template is formed by fastening and connecting the facing two inner templates using turnbuckles crew and square shape steel pipe; floor template, floor bracket and floor connecting wall template are formed on the inner template; An integrated inner wall box type template provided with opearting pedal and scaffold is formed subjacent the inner template, thus provides method of rise concrete wall pouring and drop floor pouring. It is a integrated and mechanical construction method for the formation of inner wall template and floor template components, which is suitable for high-rise construction. Scene complex working procedures can be simplified. Flying dust and noise will be prevented with continuous working, thus enhancing working efficiency and precision of the structural elements. It also reduces materials expenses and labor cost, and construction time is decreased.

Owner:河東榮

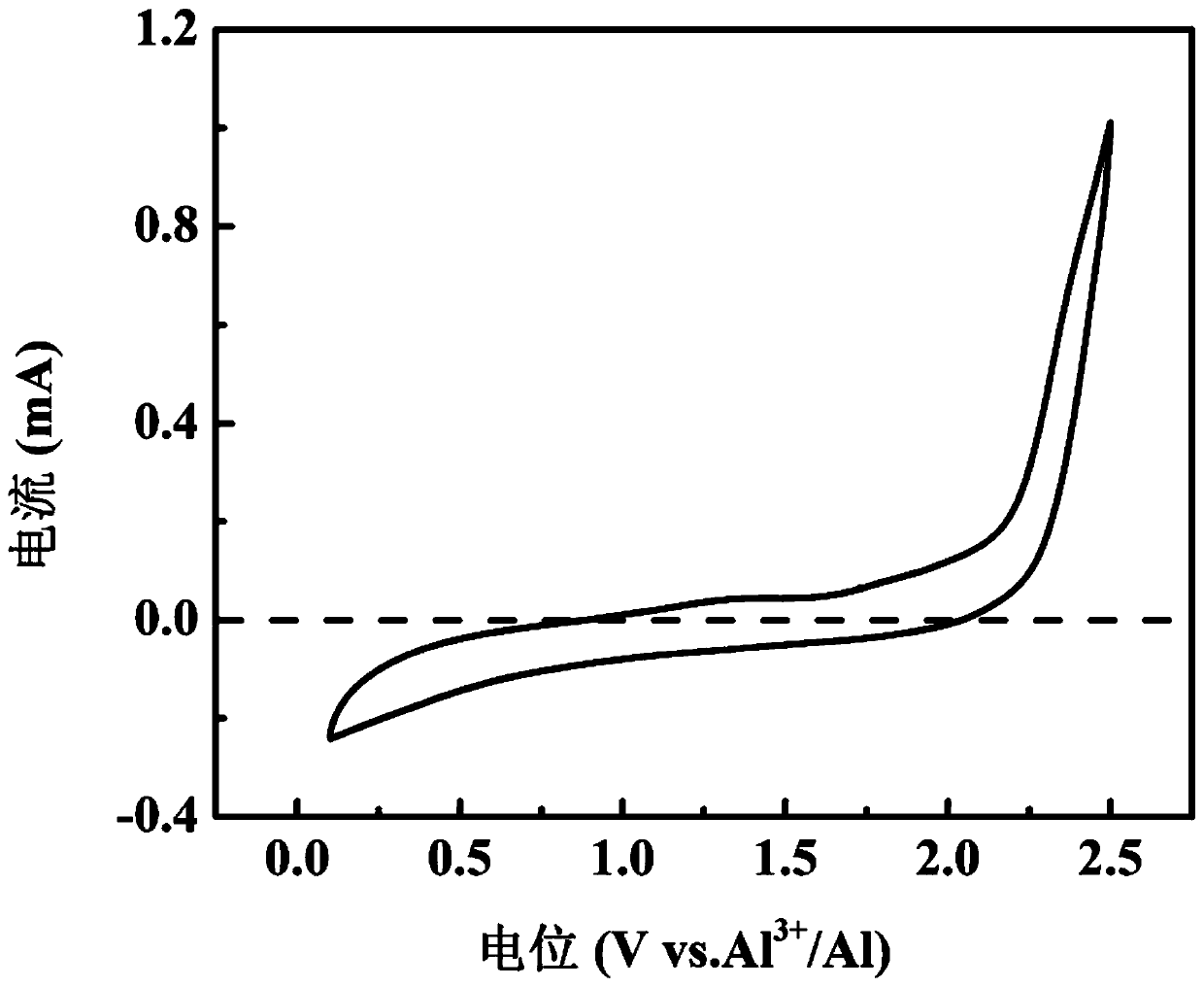

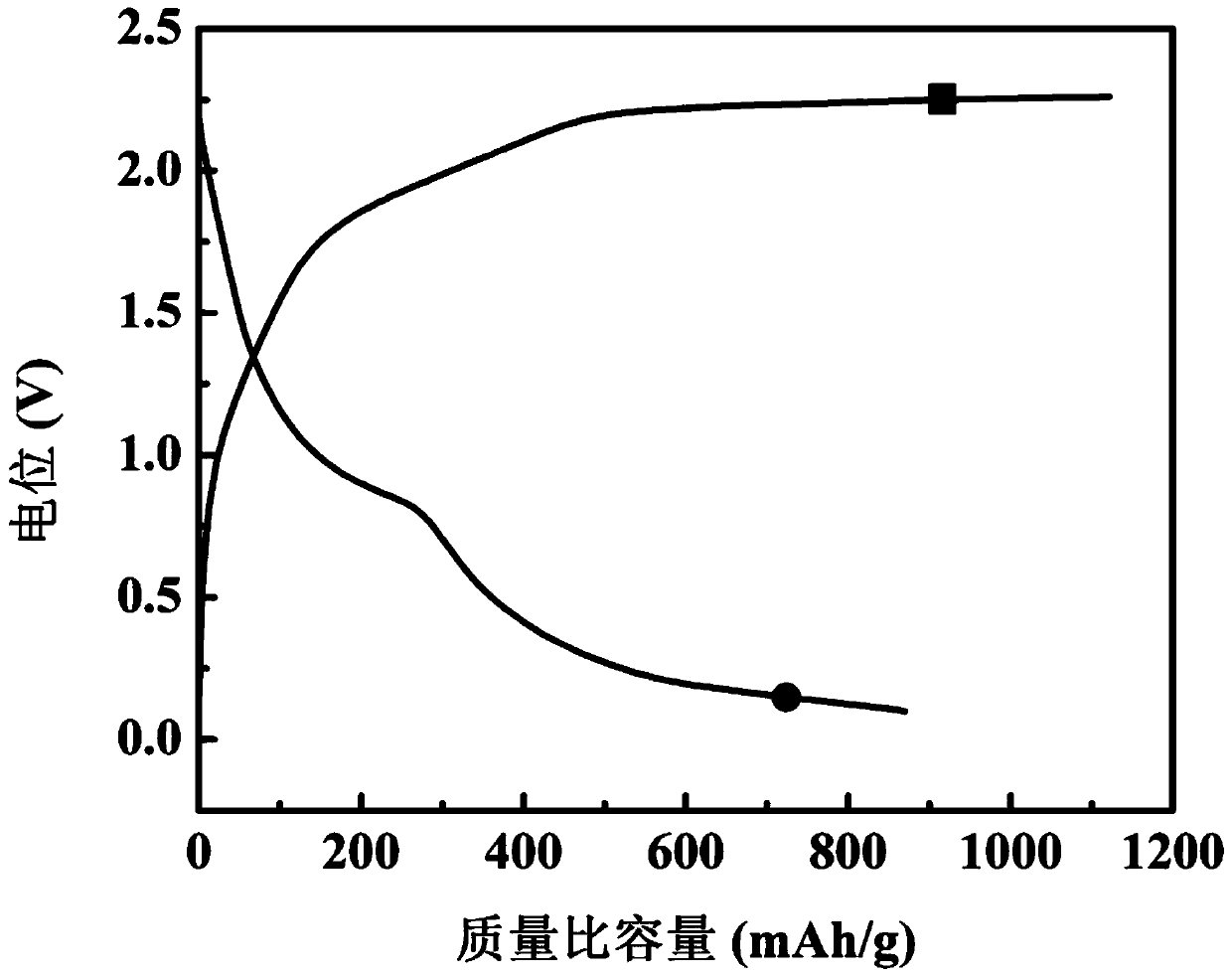

Preparation method and using method of cathode material for high-capacity aluminum cell

ActiveCN109830682AIncrease specific capacity densityCell seperators/membranes/diaphragms/spacersCell electrodesElectrochemical responseFiber

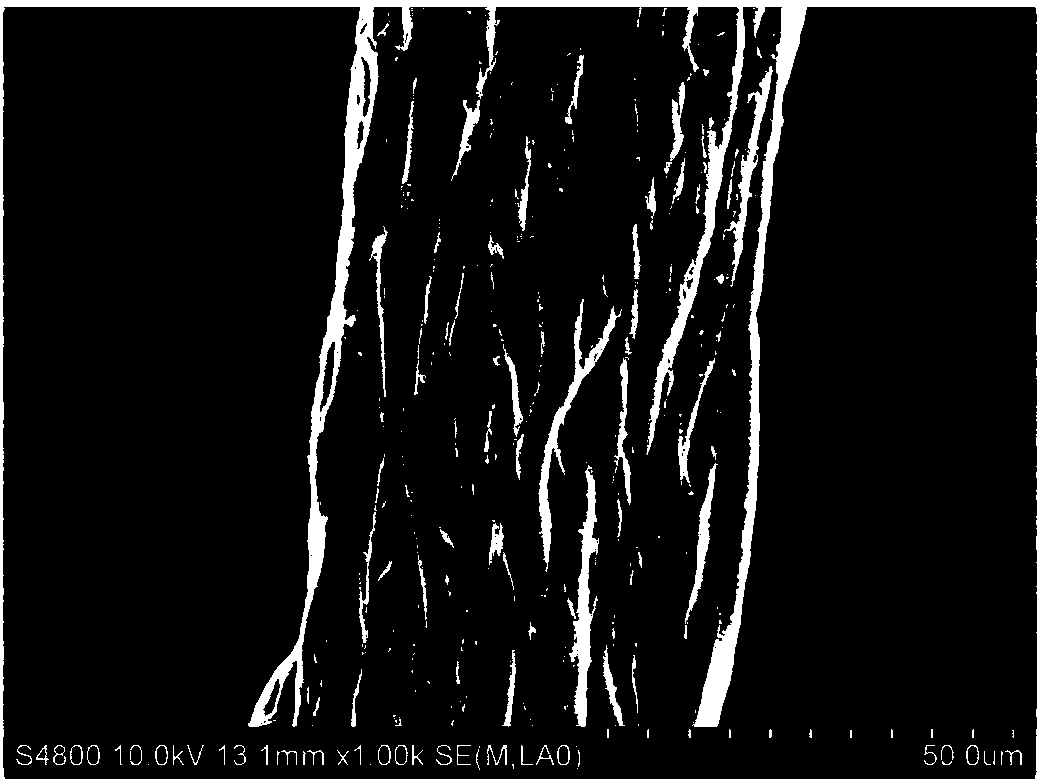

The invention relates to a preparation method and a using method of a cathode material for a high-capacity aluminum cell. The preparation method comprises that (1) an oxidized graphene-carbon fiber film is prepared by a drop casting method or a vacuum filtration method; (2) the film is dried under the condition of room temperature to 70 DEG C, and then dried at 120-200 DEG C under the vacuum condition; (3) the dry film is immersed into a hydroiodic acid solution for reduction, washed by water and alcohol, and dried; or is heated to 300-500 DEG C in the inert atmosphere and thermally insulated;or heated to 800-1000 DEG C in the reducing atmosphere and thermally insulated; and (4) microwave processing is implemented. The using method comprises that the cathode material for the high-capacityaluminum cell serves as the anode, and the anode, cathode, electrode diaphragm and an electrolyte are assembled into the aluminum cell. In the charging / discharging material, electrochemical reactionof the cathode material is embedding or removing of chloride ion [Cl]-, the theoretical capacity can reach 2231mAh.g-1, and the practical specific capacity density can reach 300-1200 mAh.g-1.

Owner:NORTHEASTERN UNIV

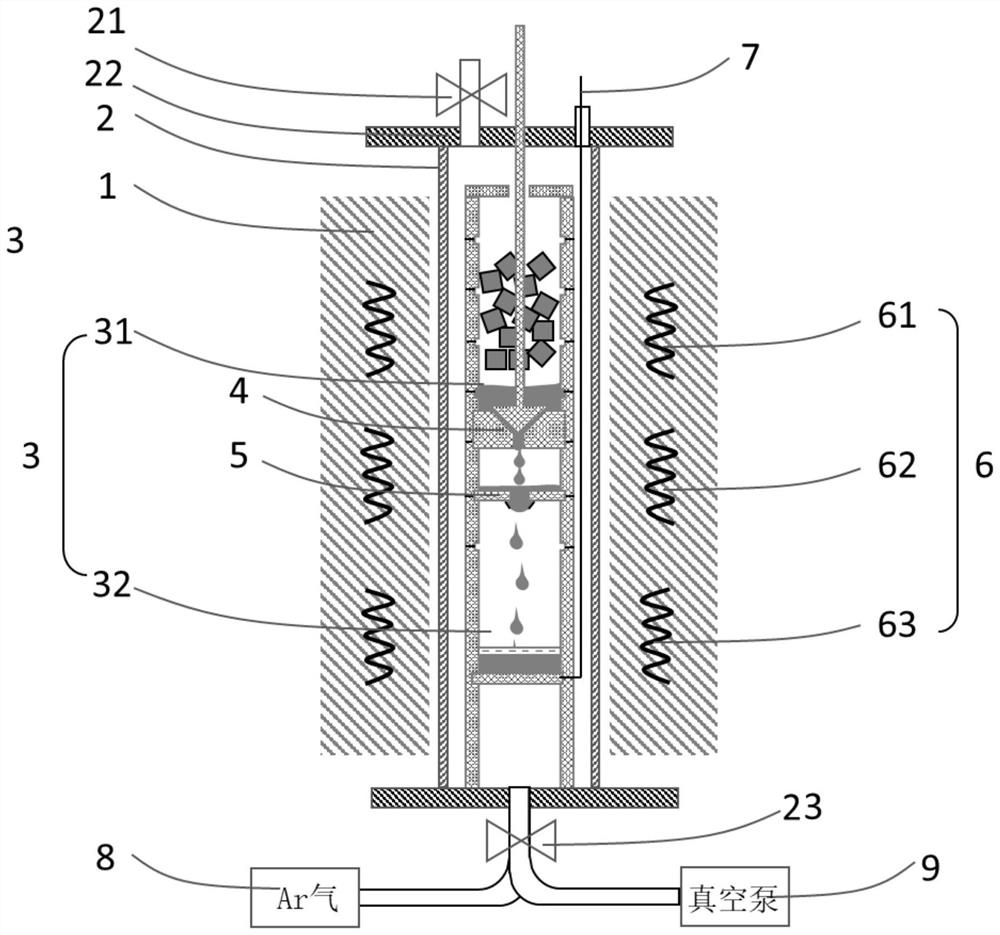

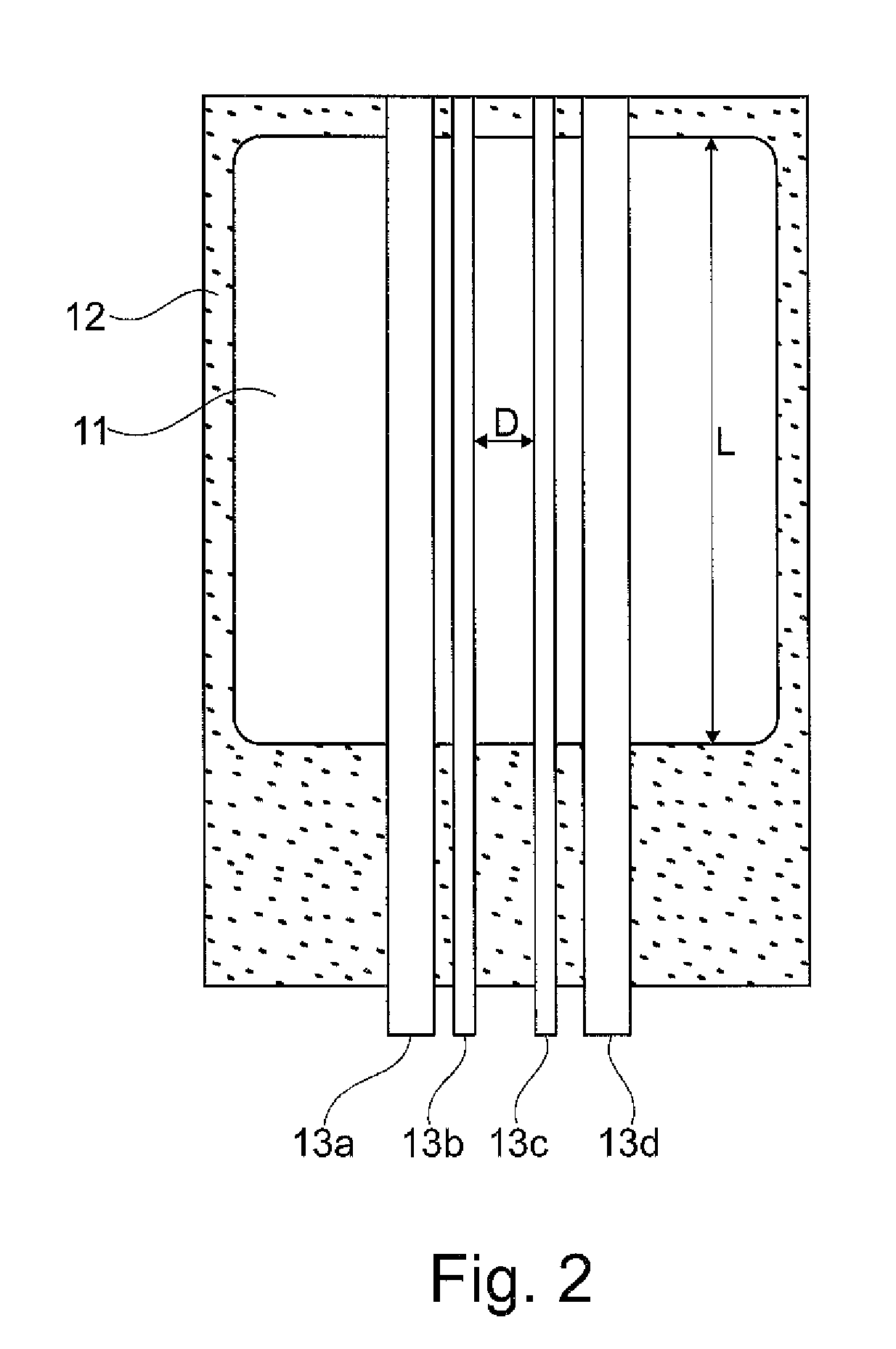

Magnesium and magnesium alloy casting device and method based on melt speed-controlled drop casting

ActiveCN114247857AAchieve layer-by-layer solidificationFacilitate liquid flowMolten metal pouring equipmentsIngot casting plantsExhaust valveDrop casting

The invention discloses a magnesium and magnesium alloy casting device and method based on melt speed-controlled drop casting. The casting device comprises an electric furnace body, a sealed cabin and a multi-section temperature control assembly are arranged in the electric furnace body, a flange end cover and an exhaust valve are arranged on the upper portion of the sealed cabin, and a bottom air inlet valve is communicated with an argon supply mechanism and a vacuum mechanism; a top pouring type integrated crucible is arranged in the sealed cabin body, a flow rate adjusting mechanism and a filtering mechanism are nested between a smelting area and an ingot casting area of the top pouring type integrated crucible, and a thermocouple is arranged at the bottom of the outer wall of the top pouring type integrated crucible; the casting method comprises the following steps: placing magnesium and magnesium alloy raw materials in a smelting area; vacuumizing to enable the whole cavity to be filled with argon; the temperature of the multi-section temperature control assembly is set, and magnesium and magnesium alloy raw materials are melted in the full argon protection atmosphere; meanwhile, the flow velocity adjusting mechanism is adjusted to control the flow velocity of the melt; the liquid drops drop into an ingot casting area in a continuous and clean liquid drop form; the device and the process are simple, the effect is excellent, and the formed casting product has high homogeneity, high compactness and high cleanliness at the same time.

