Magnesium and magnesium alloy casting device and method based on melt speed-controlled drop casting

A magnesium alloy and melt technology, applied in the control of molten metal pouring from ladles, ingot workshops, casting workshops, etc., can solve the problems of small solid phase diffusion coefficient, high equipment conditions, composition segregation, etc., and achieve suppression The degree of dendrite growth, the low degree of contamination introduction, and the effect of improving composition uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

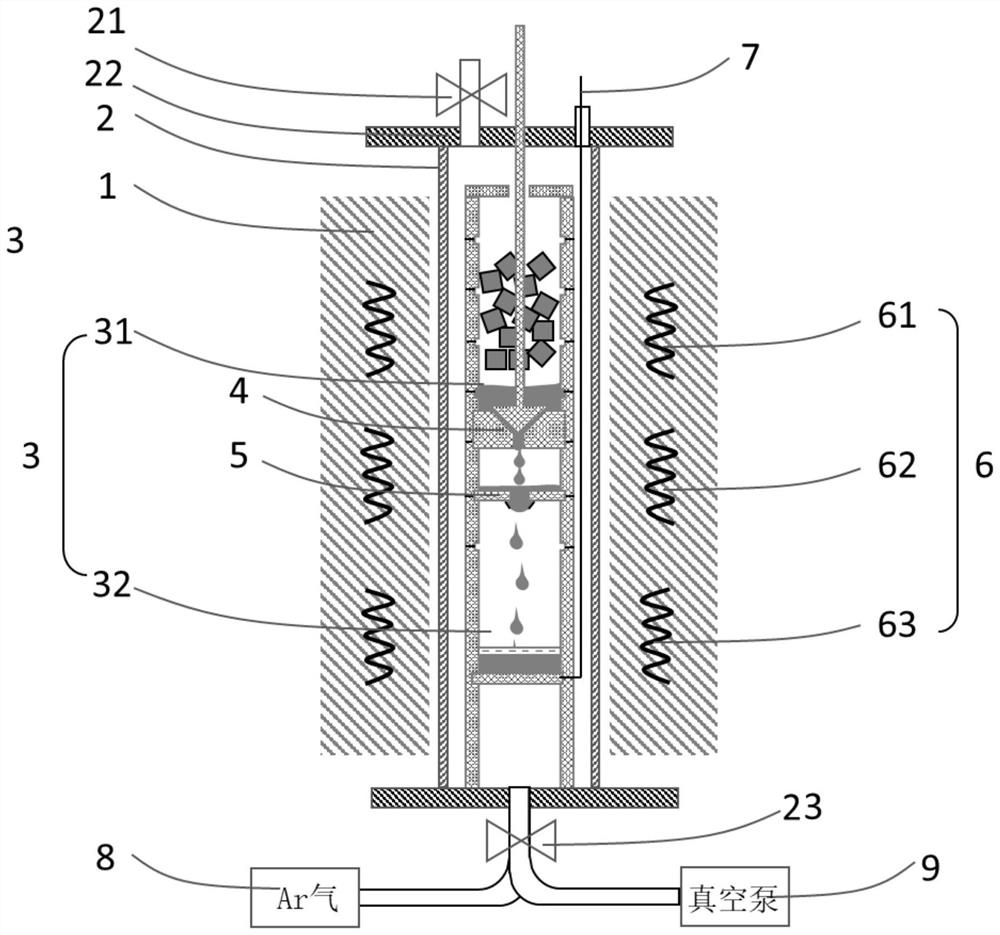

[0046] The raw material of this embodiment is 99.99% dendritic pure magnesium, in combination with the method described in the invention, adopt such as figure 1 Described device specifically comprises the steps:

[0047] Under the situation that no raw material is placed, close the exhaust valve 21, open the intake valve 23, open the vacuum mechanism 9, make the sealed cabin body 2 communicate with the vacuum mechanism 9, and make the pressure in the sealed cavity 2 be at 10Pa, at this time Set the temperature control mechanism 6 so that the temperature of the three stages of temperature control is kept at 200°C for 30 minutes, and then at 600°C for 120 minutes. After the heat preservation is completed, cool to room temperature.

[0048] 400g, 99.99% of loose dendritic pure magnesium is placed in the smelting zone 31, the filter mechanism 5 is set as a graphite plate containing 3 holes and the aperture of each hole is 8mm, at this time, the flow velocity control mechanism 4 is...

