Two-dimensional material resistive random access memory and preparation method thereof

A technology of two-dimensional materials and memristors, applied in the direction of electrical components, etc., can solve the problems of high manufacturing cost and poor quality, and achieve the effect of good uniformity, convenient preparation and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

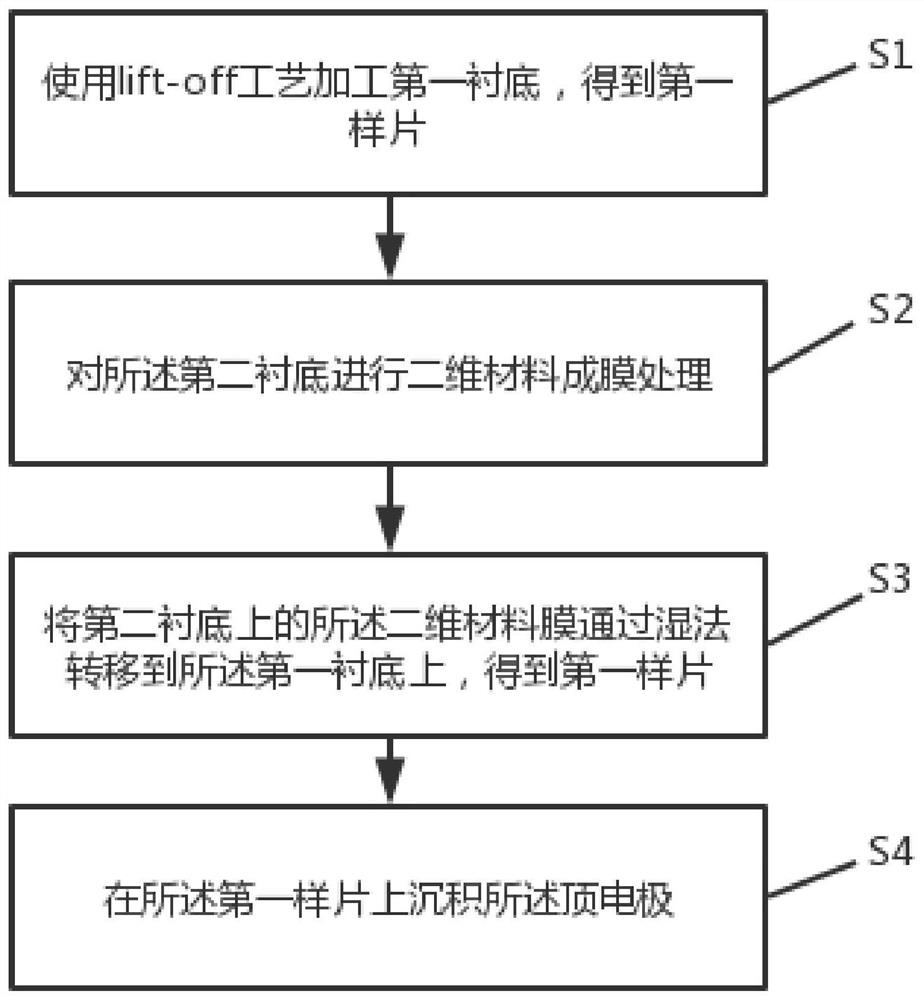

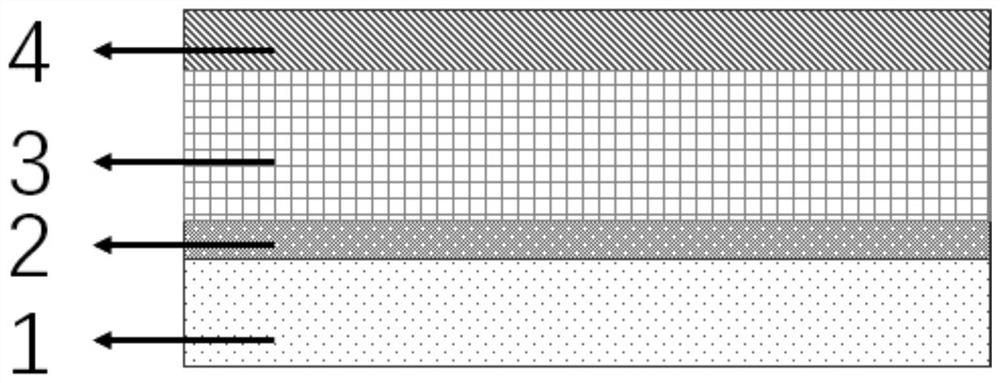

[0045] see Figure 1 to Figure 4 , the invention provides a method for preparing a two-dimensional material memristor, comprising the following steps:

[0046] S1: Process the first substrate by using a lift-off process to obtain a first sample;

[0047] S2: performing a two-dimensional material film forming process on the second substrate;

[0048] S3: transfer the two-dimensional material film on the second substrate to the sample by wet method to obtain a second sample;

[0049] S4: Depositing the top electrode on the second sample.