Owner:XI AN JIAOTONG UNIV

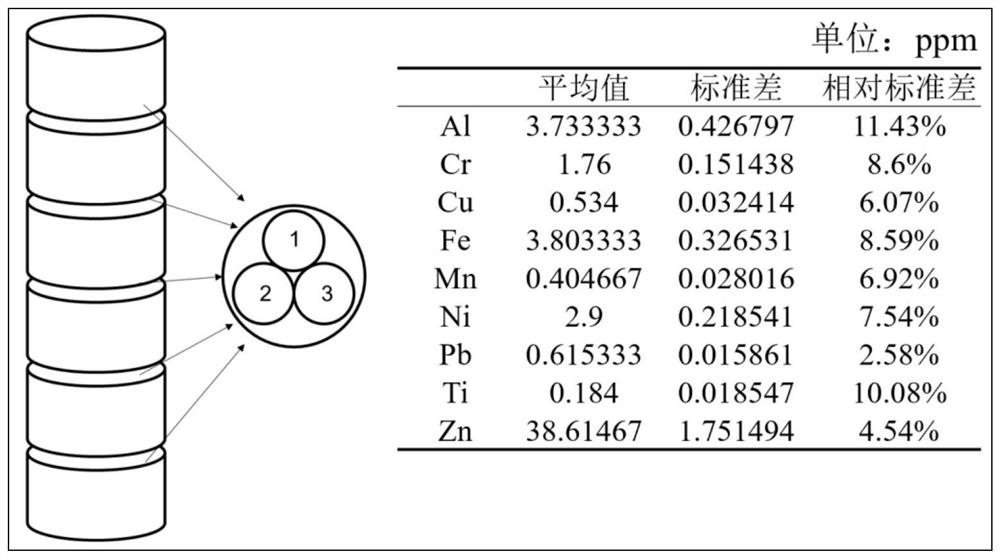

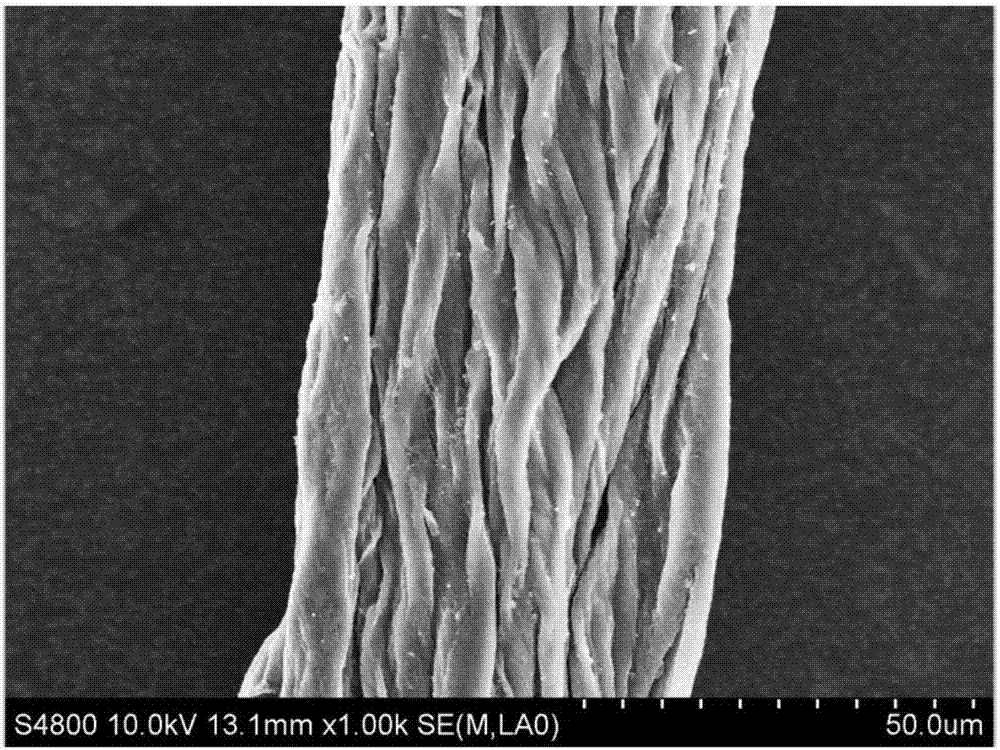

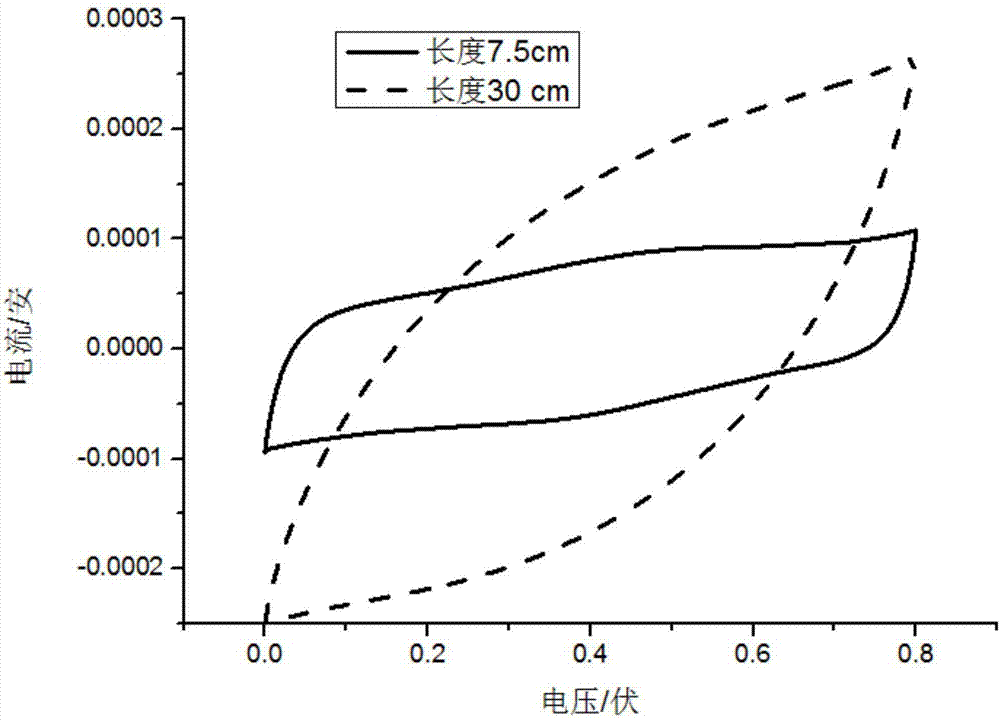

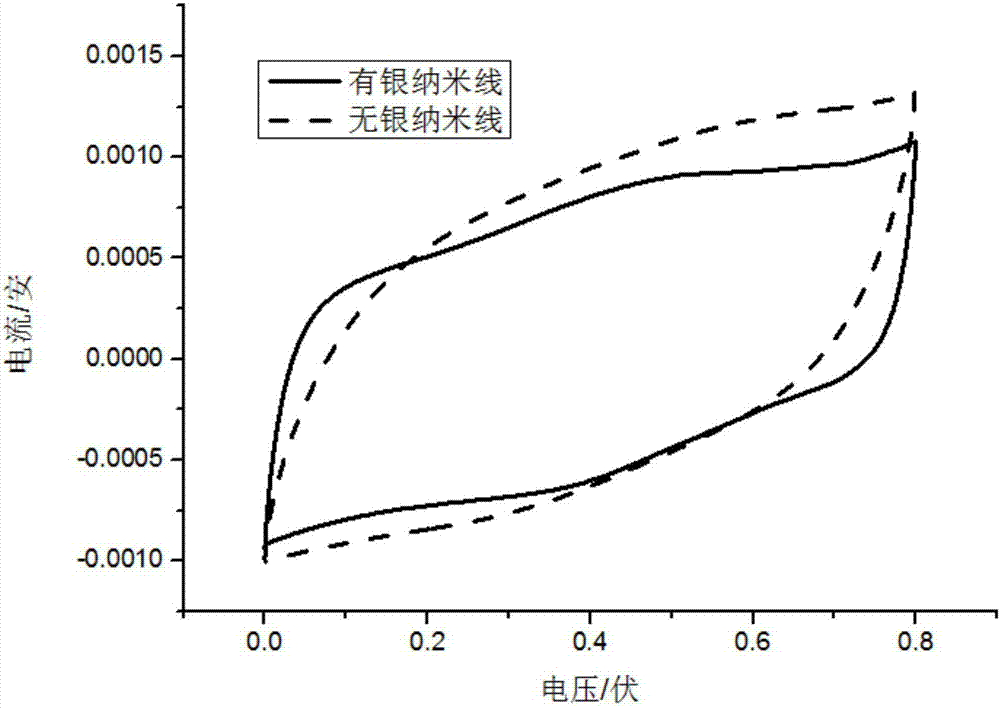

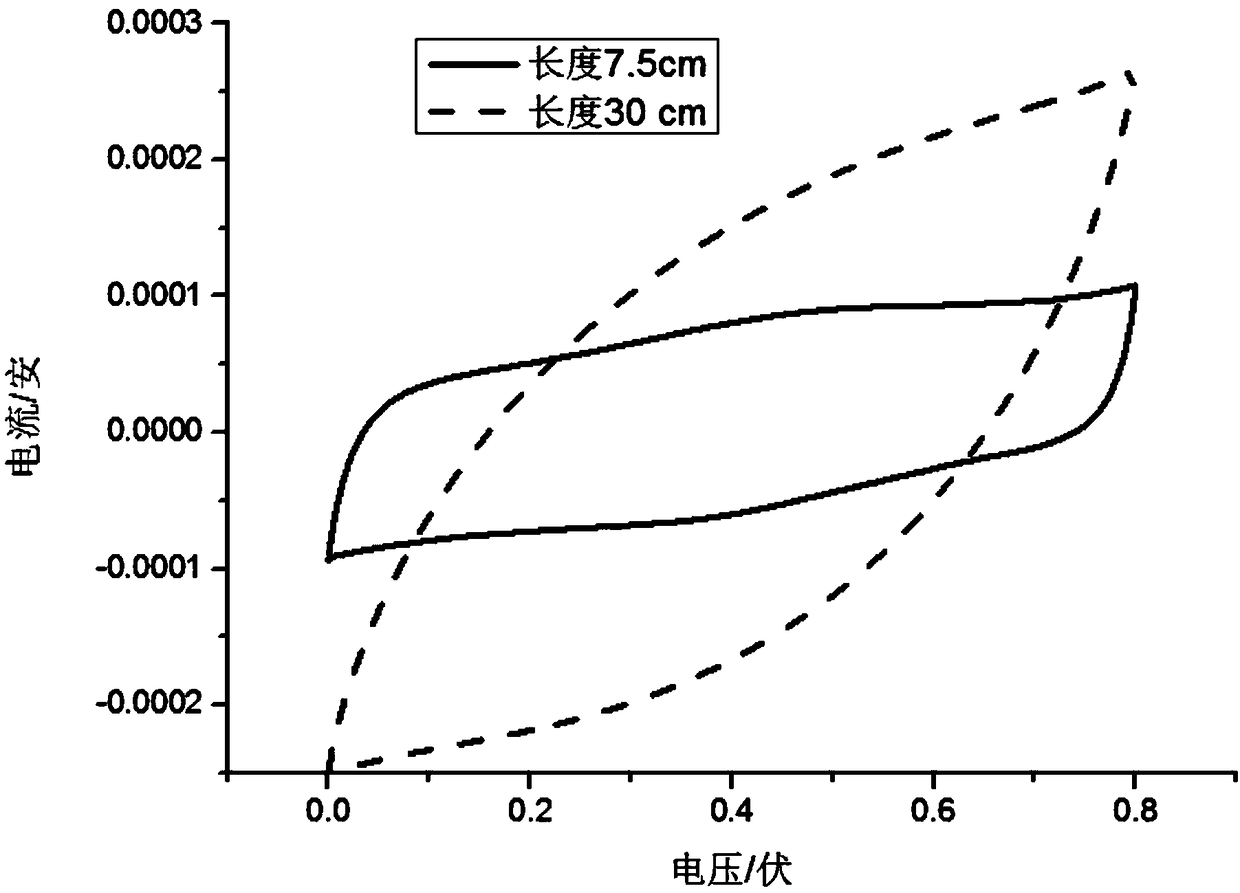

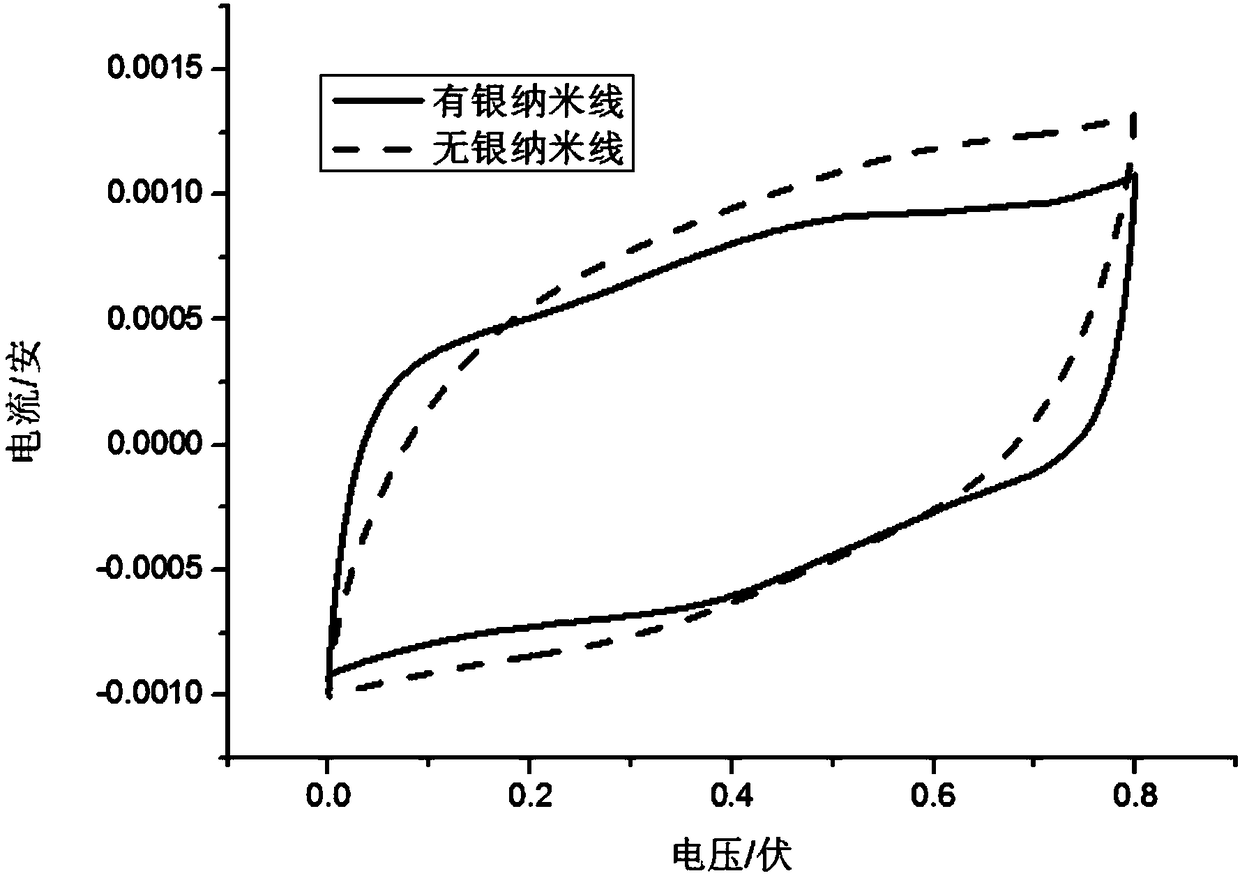

Long linear super capacitor with high power and preparation method thereof

ActiveCN107068412AImprove axial conductivityImprove power characteristicsHybrid capacitor electrolytesHybrid capacitor electrodesCarbon filmDrop casting

The invention relates to a long linear super capacitor with high power. The long linear super capacitor comprises a conductive substrate, an active material, and a gel electrolyte. The active material is arranged on the conductive substrate through drop casting. The active material is coated by a carbon nanotube film which is coated by the gel electrolyte. The conductive substrate is a sandwich structure of sequential carbon nanotube film / silver nanowires / sequential carbon film. The active material is a GO / MCNTs complex. The gel electrolyte is a PVA / H3PO4 electrolyte. A preparation method of the long linear super capacitor comprises the steps of depositing the active material on the sandwich structure of sequential carbon nanotube film / silver nanowires / sequential carbon film, twisting to form linear electrodes, and finally preparing the long linear super capacitor through twisting by using two same linear electrodes. According to the long linear super capacitor and the method, the efficiency is high, the stability is good, the realization of industrialized production is facilitated, the axial conductivity of the long linear super capacitor is improved, and thus the power characteristic of the long linear super capacitor is improved.

Owner:CHANGZHOU UNIV

Electroactive polymer based supercapacitors including a cathode having BBL or pyr-BBL

ActiveUS9068043B1Hybrid capacitor electrolytesLiquid surface applicatorsDrop castingRoom temperature

A process used to cast films including; mixing Pyr-BBL and a room temperature molten salt from a range of about 35:65 weight ratio, dissolving the mixture in about 1% methanesulfonic acid to produce a Pyr-BBL solution, drop casting the solution onto glass or gold coated glass at 140° C. in air and heating for about 2 hours to produce films, drying the films in a vacuum oven at about 100° C. for at least 24 hours under dynamic vacuum, and rinsing the films to remove residual ionic liquid.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