Embodiment 2

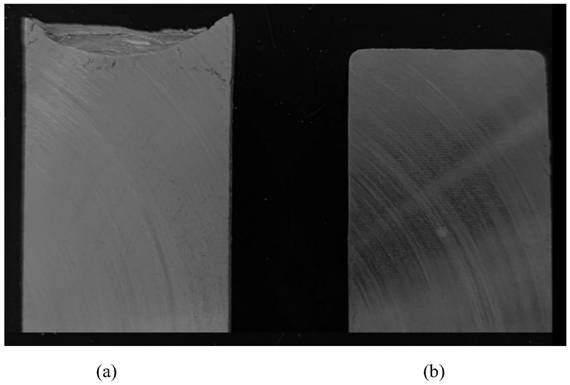

[0056] The raw material of this example is an extruded AZ31 magnesium alloy, which has more elements with higher concentration than that of Example 1, and the component segregation is serious under the conventional smelting method.

[0057] Under the situation that no raw material is placed, close the exhaust valve 21, open the intake valve 23, open the vacuum mechanism 9, make the sealed cabin body 2 communicate with the vacuum mechanism 9, and make the pressure in the sealed cavity be at 10Pa, set the control at this time The temperature mechanism 6 keeps the three-stage temperature control at 200°C for 30 minutes, then at 600°C for 120 minutes, and cools to room temperature after the heat preservation is completed.

[0058] Place 400g of extruded AZ31 in the smelting zone 31, set the filter mechanism 5 as a graphite plate with 3 holes and the diameter of each hole is 8mm, at this time close the flow rate control mechanism 4, that is, the lifting of the inverted cone inside t...

Embodiment 3

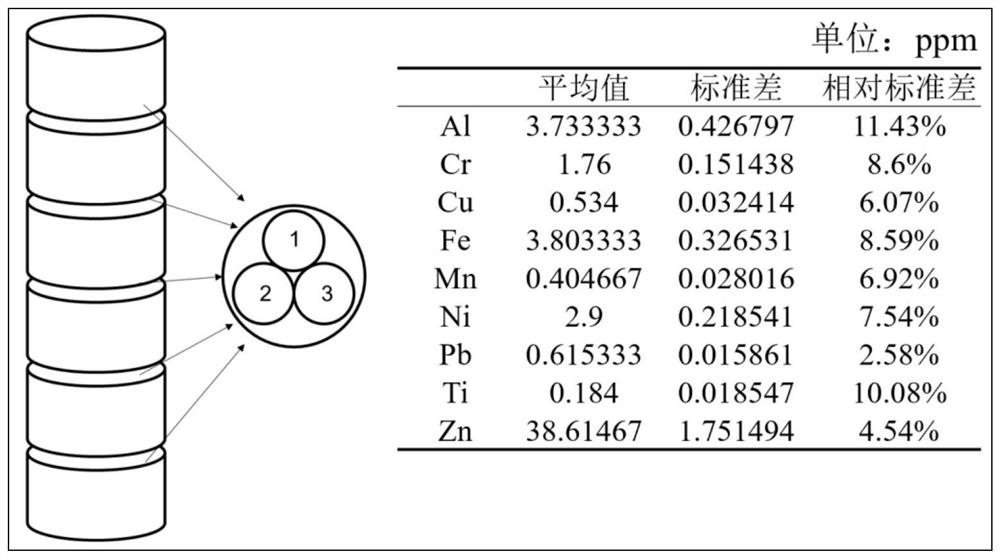

[0065] The raw materials of this example are pure magnesium and pure zinc. Compared with Examples 1 and 2, this example is mainly used to explore the feasibility of preparing a homogeneous alloy.

[0066] Under the situation that no raw material is placed, close the exhaust valve 21, open the intake valve 23, open the vacuum mechanism 9, make the sealed cabin body 2 communicate with the vacuum mechanism 9, and make the pressure in the sealed cavity be at 10Pa, set the control at this time. The temperature mechanism 6 keeps the three-stage temperature control at 200°C for 30 minutes, then at 600°C for 120 minutes, and cools to room temperature after the heat preservation is completed;

[0067] The purity is 99.99%, and the quality is 150g of dendritic pure magnesium and 10g of granular pure zinc placed in the smelting zone 31, and the filter mechanism 5 is set as a graphite plate containing 3 holes and the aperture of each hole is 8mm. Close the flow rate control mechanism 4, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com