[0050] Specifically, the steps of processing the first substrate using the lift-off process to obtain the first sample include:

[0051] photoetching an electrode pattern on the first substrate;

[0052] Depositing a bottom electrode on the first substrate, and then leaving the bottom electrode on the first substrate by deglue treatment, to obtain a first sample.

[0053] Specifically, the electrode pattern is drawn on the first substrate...

specific Embodiment 1

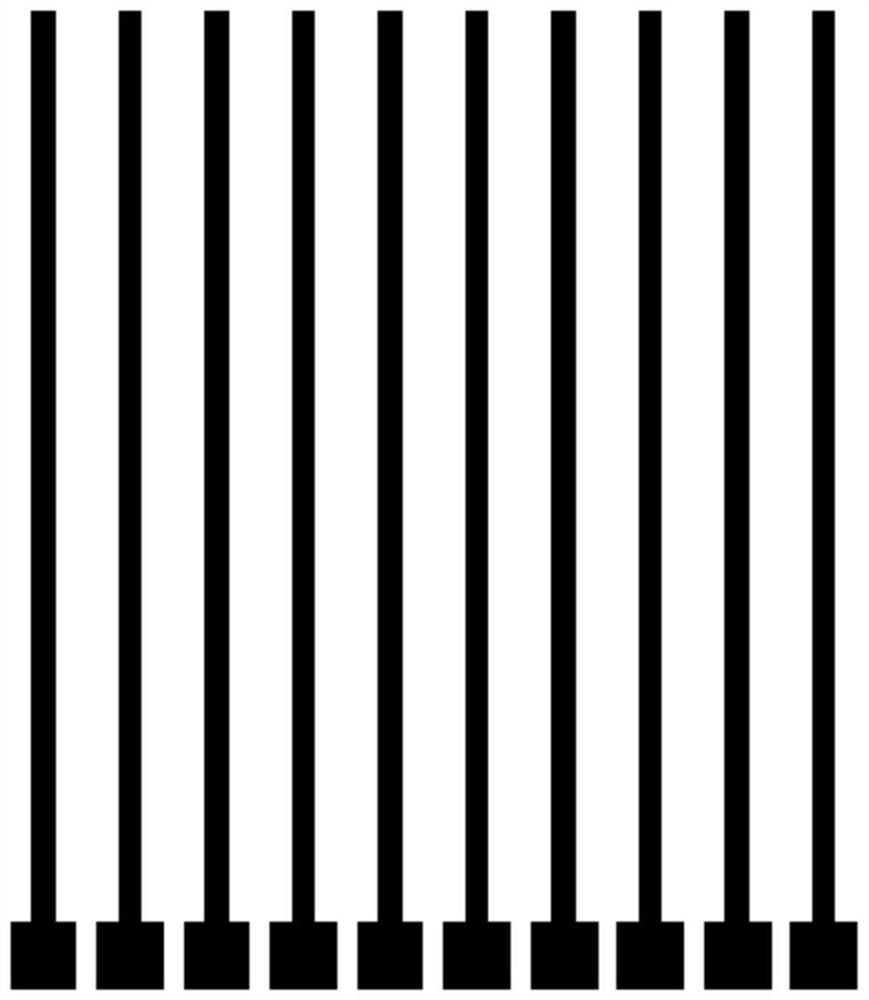

[0067] The first substrate is an ITO glass substrate, and the ITO glass substrate is patterned on the surface by photolithography, 10 lines of 40 μm.

[0068] The bottom electrode is deposited on the ITO glass substrate by magnetron sputtering or evaporation evaporation process.

[0069] Take 1 g of hexagonal boron nitride powder and dimethylformamide to make a two-dimensional material suspension, and ultrasonicate in a water bath for 10 hours to obtain the first suspension.

[0070] Subsequently, 1 / 3 of the supernatant of the first suspension was taken and its concentration was determined by vacuum filtration.

[0071] Select 1cmx1cm copper foil as the second substrate, use a beaker as the container, fix the 1cmx1cm copper foil and the syringe hose in the middle of the beaker (100ml), add deionized water, and just submerge the 1cmx1cm copper foil by 0.5cm place.

[0072] Connect the syringe to the hose, slowly absorb the mixed solution, so that the liquid level of the mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com