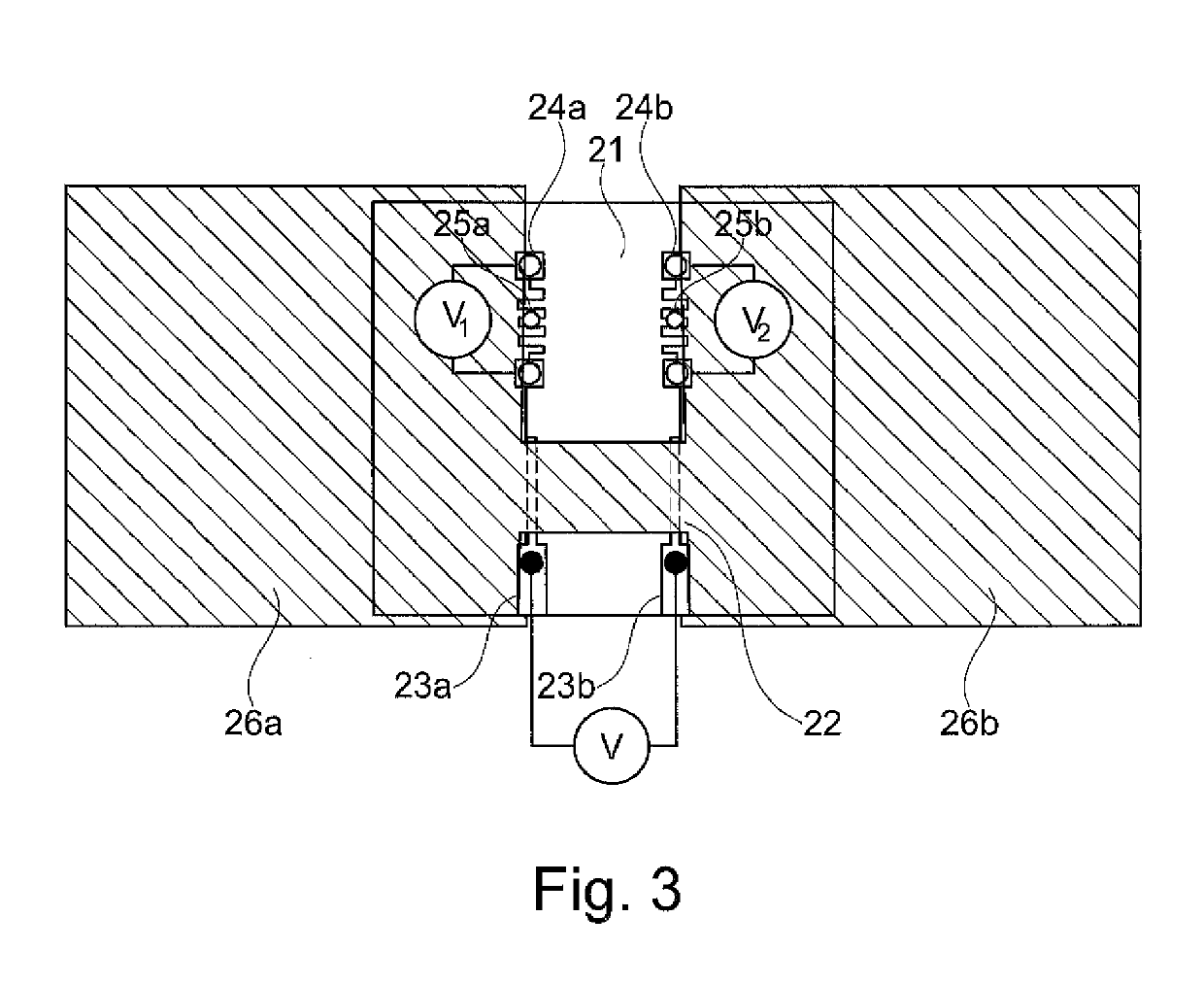

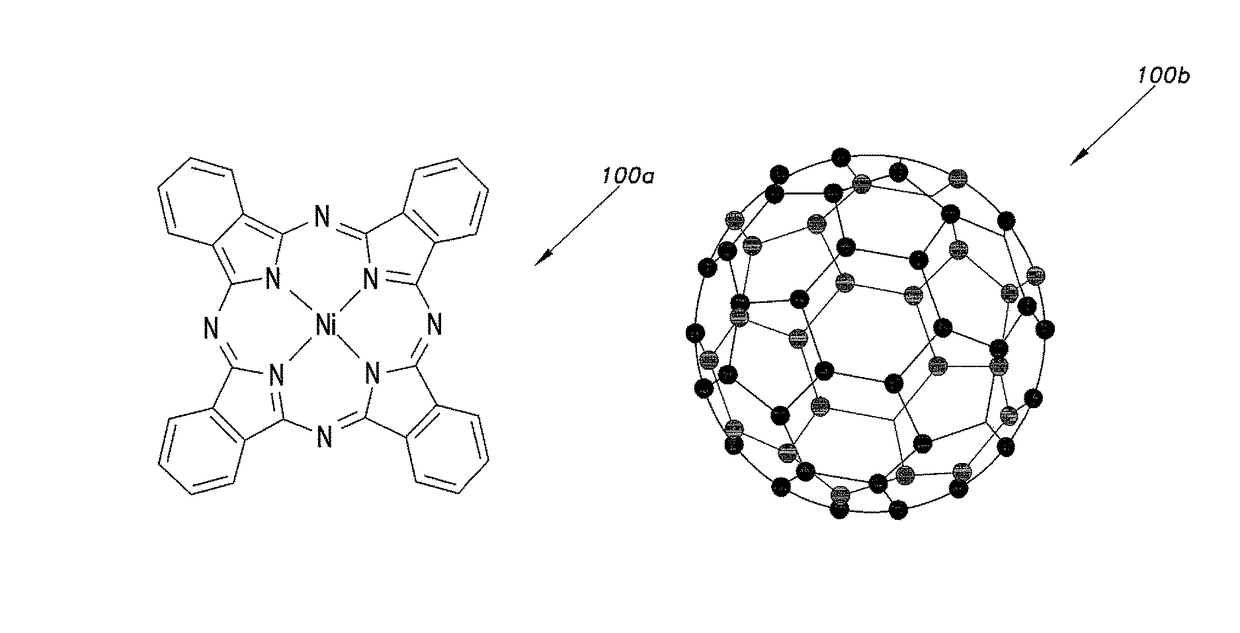

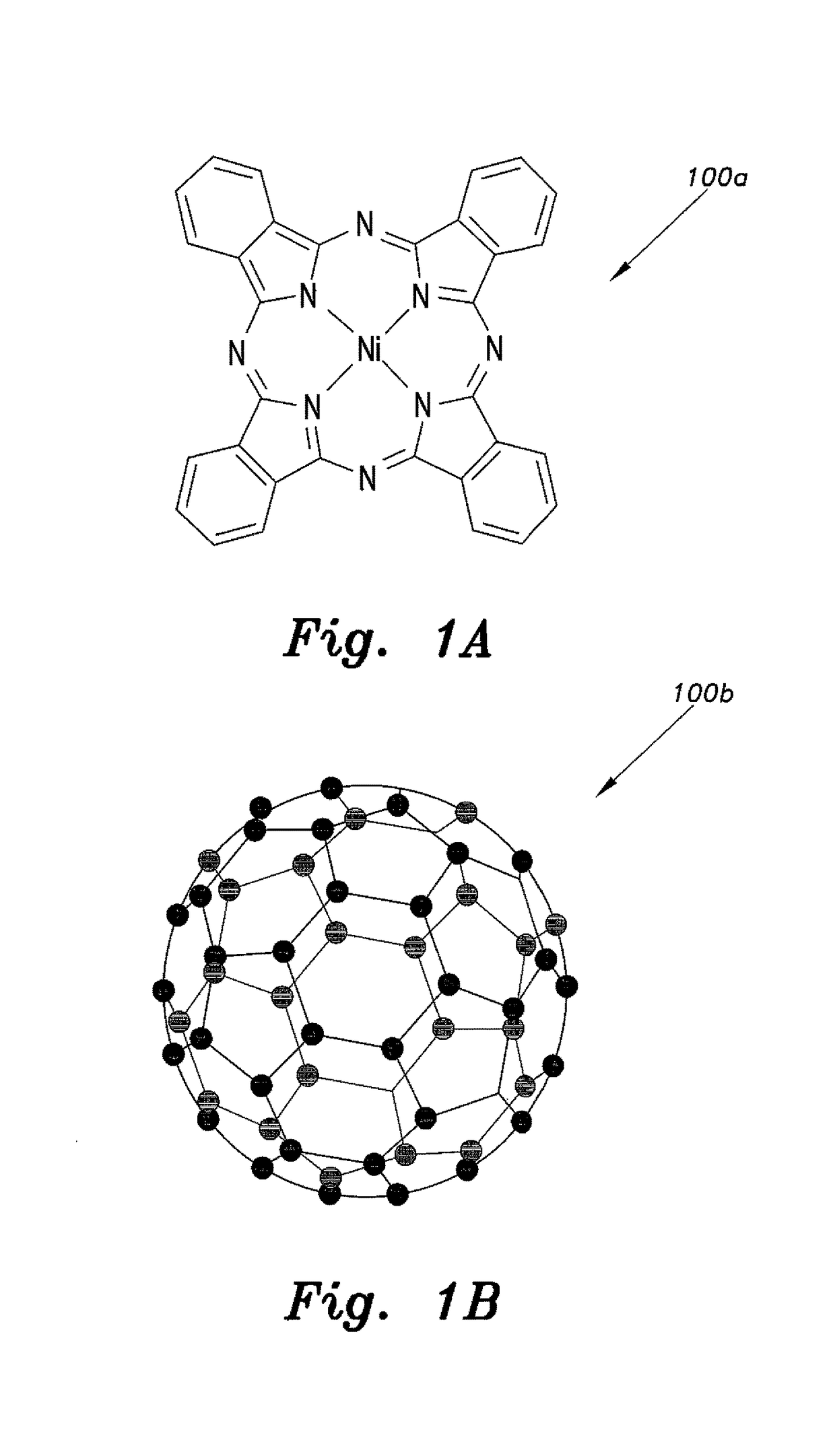

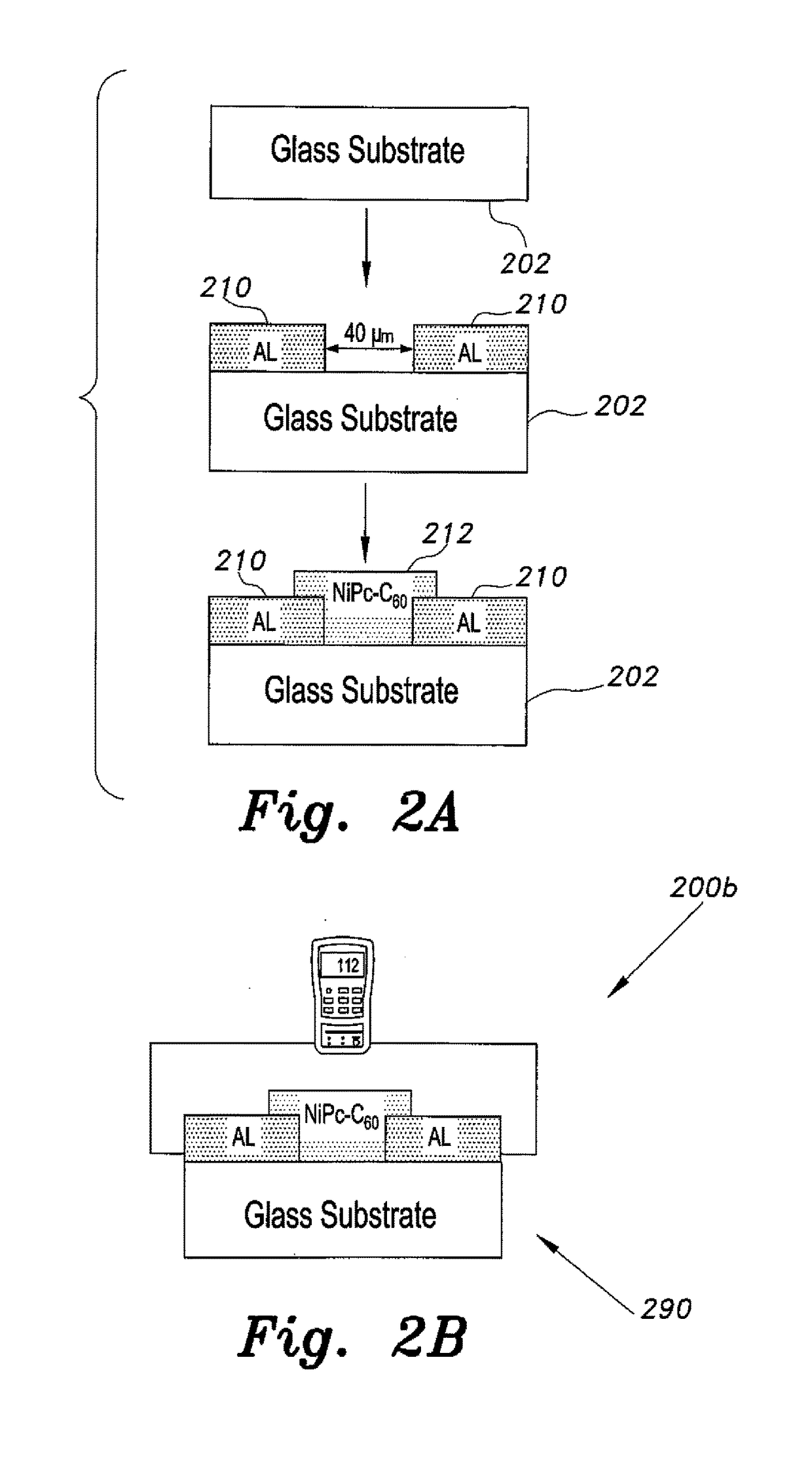

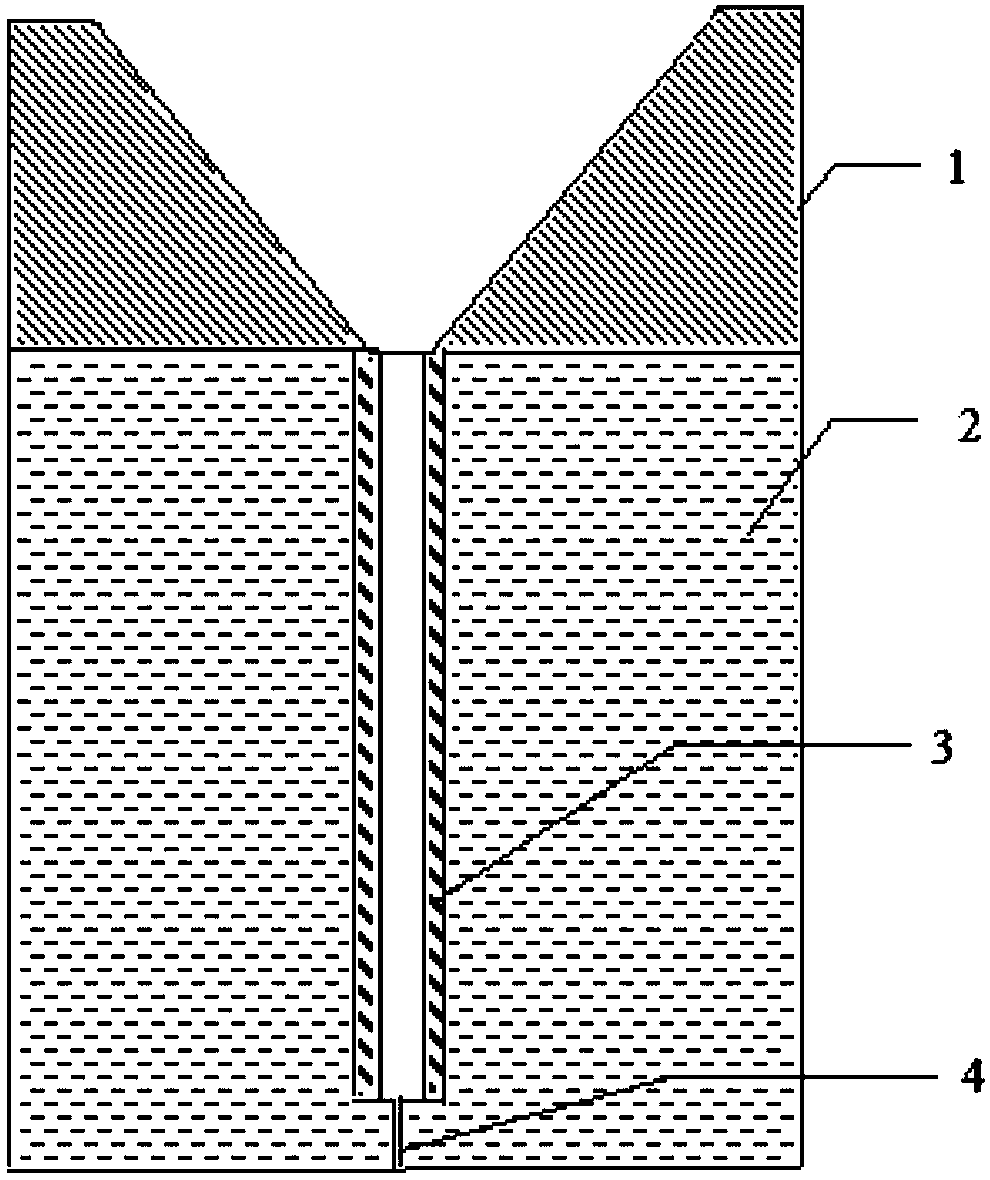

Method of making thin film humidity sensors

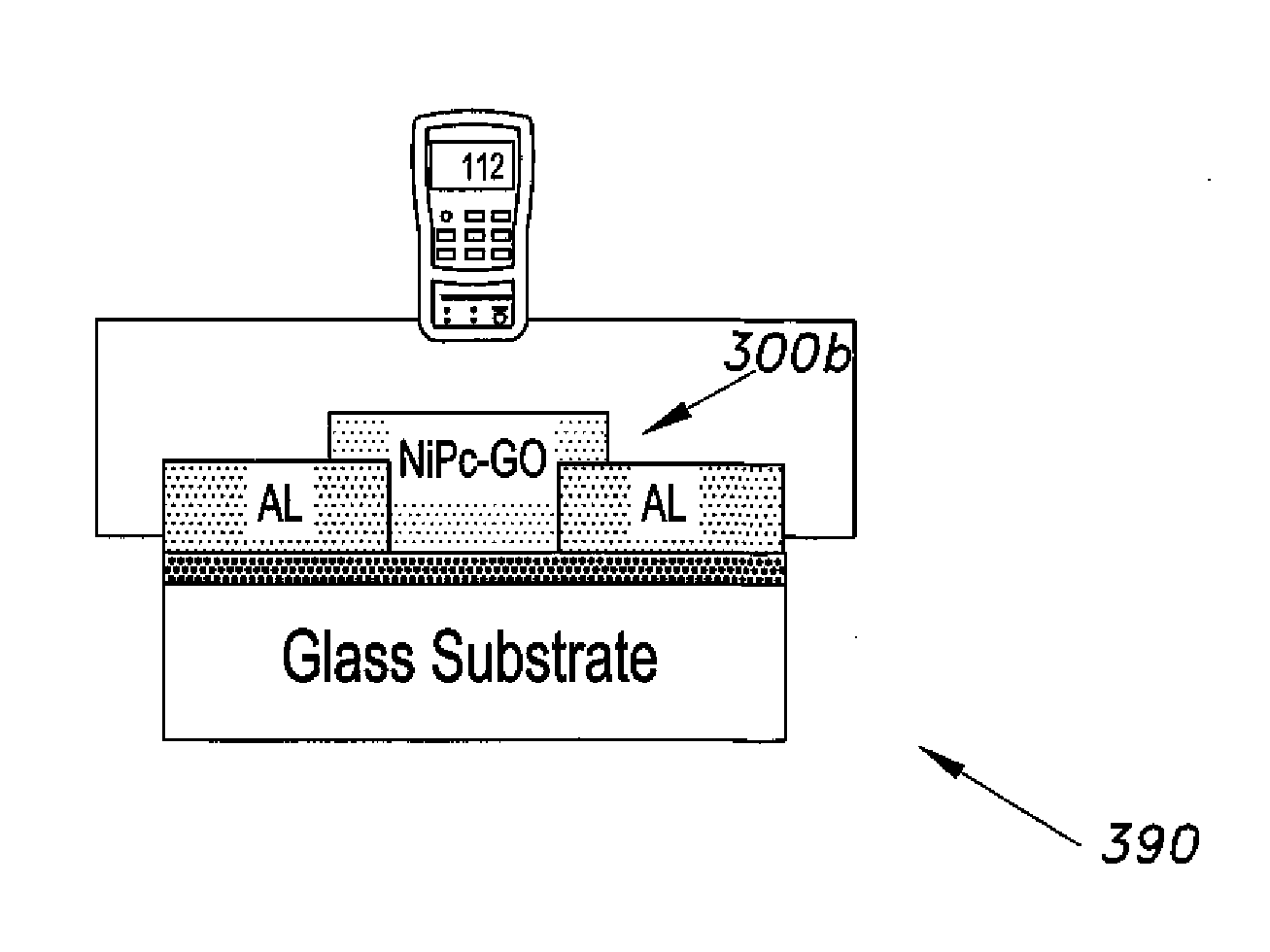

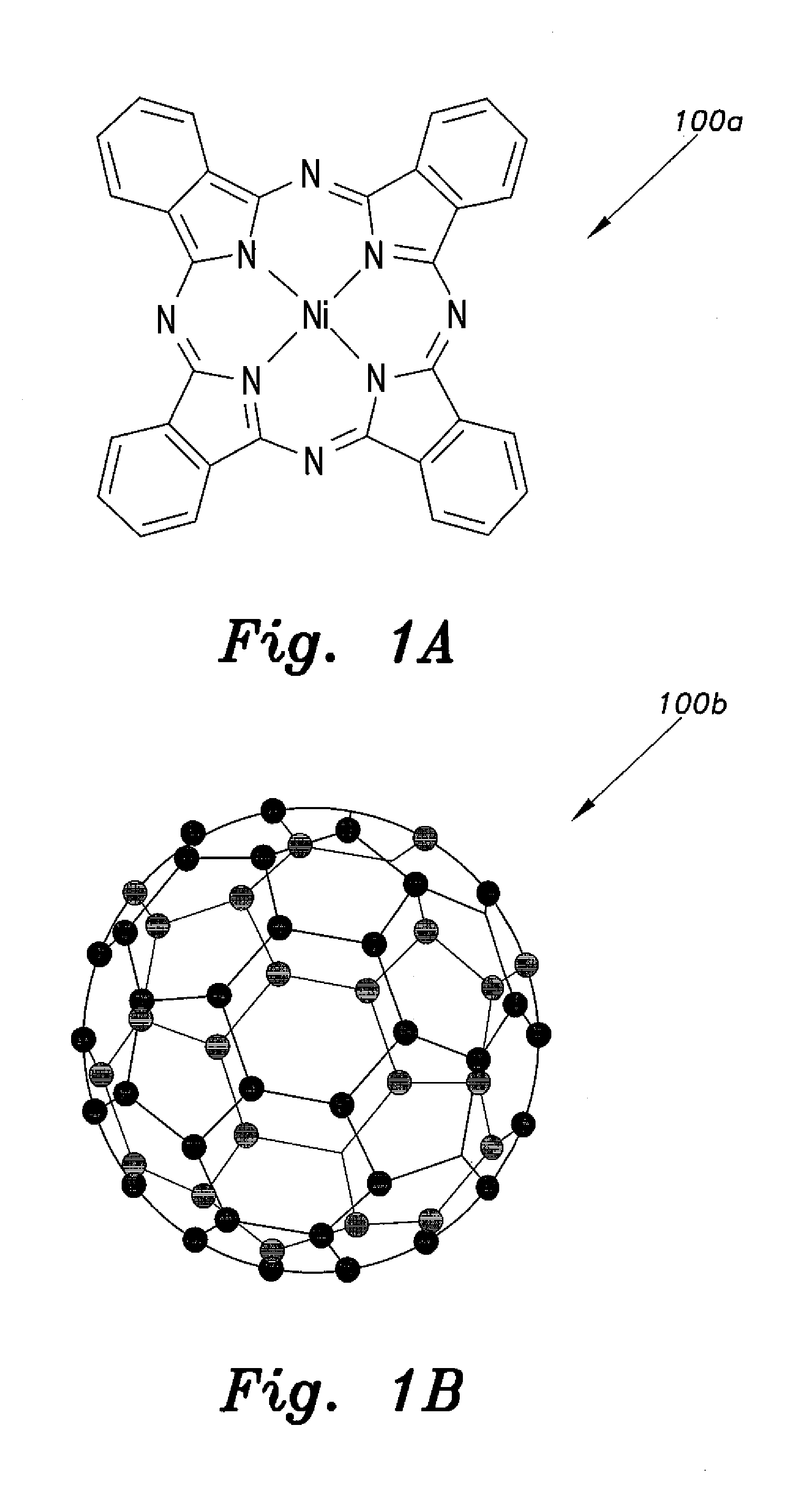

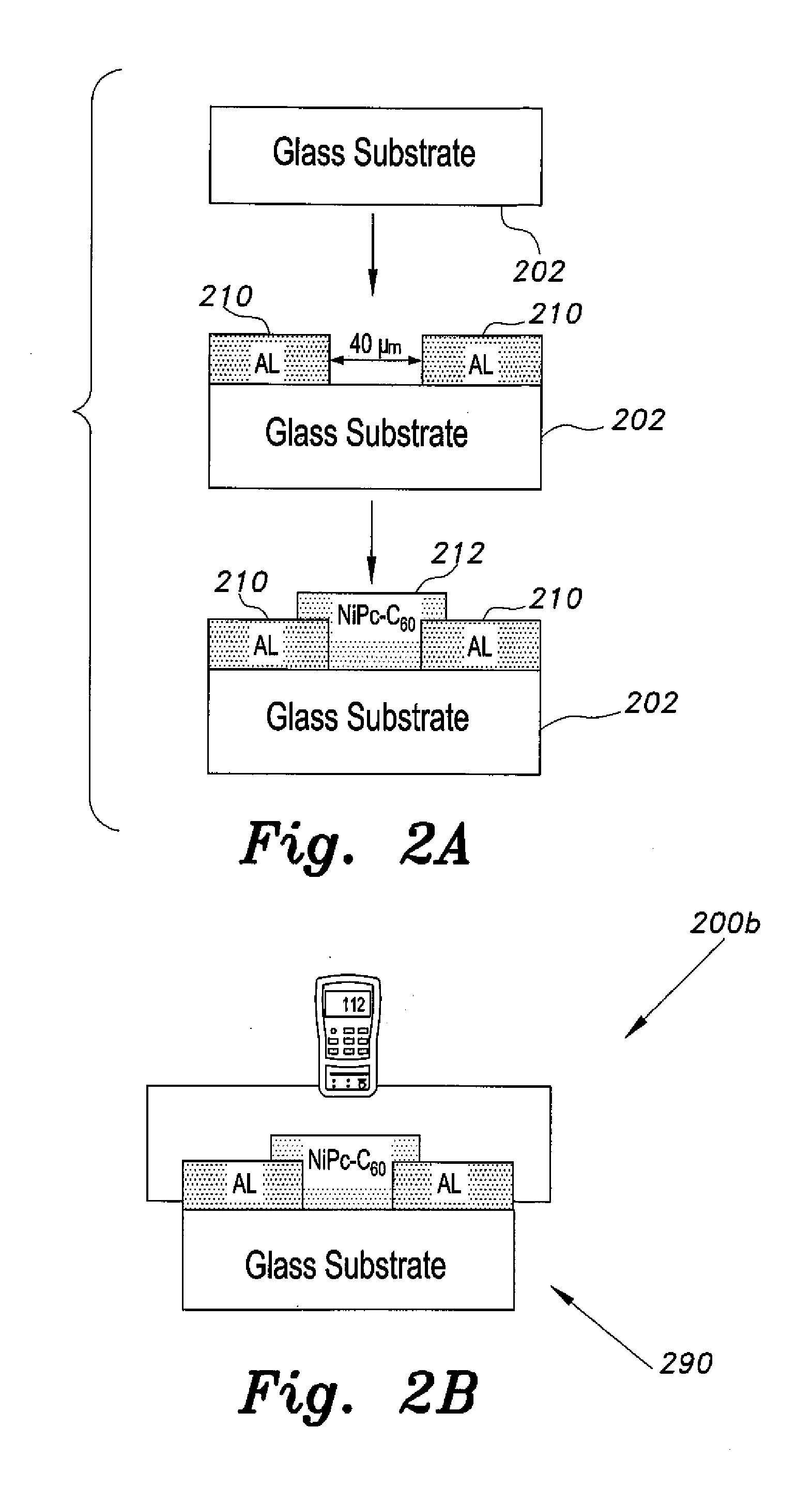

The method of making thin film humidity sensors uses thermal vapor deposition or drop casting techniques to fabricate nickel phthalocyanine-fullerene-based (NiPc-C60) quick response humidity sensors with negligible hysteresis. Prior to the deposition of aluminum electrodes, a glass substrate is cleaned by using acetone in an ultrasonic bath for 10 minutes. After cleaning, the substrate is washed with de-ionized water and then dried. A gap is created between two electrodes by masking the glass substrate with copper wire. This assembly is plasma-cleaned for 5 minutes in a thermal evaporator. Subsequently aluminum (Al) thin films are deposited on the assembly. Next, a mixture of equal parts NiPc-C60 is deposited onto the gap between the Al electrodes by thermal vapor deposition or by drop casting. A method of forming NiPc-graphene oxide (NiPc-GO) humidity sensors without using instrumentation drop casts an NiPc-GO suspension onto aluminum foil electrodes taped to a substrate.

Owner:KING ABDULAZIZ UNIV

Method of manufacturing thermoelectric module using ink formulations

InactiveUS20190237647A1Improve conductivityImprove performanceFinal product manufactureConductive materialDrop castingConductive polymer

A method of manufacturing a conductive layer includes the step of dissolving an organic semiconductor polymer in a first solvent, the first solvent being an aromatic or heterocyclic compound comprising one or more electron-rich carbon atom(s) and / or heteroatom(s). The method also includes dissolving a dopant in a second solvent, the second solvent being a polar solvent. The method also includes mixing the solutions of the organic semiconductor polymer and the dopant to form a dispersion comprising doped conductive polymer particles suspended in the solvent blend. The method also includes depositing the dispersion by a solution deposition technique to form a conductive layer. The solution deposition technique is preferably an inkjet printing, dispense printing or drop casting method. The dispersion provides a stable ink composition for the manufacturing of thick and uniform layers with excellent conductivity and thermopower, and allows simple fabrication of thermoelectric legs with enhanced performance.

Owner:CAMBRIDGE DISPLAY TECH LTD +1

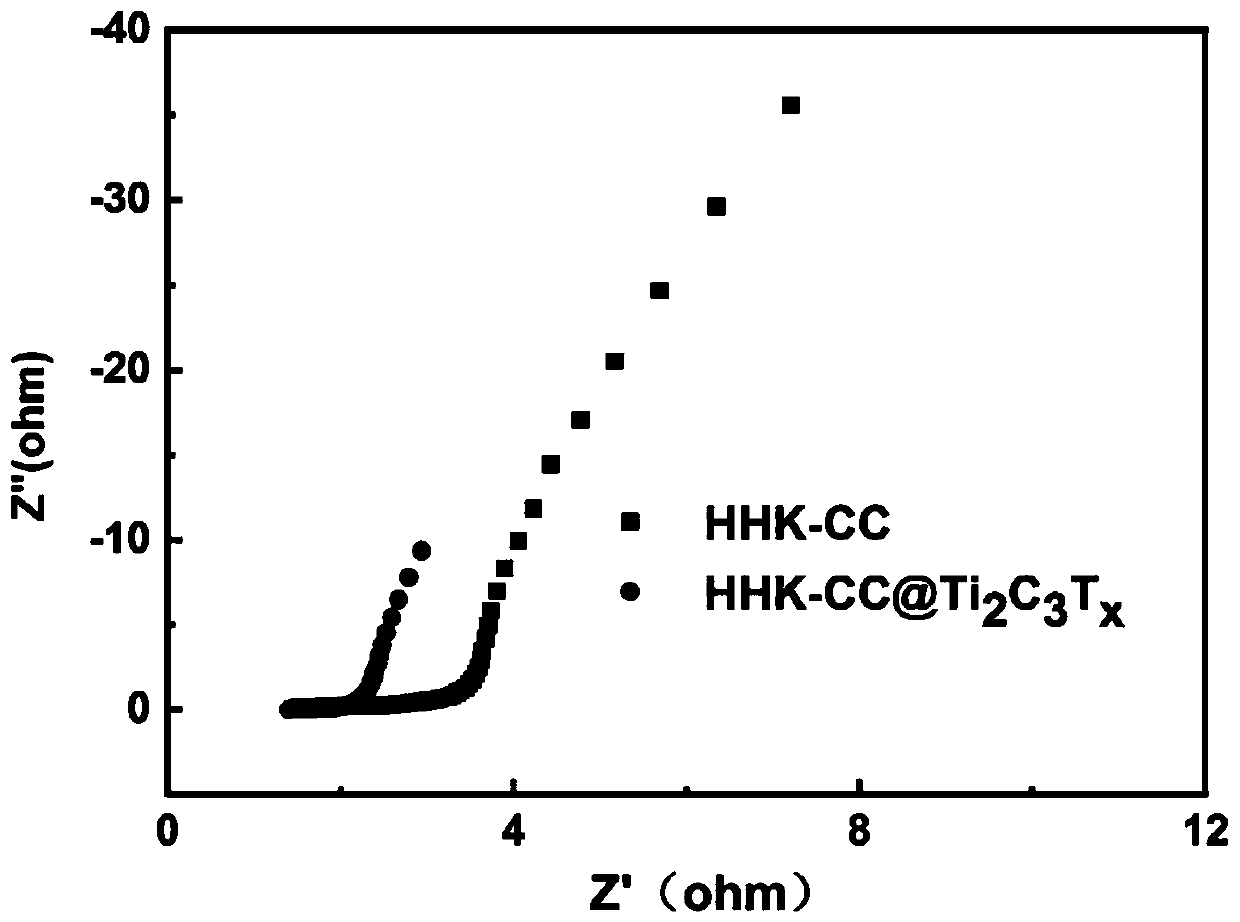

Preparation method and application of HHK-CC@-MXenes composite flexible electrode material

PendingCN110790277ASimple methodLow costHybrid capacitor electrodesCarbon preparation/purificationComposite electrodeDrop casting

The invention relates to a preparation method of an HHK-CC@-MXenes composite flexible electrode material. The method includes S1) a step of etching preparation of a multilayer Ti3C2TX material, namelya step of immersing an MAX precursor into a solution of HCl and LiF for etching to remove a phase A in the MAX precursor to obtain the multilayer Ti3C2TX material; S2) a step of screening of single-layer or few-layer Ti3C2TX nanosheet materials; S3) a step of HHK-CC preparation, namely a step of immersing CC into a strong oxidizing acid solution to be oxidized and activated to obtain HHK-CC; andS4) a step of drop casting of the HHK-CC obtained in the step S3 with a solution containing the single-layer or few-layer Ti3C2TX nanosheets. Compared with the prior art, the HHK-CC@MXenes composite electrode material is prepared by forming a film on activated CC by using a small amount of few-layer or single-layer Ti3C2TX, so that the mechanical strength of the electrode material is enhanced, theuse amount of Ti3C2TX is reduced, and the hydrophilicity of the electrode material is very good; a direct drop casting method is adopted for preparation so that the process is simple and the equipment cost is low, and the supercapacitor flexible electrode material which is stable in structure and excellent in performance can be obtained.

Owner:SHANGHAI INSTITUTE OF TECHNOLOGY

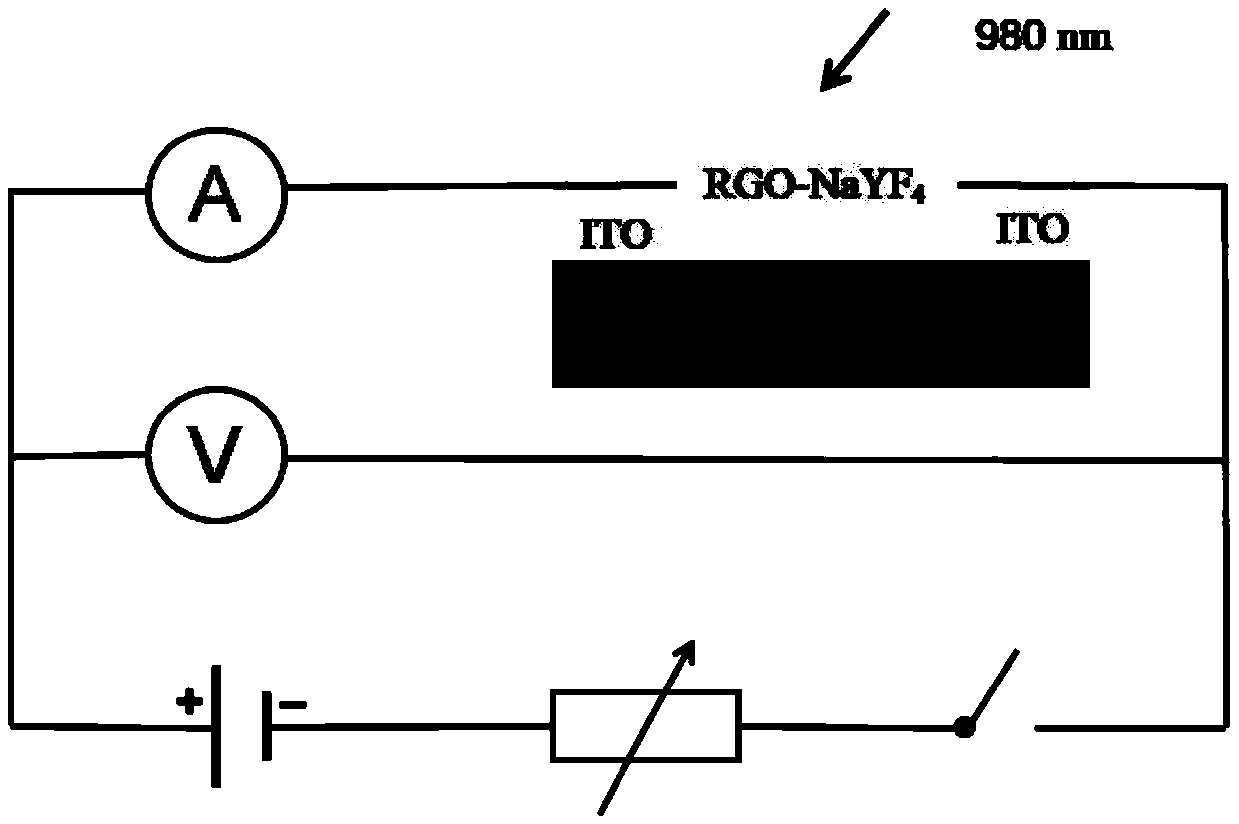

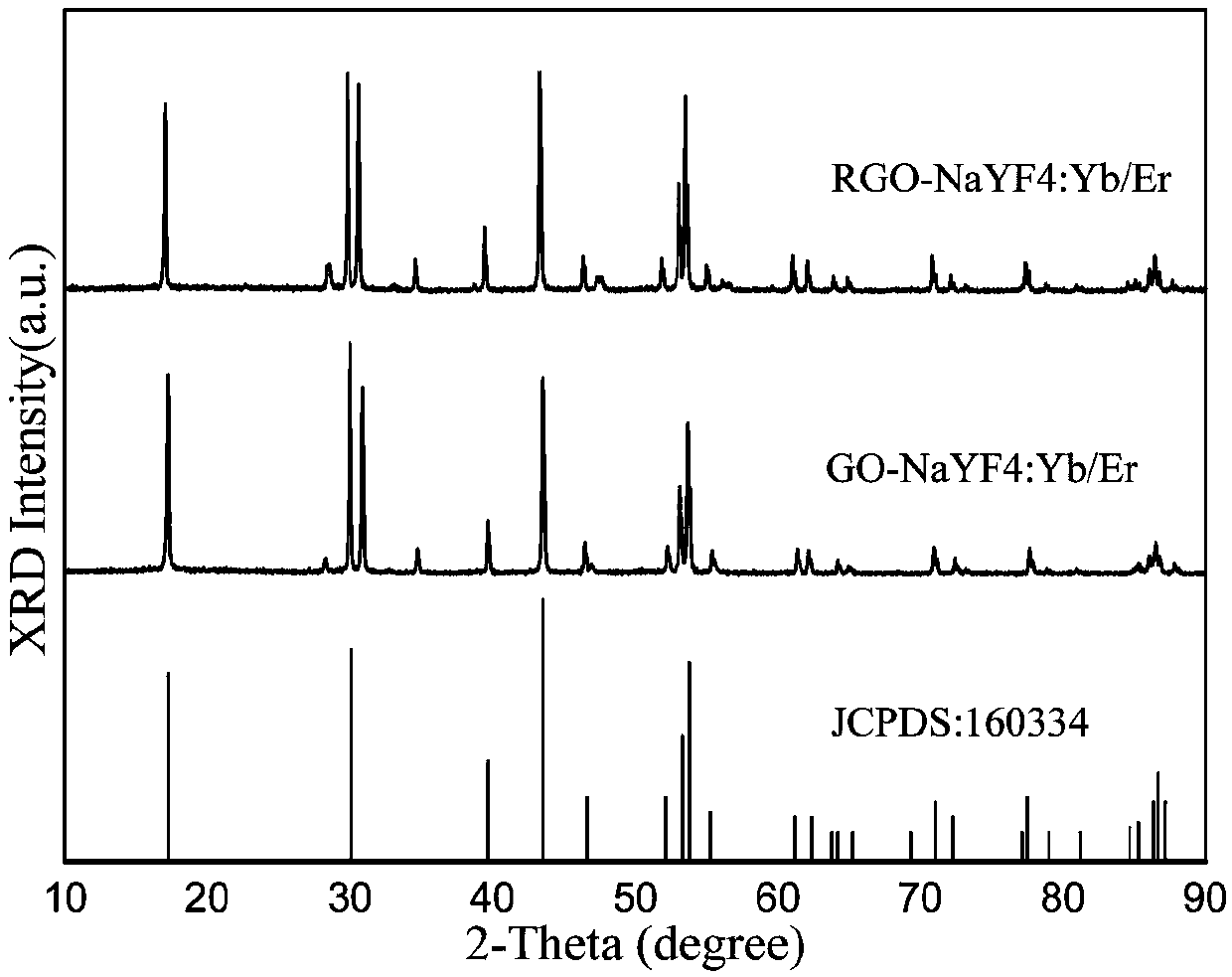

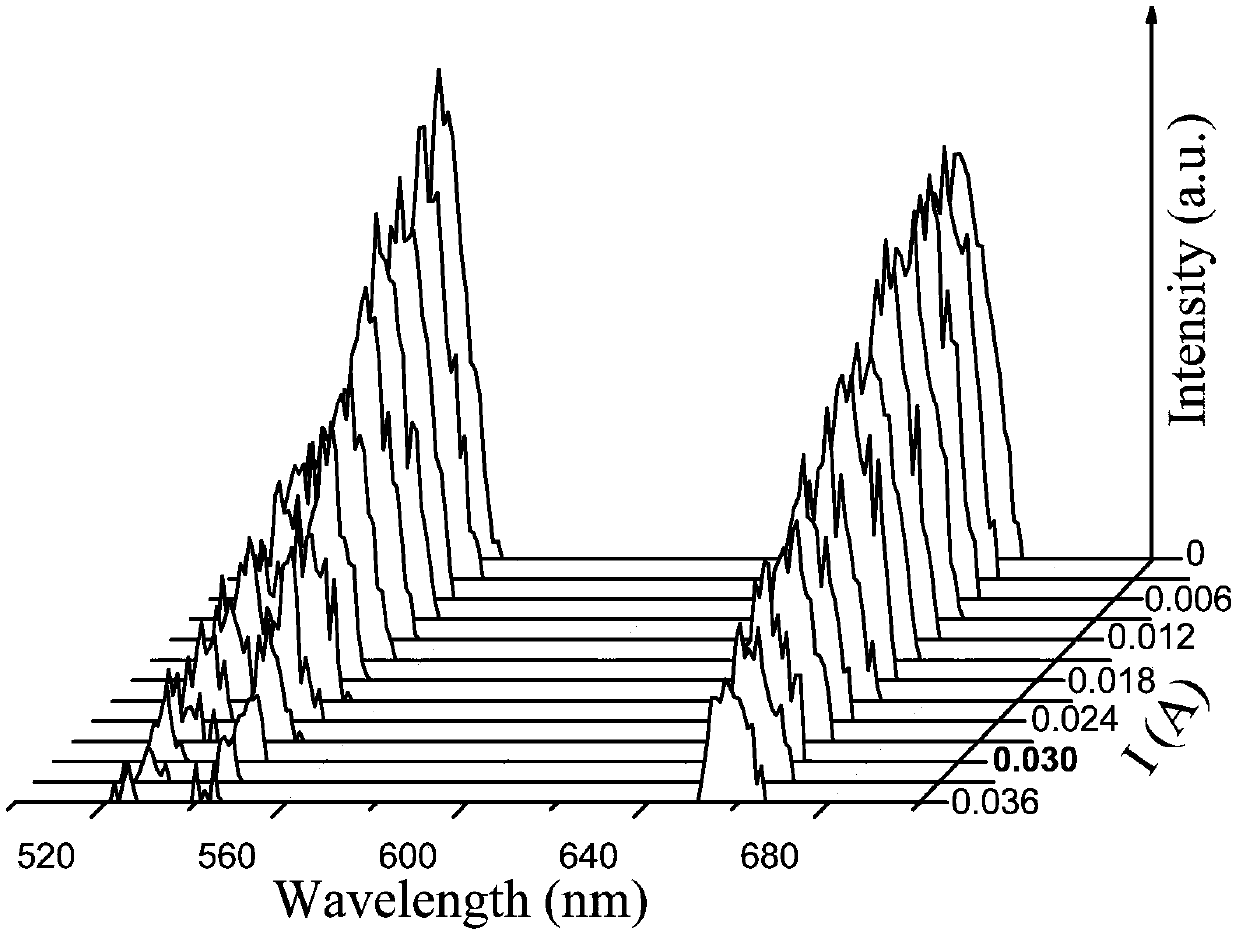

Preparation method of variable resistance sensor based on graphene/up-conversion luminescent nanocrystal composite material

InactiveCN109581059AEasy to prepareImprove stabilityResistance/reactance/impedenceManufacture of electrical instrumentsCopper wireDrop casting

The invention discloses a preparation method of a variable resistance sensor based on graphene / up-conversion luminescent nanocrystal composite materials. The method comprises the following steps of: S1, a selection of raw materials, selecting matrix materials, reagents, rare earth ions, and nitrogen as needed; S2, a preparation of a composite material, treating the raw materials in the S1 by usingan in-situ hydrothermal method and reducing the raw materials in N<2> to obtain RGO-NaYF<4>: Yb<3+> / Er<3+> graphene composite conductive material; S3, a selection of the matrix materials, putting themiddle part of an ITO conductive film in an etching solution for etching to form an open circuit; S4, a drop casting, dissolving the graphene composite conductive material obtained in the S2 in N-methyl pyrrolidone, dropping into the substrate in the S3, and drying; and S5, an extraction of an electrode, extracting a copper wire from two ends of the ITO glass substrate in the S4 to serve as electrodes to prepare a variable resistance sensor device. The preparation method is simple and convenient, high in stability, and suitable for industrial batch production.

Owner:NANJING UNIV OF POSTS & TELECOMM

Method for preparing low-cost centimeter-sized zirconium-base amorphous alloy by adopting industrial sponge zirconium

ActiveCN108070801AReduce manufacturing costFacilitate long-range diffusionElectric arc furnaceDrop casting

The invention relates to a method for preparing a low-cost centimeter-sized zirconium-base amorphous alloy by adopting industrial sponge zirconium, and relates to a method for preparing the zirconium-base amorphous alloy. In order to solve the problem that the production cost of the zirconium-base amorphous alloy is high since high-purity metal zirconium is adopted as a raw material for an existing zirconium-base amorphous alloy, the method comprises the steps of (1) weighing raw material according to the atomic percent; (2) vaccumizing an electric arc furnace, and filling a protection gas; (3) carrying out titanium smelting; (4) preparing an alloy ingot, and repetitively smelting the alloy ingot; and (5) drop casting. According to the method provided by the invention, the low-purity industrial sponge zirconium is adopted as a raw material for preparing the zirconium-base amorphous alloy, so that the production cost of the zirconium-base amorphous alloy is reduced; the method providedby the invention is beneficial to inhibiting generation of nucleation particles or eliminating impurity nucleation particles; and compared with the existing zirconium-base amorphous alloy, the zirconium-base amorphous alloy provided by the invention has the same excellent mechanical performance. The method provided by the invention is applicable to preparing the zirconium-base amorphous alloy.

Owner:HARBIN INST OF TECH

Method of making thin film humidity sensors

The method of making thin film humidity sensors uses thermal vapor deposition or drop casting techniques to fabricate nickel phthalocyanine-fullerene-based (NiPc-C60) quick response humidity sensors with negligible hysteresis. Prior to the deposition of aluminum electrodes, a glass substrate is cleaned by using acetone in an ultrasonic bath for 10 minutes. After cleaning, the substrate is washed with de-ionized water and then dried. A gap is created between two electrodes by masking the glass substrate with copper wire. This assembly is plasma-cleaned for 5 minutes in a thermal evaporator. Subsequently aluminum (Al) thin films are deposited on the assembly. Next, a mixture of equal parts NiPc-C60 is deposited onto the gap between the Al electrodes by thermal vapor deposition or by drop casting. A method of forming NiPc-graphene oxide (NiPc-GO) humidity sensors without using instrumentation drop casts an NiPc-GO suspension onto aluminum foil electrodes taped to a substrate.

Owner:KING ABDULAZIZ UNIV

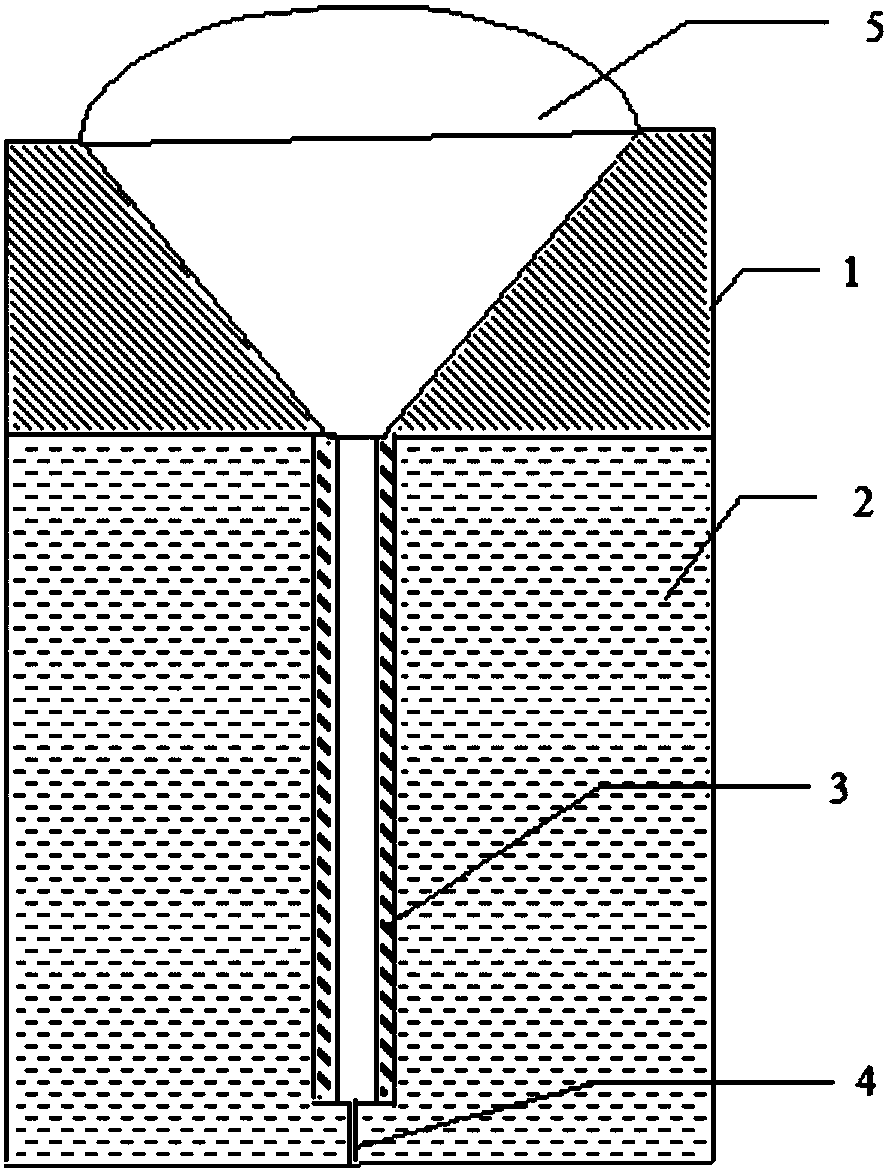

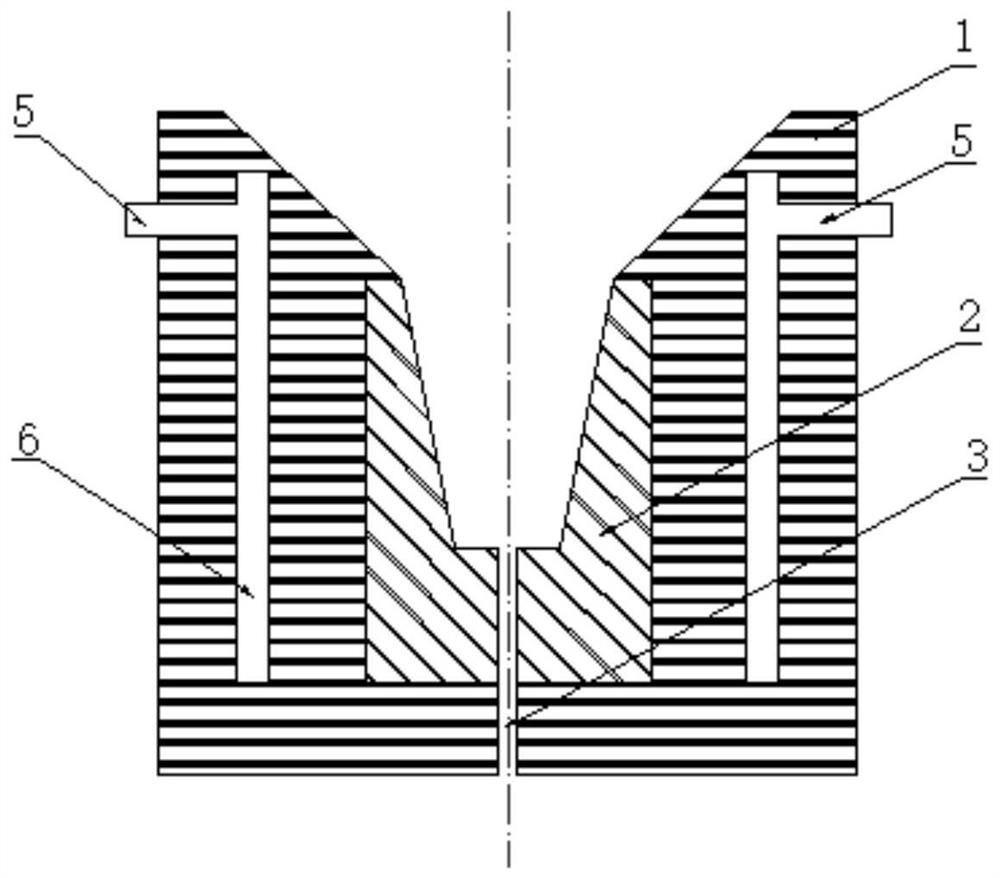

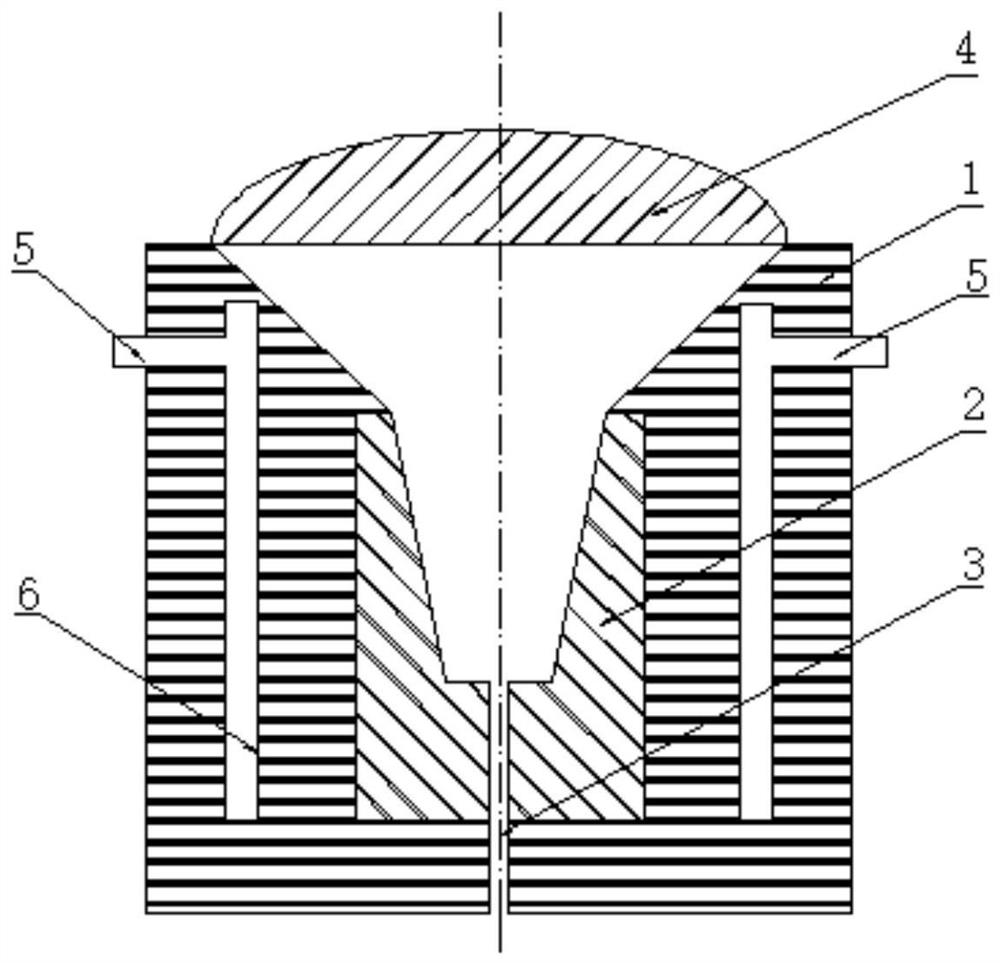

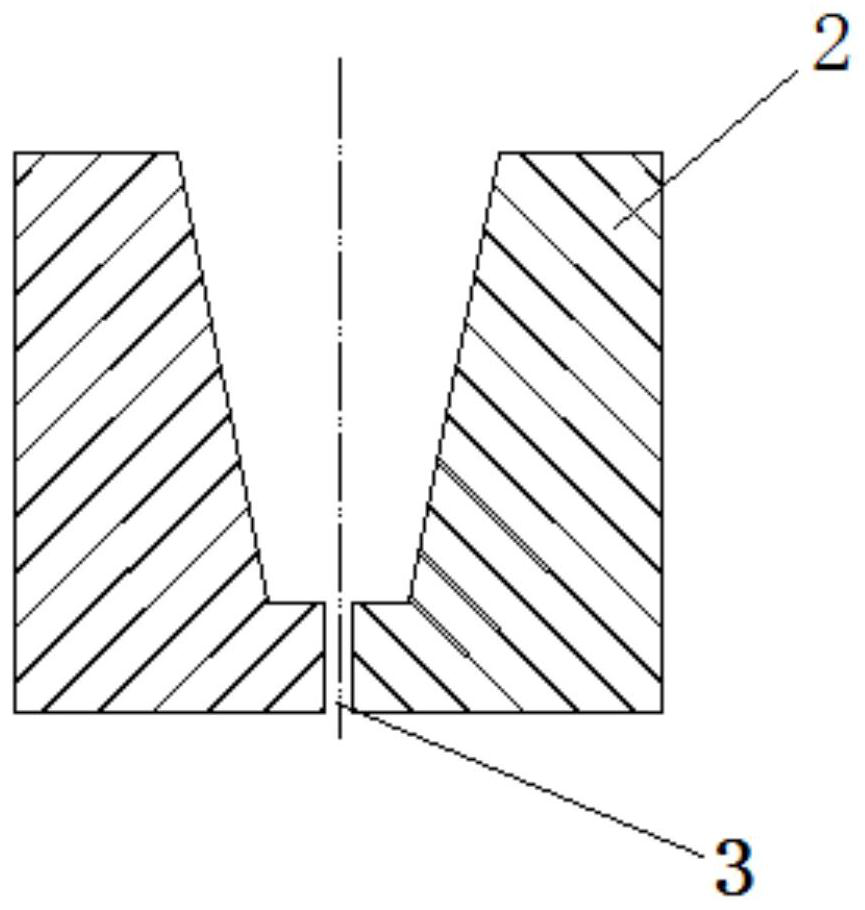

Electric arc melting drop casting mold

The invention discloses an electric arc melting drop casting mold. The electric arc melting drop casting mold comprises an outer mold, a melting station is arranged on the top of the outer mold, an inner mold is vertically arranged in the outer mold, an exhaust hole is formed in the bottom of the outer mold, the exhaust hole is communicated with the bottom of the inner mold, and the mold is simplein structure, and ingenious in design; through melting of an inverted-round-table cavity of the station, melt can be rapidly injected into the mold, through the outer mold, the inner mold is wrappedin, the melt is rapidly cooled in the mold, feeding is easy, and the problem that in the prior art, regular-size samples are prepared through electric arc melting, and air holes are easily generated is solved.

Owner:XIAN UNIV OF TECH

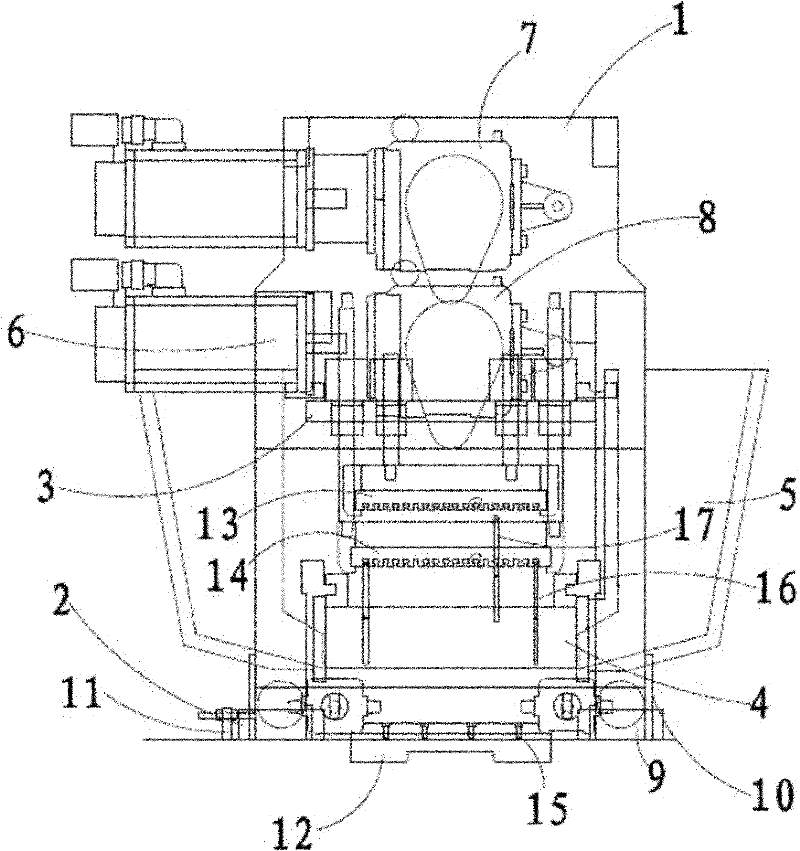

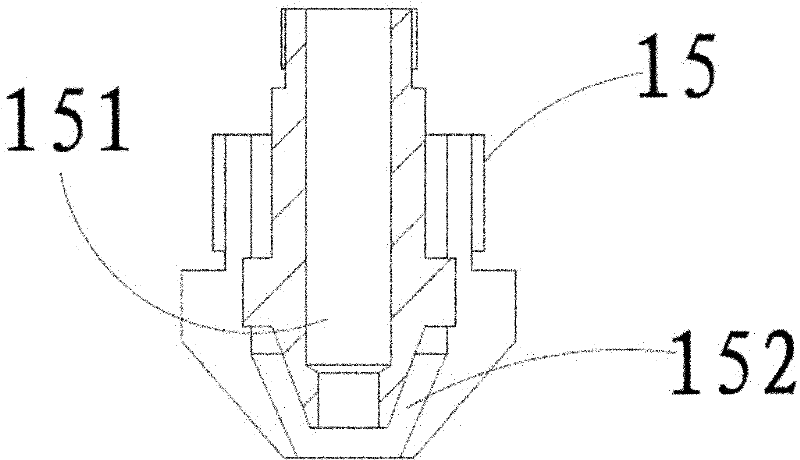

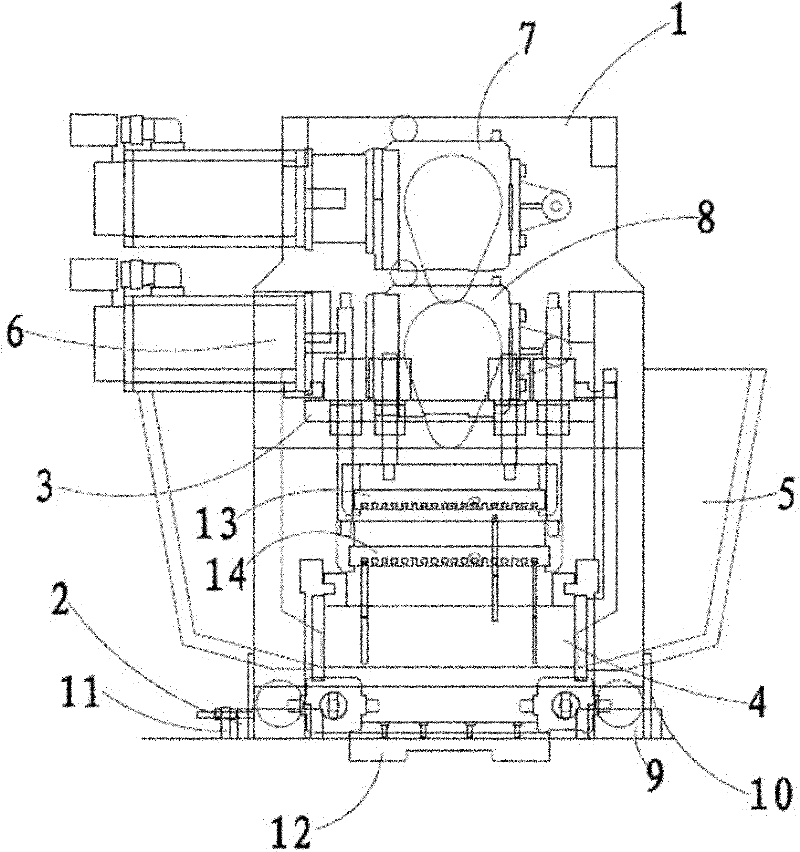

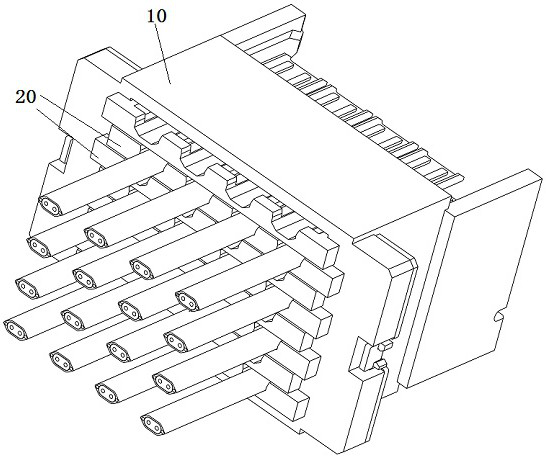

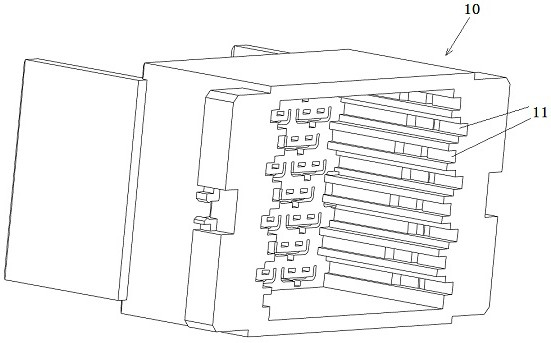

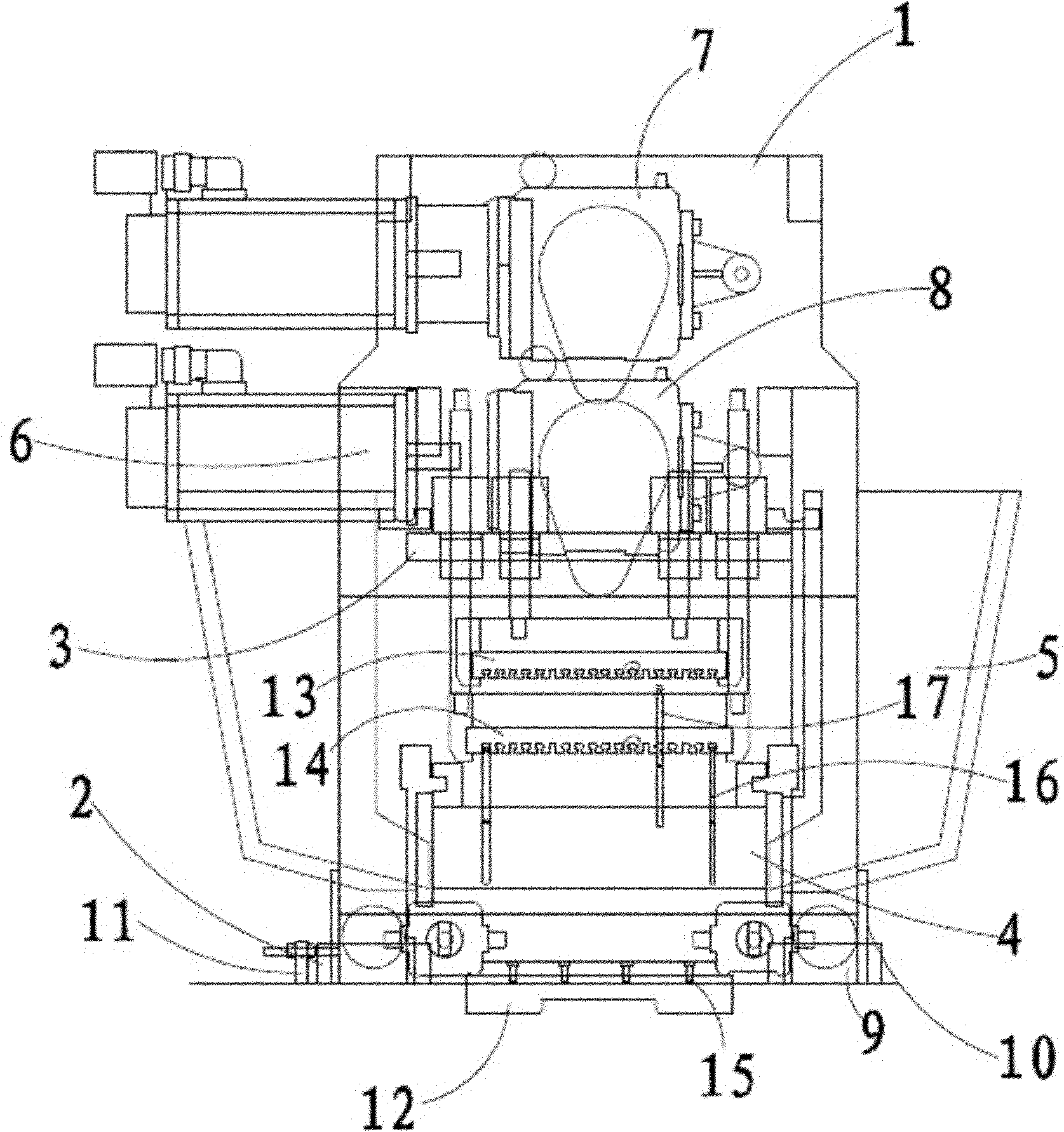

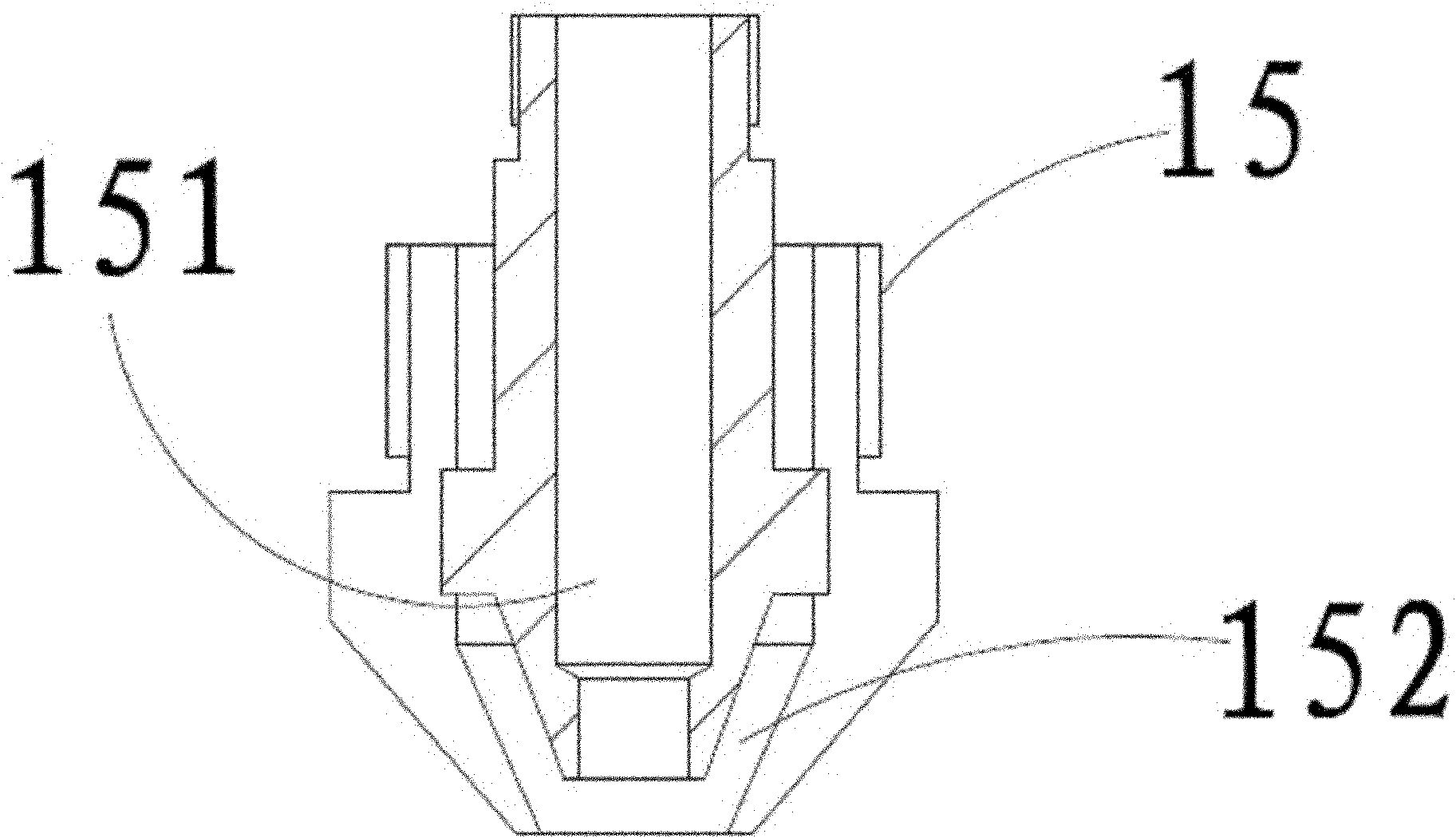

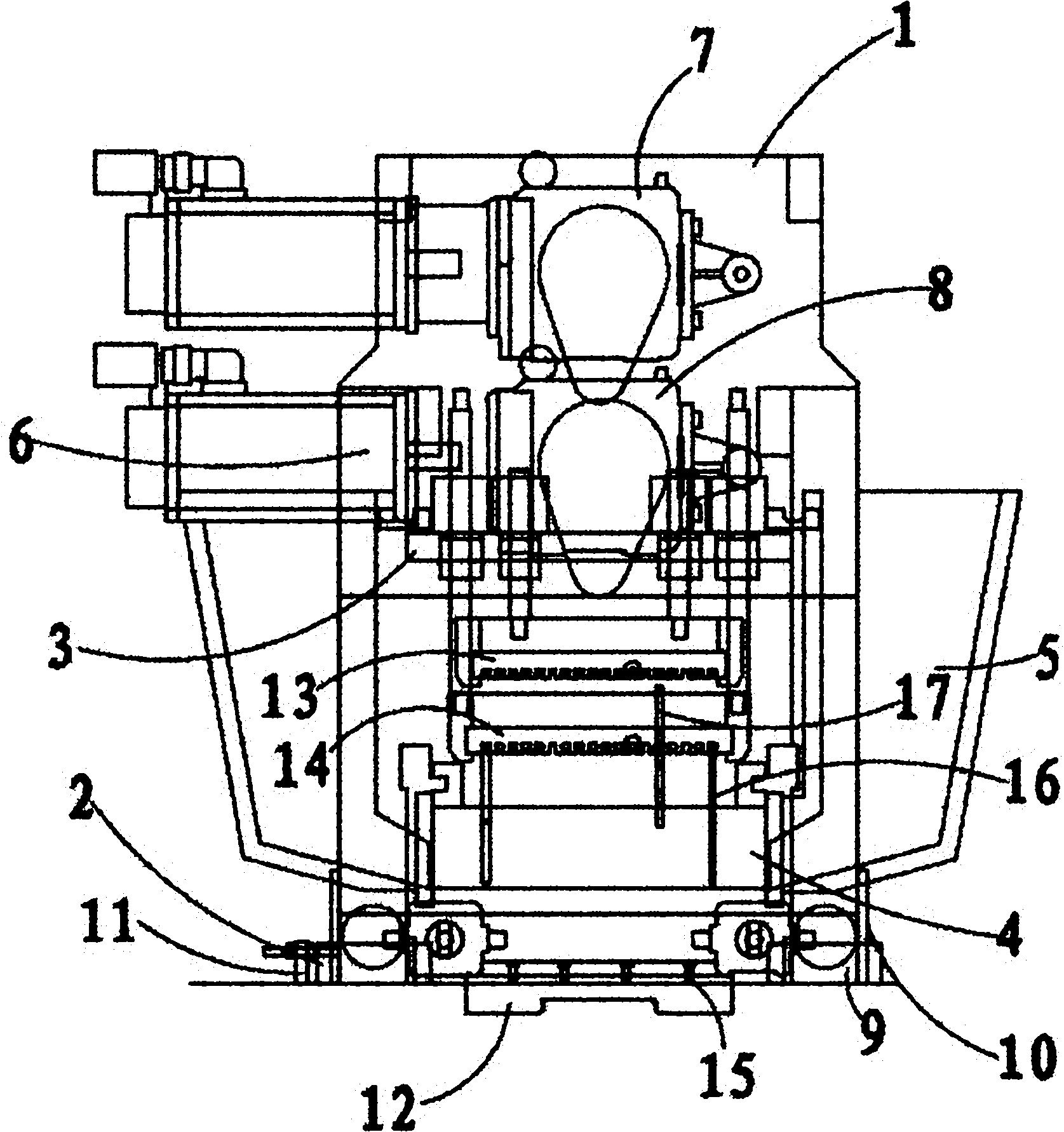

Starch mold-based jelly drop casting device

InactiveCN102028076BIncrease productionEasy to eliminateConfectionerySweetmeatsDrop castingRotary valve

The invention discloses a starch mold-based jelly drop casting device which comprises a shell. The starch mold-based jelly drop casting device is characterized in that an upper casting drive system assembly and a lower casting drive system assembly are arranged in the shell, wherein the upper casting drive system assembly is connected with a syrup sucking / releasing assembly by a pump rod, the lower casting drive system assembly is connected with a filling sucking / releasing assembly by a pump rod, and the lower casting drive system assembly is provided with a filling casting machine frame; both sides of the shell are provided with loading hoppers which are communicated with a filling casting assembly in the shell, and the filling casting assembly is arranged below the filling sucking / releasing assembly; a discharging system composed of a rotary valve drive system assembly, a rail plate and a regulating seat is arranged at the bottom of the shell; and a casting nozzle is arranged in thedischarging system, and a template is arranged in a position corresponding to the discharging system. By using the servo casting mode, the invention improves the casting quality of the product, greatly increases the yield of the jelly drops and greatly shortens the production time.

Owner:宁波华栋机械有限公司

A kind of high power long linear supercapacitor and preparation method thereof

ActiveCN107068412BImprove axial conductivityImprove power characteristicsHybrid capacitor electrolytesHybrid capacitor electrodesCarbon filmDrop casting

The invention relates to a long linear super capacitor with high power. The long linear super capacitor comprises a conductive substrate, an active material, and a gel electrolyte. The active material is arranged on the conductive substrate through drop casting. The active material is coated by a carbon nanotube film which is coated by the gel electrolyte. The conductive substrate is a sandwich structure of sequential carbon nanotube film / silver nanowires / sequential carbon film. The active material is a GO / MCNTs complex. The gel electrolyte is a PVA / H3PO4 electrolyte. A preparation method of the long linear super capacitor comprises the steps of depositing the active material on the sandwich structure of sequential carbon nanotube film / silver nanowires / sequential carbon film, twisting to form linear electrodes, and finally preparing the long linear super capacitor through twisting by using two same linear electrodes. According to the long linear super capacitor and the method, the efficiency is high, the stability is good, the realization of industrialized production is facilitated, the axial conductivity of the long linear super capacitor is improved, and thus the power characteristic of the long linear super capacitor is improved.

Owner:CHANGZHOU UNIV

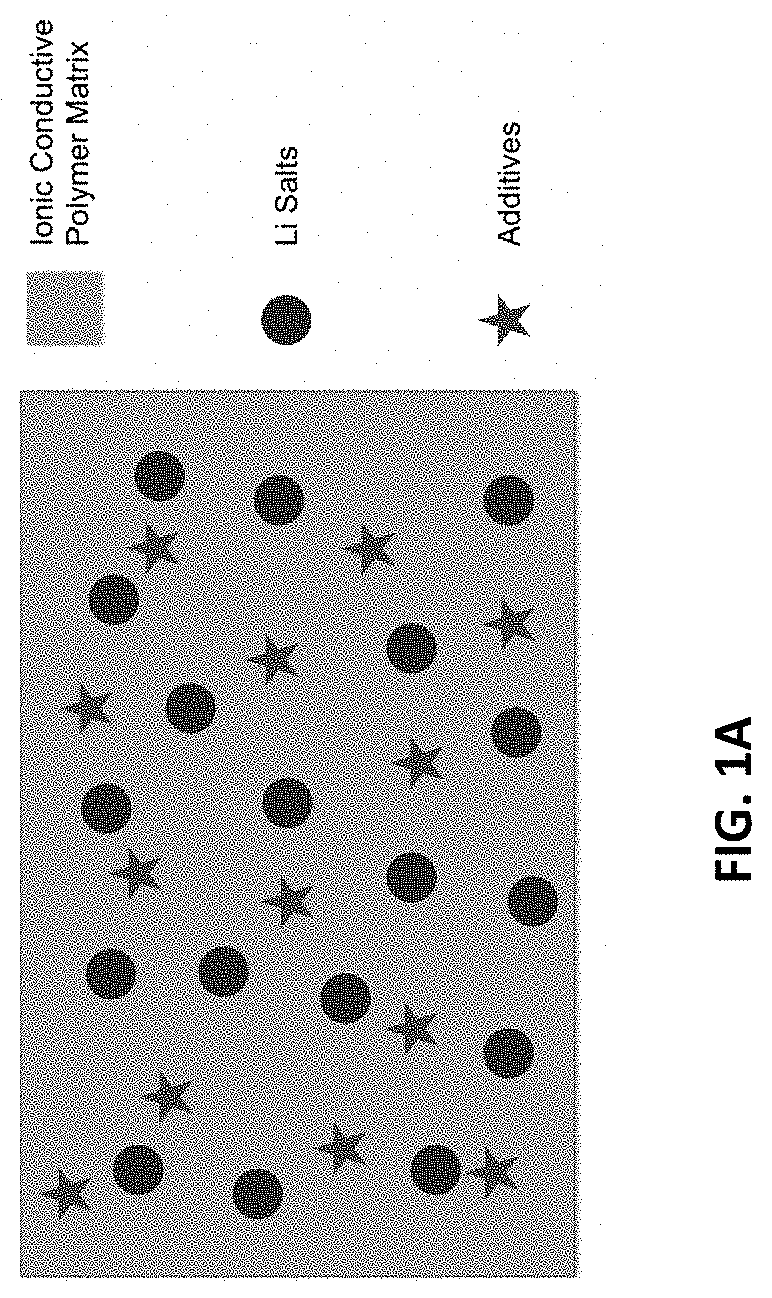

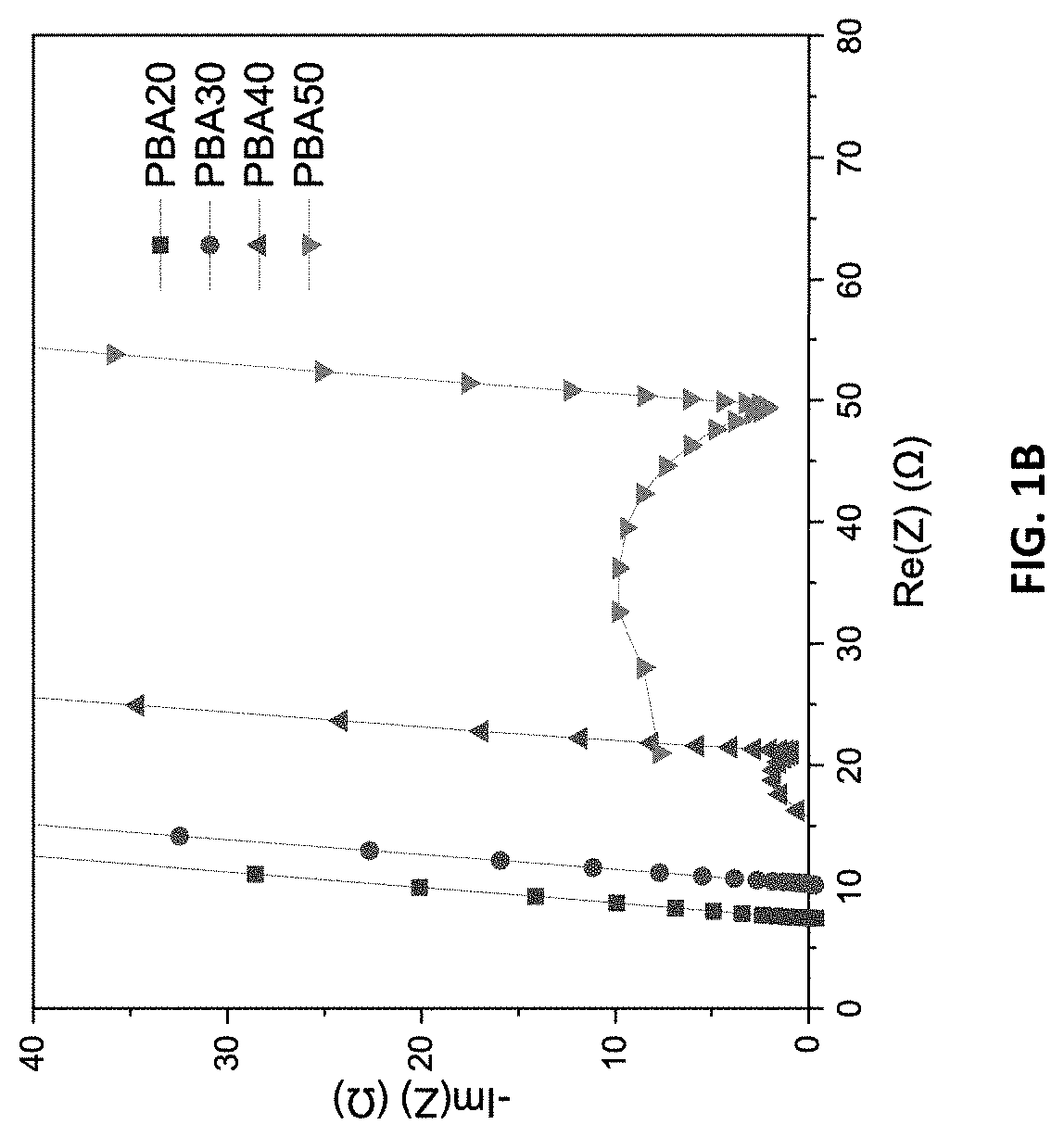

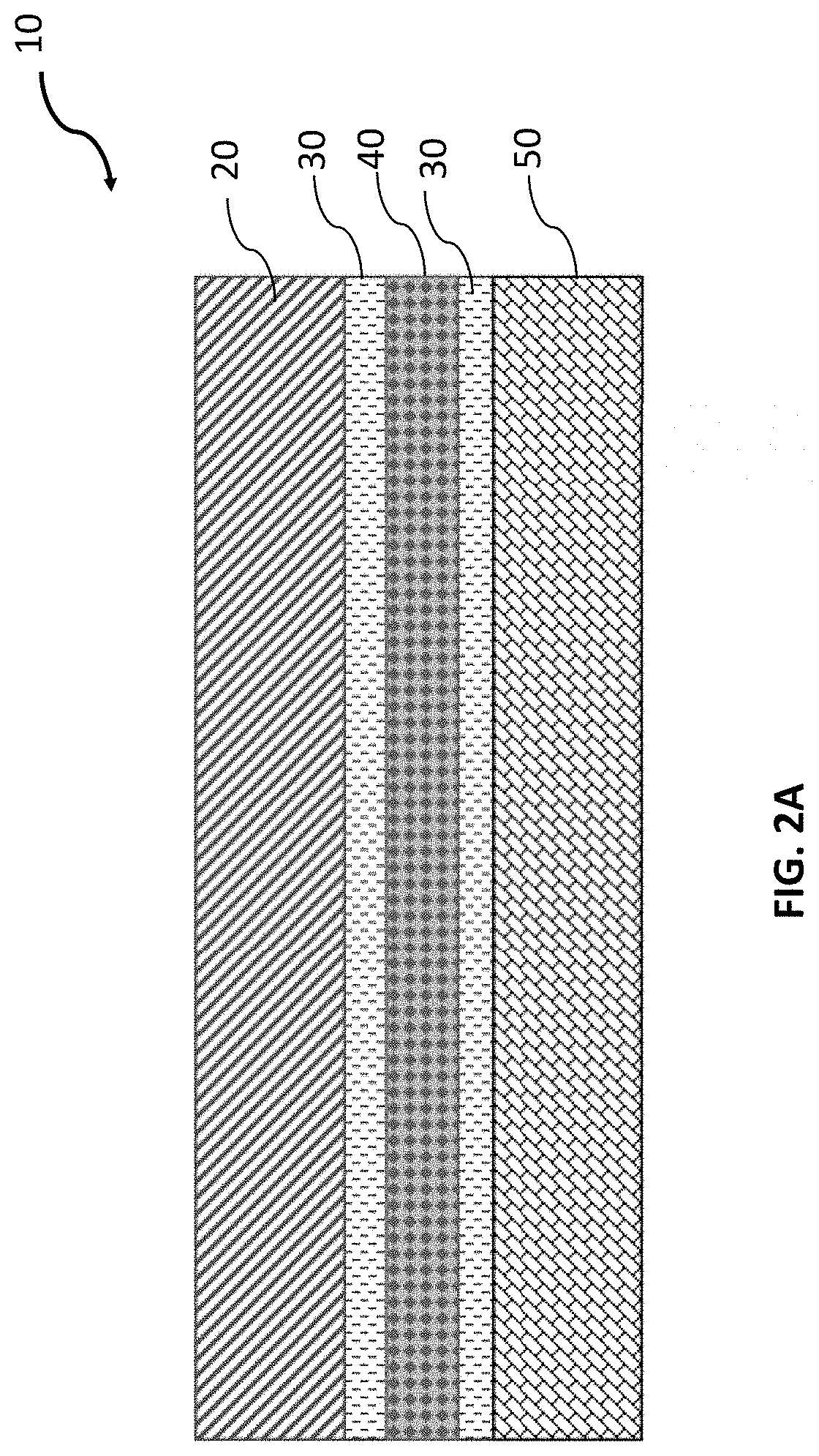

Synchronous polymerized non-flammable quasi-solid-state electrolyte for solid-state batteries

PendingUS20220367910A1Increase profitReduce interfacial resistanceSolid electrolytesNegative electrodesSolid state electrolyteDrop casting

A rechargeable battery has a cathode including a cathode active material selected from lithium iron phosphate, lithium cobalt oxide, lithium manganese oxide, lithium nickel cobalt aluminum oxide, or lithium nickel manganese cobalt oxide. An anode includes an anode active material selected from lithium, lithium titanium oxide, graphite, or silicon. A separator is positioned between the cathode and the anode. The separator is impregnated with an in-situ-formed and synchronously polymerized non-flammable quasi-solid-state electrolyte. The electrolyte is formed from a solution of monomer, lithium salt, and cross-linker. The solution wets the cathode active material and the anode active material such that the polymerized non-flammable quasi-solid-state electrolyte impregnates the cathode active material and the anode active material. The manufacturing procedures are compatible with production methods of Li-ion batteries, such as drop casting, impregnating, injecting, and printing.

Owner:THE HONG KONG UNIV OF SCI & TECH

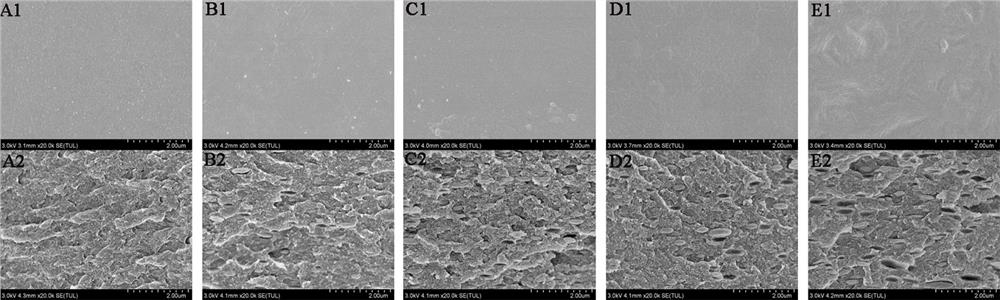

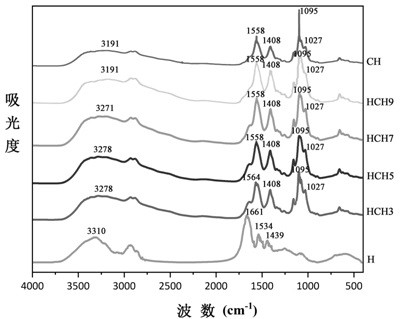

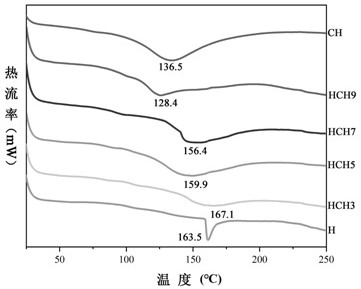

A kind of high-strength hordein-chitosan composite film and preparation method thereof

Owner:CHINA AGRI UNIV

Construction method of lifting casting wall and droping casting floor

InactiveCN1148497CHigh precisionSimplify complex work proceduresForms/shuttering/falseworksFalseworkFloor slab

Owner:河東榮

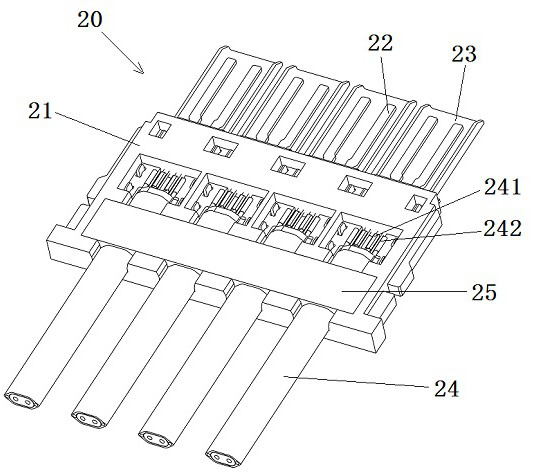

cable connection assembly

ActiveCN111509451BHigh strengthGuaranteed stabilitySecuring/insulating coupling contact membersDrop castingStructural engineering

The invention provides a cable connection assembly, which can solve the problem of poor connection reliability caused by the existing cable holders being connected to an insulating substrate only by adhesive force and easily falling off from the insulating substrate when subjected to a relatively large external force. . The cable connection assembly includes: cable; connector; the connector includes an insulating substrate; the contact assembly is installed on the insulating substrate and connected with the cable core in the cable; the injection molded holding part is used for inserting the cable to make the cable and the insulating substrate The substrate is relatively fixed; the insulating substrate has a molding surface for forming an injection-molded holding part, and an anti-off molding cavity communicated with the molding surface; the anti-off molding cavity includes an overflow channel extending from the molding surface into the insulating substrate, and a flow channel communicating with the overflow channel. The anti-off pouring cavity; and the anti-off pouring cavity has an anti-off cavity wall, and the anti-off cavity wall and the part formed in the anti-off pouring cavity in the injection molding holding part block and cooperate in the thickness direction of the insulating substrate to prevent the injection molding holder from The insulating substrate is peeled off.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

A water-cooled composite mold for arc melting drop casting

InactiveCN108687314BShape continuously adjustableSolve the problem that the cooling speed cannot be controlledDrop castingIngot

The invention discloses a water cooling assembling die for electric arc melting drop casting. The water cooling assembling die comprises an outer die body and an inner die body wrapped with the outerdie body. A cavity is formed in the top of the outer die body and communicates with the top of an inner cavity of the inner die body. Water cooling flow guiding groove perpendicular to the bottom faceis formed in the side walls of the outer die body. Through holes are formed in the side walls of the outer die body and penetrate through the side wall of the outer die body to communicate with the water cooling flow guiding groove. A vent hole is formed in the bottom of the outer die body and communicates with the bottom of the inner die body. Through the water cooling assembling die for electric arc melting drop casting, the problems that in the prior art, electric arc melt ingots are simplex in shape, and cooling speed cannot be controlled are solved. The die is simple in structure, the outer die body and the inner die body are matched closely, the inner die body is wrapped with the outer die body and can be replaced for use, the boundary dimensions of samples are replaced while the water cooling outer die body remains unchanged and can continue being used, the die application efficiency is improved, and the die application cost is reduced.

Owner:XIAN UNIV OF TECH

Starch mold-based jelly drop casting device

InactiveCN102028076AProduction increaseEasy to eliminateConfectionerySweetmeatsDrop castingRotary valve

The invention discloses a starch mold-based jelly drop casting device which comprises a shell. The starch mold-based jelly drop casting device is characterized in that an upper casting drive system assembly and a lower casting drive system assembly are arranged in the shell, wherein the upper casting drive system assembly is connected with a syrup sucking / releasing assembly by a pump rod, the lower casting drive system assembly is connected with a filling sucking / releasing assembly by a pump rod, and the lower casting drive system assembly is provided with a filling casting machine frame; both sides of the shell are provided with loading hoppers which are communicated with a filling casting assembly in the shell, and the filling casting assembly is arranged below the filling sucking / releasing assembly; a discharging system composed of a rotary valve drive system assembly, a rail plate and a regulating seat is arranged at the bottom of the shell; and a casting nozzle is arranged in the discharging system, and a template is arranged in a position corresponding to the discharging system. By using the servo casting mode, the invention improves the casting quality of the product, greatly increases the yield of the jelly drops and greatly shortens the production time.

Owner:宁波华栋机械有限公司

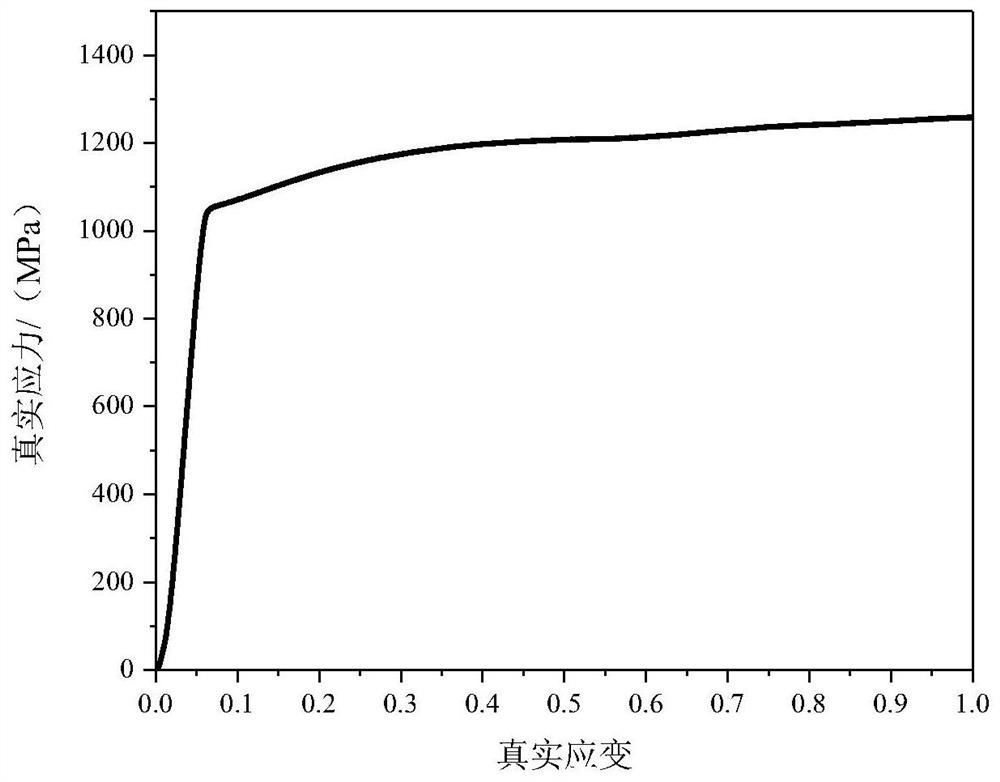

A precipitation-strengthened high-entropy alloy without sigma phase precipitation tendency and its preparation method

ActiveCN111826573BImprove mechanical propertiesEliminate precipitation tendencyElectric arc furnaceHigh entropy alloys

The invention discloses a precipitation-strengthened high-entropy alloy without σ phase precipitation tendency and a preparation method thereof, belonging to the field of high-entropy alloys. The high-entropy alloy is composed of four elements, Fe, Ni, Mn and Cu, in an equimolar ratio. The preferred preparation method of the high-entropy alloy is as follows: the prepared raw materials are first smelted in an electric arc furnace under the protection of vacuum argon, and then through the steps of drop casting, homogenizing annealing, cold rolling, and aging to obtain the sigma-free phase. Precipitation-strengthened high-entropy alloys. The optimum room temperature yield strength and tensile strength of the precipitation-strengthened high-entropy alloy without σ phase precipitation tendency can reach 825MPa and 933MPa respectively, and the elongation rate is greater than 15%, and its mechanical performance index can be adjusted by aging parameters. The precipitation-strengthened high-entropy alloy of the present application without the tendency of σ phase precipitation has excellent comprehensive mechanical properties at room temperature.

Owner:HUAZHONG UNIV OF SCI & TECH

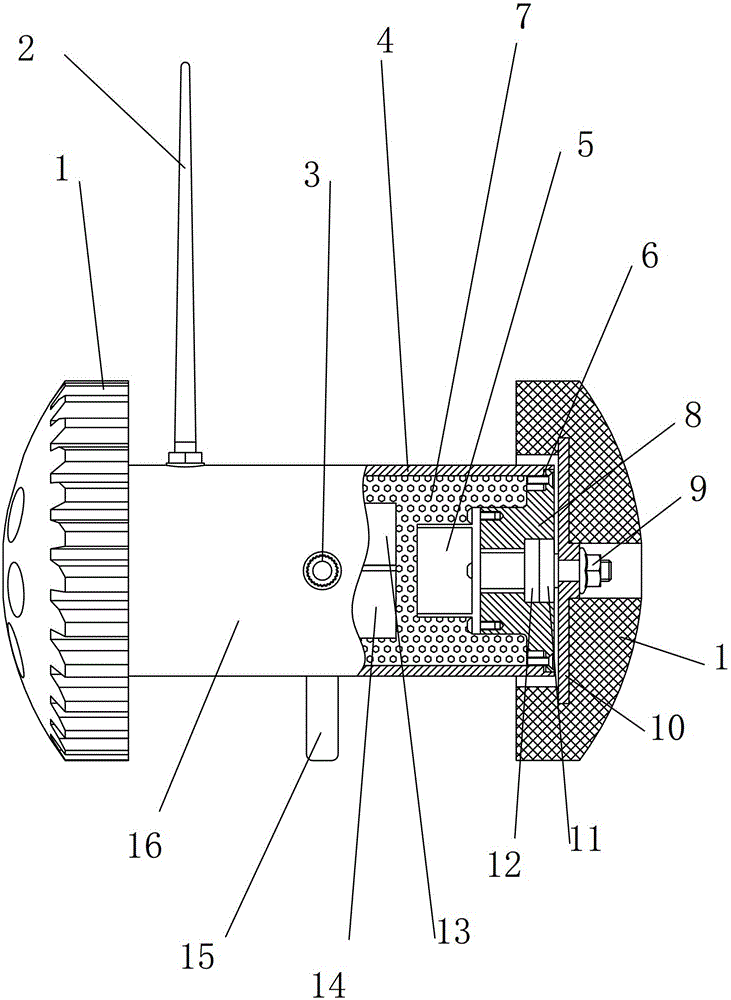

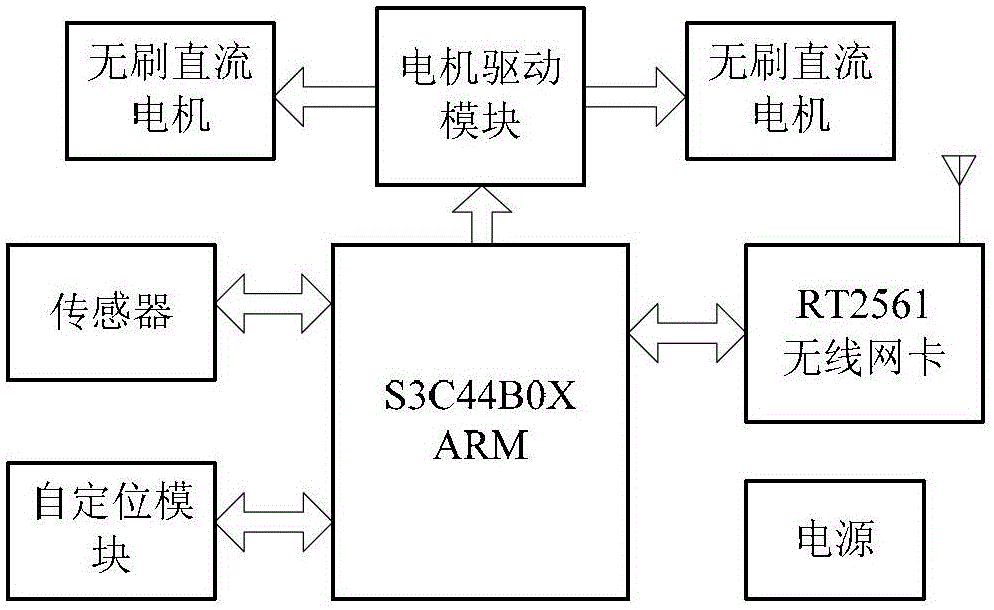

A Throwing Detection Robot

ActiveCN103213117BGood value for moneyGuarantee the safety of lifeMicromanipulatorMotor driveDrop casting

The invention discloses a tossing type robotic explorer which comprises a machine body and two solid rubber wheels arranged at two ends of the machine body respectively, wherein the machine body is cylindrical and comprises an outer shell, a battery, an electric control gear, servo motors, end covers and bearings arranged in the end covers, the battery, the electric control gear and the servo motors are all arranged in the outer shell, the number of the end covers is two, the two end covers are arranged at two ends of the outer shell respectively, a sensor is arranged on the machine body, wheel shafts of the rubber wheels are inserted in the bearings, the number of the servo motors is two, the front end of each servo motor is fixed on the inner side of a corresponding end cover, the rotary shaft of each servo motor drives a corresponding rubber shell to rotate, the servo motors are controlled by the electric control gear, an antenna and a stabilizing tail also serving as a tossing handle are arranged on the top and on the bottom of the outer shell respectively, a camera is arranged on one lateral side of the outer shell, and anti-shocking sponge is filled in the outer shell. The tossing type robotic explorer has the advantages of being severe environment resisting and high in mechanical strength.

Owner:湖南睿图智能科技有限公司

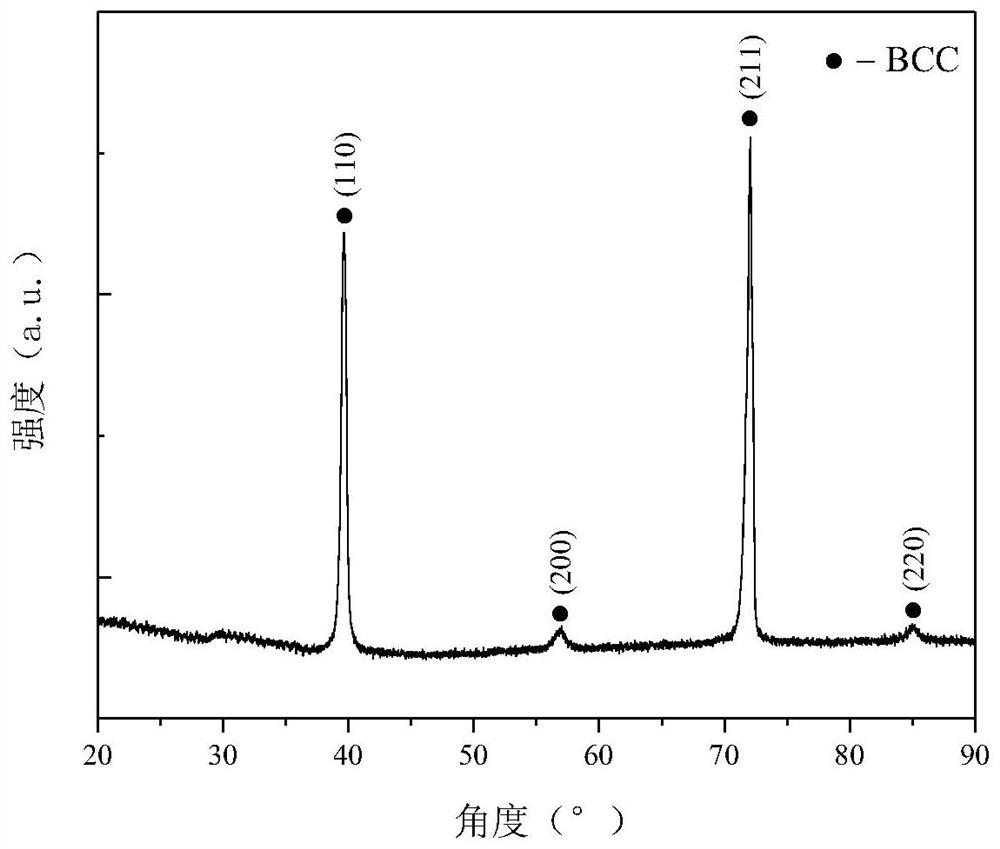

A high-niobium low-density refractory multi-principal element alloy and its vacuum drop casting method

The invention belongs to the technical field related to metal materials, and discloses a high-niobium, low-density refractory multi-principal alloy and a vacuum drop casting method thereof. The constituent elements of the multi-principal alloy include niobium, aluminum, titanium and vanadium, and the niobium , the atomic ratio of the aluminum, the titanium and the vanadium is (35-45): (18.33-21.67): (18.33-21.67): (18.33-21.67), and the phase of the multi-principal alloy The structure is a single BCC structure. Among the constituent elements of the multi-principal alloy, niobium is the main refractory element and plays a major role. The high niobium content makes the alloy have refractory and high toughness characteristics, and the moderate aluminum content is conducive to maintaining good oxidation resistance and low density. , the moderate titanium content is conducive to maintaining good oxidation resistance and certain toughness; and the drop casting method is used to effectively make up for the difficulty of preparing a small ingot of a certain size due to the high viscosity of the refractory multi-principal alloy in the traditional suction casting technology lack of.

Owner:HUAZHONG UNIV OF SCI & TECH

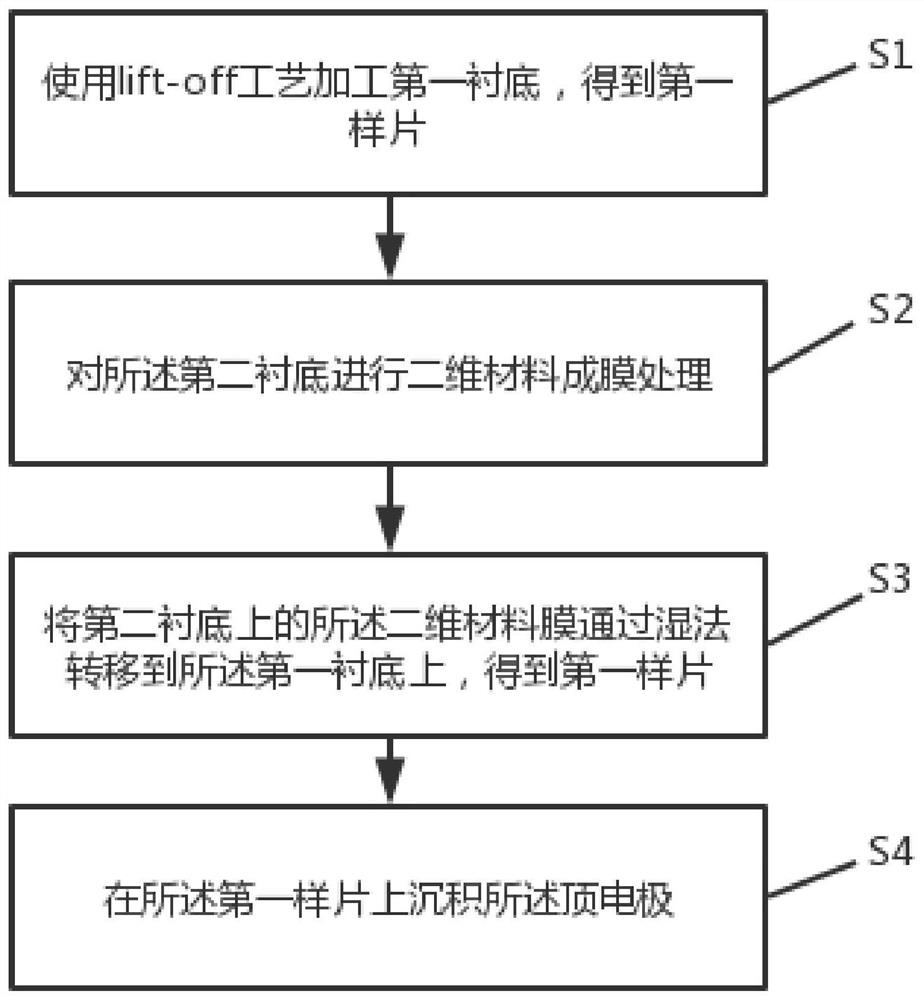

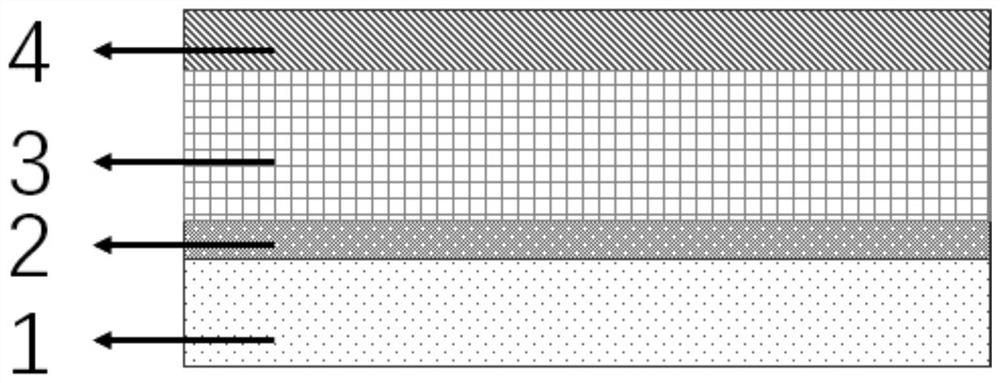

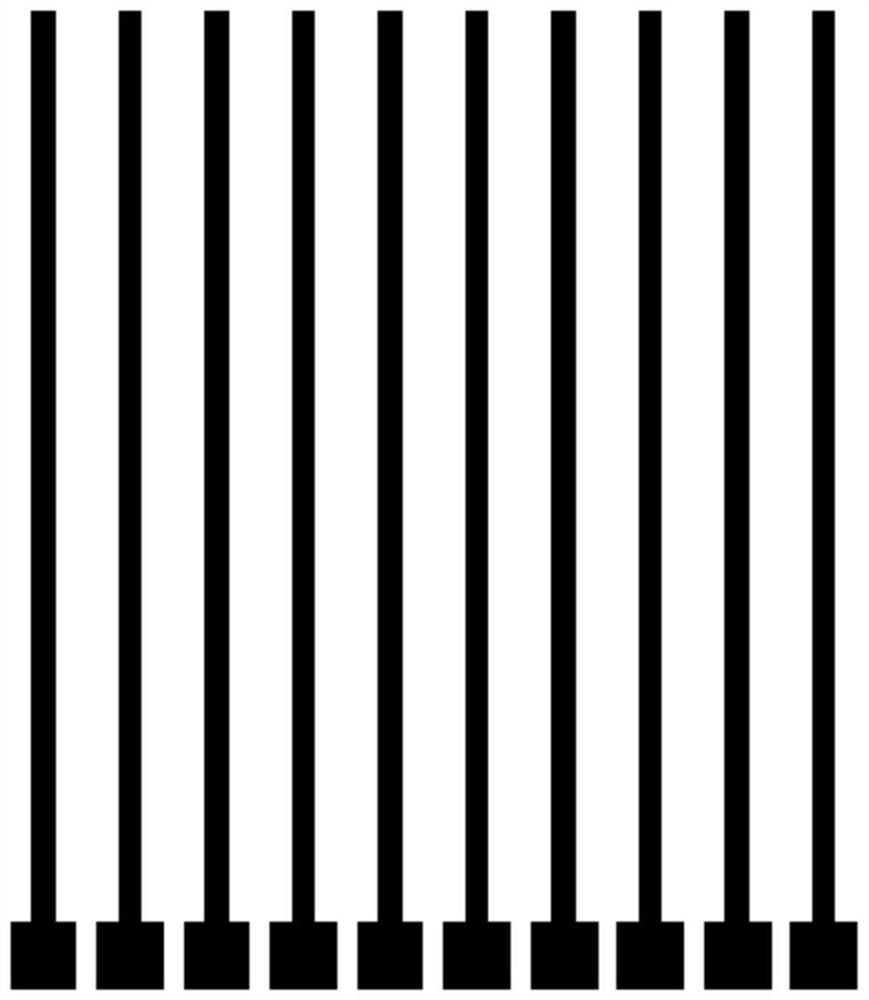

Two-dimensional material resistive random access memory and preparation method thereof

ActiveCN113241406AEasy to manufactureEasy to makeElectrical apparatusStatic random-access memoryRandom access memory

The invention discloses a two-dimensional material resistive random access memory and a preparation method thereof. Compared with a resistive random access memory prepared by chemical vapor deposition, the two-dimensional material resistive random access memory has the advantages of convenience in preparation, no dependence on equipment and the like, and has the advantages of good uniformity, good repeatability, simplicity in preparation and the like for resistive random access memories prepared by drip casting, spin coating and other methods. The two-dimensional material resistive random access memory prepared by the method disclosed by the invention shows a switch ratio of 6 orders of magnitude, has obvious advantages in comparison with 2-3 orders of magnitude shown by other traditional materials below dozens of nanometers, and is 4-5 orders of magnitude shown by a two-dimensional material resistive random access memory prepared based on a drop casting method and a spin coating method; under the conditions of simple preparation and low dependence on equipment, the on-off ratio similar to that of a two-dimensional material resistive random access memory (7 orders of magnitude) prepared by chemical vapor deposition can be achieved, and the resistive random access memory also has the potential of multi-stage storage under the high on-off ratio.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com